Slender Concrete Shells

Structural Implementation of Slender Concrete Shells with Prefabricated Elements

Philipp Eisenbach1, Manfred Grohmann2

1 Bollinger + Grohmann Ingenieure

2 Universitat Kassel

Figure 1: ILEK, Stuttgart, Germany by Frei Otto – Form active and tensile only structure

Lightweight concrete structures and structurally optimized systems are the focus of several research efforts. This is due to esthetical reasons but also in order to use material in a resource conserving way. Advancements in digitizing planning and fabrication processes, but also ongoing enhancements in material science for cementitious composites enable designers to build complex geometries of slender concrete structures.

However, it can be observed that built architecture does not reflect the present possibilities at hand. One reason is the implementation on site; with increasing material performance, the sensitivity of concrete production increases to assure sufficient accuracy, workability and post-treatment. In combination with demands for quick assembly and simple disassembly of structural components, a prefabrication of concrete elements is indispensable.

Figure 2: Service station in Deitingen ´68, Switzerland by Heinz Isler – Form passive and compressive only structure

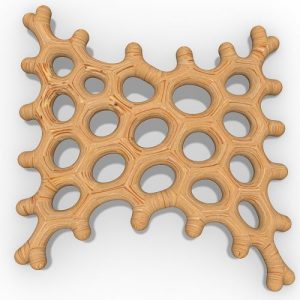

The possibility to reduce cross section dimensions on the one hand and the arising challenge how to realize load bearing connections on the other hand, is a contradiction investigated within this survey. The identification of mechanical principles of structural connections enables the development of design strategies for load bearing connections.

Two selected case studies, illustrating adhesive and interlocking bonding of concrete elements are presented, verifying the feasibility on site. An adhesive bonding is presented for a concrete bench, designed as a Möbius strip. This innovative, thin concrete shell structure is built on the campus of the University of Kassel.

Due to prefabrication in a concrete laboratory the partition of the object was necessary. An interlocking bonding is applied for the construction of a concrete mobile, designed for an exhibition in Amsterdam. With the focus on a quick and easy assembly and non-destructive disassembly, a micro-prestressing connection method is developed.

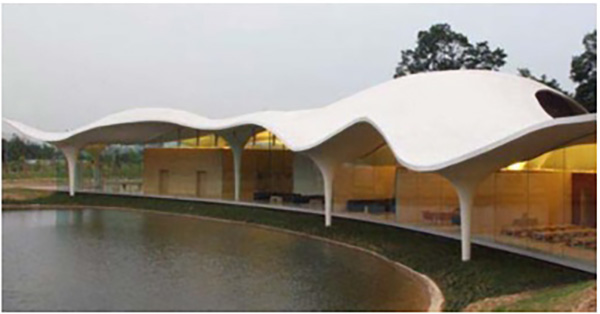

Figure 3: Oceanographic Valencia, posthumous construction after the design of F. Candela – Form passive membrane structure with compressive and tensile stresses

The construction of thin-walled concrete structures is – beside its aesthetic benefits – one approach to utilize materials in a resource conserving way. Enormous developments over the past decade in digitizing design and fabrication processes enable the analysis of complex geometries under consideration of multiple boundary conditions. Digital aided manufacturing allows for computer controlled fabrication without an interruption of the digital process chain.

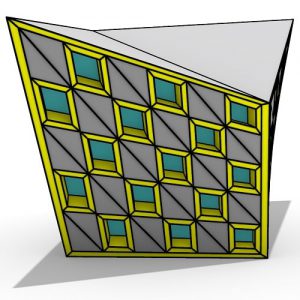

Despite the possibilities of digital tools and production methods, the way of thinking of the construction industry is dominated by the standards of industrial production. Buildings are generally assembled from massive elements under flexural stress (Mainka et al.), enabling an unpretentious handling of geometrical data and the construction processes respectively.

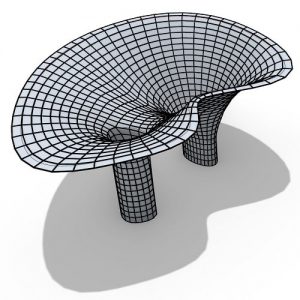

Figure 4: Crematory in Kakamigahara, Japan ´06 by Toyo Ito – Freeform structure bearing compressive, tensile and bending stresses

Material savings and slenderness are achieved by both the application of high performance materials and the negotiation of the force flow by generating form-relevant structures. The form manipulation towards a load bearing with axial, avoiding in-plane bending stresses, leads to an activation of membrane actions with an optimized utilization of the material, as described by Eisenbach et al.

Figure 6: Concrete bench ‘Möbiusban(k)d’ after construction on the University campus

The envisaged concept of the concrete bench reflects the omnipresence of science at universities. The bench-like sculpture has areas to sit on, to lie on or to lean against. Those areas are defined through the different heights of the bench. The sculpture opens up towards the canteen to invite visitors to take a rest on it.

The geometry is parametric and was built with Grasshopper, a plugin for the 3D modeling software Rhinoceros3D. First and foremost, the shape of the bench is driven by the design and functional aspects in order to achieve a convenient bench furniture. Having the initial geometry satisfying all functional boundary conditions, the shape has been adapted with an optimization process performed with Karamba, itself a plugin of Grasshopper.

Karamba allows for a live analysis of the structure, while manipulating the input parameters. With the help of Galapagos, an evolutionary solver, the geometry can be optimized in predicted frames by the allocation of fitness criteria; in this case, the self-weight deflection.

Figure 17: Installed concrete mobile at the exhibition venue Muziekgebouw in Amsterdam

Advancing material properties, especially for cementitious compounds, enable cross section reductions and resource-conserving building constructions. The necessity of prefabrication under laboratory conditions is discussed, revealing the contradiction of the possibility to reduce system dimensions on the one hand, and the need of discontinued element joints, ideally designed to bear unpreventable bending, on the other hand.

Mechanical principles of load bearing connections are identified in order to develop strategies to join prefabricated concrete elements appropriate for the structural system and material involved.

Figure 19: Construction principle of a form-fit connection technique demonstrated on a toy giraffe. Internal prestressing is applied with a spring in the base leading to a self-stabilizing structure

The mechanical principals of adhesive and interlocking bonding are investigated and tested for load bearing connections of a high performance micro mesh reinforced concrete. The considerations are executed in two architectural case studies, verifying the feasibility of implementation on site.

The survey presents a range of opportunities to realize slender concrete shells and structures with prefabricated elements. The techniques developed are applicable for any geometry at any scale and open up a new variety in the process of slender concrete shell construction for architects and engineers.

Comments