Ice Formwork

Robotically Fabricated Ice Formwork:

An Exploration on Casting Morphologically

Programmed Complex Concrete Elements

with Robotically Milled Ice Formworks

Enrico Pontello1, Martin Tamke2, and Vasily Sitnikov3

1BSc. Arch, M.Arch. MAA Architect

2CITA Centre for Information Technology and Architecture, The Royal Danish Academy of Fine

Arts Schools of Architecture, Design and Conservation, Copenhagen, Denmark

3KTH Royal Institute of Technology, Stockholm, Sweden

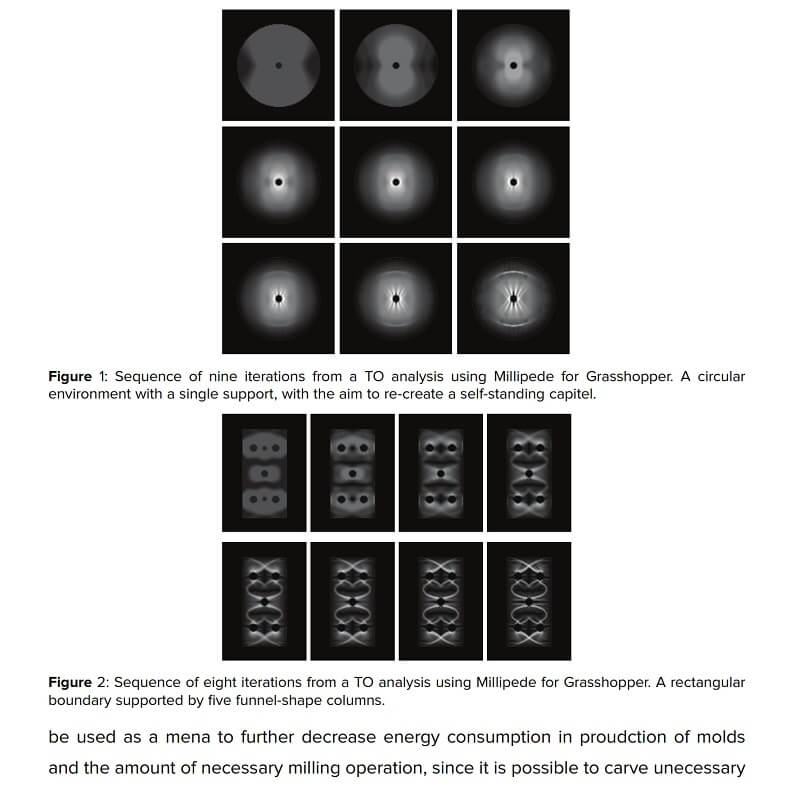

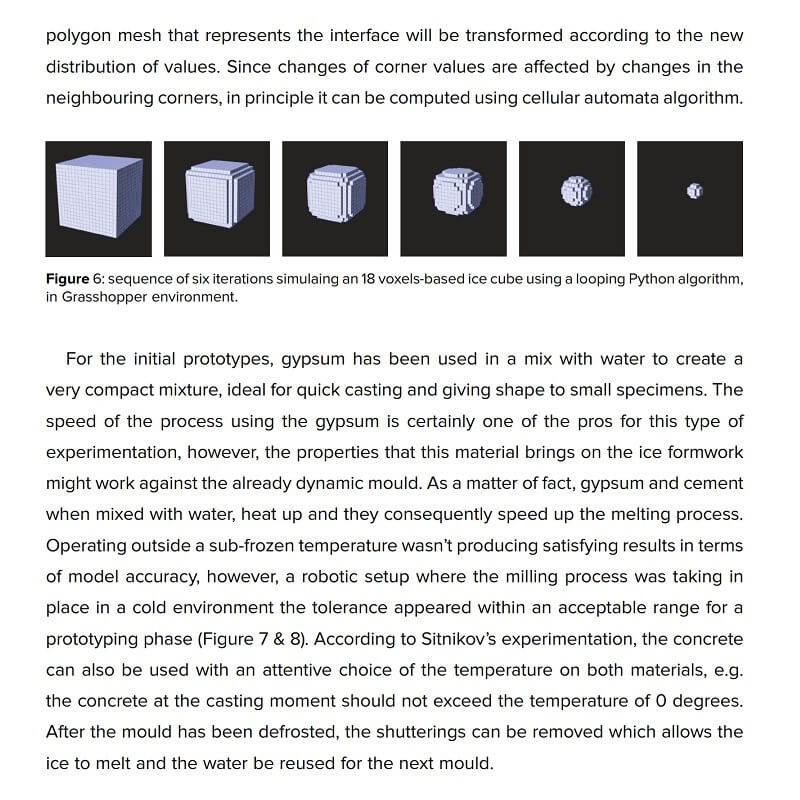

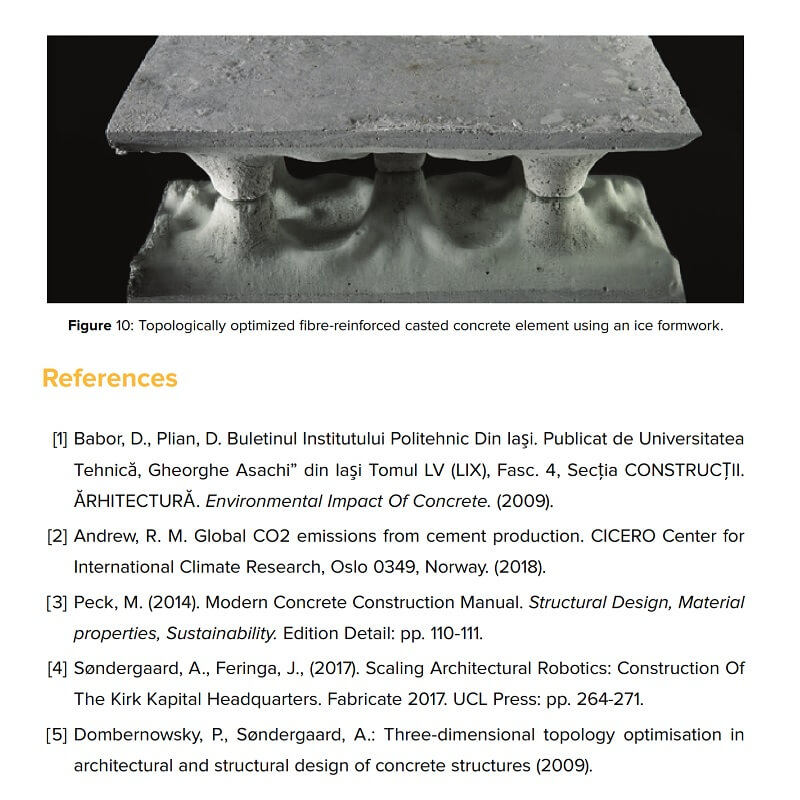

This document by Enrico Pontello, Martin Tamke and Vasily Sitnikov, focuses on the exploration of casting complex concrete architectural elements with ice formwork. Replacing conventional concrete formwork with ice formwork, allows to produce architectural elements with complex geometries in a highly controlled offsite production process, with almost complete reuse of the mold material.

Using digitally driven fabrication tools such as a robotic arm milling, the goal is to achieve 3d shapes made from one or more ice molds, able to be stacked, assembled and merged together in order to define architectural partitions.

Using digitally driven fabrication tools such as a robotic arm milling, the goal is to achieve 3d shapes made from one or more ice molds, able to be stacked, assembled and merged together in order to define architectural partitions.

One of the main instigators of this research is the sustainability, showcased both through the usage of ice as a mold material that is 100% reusable, and the unique ability of the described process to produce topology optimised shapes in concrete, which reduces the use of this high carbon footprint materal to a bare minimum.

One of the main instigators of this research is the sustainability, showcased both through the usage of ice as a mold material that is 100% reusable, and the unique ability of the described process to produce topology optimised shapes in concrete, which reduces the use of this high carbon footprint materal to a bare minimum.

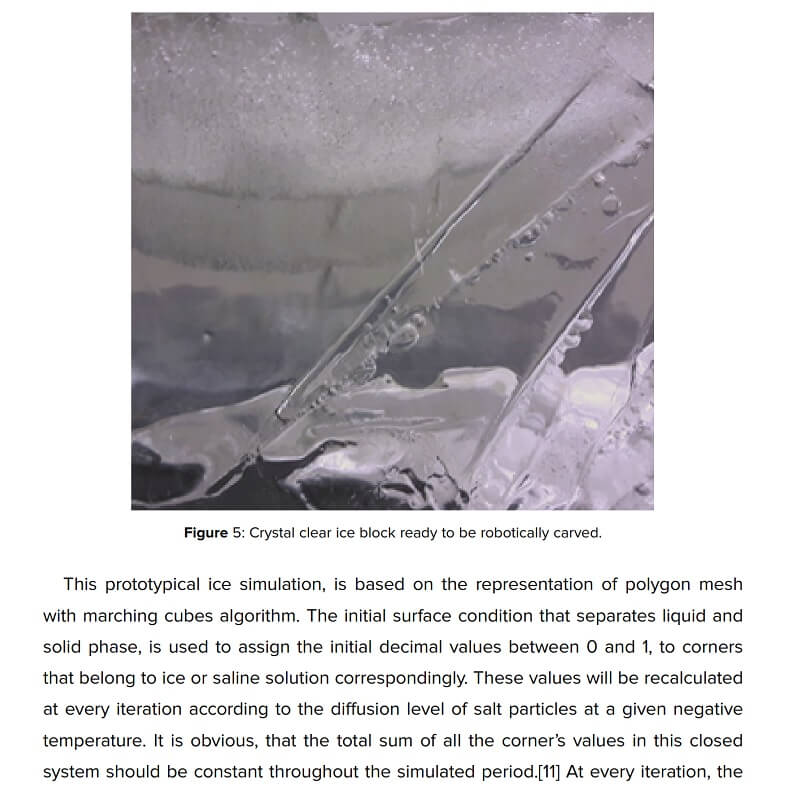

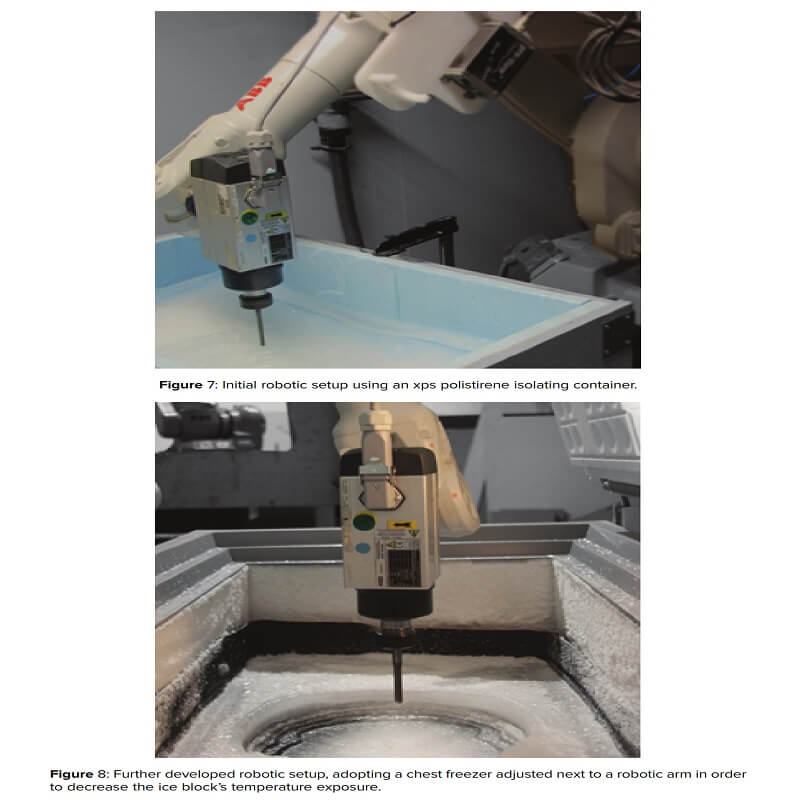

Ice formwork allows furthermore, to create bespoke shapes for every single element in an efficient way. This opens new avenues for architectural design and construction. This project uses a design based research methodology, where each physical iteration is carefully evaluated against the digital model, embracing morphological material programming.

Ice formwork allows furthermore, to create bespoke shapes for every single element in an efficient way. This opens new avenues for architectural design and construction. This project uses a design based research methodology, where each physical iteration is carefully evaluated against the digital model, embracing morphological material programming.

Comments