Crafting Decisions

CRAFTING DECISIONS

Integrating design, fabrication, and assembly for six-axis robotic arms

Molly Mason

Submitted to the Department of Architecture

in Partial Fulfillment of the Requirements for the Degree of Master of Science in Architecture Studies

at the Massachusetts Institute of Technology

May 2020

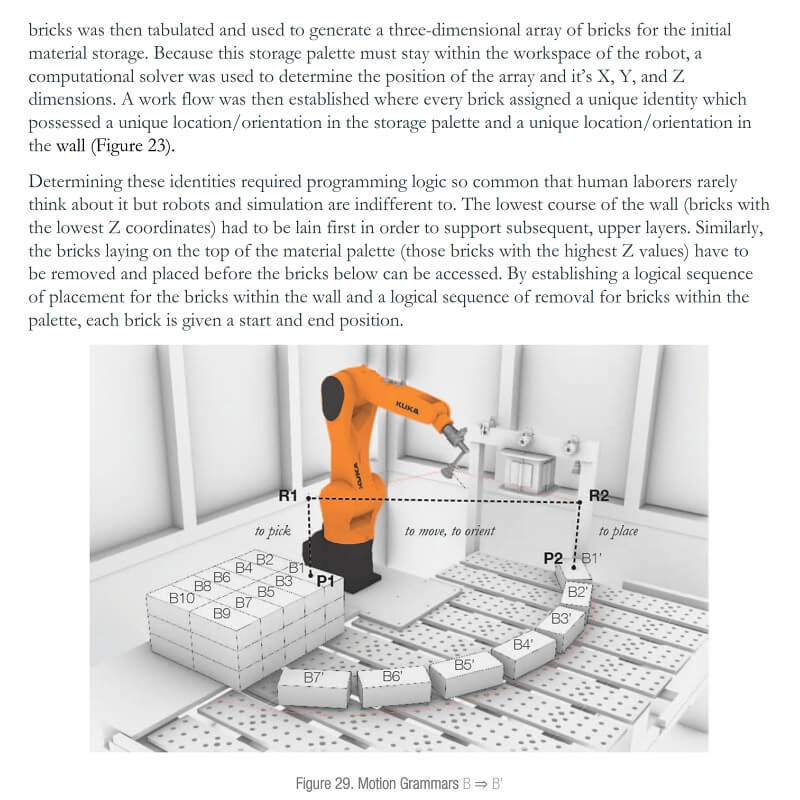

Within the contemporary practice of architecture, what we design determines how we make it. Digital fabrication provides designers the opportunity to directly link digital models with CNC equipment such as robotics. While beneficial this direct link eliminates the ability for a craftsperson to adjust forms on-site using their knowledge of material and process.

To reintroduce the flexibility of the crafts process and take advantage of material and tool capabilities, it is necessary to embed this craft knowledge into the design model itself in a series of craft decisions. Such craft decisions include both the “live” choices made while making, which pull from past experiences, material behavior, and tacit knowledge, and the choice of how one formalizes descriptions of making.

To reintroduce the flexibility of the crafts process and take advantage of material and tool capabilities, it is necessary to embed this craft knowledge into the design model itself in a series of craft decisions. Such craft decisions include both the “live” choices made while making, which pull from past experiences, material behavior, and tacit knowledge, and the choice of how one formalizes descriptions of making.

The act of making consists of both how material is shaped into parts and how these parts come together to participate as a whole. However, fifteen years of industrial robotic research has examined the acts of fabrication and assembly separately. This does not consider bidirectional relationship between part formation and assembly where customized parts require new modes of assembly and assembly requires certain formal part characteristics for handling.

The act of making consists of both how material is shaped into parts and how these parts come together to participate as a whole. However, fifteen years of industrial robotic research has examined the acts of fabrication and assembly separately. This does not consider bidirectional relationship between part formation and assembly where customized parts require new modes of assembly and assembly requires certain formal part characteristics for handling.

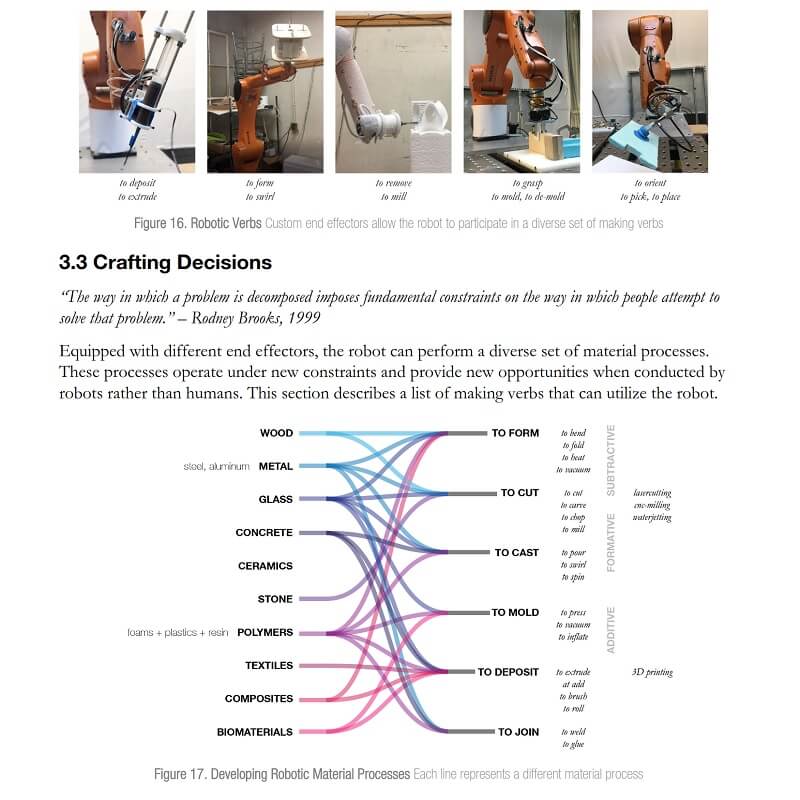

In this thesis by Molly Mason, author proposes the integration of robotic fabrication and assembly constraints into the design process to use as drivers for form-finding. The framework for this is created through codifying material processes and assembly logics into making verbs which act as descriptions of tools, material, and movement.

In this thesis by Molly Mason, author proposes the integration of robotic fabrication and assembly constraints into the design process to use as drivers for form-finding. The framework for this is created through codifying material processes and assembly logics into making verbs which act as descriptions of tools, material, and movement.

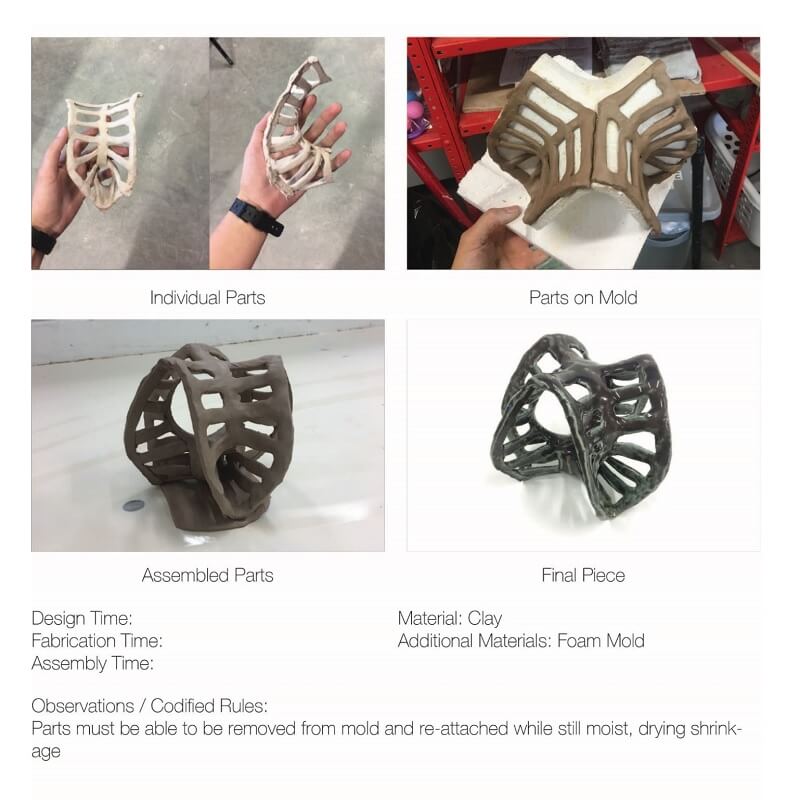

Through the combination of multiple verbs, the designer is able to explore formal design spaces which are informed by fabrication and assembly constraints. The design of parts is kept “live” during the process of making, capable of being altered based on constraints of material process and assembly.

Through the combination of multiple verbs, the designer is able to explore formal design spaces which are informed by fabrication and assembly constraints. The design of parts is kept “live” during the process of making, capable of being altered based on constraints of material process and assembly.

The resultant workflows propose an active dialogue between design, fabrication, and assembly where the act of making is described through actions rather than explicit geometrical models.

Comments