Concrete Microstructure

From Fresh Concrete Microstructure to Digitally Fabricated

HPFRC: A Challenging Journey up From the Nanoscale in Search

of Precious Digital Macro-Applications

NICOLAS RUFFRAY

A thesis submitted to attain the degree of

DOCTOR OF SCIENCES of ETH ZURICH

2020

Since the invention of Portland cement during the first industrial revolution, concrete has become an inseparable aspect of modern societies by being the predilection material used for the construction of the vast majority of housing and infrastructure.

The recent development of concrete digital fabrication holds promises of a much more efficient way to build by granting access to free form geometrical complexity with appealing cost efficiency, reduced environmental footprint and increased worker safety. However, this transition to the digital era of concrete requires a greater mastery of this complex material which calls for a deeper and better understanding of its chemistry and microstructural behaviour.

The recent development of concrete digital fabrication holds promises of a much more efficient way to build by granting access to free form geometrical complexity with appealing cost efficiency, reduced environmental footprint and increased worker safety. However, this transition to the digital era of concrete requires a greater mastery of this complex material which calls for a deeper and better understanding of its chemistry and microstructural behaviour.

In this regard, the rheology of low water to cement ratio concretes and in particular the behaviour of superplasticisers in such systems remains difficult to predict and control, not only for digital fabrication, but much more broadly for concrete technology at large.

In this regard, the rheology of low water to cement ratio concretes and in particular the behaviour of superplasticisers in such systems remains difficult to predict and control, not only for digital fabrication, but much more broadly for concrete technology at large.

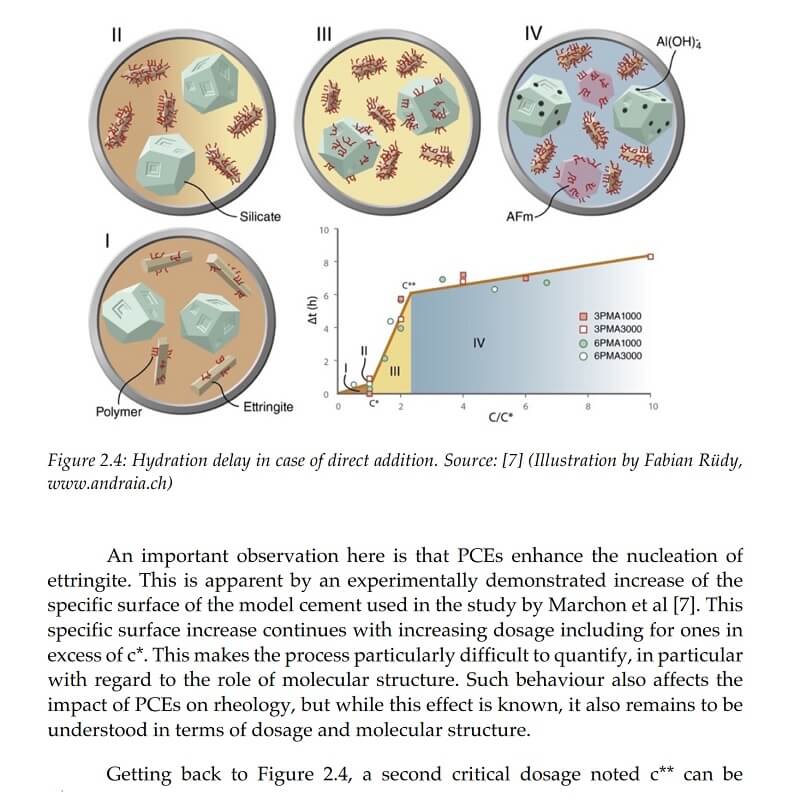

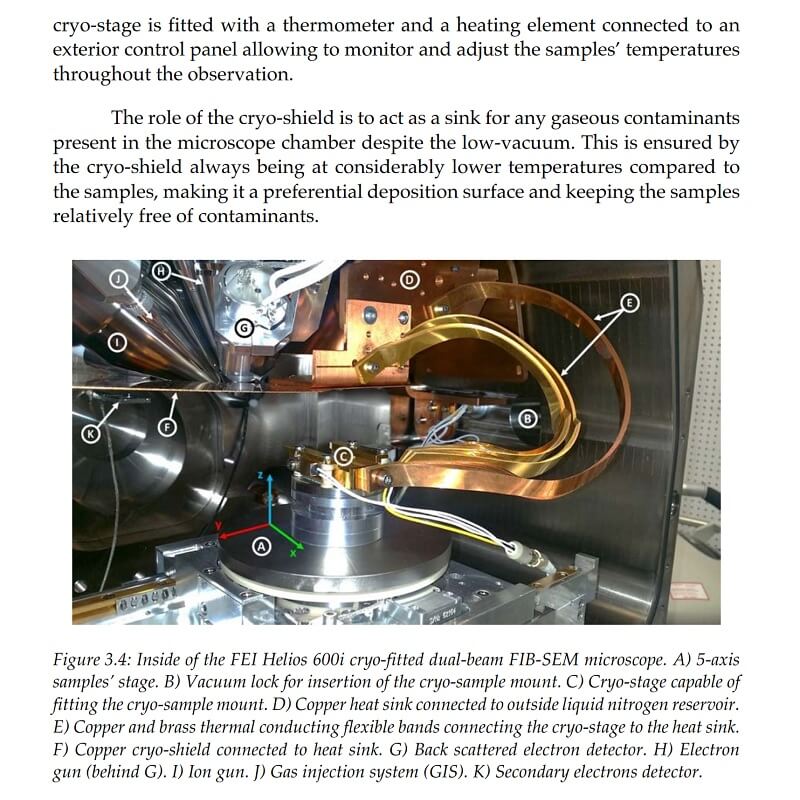

In this thesis by Nicolas Ruffray, the impact of PCE superplasticisers on the nucleation and formation of hydrates in fresh model cement pastes was investigated by using cryo-FIB-SEM nano-tomography. Qualitative results showed that direct addition of PCE increases the dispersion as well as the amount of formed hydrates while reducing their size.

In this thesis by Nicolas Ruffray, the impact of PCE superplasticisers on the nucleation and formation of hydrates in fresh model cement pastes was investigated by using cryo-FIB-SEM nano-tomography. Qualitative results showed that direct addition of PCE increases the dispersion as well as the amount of formed hydrates while reducing their size.

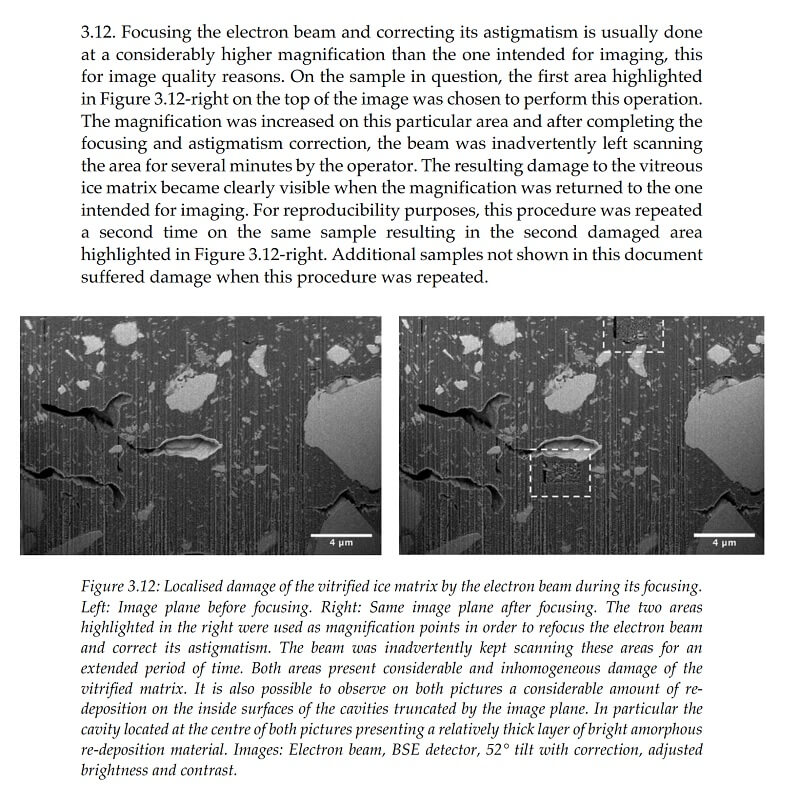

However, this work faced insurmountable holdbacks with regard to the acquisition of unbiased tomographic quantitative data due to a recurring imaging issue budded “scaling artefact” and supposedly originating from the inhomogeneous nature of frozen cement pastes.

However, this work faced insurmountable holdbacks with regard to the acquisition of unbiased tomographic quantitative data due to a recurring imaging issue budded “scaling artefact” and supposedly originating from the inhomogeneous nature of frozen cement pastes.

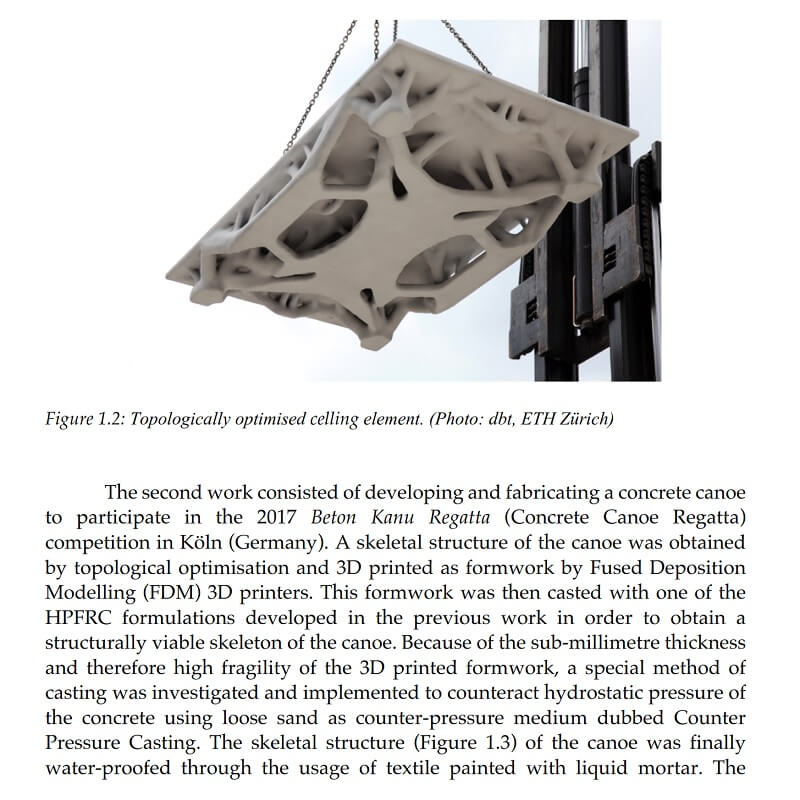

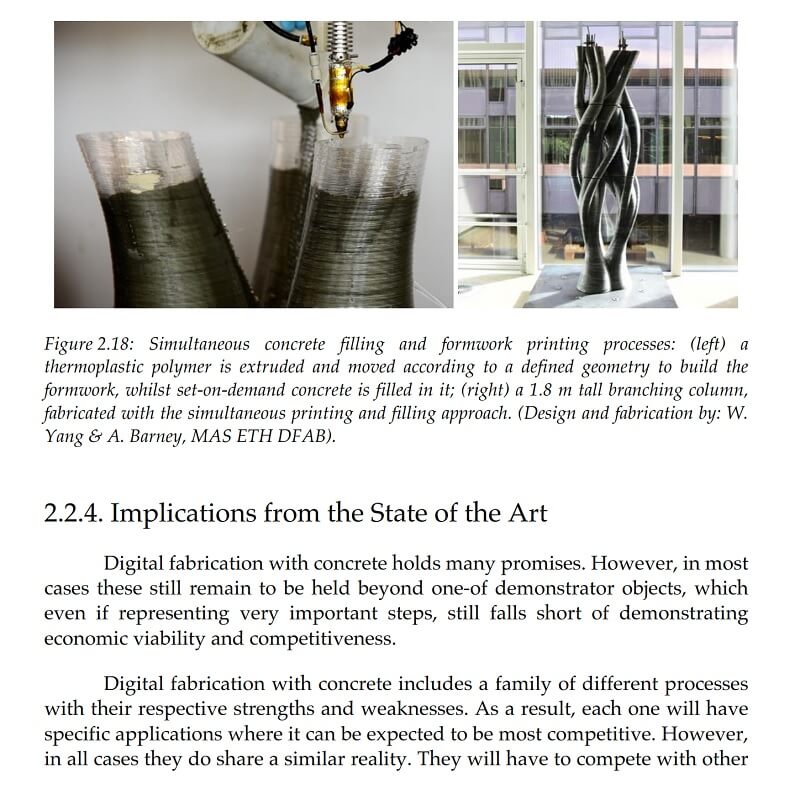

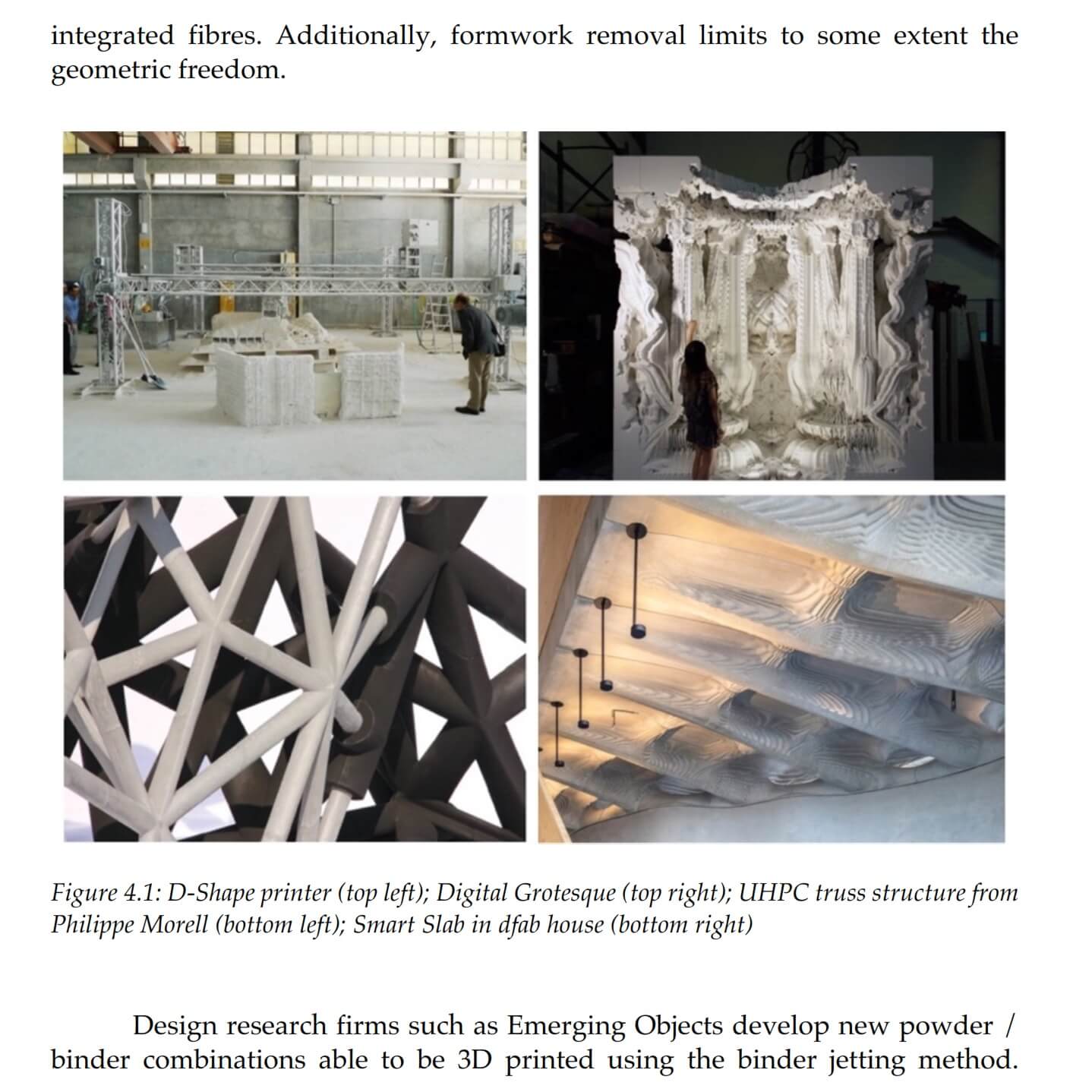

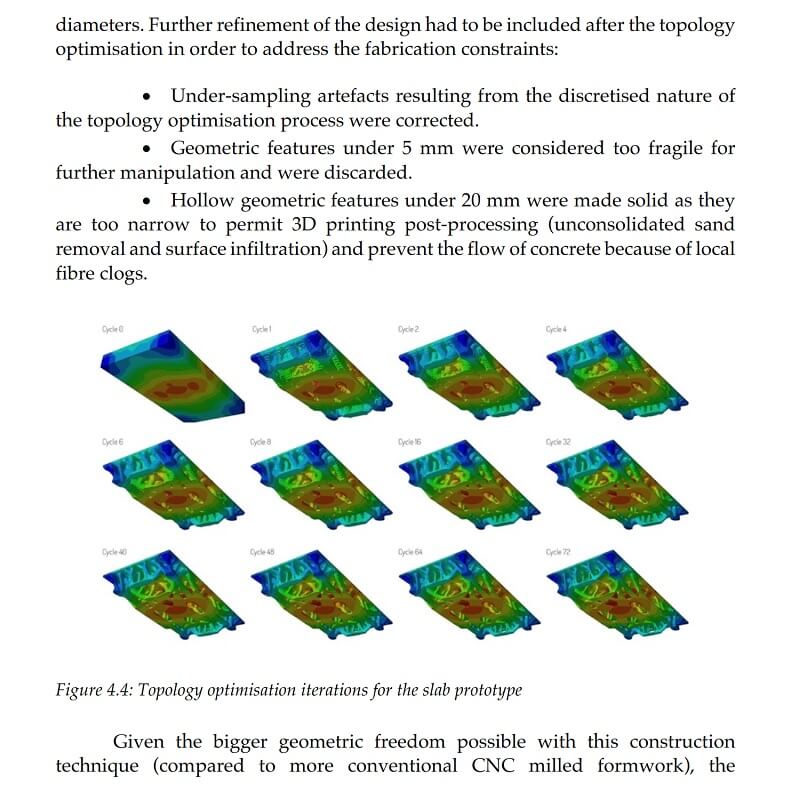

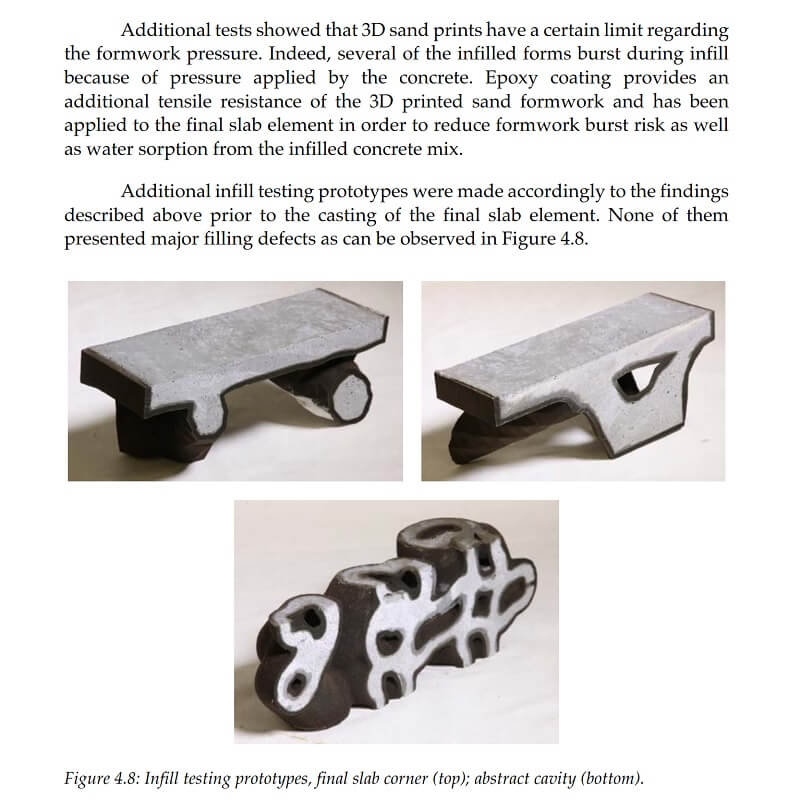

The second part of this PhD was dedicated to investigating the possible usage of thin digitally fabricated formworks in combination with low water to cement ratio fibre-reinforced concretes in order to produce topologically optimised elements. The approach chosen by this work was to avoid any advanced setting and hardening controls of the concrete in opposition to other techniques of digital casting.

The second part of this PhD was dedicated to investigating the possible usage of thin digitally fabricated formworks in combination with low water to cement ratio fibre-reinforced concretes in order to produce topologically optimised elements. The approach chosen by this work was to avoid any advanced setting and hardening controls of the concrete in opposition to other techniques of digital casting.

Two structurally viable elements were produced over two collaborative projects with the dbt research group (D-ARCH, ETH Zürich). The production of these elements led to the development and usage of several HPFRC formulations that were meeting the specific rheology and mechanical requirements of the projects.

Two structurally viable elements were produced over two collaborative projects with the dbt research group (D-ARCH, ETH Zürich). The production of these elements led to the development and usage of several HPFRC formulations that were meeting the specific rheology and mechanical requirements of the projects.

The first produced element was a celling/flooring panel cast in a sand binder-jetting 3D printed lost formwork. The second element was a fully functional concrete canoe, the load bearing skeletal structure of which was 3D printed as a sub-millimetric formwork by FDM. Cast using a specially developed technique called “counter-pressure casting” to counteract the mechanical fragility of the formwork, the “skelETHon” canoe successfully participated in the 2017 Concrete Canoe Regatta wining the first prise of Design Innovation Awards.

The first produced element was a celling/flooring panel cast in a sand binder-jetting 3D printed lost formwork. The second element was a fully functional concrete canoe, the load bearing skeletal structure of which was 3D printed as a sub-millimetric formwork by FDM. Cast using a specially developed technique called “counter-pressure casting” to counteract the mechanical fragility of the formwork, the “skelETHon” canoe successfully participated in the 2017 Concrete Canoe Regatta wining the first prise of Design Innovation Awards.

These two demonstrators showed the great potential of 3D printing thin formworks for complex concrete elements highlighting the “complexity for free” promise made by concrete Digital Fabrication in general. Importantly it has served to define a new digital fabrication process with concrete, defined as counter-pressure casting that presents many advantages for a possible adoption by industry. In summary, this thesis relates the importance of a better understanding of concrete chemical and microstructural aspects that are unconditionally needed for any advanced macro-application, including but not limited to concrete digital fabrication.

These two demonstrators showed the great potential of 3D printing thin formworks for complex concrete elements highlighting the “complexity for free” promise made by concrete Digital Fabrication in general. Importantly it has served to define a new digital fabrication process with concrete, defined as counter-pressure casting that presents many advantages for a possible adoption by industry. In summary, this thesis relates the importance of a better understanding of concrete chemical and microstructural aspects that are unconditionally needed for any advanced macro-application, including but not limited to concrete digital fabrication.

Comments