Modular Kinematic Timber

Modular kinematic timber gridshell; a simple scheme for constructing advanced shapes

Steinar H. DYVIK1, John H. MORK2, Magnus NILSEN3, Marcin LUCZKOWSKI4

1Faculty of Architecture and Fine Art, NTNU, Norwegian University of Science and Technology, Trondheim Norway

2Faculty of Architecture and Fine Art, NTNU, Norwegian University of Science and Technology, Trondheim Norway

3Department of Structural Engineering, NTNU, Norwegian University of Science and Technology, Trondheim Norway

4Department of Structural Engineering, NTNU, Norwegian University of Science and Technology, Trondheim, Norway, Poland

Figure 1 Photo of the gridshell pavilion built in Trondheim.

This paper explains the construction scheme of a modular post formed gridshell. The scheme uses timber modules connecting laths of 900 mm length into a 2-layer module.

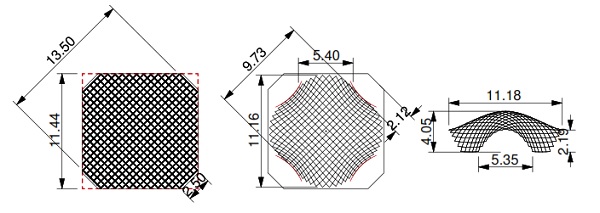

Figure 2 Dimensions of the planned gridshell pavilion built in Trondheim. The dimensions varied slightly in the final pavilion. Left: Size of the flat grid. Right: Sizes of the raised construction.

The scheme and the module are designed to efficiently handle both Form Finding, Fabrication and Raising, and they are tested through the construction of a full scale pavilion in Trondheim, Norway.

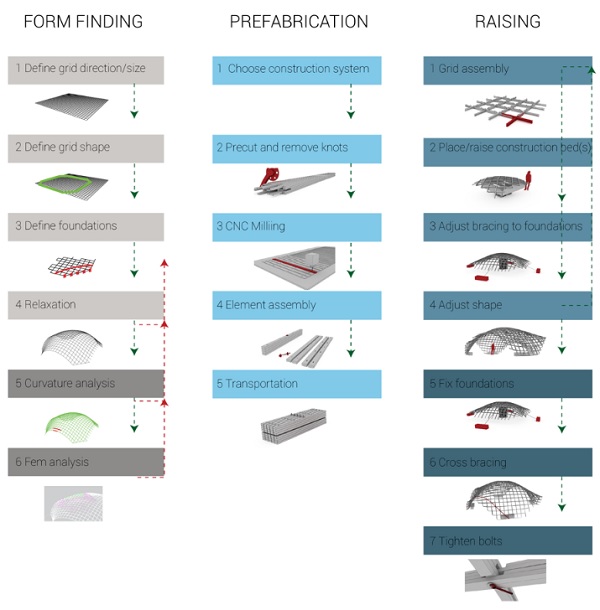

Figure 3 The three parts of the construction scheme are described in this paper

Kinematic Gridshells are elegant and light structures that can create complex shapes by simple means.

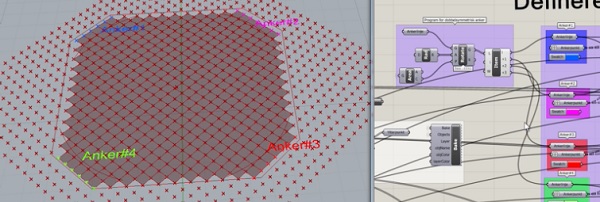

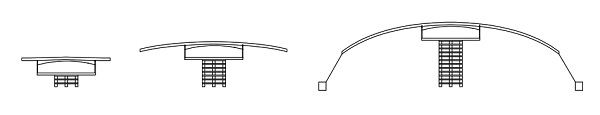

Figure 4 The form finding starts by deciding grid size and direction, and by drawing an approximate outline of the flat grid. The anchor points are then extracted and connected to the code.

Gridshell structures have been constructed in various forms from the beginning in Vyksa, to Edmund Happold’s experiments with lattice roofs in the 1960s and Frei Otto’s design of Mannheim Multihalle in 1975.

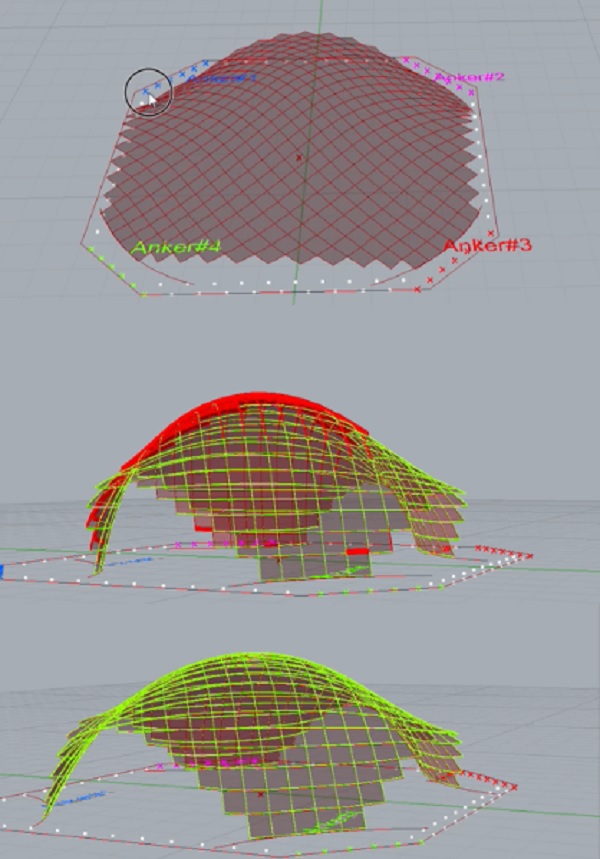

Figure 5 Further steps of the form finding. With a minimum curvature analysis based on material quality, the model can check whether it is possible to construct the found shape.

The last decades in United Kingdom, timber gridshells returned in the form of the Weald and Downland Museum (2002), Chiddingstone Orangery (2004) and the Savill Building (2006).

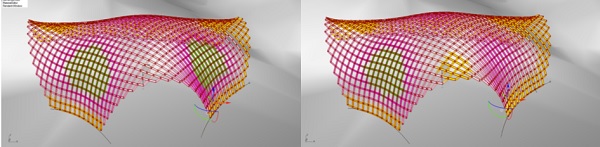

Figure 6 Structural performance testing with Karamba. The image to the right has a slightly change in the foundation curve.

More recently Sergio Pone and Sofia Colabella with their group: gridshell.it, performed several gridshell experiments on a smaller scale, and set the agenda for the development.

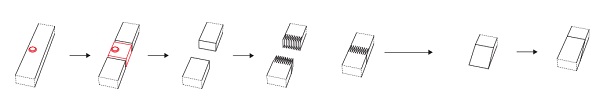

Figure 7 The Segment Lath. From module to assembly.

While buildings with simple shapes easily can be constructed by simple, repetitive procedures, advanced shapes often demand complex construction schemes.

Figure 8 Knot removal in Saville building. The Segment Lath gives another solution to these issues. Top: Knots were removed, and finger joint up to 6 meter lengths. Bottom: In this case they were also extended from 6 to 36 meters using lap-joints.

With new tools for both designing and manufacturing, the construction of gridshells have again resurrected.

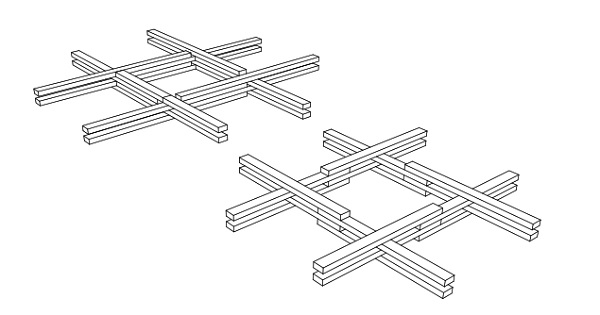

Figure 9 The overlap in the Segment Lath has the same function as the shear blocks. Same grid size can be archived with different overlaps.

The work of Pone and Colabella has shown the potential of gridshells with the construction of several structures the last decade.

Figure 12 The shape of the grid-bed is taken directly from the 3D model, and cut to fit the final shape.

The development at the same time of the modelling add-in: Kangaroo from Daniel Piker has been crucial for performing any form finding process.

Figure 13 Adding pallets raises the shell evenly and helps keeping a good working height. Gravity participates to shaping the shell gradually as more weight is added. At a point, temporary bracing is added to keep the structure mode in balance.

This paper highlights the possibilities of a modular kinematic gridshell construction scheme. The Segment Lath solution provided substantial improvements to many known challenges of kinematic gridshells, among others: knot removal, shear blocks, fabrication and transportability.

Comments