Parametric Design furniture

Michaela Crie Stone lives and works in Rockport, Maine, where she creates pieces that push the parameters of function by blurring the lines between art, craft, and design.

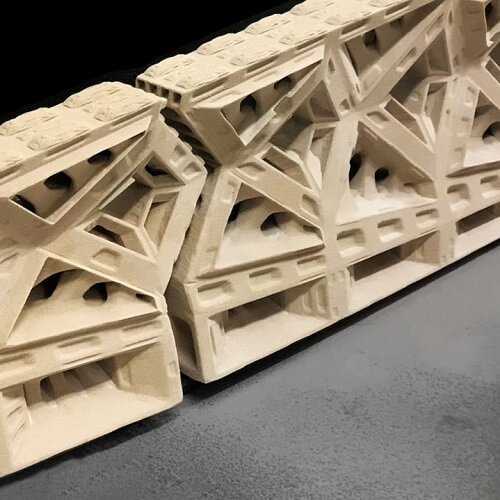

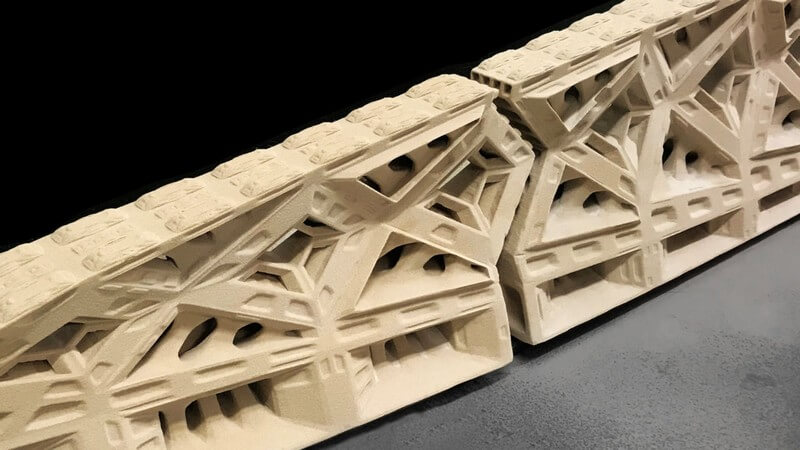

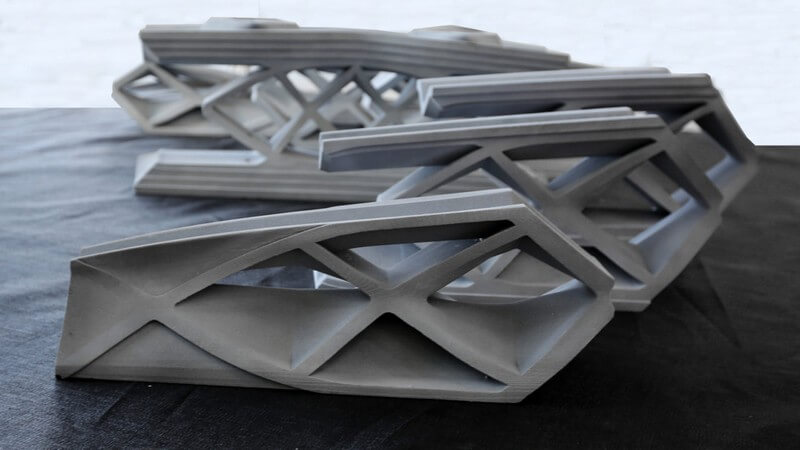

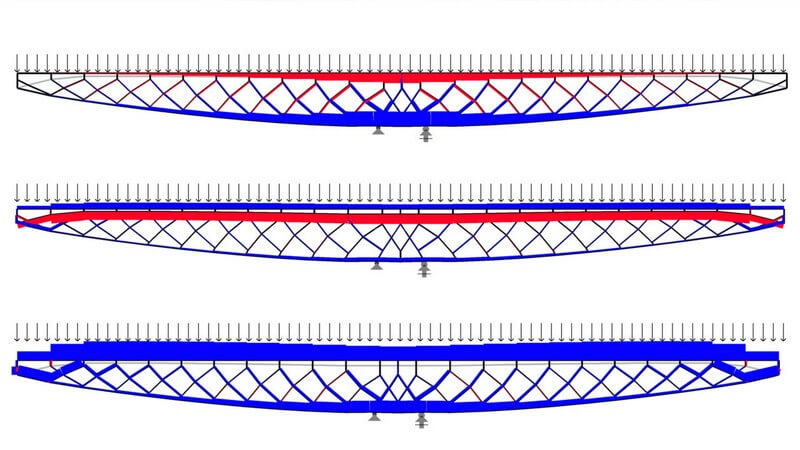

The 3D Printed Reinforced Beam is part of the ongoing research of Digital Building Technologies into 3D printed, structural building components. Two-sided cantilevering beams, up to 4.5 meters long, are fabricated out of sandstone.

Components are 3D printed on a large-scale binder-jetting machine. All seven interlocking segments are dimensioned to fit the printer’s maximum volume. Binder-jetting allows for the multiple functionalities such as integration of custom enclosures, for post-tensioning cables and complex joints for assembly.

Components are 3D printed on a large-scale binder-jetting machine. All seven interlocking segments are dimensioned to fit the printer’s maximum volume. Binder-jetting allows for the multiple functionalities such as integration of custom enclosures, for post-tensioning cables and complex joints for assembly.

Because sandstone printed elements can only take compression forces, the structural system is designed so that, after pre-stressing, the printed elements become compression-only. The structural evaluation regards the beam as one structural element, with no degrees of freedom between its components.

Because sandstone printed elements can only take compression forces, the structural system is designed so that, after pre-stressing, the printed elements become compression-only. The structural evaluation regards the beam as one structural element, with no degrees of freedom between its components.

Through several design iterations joints that interlock the components have been developed, making the beam one structural element.

Through several design iterations joints that interlock the components have been developed, making the beam one structural element.

Designing for 3D printed building components means creating a computational design system that generates printable complex geometries with high resolution of detailing. Such a system profits from the geometric freedom that binder-jetting offers and integrates mass customization into the design and fabrication.

Designing for 3D printed building components means creating a computational design system that generates printable complex geometries with high resolution of detailing. Such a system profits from the geometric freedom that binder-jetting offers and integrates mass customization into the design and fabrication.

Michaela Crie Stone lives and works in Rockport, Maine, where she creates pieces that push the parameters of function by blurring the lines between art, craft, and design.

in this video, you can look at different parametric towers with parametric designs.

Drone based technology is the solution to overcome the limitation of surface road capacity in cities.

Augmented reality (AR) is the integration of digital information with the user’s environment in real-time.

Parametric Ideas for Architects @2025