3D Printing Concrete

3D PRINTING OF CONCRETE STRUCTURES

R.J.M. Wolfs

Eindhoven University of Technology, Department of the Built Environment

Master Architecture, Building and Planning

Specialization Structural Design

February 2015

3D Printing is one of the most promising developments of today. It has shown its potential in a wide range of disciplines, varying from the medical world to the food industry and from aerospace engineering to household uses. Unsurprisingly, the building industry has adopted this technique and aims to apply it on a larger scale.

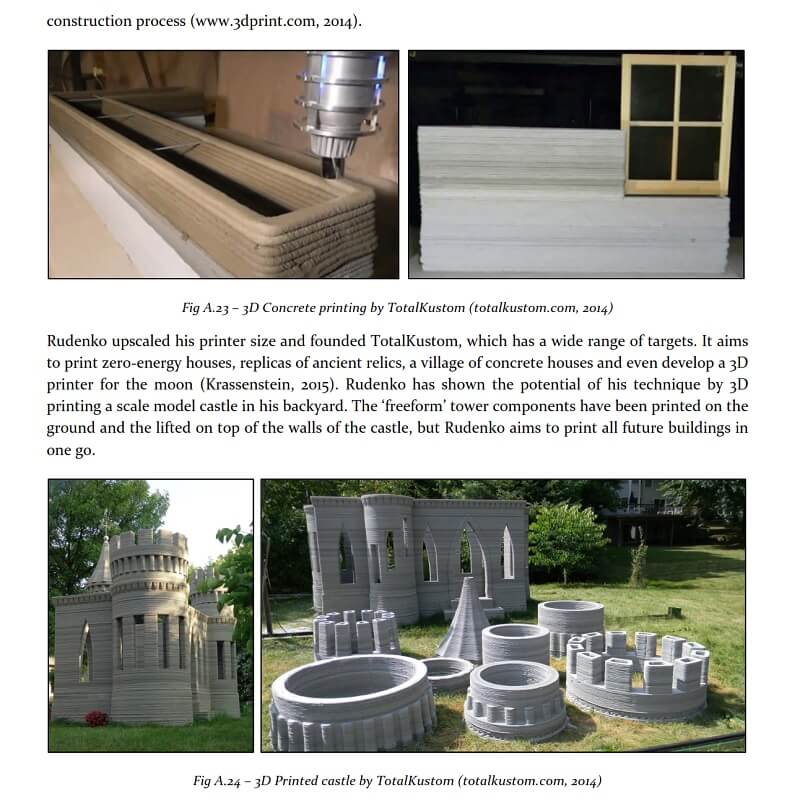

*Pix

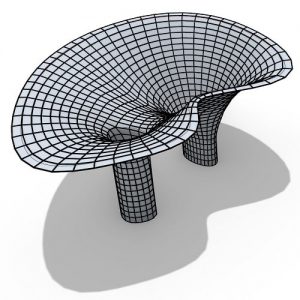

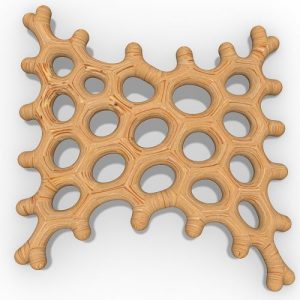

3D Concrete printing results in a low cost and high speed construction method, which allows for a greater freedom in both architectural and structural design. Despite these clear benefits shown by a handful of pioneering companies and institutes spread around the world, the building industry is still behind in the development of 3D printing. This may be attributed to the lack of fundamental research on the (structural) behaviour of the to-be-printed shapes and materials.

*Pix

This graduation thesis by R.J.M. Wolfs, aims to contribute to the foundations of this research, by designing a method to study 3D concrete printing technique. Initially the state-of-the-art of 3D concrete printing is studied, considering the printed shapes, material behaviour, applied forces and the choice of print technique and strategy. The study shows that the different components involved in this construction method are clearly connected, but the relationships are generally unknown.

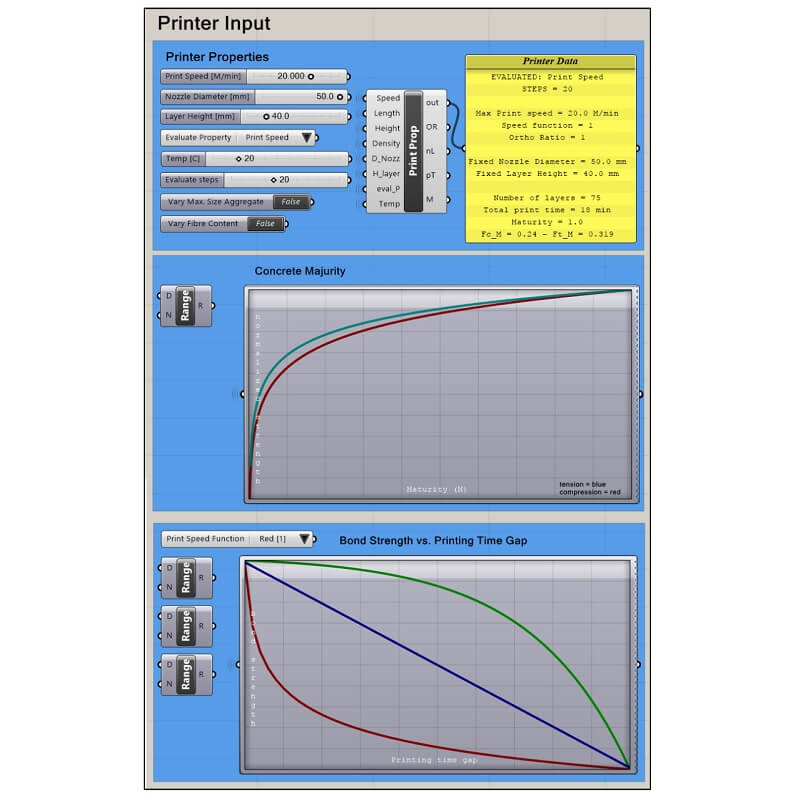

A research model is developed to evaluate these relations in a smart, efficient way. Because of the great quantity of variables involved, a parametric approach is adopted for this thesis, allowing for a high adaptability of the parameters involved and the relationships between them. This however results in a vast amount of combinations and variations, unable to provide useful solutions, let alone optima, without an extensive amount of (trial-and-error) calculations and time.

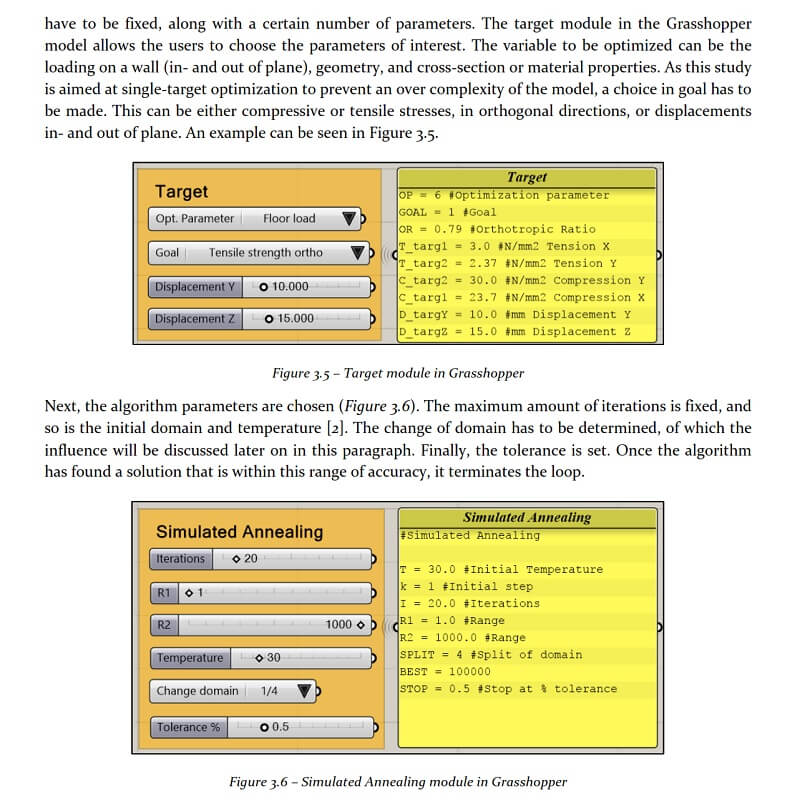

For this reason the optimization technique of Simulated Annealing (SA) is incorporated in the research model. SA is a problem-solving strategy which allows for a quick evaluation of an unknown domain of parameters, escaping local optima during the iterations and eventually converging to a global optimum.

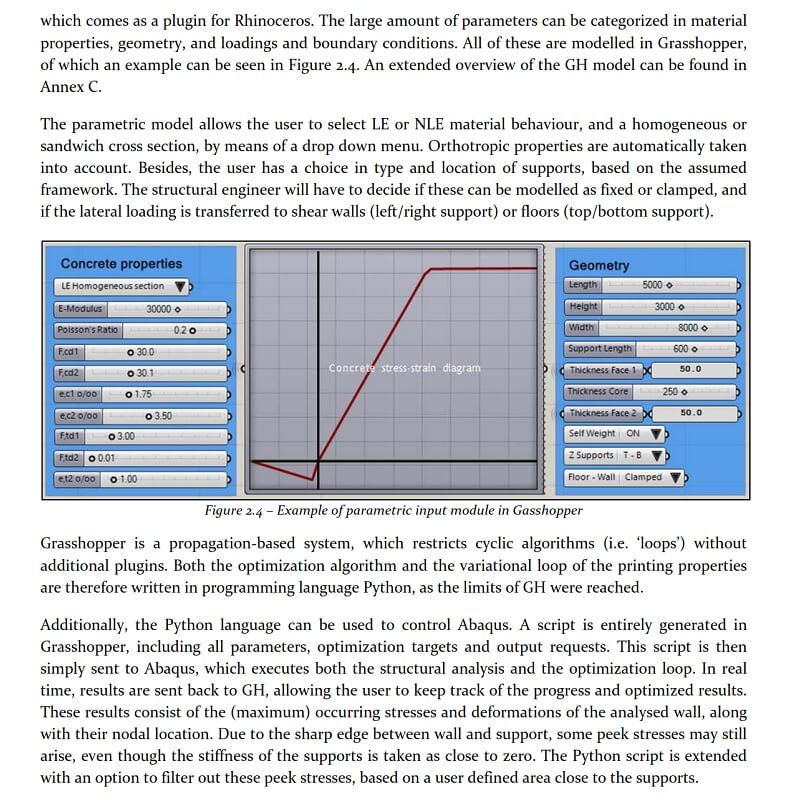

The parametric relationships between the different 3D printing components are realized in Grasshopper, a graphical algorithm editor, which comes as a plugin for Rhinoceros. Additionally, programming language Python is used to write the required algorithms.

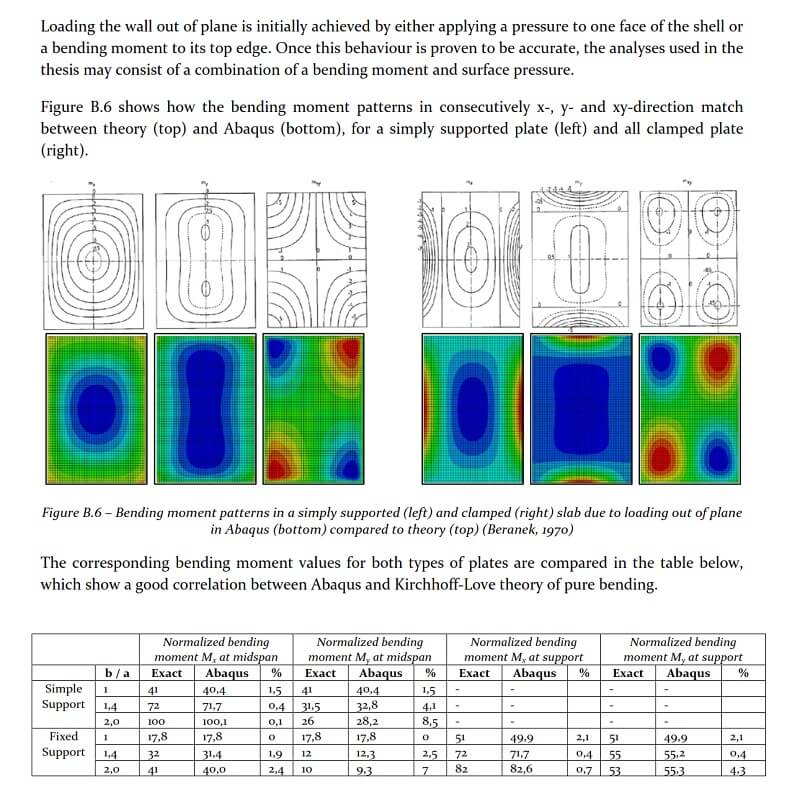

Together they act as the input for Finite Element Method (FEM) software Abaqus, which is used to study the 3D printed concrete wall in a structural way. The FEM model allows the printing behaviour to be studied, as it includes orthotropic behaviour which is a typical result of the layered production method. Considering the developments of new printable materials and shapes, non-linear elastic material properties and sandwich cross sections are also incorporated in the FEM model.

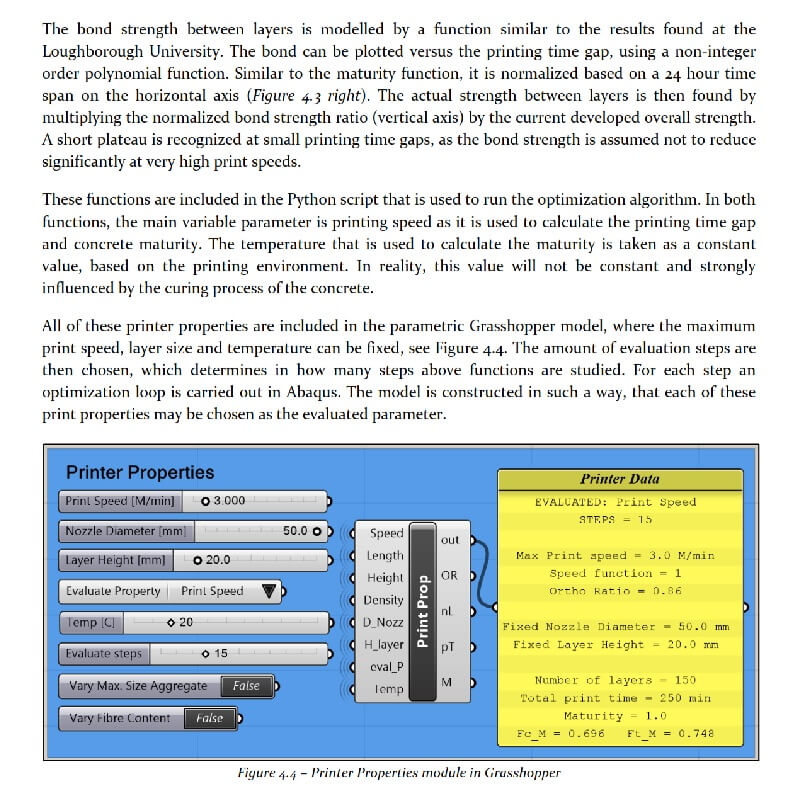

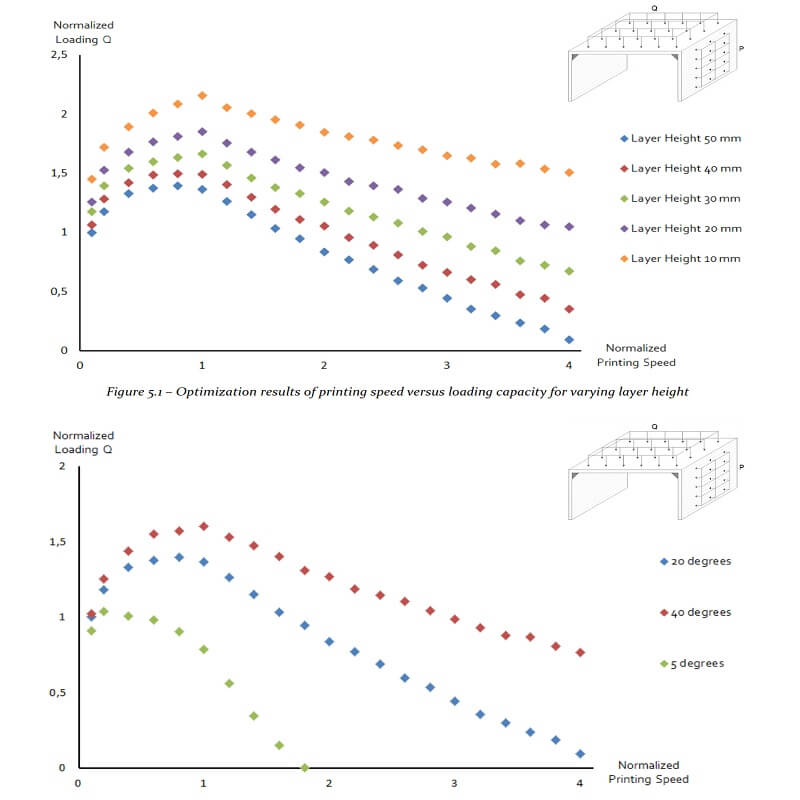

Once an efficient link between parametric input, structural analysis and optimization method is established, the 3D printing parameters are included in the research model. The printing speed is chosen as the to-be-studied variable, as this printer property influences two important material characteristics: the bond strength between the printed layers and the overall strength development of the concrete.

The relationship between printing time gap (i.e. the time it takes to print a new layer on top of the previous one) and bond strength is applied in varying forms, showing an improvement in interaction between layers as the printer speed increases. Additionally, the strength development is implemented by a concrete maturity method, including tensile and compressive strength development based on (printing) time and temperature.

The impact of 3D concrete printing is finally shown for varying print strategies, i.e. speed, layer size and printing environment (in-situ or prefab).

The analyses of the research model show that the loading capacity initially increases along with a higher print speed, as the bond between layers strengthens. However, at higher print speeds the overall strength development of the printed element becomes governing, and the capacity decreases. A reduction of layer height is beneficial for the overall strength development, but does strongly increase the total construction time. The choice of printing environment clearly influences the end result as well, as the low temperatures of in-situ printing result in much slower strength development compared to controlled, prefab printing.

These simple analyses on a printed structural wall have proven that the influence of 3D printing must not be underestimated and that the printing strategy has to be taken into account during each step from early design to construction. Additional research will have to be carried out aimed at gaining more insight in the components linked to 3D printing. By studying new printable materials and optimizing shapes including the typical properties of 3D printed concrete, the potential of this promising technique can be realised in practice. Using a research model as discussed in this thesis, and expending it with newly available data, will guide future developments on 3D concrete printing and support its successful implementation in the building industry.

Comments