Self Assembling Parts

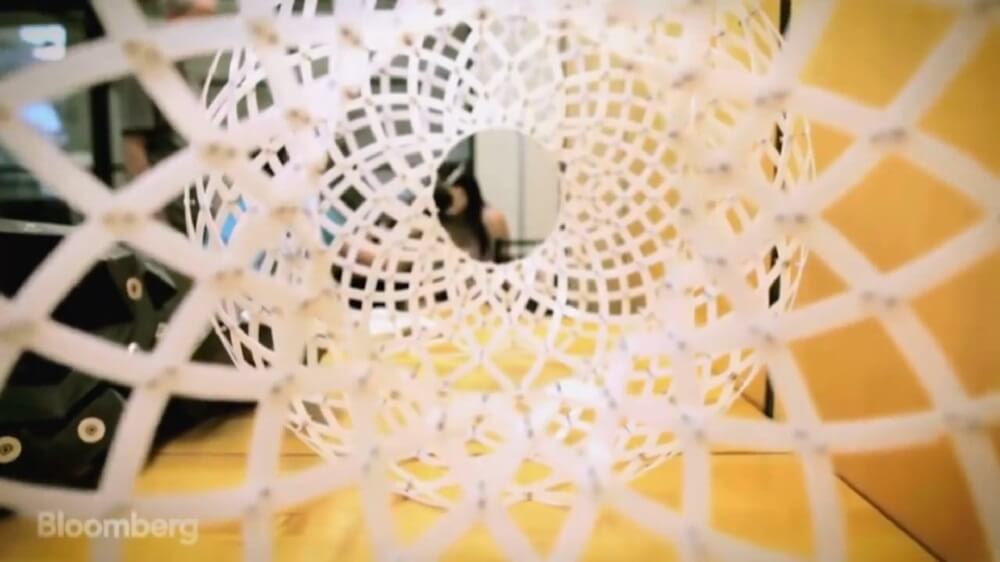

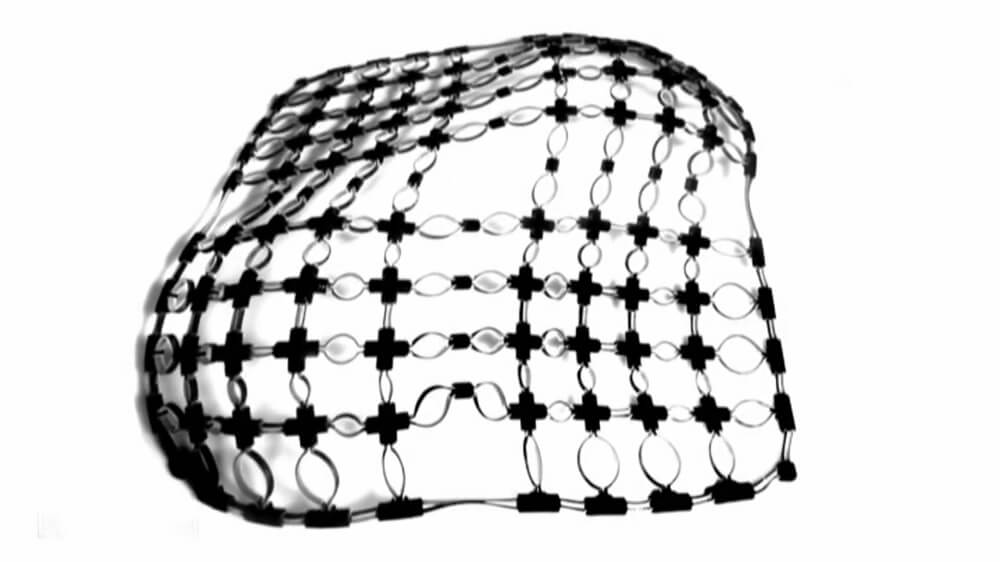

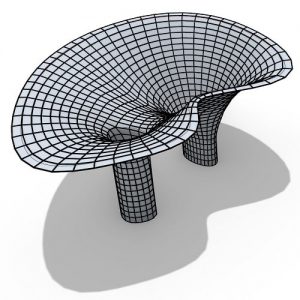

What if a table or a bridge could build itself? If researchers at the self-assembly lab at MIT have their way, parts will someday put themselves together. In This article Skylar Tibbits explains what a self-assembling future could look like: “There’re three principles or ingredients to self-assembly. The first is geometry, the second is how to connect and the third is energy. in terms of geometry, if you change the shape or the geometric structure of the material, it’ll produce different global structures. Then you need connections. You can use magnets, you can use surface tension, velcro or lock and key mechanisms for that. Very important: you want these things to come together and stick in just the right places. They should disconnect when they are not right.”

“So you need energy to somehow shake the pieces around and tumble them in order to put them in contact with one another. You can do that in different ways in different environments: underwater with pumps or with fans in the air. It does not matter. You just need some type of energy to get them all excited and find one another, connect in just the right places with just the right geometry, and then they’ll assemble into precise structures.”

“Look around the world and you will see we’re surrounded by physical materials, whether that’s products, clothing, buildings, cars, planes, shoes. All of these are based on materials. At the same time there’s clearly a direction to make all these things smarter and smarter. Today the only way to make something smarter, we typically think, is to make it more robotic or more like a computer. The problem with that is that it costs a lot of money, it has a lot of potential failure, it has a lot of energy, there’s a lot more assembly time. So our principle is that we want to program the materials themselves so they become smarter without turning them into robots or computers.”

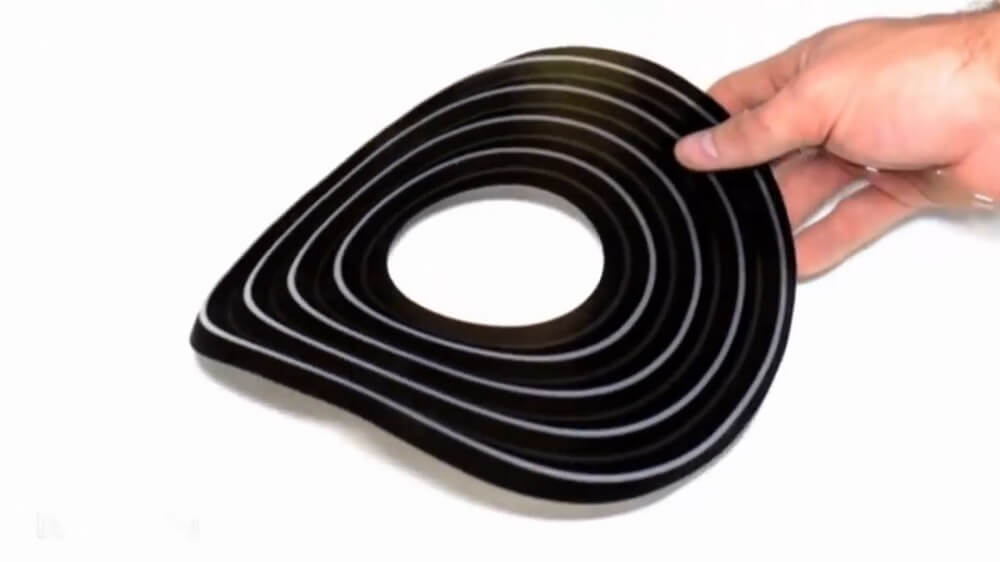

“So there are three principles to programmable materials, one is the material that you’re using so maybe you’re going to use wood or you’re going to use metal or plastics or foams or whatever. The second one is energy, you want to link up the material properties with the activation energy. With wood you might use moisture to activate the material, if you use plastics or metals you may use temperature. And if you put the materials in just the right way, using multiple materials or multiple structures like micro and macro structures, the geometric information encodes a transformation. So the third principle is that you want some kind of transformation. This transformation can be a fold or a curl or an expansion or contraction and you do that by linking the material structure with just the right activation energy. So you can make wood that can fold, curl, twist in the right way or you can make textiles that respond to temperature or carbon fiber that transforms based on light.”

Comments