MSc2 Hyperbody

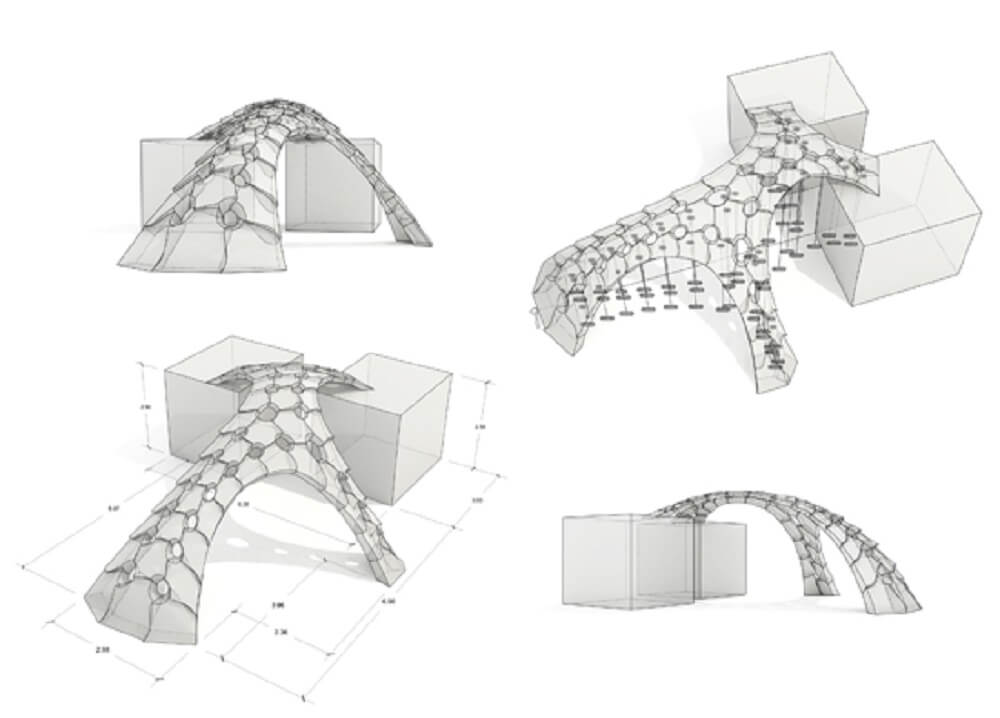

1:1 prototypes (Spring 2012) conducted by Jelle Feringa at the Hyperbody research group of the Faculty of Architecture, TU Delft, Netherlands, invited Matthias Rippmann to teach about designing funicular shells with RhinoVAULT. rV was used for the design of the exciting cut-foam pavilion resulting from the 2 week design-build digital fabrication workshop.

The aim of this project was to underline the reciprocity between analyzing and rethinking complex free form geometries in terms of manufacturing constraints. The future of these developments will be decided in the market by the market but one can already see how similar digitally based design and manufacturing techniques could be used to construct non-standard architecture. Qualitatively, approach could involve not only EPS, but other materials.

One can imagine how diamond-wire could be used to cut stone or concrete blocks. It is also possible to use EPS foam forms to cast concrete. By doing this, construction would gain so much needed strength which would allow for the creation of largescale free-form structures. Quantitatively, it is possible to see how the process, exploited in this studio, could be completely automated or scaled up to suit many different designs and needs.

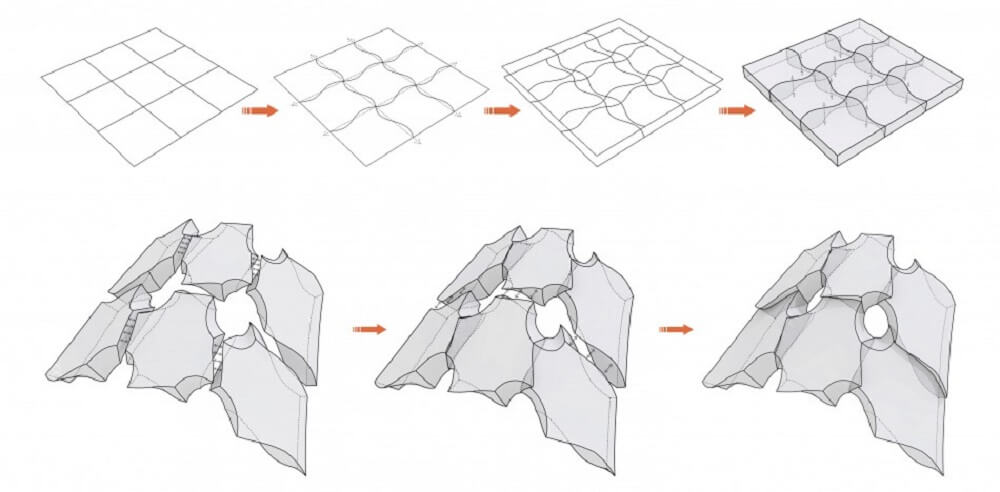

This technique goes hand in hand with the idea of digital discretization of architectural objects because componential subdivision of surfaces and volumes allows large amounts of freedom in adjusting element size, number, and geometry. This is also true when considering ruled surfaces as a limitation for hot-wire cutting. Although individual components must obey rules of ruled surface mathematics, overall shapes can still be free – concave, convex, etc. This is the biggest advantage of the parametric – robotic approach.

Comments