SpacerFabric Pavilion

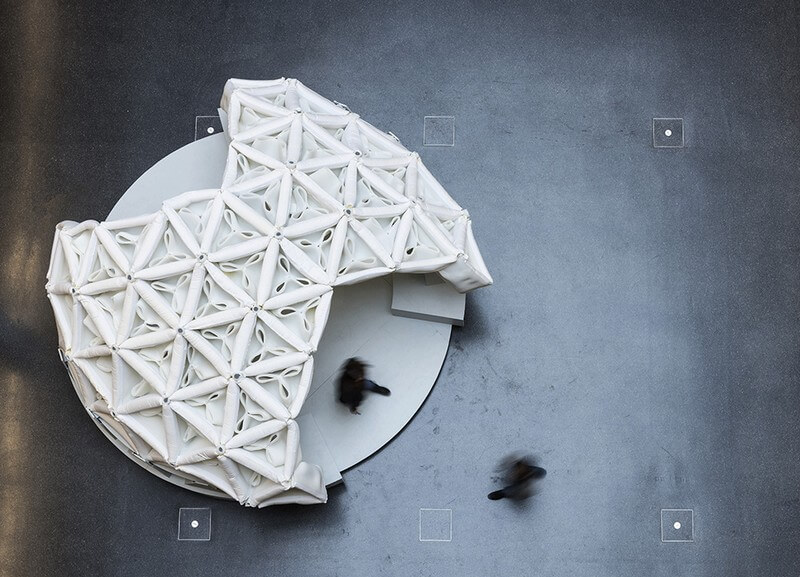

Students realized an innovative, self-supporting lightweight pavilion made of partially foamed spacer textiles in Frankfurt. With a diameter of approximately five meters and a height of approximately three meters, the pavilion exemplifies the future possibilities of building with three-dimensional textiles.

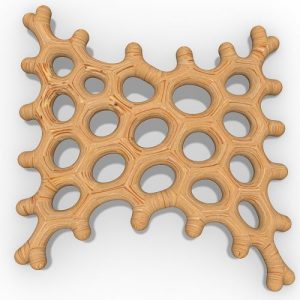

The experimental pavilion is part of the research activities on new composite materials at the Frankfurt Research Institute (FFin) under Prof. Claudia Lüling and was designed and implemented in the 2015 summer semester. Three-dimensional textiles such as spacer textiles consist of two cover layers, which are kept at a distance using so-called pile threads and are industrially manufactured in a single operation.

At the moment these three-dimensional textiles are mainly used for breathable mattresses and seat covers. In the building industry, these textiles have so far only been used invisibly and as textile reinforcement in concrete construction. But their locally definable and programmable textile structure, as well as the diverse selection of fiber materials, offer unimagined possibilities.

Lightweight constructions such as the pavilion are intended as a synthesis of function, material and design. In addition to load-bearing, insulating, sealing and damping properties, spacer textiles could also be used in an energy-efficient way to generate heat through solar thermal energy or, in the future, to generate electricity through photovoltaics.

However, functionality and sustainability were not the only decisive criteria in the development, the selection and cutting of the textiles used enable completely new space-forming options in the design. These other visible and creative possibilities of using spacer textiles in construction are currently being researched at Frankfurt University in the module design, master’s degree in architecture under the main theme ‘FabricFoam ©’.

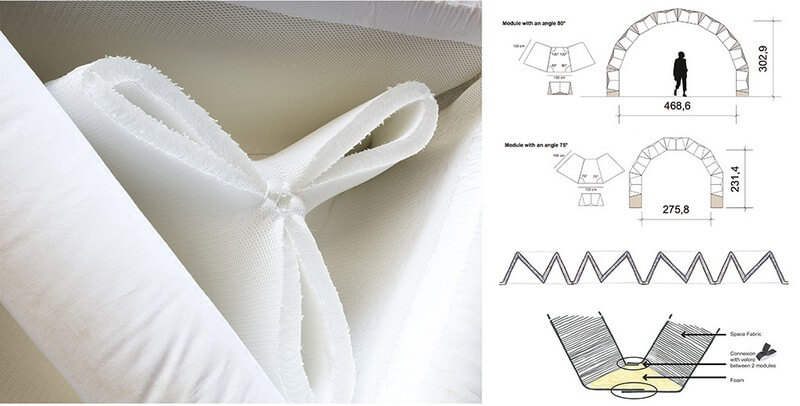

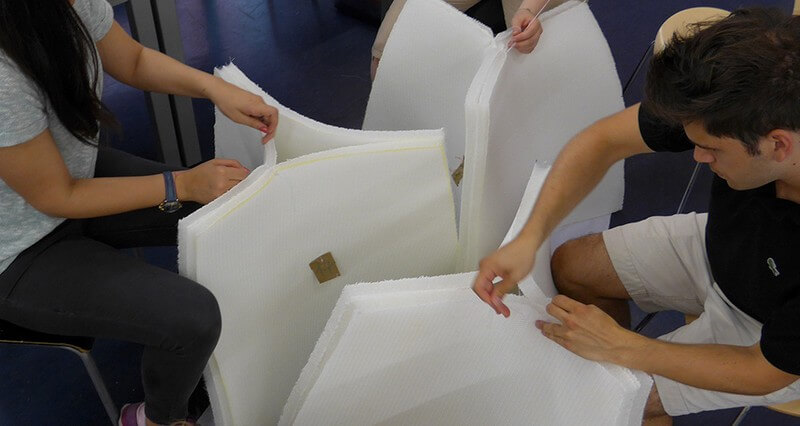

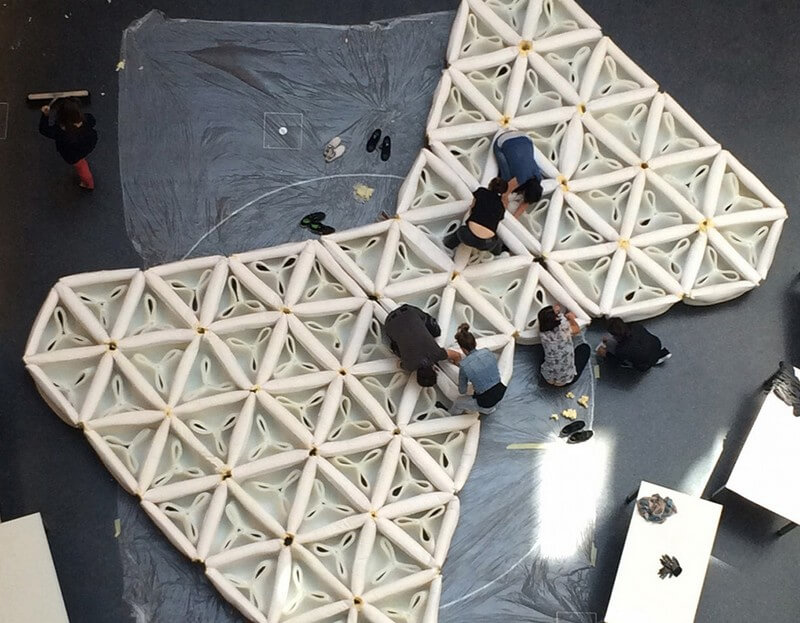

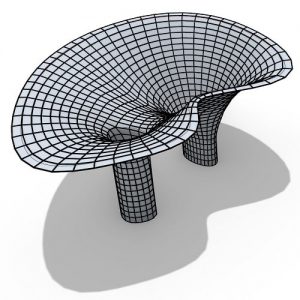

The realized pavilion uses the structure of the spacer textile to produce a modular, light and translucent dome shape. For this purpose, open, pyramid-shaped modules are first folded from 30 mm thick textile, sewn together in the middle and then turned inside out. Like a hat, they get additional stability.

The modules are then joined together by foaming defined cavities between the modules. The individual parts of the pavilion finally fit into a vault due to the tapered individual elements. The initial test already showed the enormous stability of the new composite material FabricFoam ©, but it also showed the need to bring the geometry closer to a chain line during a revision.

Comments