Flexible Textile

3D printed knitted textiles

By: Mark Beecroft

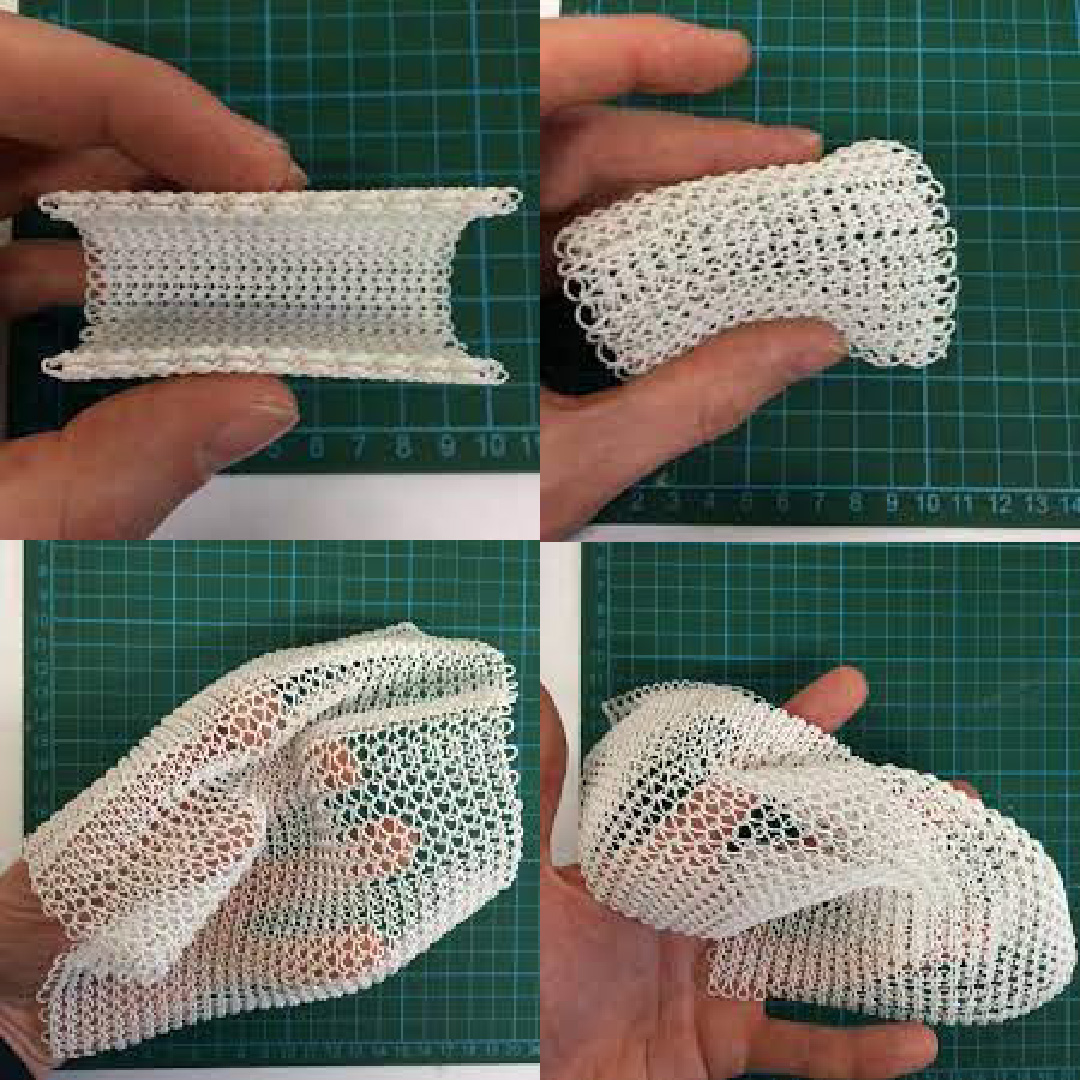

The technology of 3D printing is perfectly suited to this type of textiles manufacturing, and specifically, using selective laser sintering (SLS) in the fabrication of tubular forms of varying sizes. The use of 3D printing is also appropriate for the production of apparel as the technology has lent so much already to the bold realm of fashion, from dresses to bathing suits to shoes.

The technology of 3D printing is perfectly suited to this type of textiles manufacturing, and specifically, using selective laser sintering (SLS) in the fabrication of tubular forms of varying sizes. The use of 3D printing is also appropriate for the production of apparel as the technology has lent so much already to the bold realm of fashion, from dresses to bathing suits to shoes.

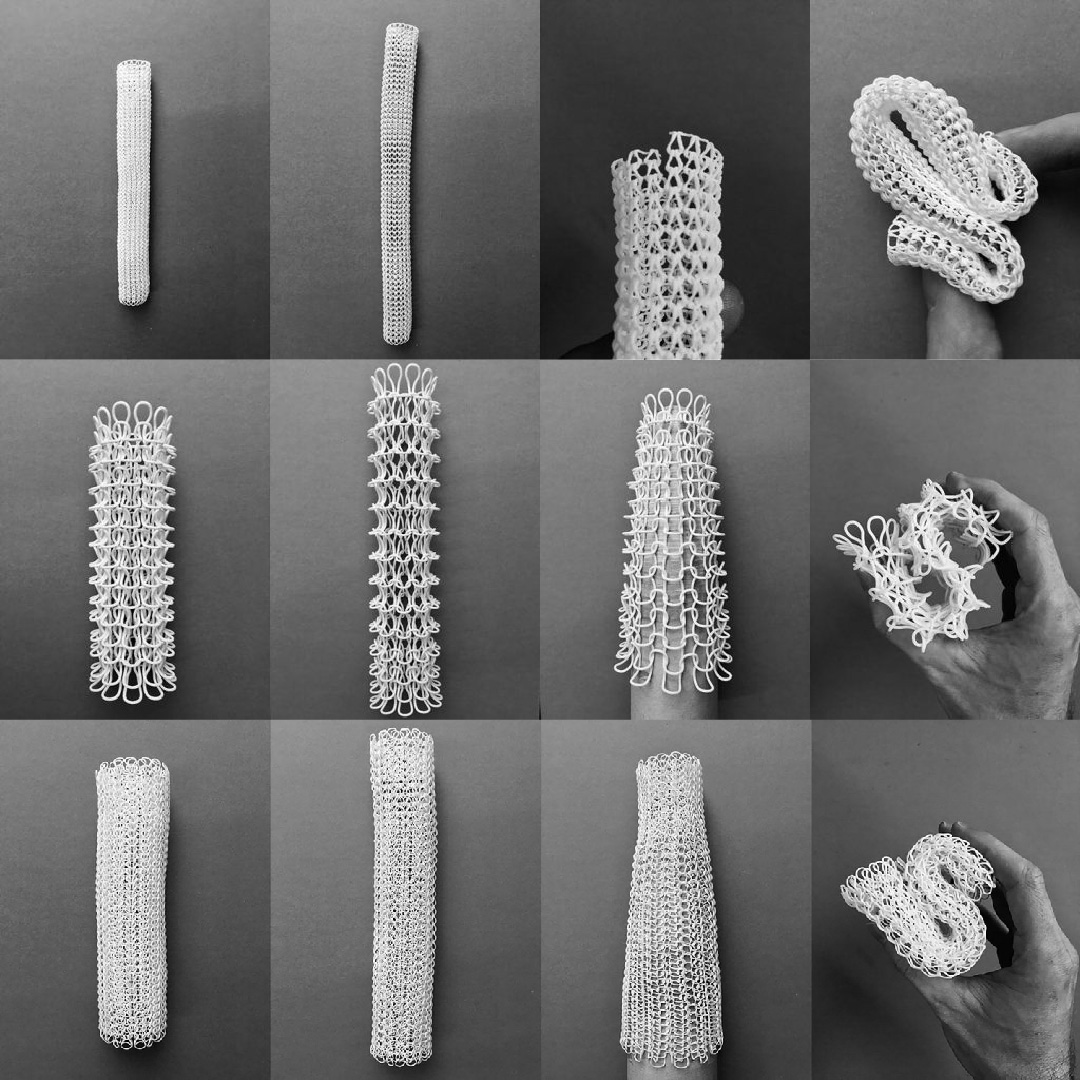

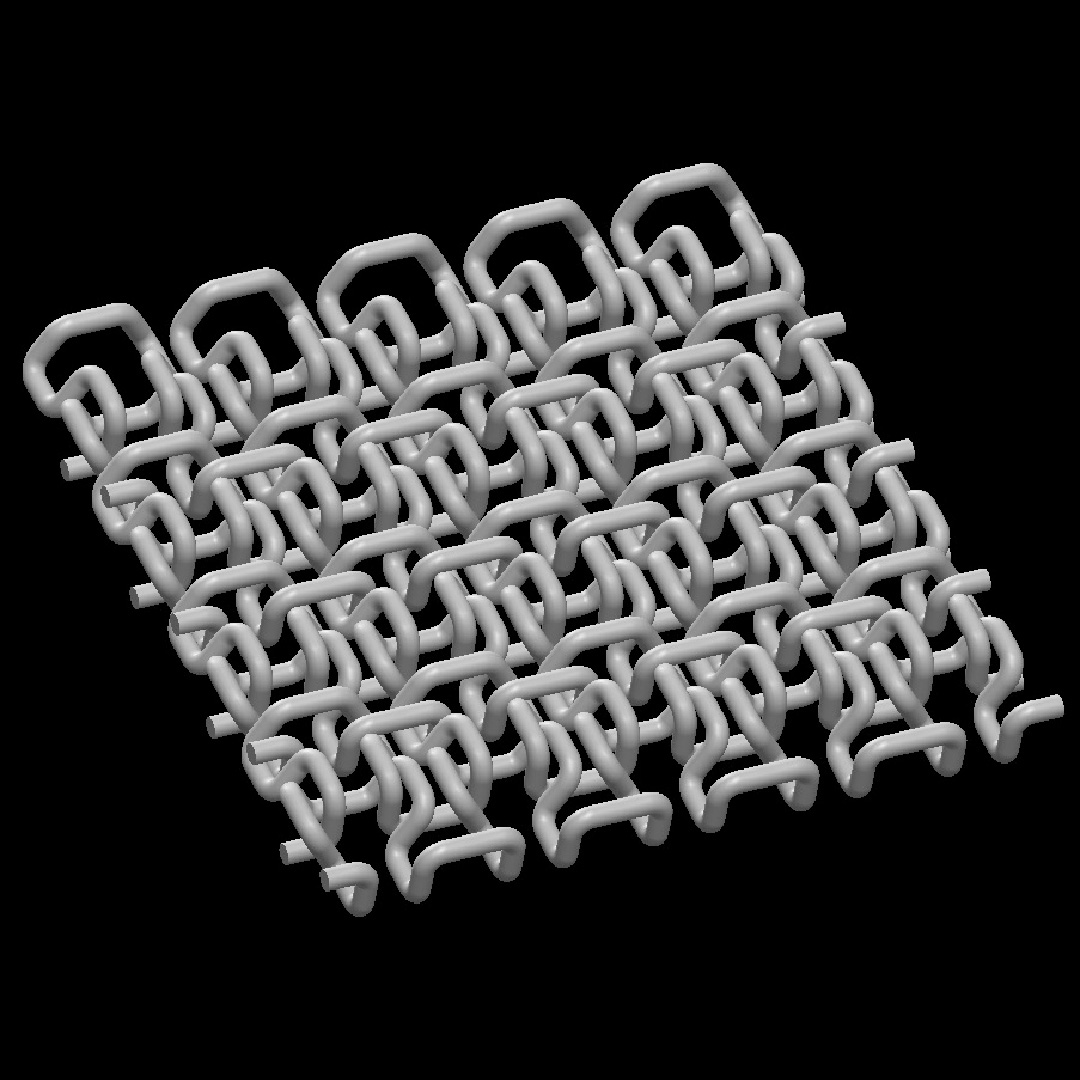

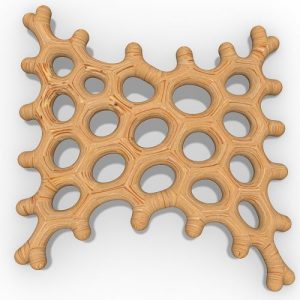

By 3D printing knit-based structures it’s possible to embed knit’s inherent properties of stretch and flexibility, whilst exploiting the mechanical properties of the material used to print with. While previous research into 3D printing knitting structures has been performed, it mainly pertained to non-continuous, linked geometries. Here, Beecroft examines the use of 3D printing continuous fiber type geometries and testing resulting structures that are both single- and double-face. Evaluation of each structure includes checking how well they handle being compressed and extended, along with total flexibility.

By 3D printing knit-based structures it’s possible to embed knit’s inherent properties of stretch and flexibility, whilst exploiting the mechanical properties of the material used to print with. While previous research into 3D printing knitting structures has been performed, it mainly pertained to non-continuous, linked geometries. Here, Beecroft examines the use of 3D printing continuous fiber type geometries and testing resulting structures that are both single- and double-face. Evaluation of each structure includes checking how well they handle being compressed and extended, along with total flexibility.

The knit structures studied by Beecroft were 3D printed on an EOS Formiga P110, with Nylon PA12 as the selected material, requiring no extra supports apart from loose powder, and offering the required stability and strength.

The knit structures studied by Beecroft were 3D printed on an EOS Formiga P110, with Nylon PA12 as the selected material, requiring no extra supports apart from loose powder, and offering the required stability and strength.

Comments