Tree-Structure Canopy

Tree-Structure Canopy:A case study in design and fabrication of complex steel structures using digital tools

Asterios Agkathidis and André Brown

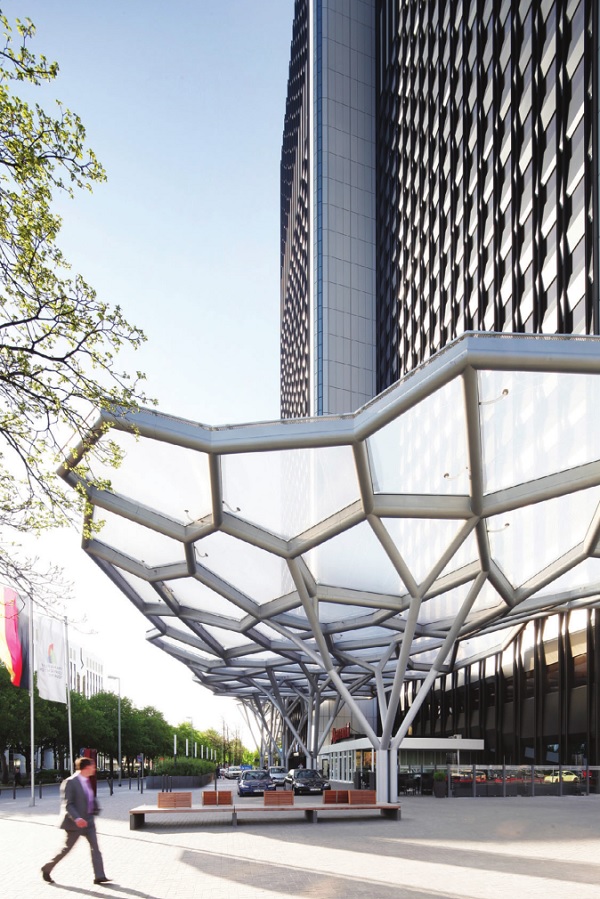

Figure 1.Aerial photograph of the Tree-Structure Canopy in Frankfurt. (Photography by Eibe Sönnecken.).

This paper describes and reflects on the design and manufacturing process of the Tree-Structure canopy for the WestendGate Tower in Frankfurt upon Main, completed early 2011.

The project investigated fabrication and assembly principles of complex steel structures as well as the integration of contemporary computational design, engineering, optimization and simulation techniques in a collaborative design approach.

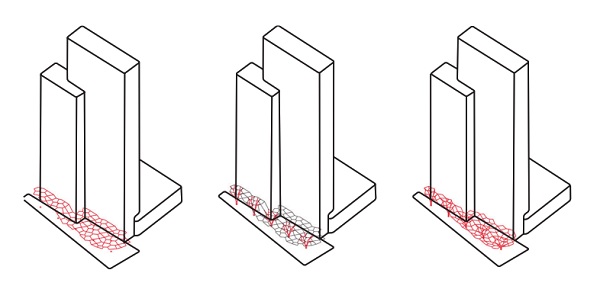

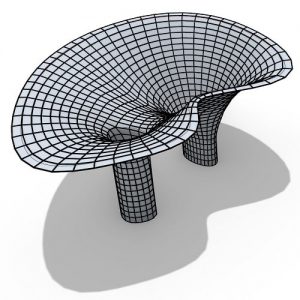

Figure 2. Iterations of mesh structures.

This paper focuses on the notion of modular standardization as opposed to non standard customized components. It also engages with issues relating to digital production tools and their impact on construction cost, material performance and tolerances.

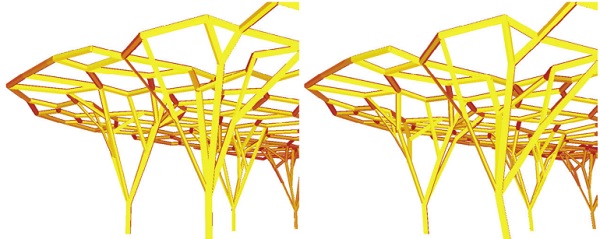

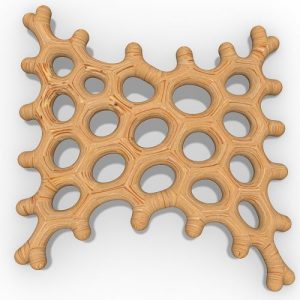

Figure 3. Design process: Generation of columns from voronoi grid.

In addition it examines the reconfiguration of liability during a planning and construction process, an aspect which can be strongly determined by fabrication companies rather than the architect or designer.

This paper is written as a reflection on the complete building process when contemporary digital tools are used from design through to fabrication.

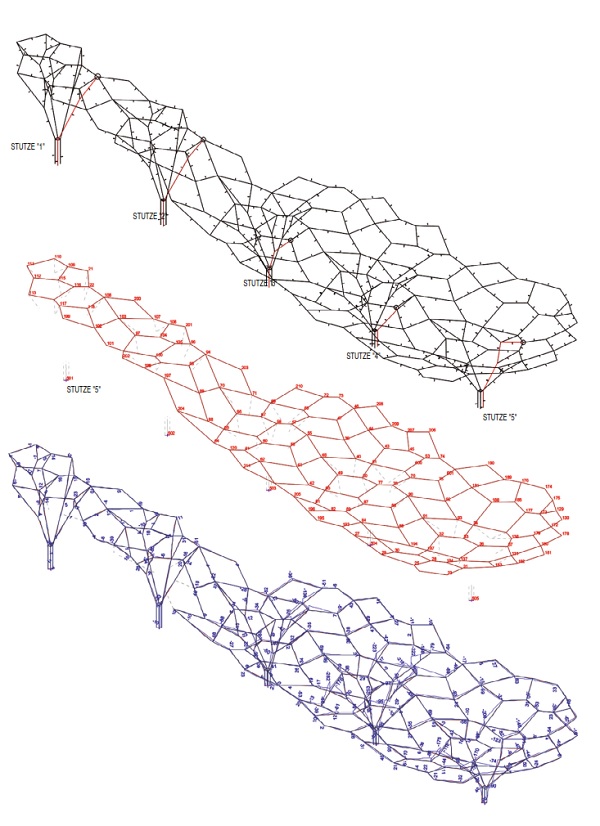

Figure 4. Optimization process, Finite Element Analysis.

It studies both the generation of the steel structure as well the ETFE cushion skin. It reports on a collaborative project, where the main author was responsible for the canopies design, parameterization, digitalization and fabrication, as well as for the dissemination of the outcomes and findings during the design and realization process.

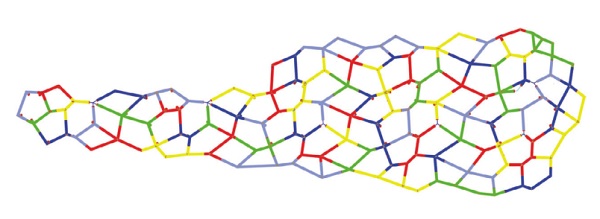

Figure 5. Optimization result: double curved surface, composed of unique, non standard polygonal frames.

As such it represents an example of research through design in a contemporary and evolving field. The canopy received a design award by the Hellenic Architecture Association.

Figure 8. Construction units, Divisions of different Branches.

WestendGate, also known as the Marriott Hotel, is one of the most iconic towers in Frankfurt. At a height of 159 meters and 47 storeys, the original structure ranked as the highest tower Germany during the 70s and early 80s.

Built in 1976 by the architects Siegfried Hoyer and Richard Heil in the Westend of Frankfurt am Main, the building became the trend setter and exemplar for high-rise construction in both this district and the broader city of Frankfurt.

Figure 9 (left). Drainage system (Photography by Eibe Sönnecken).

The Marriott Hotel Group moved there in 1989, and the building remains the highest hotel in Europe. The Hotel occupies the top 18 of the 46 storeys of the building; a three winged structure in plan.

It has its own lobby on the ground floor and uses the second floor as a ball room. All the remaining levels, which are accessible via a second lobby, are occupied as office space and building services.

Figure 10. ETFE cushion fabrication drawing.

The project described in this paper is a canopy, referred to generally in this paper as the ‘Tree-Structure’. This Tree-Structure canopy was designed in order to protect the newly designed outdoor entrance and departure area.

Figure 16. Spray painting the branch.

Besides providing performance needs such as weather protection the brief for the canopy included the key criterion to generate a prestigious new entrée to the hotel experience.

A requirement was that the new addition should contribute significantly to the building’s visual impact at the human scale: it already had significant impact at the urban scale. It was also to provide visual signals to reinforce primary pedestrian movement flows.

The Tree-Structure covers an area of 1200 m2 with its height varying between 8 and 14 meters. The defining perimeter is between 85 and 14 meters in length depending on section location. The lead author worked with Just/Burgeff Architekten in collaboration with structural engineer Viktor Wilhelm.

Figure 18.Assembly process, tightening the joints. Photography by Eibe Sönnecken.

Looking back in the overall design and realization process of the TreeStructure canopy, it is apparent that the conventional design procedure became naturally transformed into a collaborative virtual system, where architects, engineers and manufacturers were linked together in a constantly updated common flow of information.

Typical architectural drawings, such as sections, elevations and floor plans are losing their importance, because they are unable to entirely describe complex geometrical structures. Meanwhile, the role of interactive digital models is gaining in importance.

Figure 19.Tree-Structure Canopy (Photography by Eibe Sönnecken).

Various CAD file types and application formats such as DWG, IGES or STL are becoming the common data currencies, that both define the building, and carry the responsibility for efficient transmission of design information between the actors.

Thus, our understanding of advanced design, precision and structural tolerance is being transformed. We can relate ideas and decisions directly to the relevant requirements of each manufacturing machine.

Comments