Responsive Surface

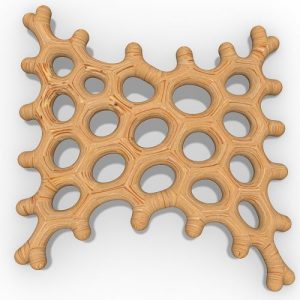

The project “Responsive Surface Structure” by Steffen Reichert is based on an experimental, inductive design approach. The project aims at creating a differentiated skin structure that can change its porosity in response to changes in ambient humidity and moisture. Thus, the project instrumentalizes the moisture absorbing properties of wood and the related surface expansion as a means to embed climate sensor, actuator and regulating element all in one very simple component. One typical example of various biological systems operating on the principle of surface changes due to differential expansion is the pine cone.

The shape and materiality of the cone are synthesized in such a way that every cone element is in one the sensoric, kinetic and regulative element. Once fallen off the tree the dry cone awaits a suitably moist condition. Then the desiccated material of the cone opens and the seeds are released. What is particularly interesting is that due to the fact that the behavioural response is latent in the material this system works without any contact to the tree and the opening and closure can be repeated in a large number of cycles.

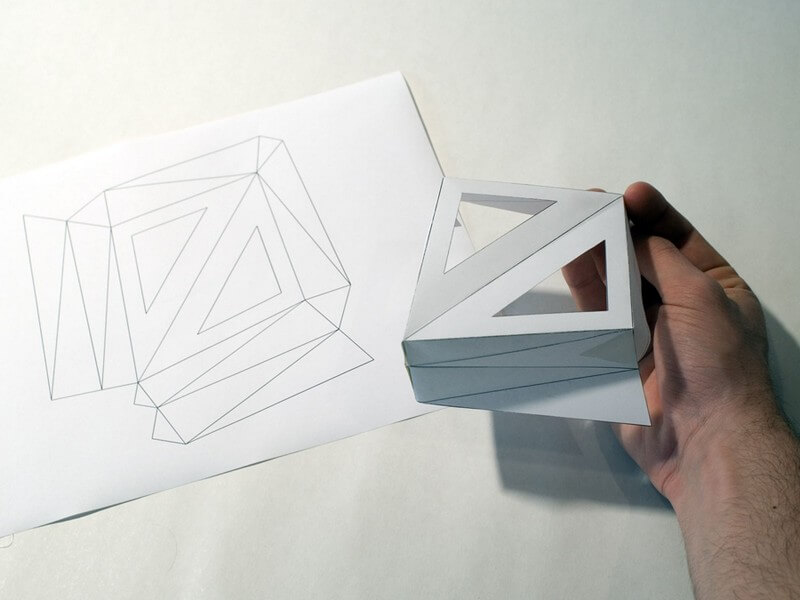

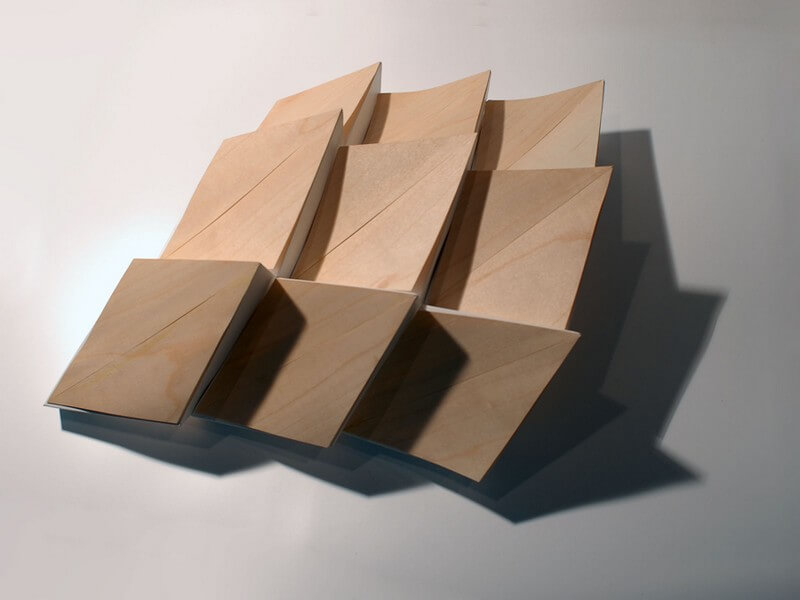

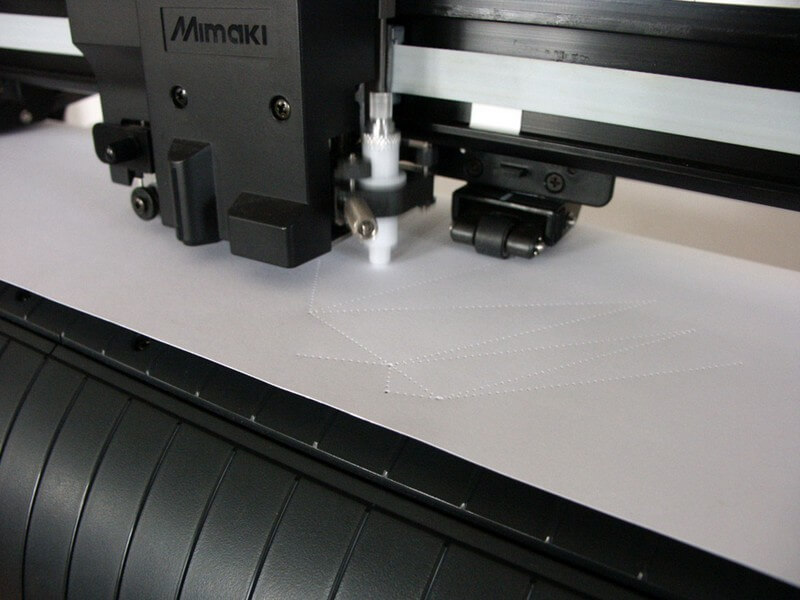

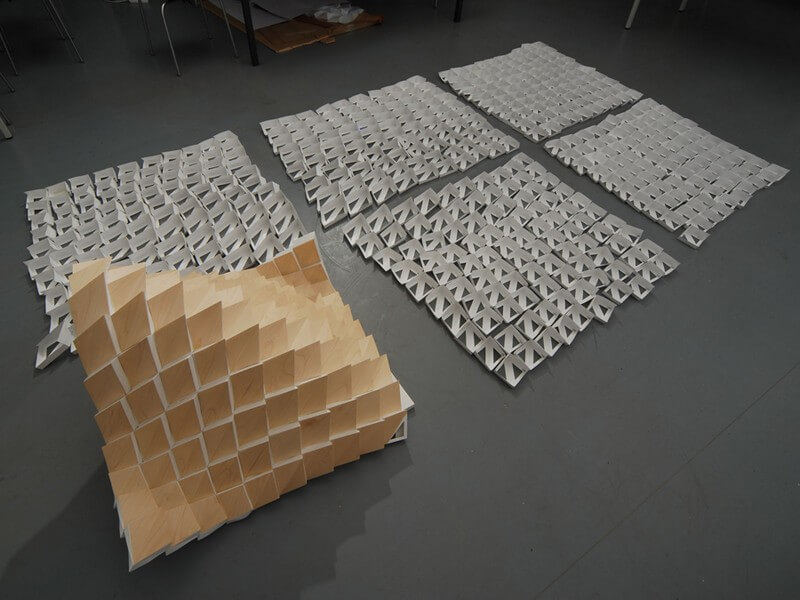

The research project aims at constructing a differentiated structure, referring to the principal of the pine cone with its differentiated scales while maintaining coherence in the set up and fabrication of all individual surface elements. Thus every component of the structure is based on manufacturing constraints of a folded sheet digitally cut from planar material. The design evolution is driven through the definition of those system internal as well as external constraints and information such as the aforementioned manufacturing possibilities and specific material properties which are all integrated in the design process right from the beginning.

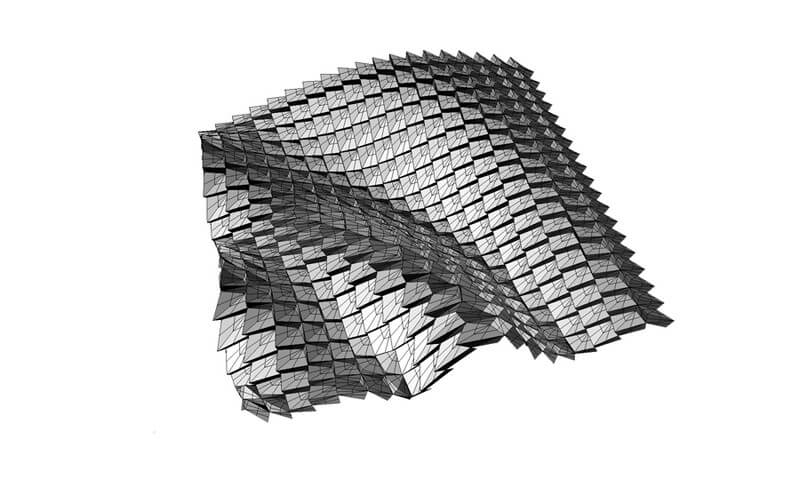

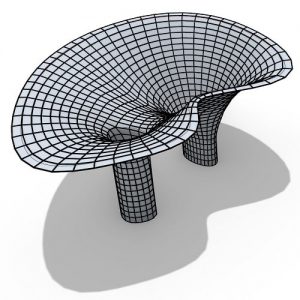

The overall geometry is associative and hierarchically subordinated to the normal direction embedded in the local coordinate systems of the mathematically defined overall surface. In a subsequent step, the component is populated over this parametric surface and subsequently adjusts all individual shapes and orientations to the curvature of the surface. As a result, every element of the structure has unique dimensions, yet it is fully defined through its geometric associations and related constraints.

The development of such a differentiated structures that is mainly derived from a number of complex and nonlinear relations ranging from material behaviour to the thermodynamics of the environment requires an adaptive design approach. Using the versatility of parametric design tools allows the set-up of a design evolution in which changes to the system can be made at all times as the three-dimensional structure as well as the related cut pattern of each individual component automatically adopt to changes in the overall system and vice versa.

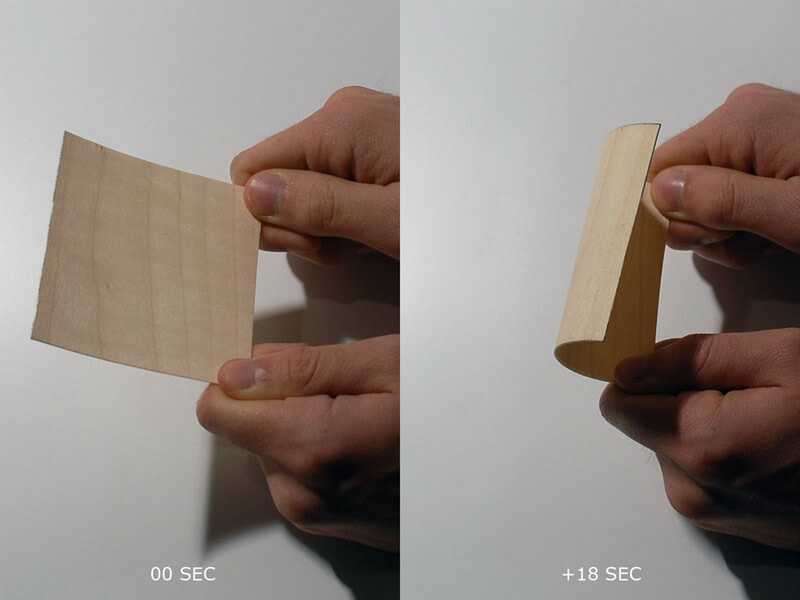

Finally this parametric substructure built up from individual components is clad with a moisture sensitive layer of veneer composite. The veneer composite developed and employed here has the particular ability of controlled shape changes by reacting to ambient humidity and moisture and thus enables the system to interact with its environment without being controlled by electronic or mechanic devices.

Changes in ambient humidity facilitate the opening and closure of the components resulting in different degrees of porosity across the surface which is in one structure and performative skin.

Comments