Structural Optimization

NON-STANDARD PATTERNS FOR GRIDSHELL STRUCTURES: FABRICATION AND STRUCTURAL OPTIMIZATION

Romain MESNIL1, Cyril DOUTHE1, and Olivier BAVEREL1,2

1Laboratoire Navier, UMR 8205, Ecole des Ponts, IFSTTAR, CNRS, UPE, Champs-sur-Marne, FRANCE

2Laboratoire GSA, ENSA, Grenoble, FRANCE

Figure 1: A node with torsion (picture: Romain Mesnil)

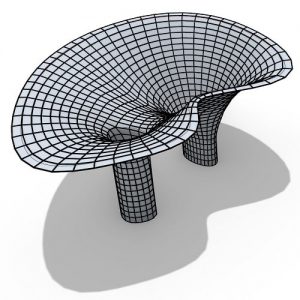

The design of gridshells is subject to strong mechanical and fabrication constraints, which remain largely unexplored for non-regular patterns. The main technological constraints for glazed gridshells are related to the planarity of facets and the existence of torsion-free offsets.

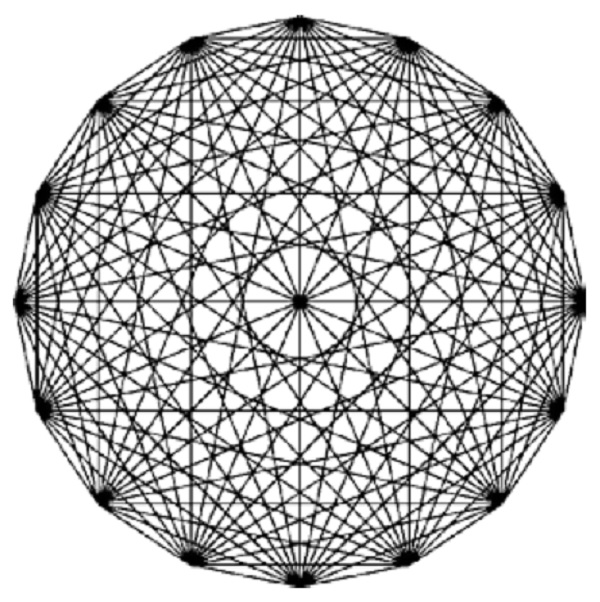

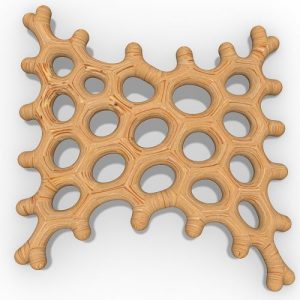

Figure 2: Grid pattern used as a basis for the Dutch Maritime Museum

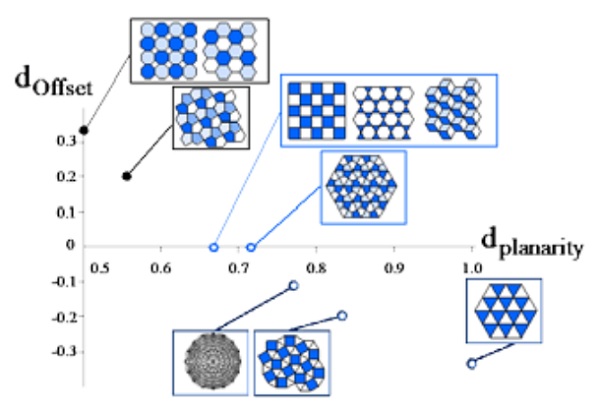

The authors propose indicators to evaluate a priori the quality of design space of gridshells covered with different patterns for these fabrication constraints.

By comparing these metrics, the kagome grid pattern is identified as a pattern with a complexity similar to the ubiquitous quadrilateral pattern.

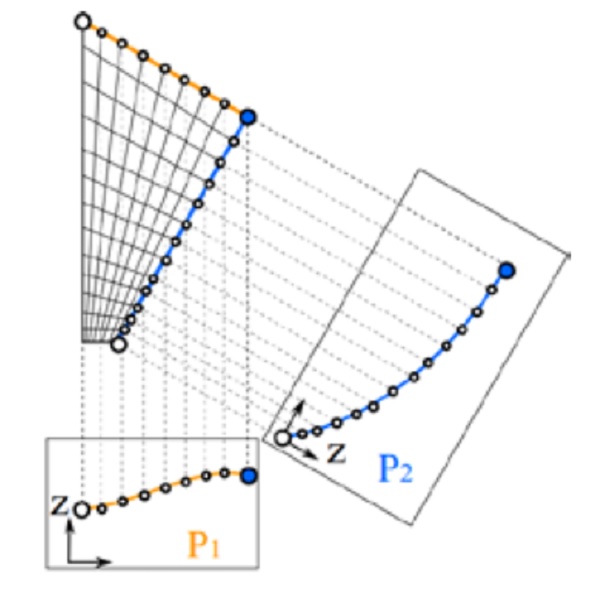

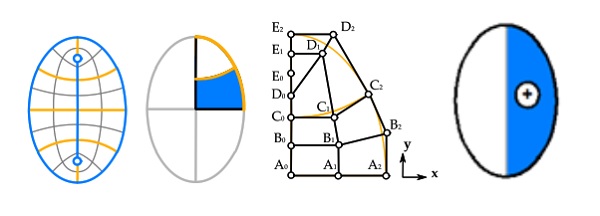

Figure 3: A unique PQ-mesh can be determined from a planar projection and two elevations

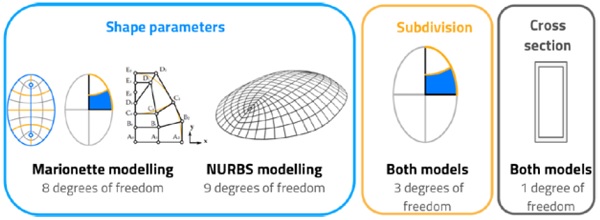

Finally, the authors propose to generate gridshells with planar facets with the marionette technique and to explore the resulting design space by the means of multi-objective optimization.

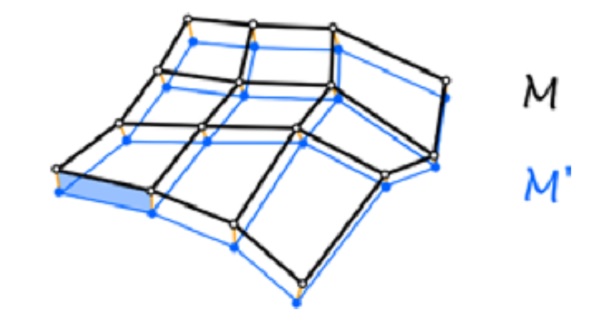

Figure 4: Two parallel meshes and the corresponding planar beam layout

The results of the study show that our framework for shape modeling has similar performances as more usual frameworks, like NURBS modeling, while maintaining the facet planarity.

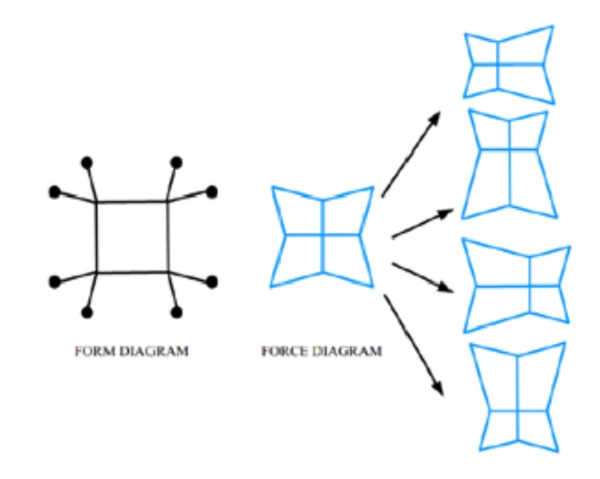

Figure 5: Form-force reciprocal diagrams: applying a Combescure transformation to the force diagram leaves the force diagram invariant

The construction of doubly curved structures is characterized by the compromise made by the architect and the structural engineer between the respect of design intent, the structural reliability and the constructability of the envelope and structure.

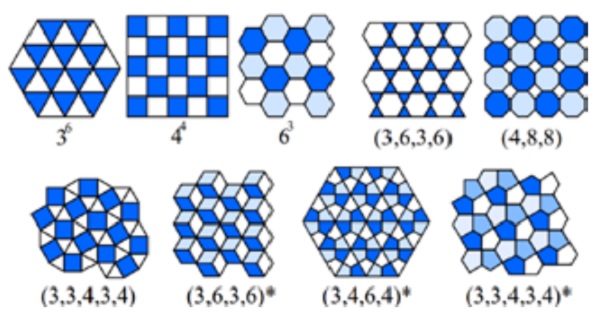

Figure 6: Periodic patterns studied in this paper and their vertex configuration (stars indicate dual patterns)

This interaction between technology, structure and geometry is the purpose of structural morphology. Such interplay is particularly important in the case of glazed gridshells, where structural pattern and envelope are strongly interdependent.

Figure 7: Classification of patterns with respect to fabrication constraints

Jörg Schlaich and Hans Schober identified the planarity of glass panels as one of the key aspects in the economy of gridshells and proposed surfaces of translations and scale-trans surfaces to generate gridshells with planar quadrilateral facets.

Figure 8: Left: parameterization of a dome with NURBS patches, right: load distribution of non-symmetrical load

The second key technological constraint, represented in Figure 1, is to build with so-called torsion-free nodes, to fabricate planar beams whose planes of symmetry intersect a common node axis. Such configurations cannot be obtained for triangulated gridshells, besides “trivial” offsets (e.g. extrusion of the sections in the vertical direction). On contrary, quadrilateral meshes can yield non-trivial offsets, where the nodal axes are close to the normal vectors of the underlying smooth surface.

Figure 9: Parameters used for the optimization

The design of doubly-curved structures challenges architects, engineers and builders. Usual grid patterns, like triangular and quadrilateral patterns for gridshells are well understood both in terms of constructability and structural performance.

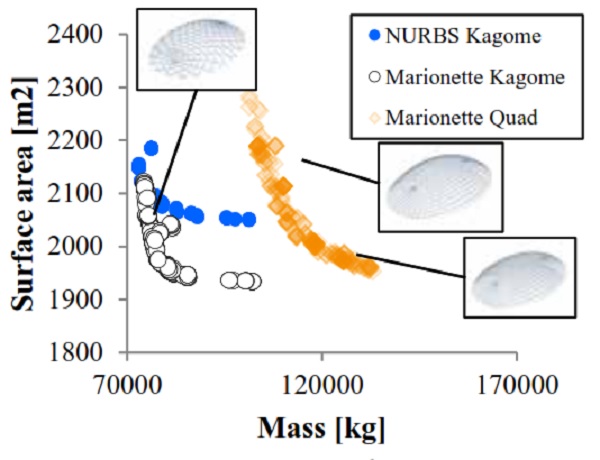

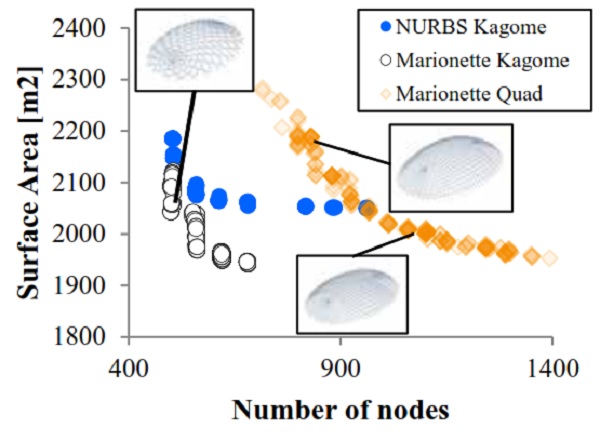

Figure 10: Pareto front after multi-criteria optimization with some optimal designs in the (Area,mass) objective space

This article proposed a methodology to assess and explore design spaces offered by non-standard patterns. First, the authors proposed simple metrics to evaluate the dimension of the design space with different fabrication constraints.

Figure 11: Pareto front after multi-criteria optimization with some optimal designs in the (Area, Nodes) objective space

Second, the marionette technique is proposed to generate nonstandard patterns with planar facets. Finally, the multi-objective optimization of gridshells with planar facets was proposed.

These tools of increasing complexity could be used in different design stages, and provide the designer with a growing understanding of the design he or she is proposing.

Comments