Monolithic Shells

Digital fabrication phasing for monolithic shells

Stephanie CHALTIEL*, Maite BRAVOa

* PHD Candidate, Universidad Polytecnica de Catalunya UPC, Institute for Advanced Architecture of Catalunya

[Iaac] [email protected]

a PHD Architect, Institute for Advanced Architecture of Catalunya [Iaac].

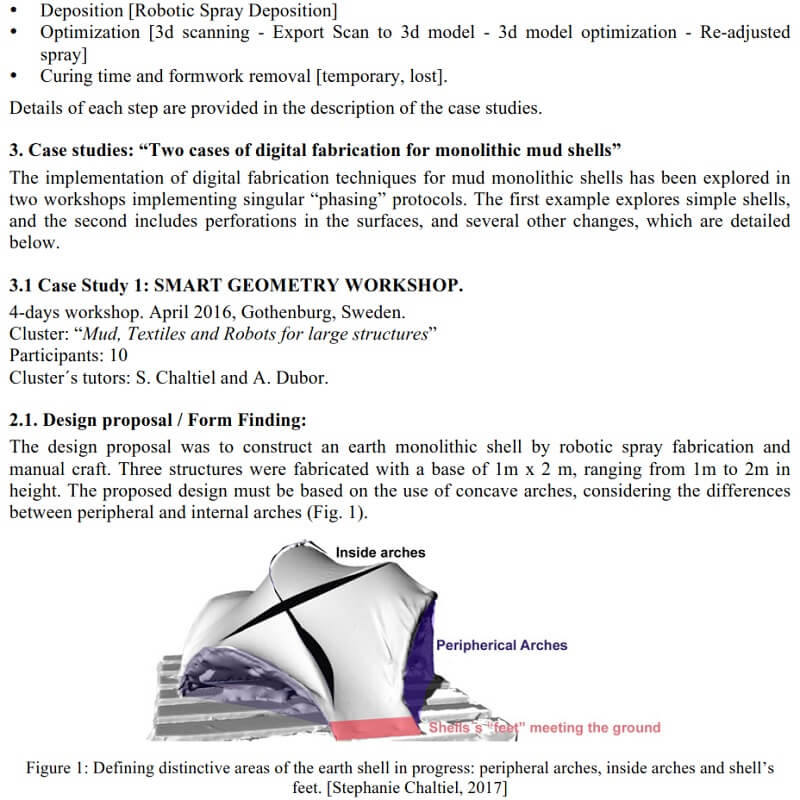

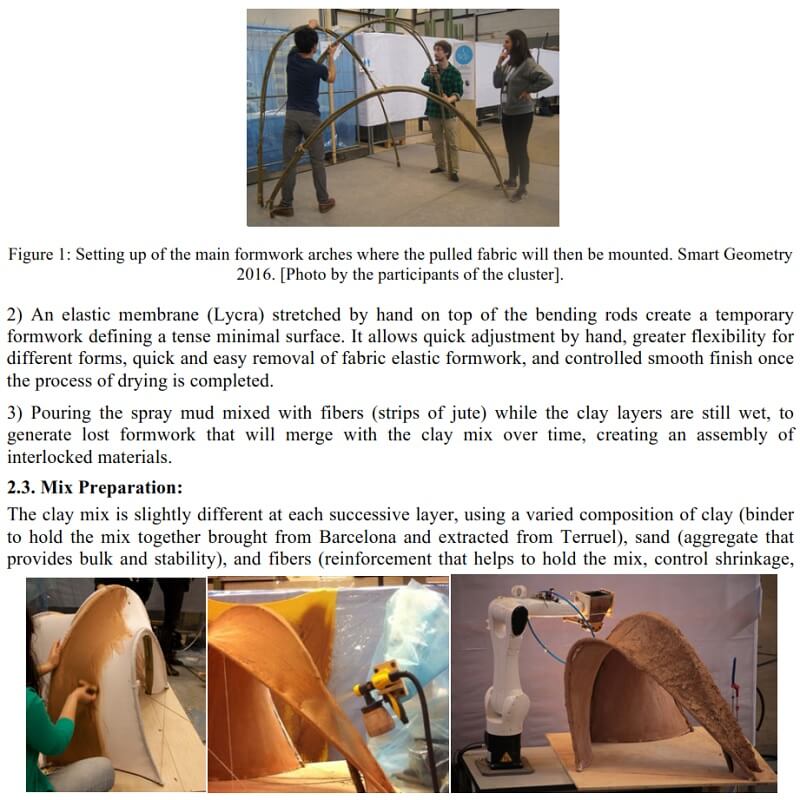

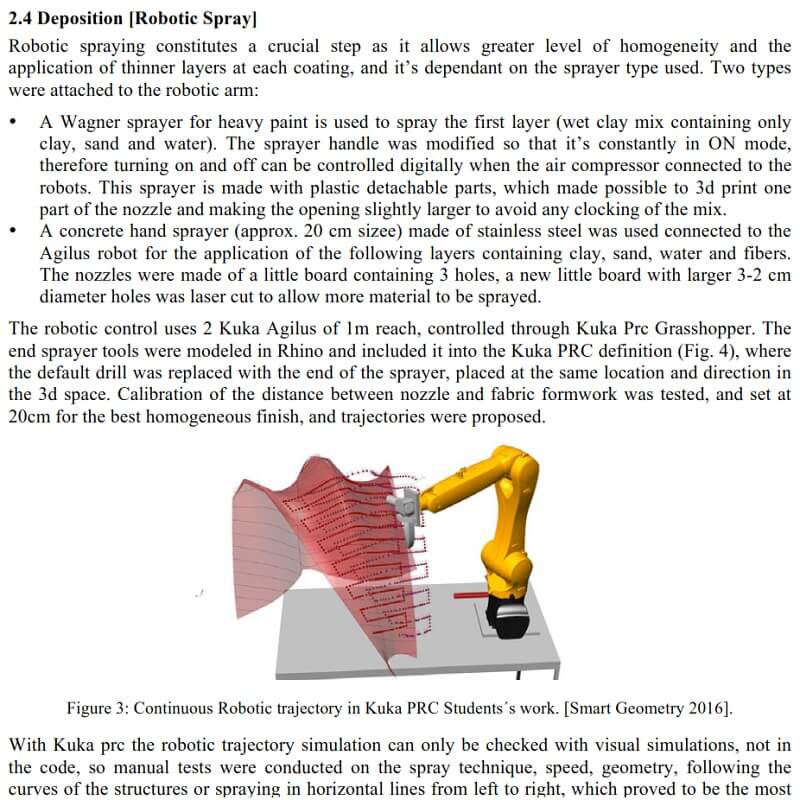

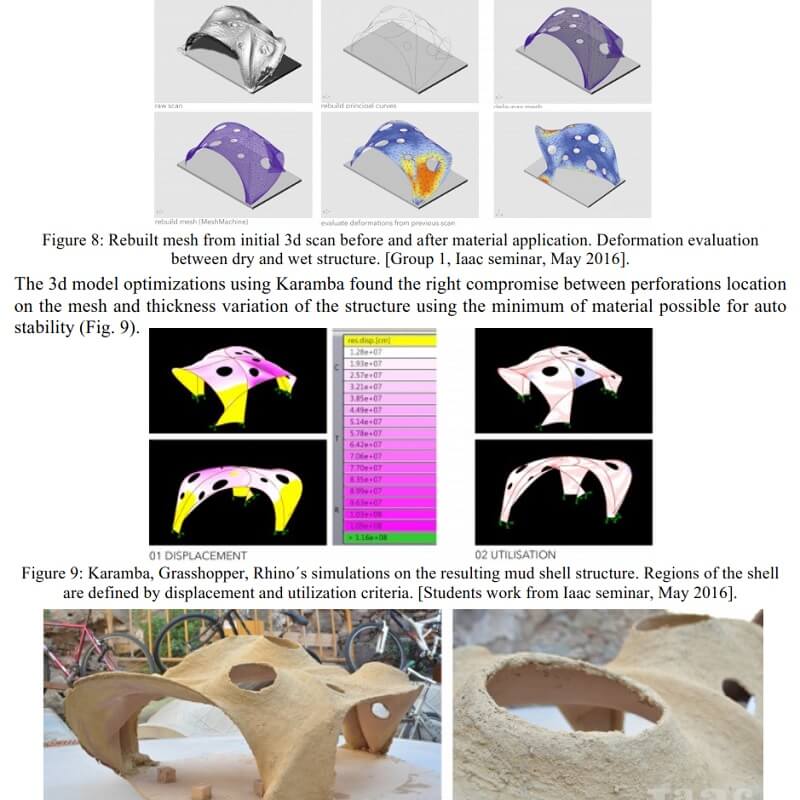

The digital formulation of monolithic shell structures present some challenges related to the interface between computational design and digital fabrication techniques, such as the methods chosen for the suitable parametrization of the geometry (Bravo, M., 2013), the optimization criteria of variables, the translation of the relevant code for digital fabrication, and especially the phasing related to the matter becoming material within the digital fabrication process.

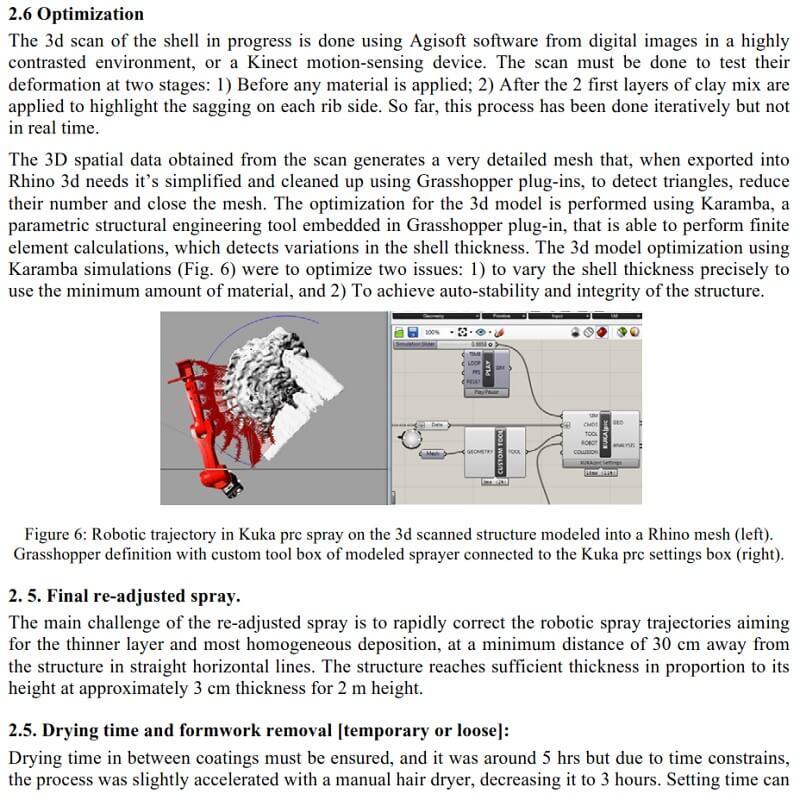

This paper by Stephanie CHALTIEL and Maite BRAVO exposes the process for the implementation of new digital and physical methods for monolithic shells design and construction using digital fabrication techniques combined with enjoyable manual craft. It explores the potential of carefully recalibrating the phasing between digital parametric modeling formulation and simulations with the physical translation aiming at renewing shells construction processes, in terms of the time it takes to build them, the optimization of materials and labor, and the feasibility of the dweller to be involved during different phases of construction. In addition, it will highlight significant changes that digital fabrication can engender in the use and the resulting aesthetics. (Huijben, Van Herwijnen, Nijsse, 2011).

The paper will feature 2 case studies, detailing the steps required to take advantage of the circular data flow involved in digital modeling techniques, matter characteristics, structure distortion, and digital fabrication tools using robotics (Block, Veenendaal, 2015). It will explore examples implemented with an easily mounted temporary or lost formwork, and the methods of 3d scanning iteratively or in real time, so the form in progress can inform the system when at a later stage the fabrication tools will be depositing the material.

The potential of integrating sensors and radars used in the car industry to create new protocols of construction will be explored, such as having a set rule between the angle of extrusion and the level of material’s viscosity. New interfaces between 3d modeling programs will be presented (such as rhino and robotic fabrication – Kuka prc for example – and the resulting novel monolithic shell construction experiments will be revealed.

Comments