Timber Voronoi Shells

Optimization and prefabrication of timber Voronoi shells

Hao Hua1,2, Ludger Hovestadt3, Peng Tang1,2

1School of Architecture, Southeast University, Sipailou 2, Nanjing, China

2Key Laboratory of Urban and Architectural Heritage Conservation (Southeast University), Ministry of Education, Nanjing, China

3CAAD, ETH Honggerberg, Z¨ ¨ urich, Switzerland

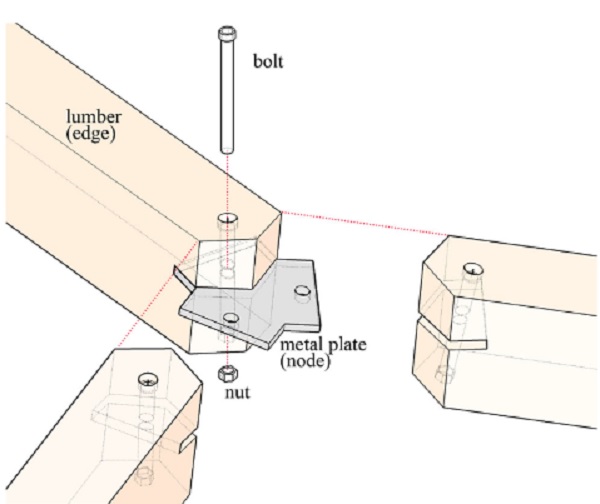

Fig. 1 Left: The mero pavilion as a timber Voronoi Shell. Right: Every metal plate (node) connects three pieces of timber (edges)

We introduce a variant of the timber grid shell, the timber Voronoi shell, whose surface is reticulated by Voronoi tessellation and whose edges are made of discrete dimensional timber. This work explores form-finding methods of the Voronoi shell as a compressive funicular shell.

Two closed-form solutions to shape initialization are proposed. We develop methods for minimizing the deviation from coplanarity between timber members and adjacent surface normal in order to facilitate manufacturing.

Fig. 2 The joint details of timber Voronoi Shell. There are gaps (ca. 0.25 mm) between the metal plate and the cut in the timber; thus, the compression is transmitted through each pair of neighboring pieces of timber rather than through the metal plate

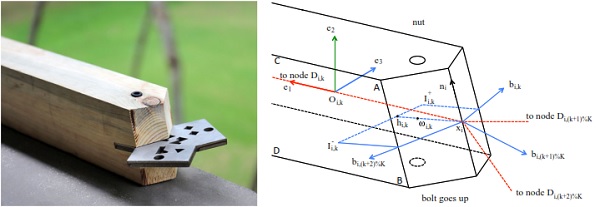

A well-defined fabrication process is important for making the physical structure consistent with the structural model. A 6-axis robot with a motor spindle is employed to prefabricate the timber so the in situ manual assembly becomes easier.

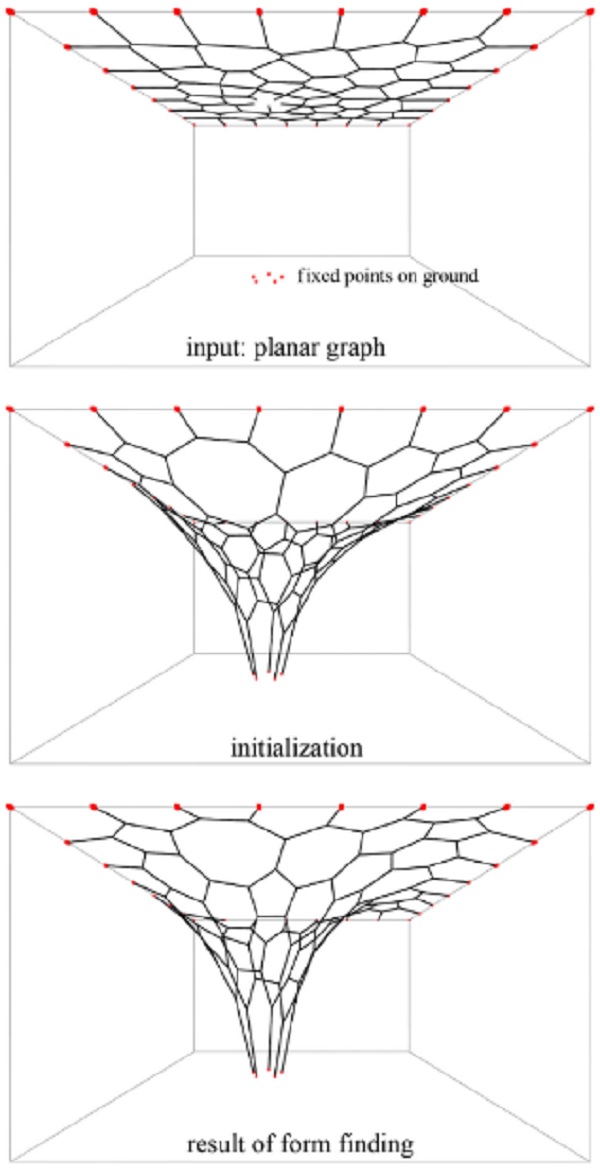

Fig. 4 The input planar graph, shape initialization (LSL), and form finding in the Upsilon project. Fixed points are marked in red

A parametric model describes the joint details. We formulate the robotic toolpath as a closed-form function of the resultant mesh from form finding.

Thus, a general-purpose programming language can directly implement the mesh optimization and manufacturing processes without CAD or CAM software. The physical implementations, including an exhibition pavilion, validated the approach.

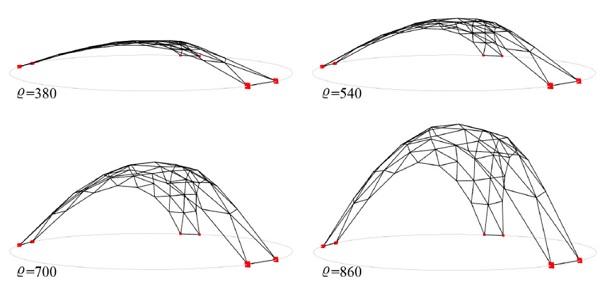

Fig. 5 The results of the spring system method with different settings of initial length. The initial geometry of the four cases are identical. The fixed points are marked in red

The shell structure is a thin curved plate structure that transmits applied forces by normal forces and shear forces developed on the surface. The thickness of the shell is often much smaller than other dimensions of the entire structure.

Thus, thin shells are efficient structural systems covering large spaces with a relatively small amount of materials. Much research has contributed to the theory of shell structures and the practical techniques of construction.

Fig. 10 Joint geometry. The metal plate is not orthogonal to the bar’s cross section

Recently, the rapid integration of digital fabrication technologies and computational design approaches has led to a new peak on this topic. Following this line, this work focuses on the form finding of shell structures and on the digital prefabrication of the components.

The rationalization of the manufacturing process contributes to a true, precise implementation of the virtual geometry. Our approach drives a fabrication-oriented design in the early stages, especially concerning the joint details.

Fig. 11 The robotic milling system

Fabrication-oriented geometry design has gained great interest from both the academy and practice. Based on the advanced computational methods and fabrication technology, people now try to unlock the relation between form, structure and material, which follow an established set of preconceived rules (Menges 2016; Willmann et al. 2018).

For example, one will probably avoid connecting three pieces of timber at one point (because it seems tedious to describe and materialize the geometry) and prefer triangles to polygons in a timber-framed shell (because triangles are stable).

However, our method makes the timber Voronoi shell feasible by minimizing undesirable forces and defining the fabrication process with closed-form expressions. The interplay between formal logic and materialization processes could be an active and fruitful participant in shell design.

Fig. 13 The Upsilon pavilion as a timber Voronoi shell

Recent years have seen two trends in shell structures design. On the one hand, user-friendly software (or plug-ins) make shell design accessible to non-experts. For example, Kangaroo and the RhinoVAULT plug-in for Rhinoceros are easy-to-use form-finding tools for architects.

People can also find convenient software that translates given geometry into robot toolpath. On the other hand, the cutting-edge development of shell design (e.g., the Armadillo vault Block et al. 2018) demands deep expertise on structural analysis, spatial design, material science, and CNC fabrication.

Without intensive cooperation between different disciplines, very little progress can be made. In this work, we propose a well-defined link from the form finding to the toolpath for fabrication and attempt to establish an explicit, consistent formalism from form finding to CNC manufacturing.

As a result, researchers from different fields can work together and new user-friendly software may link experts and new users.

Comments