4D Printing In Action

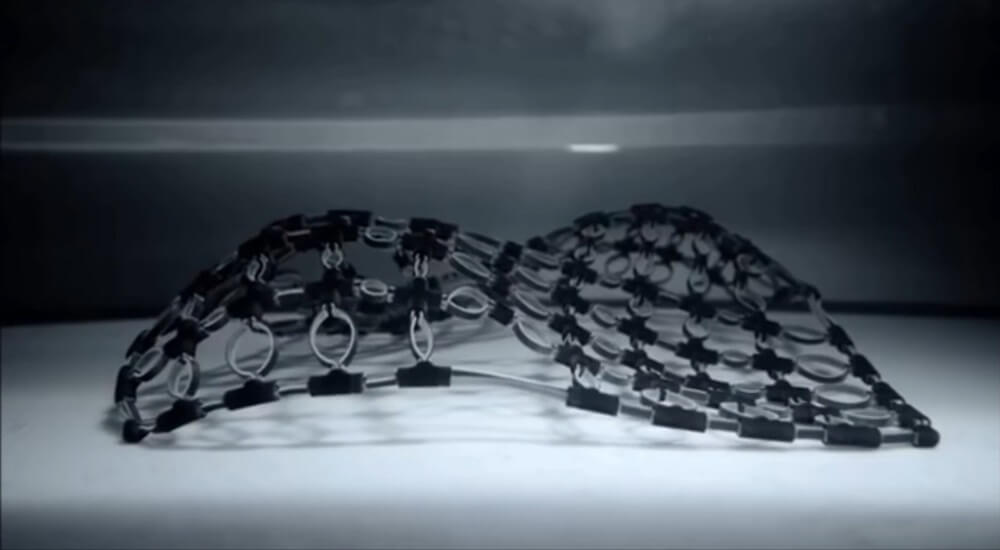

This is a 4D printing video by Pranavee M of 4D printing in action. 5 videos put together showing tests from MIT Self assembly laboratory demonstrating the functionality of shape transformation. Flat-printed structures that, once placed in hot water, slowly folds themselves into another structure. 3D Printing technology has existed for almost 30 years now. Yet, while the Additive Manufacturing industry is still discovering new applications, new materials and new 3D printers, another technology is arising. It is called 4D Printing and is coming straight from the future! 4D printing is the process through which a 3D printed object transforms itself into another structure over the influence of external energy input as temperature, light or other environmental stimuli.

This technology is part of the project of MIT Self-assembly Lab. The purpose of this project is to combine technology and design to invent self-assembly and programmable material technologies aiming at reimagining construction, manufacturing, product assembly and performance.

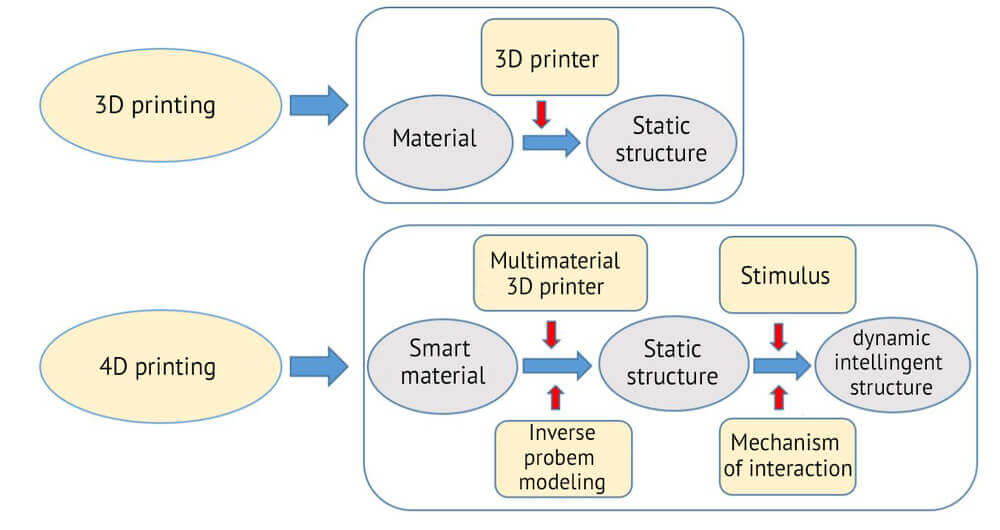

Obviously, 4D Printing has one more “D” than 3D Printing. What does that mean and why does it bring so much added value to the technology? 3D Printing is about repeating a 2D structure, layer by layer in a print path, from the bottom to the top, layer by layer until a 3D volume is created. 4D Printing is referred to 3D printing transforming over time. Thus, a 4th dimension is added: time. So, the big breakthrough about 4D Printing over 3D Printing is its ability to change shape over time.

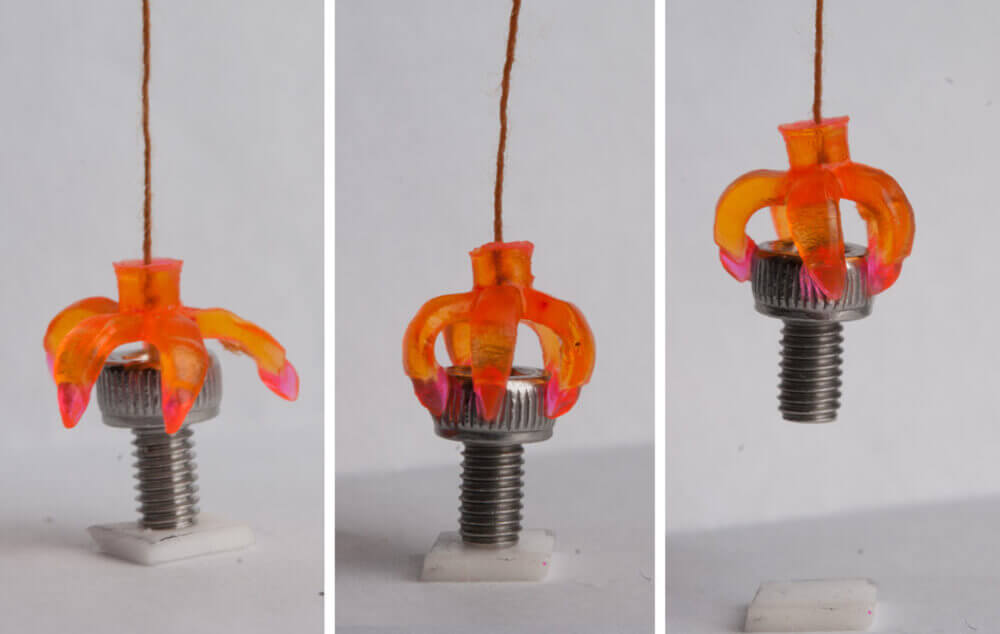

A 4D printed object is printed just like any 3D printed shape. The difference is that the 4D Printing technology uses programmable and advanced materials which perform a different functionality by adding hot water, light or heat. That’s why a non-living object can change its 3D shape and behavior over time. 4D printing technology uses commercial 3D printers, such as Polyjet 3D printers. The input is a “smart material”, that can be either a hydrogel or a shape memory polymer. Thanks to their thermomechanical properties and other material properties, smart materials are given the attributes of shape change and are differentiated from the common 3D printing materials. On the other hand, objects printed with 3D Printing technology, are characterized by rigidity. That means that the 3D printed objects are going to keep their 3D shape once printed.

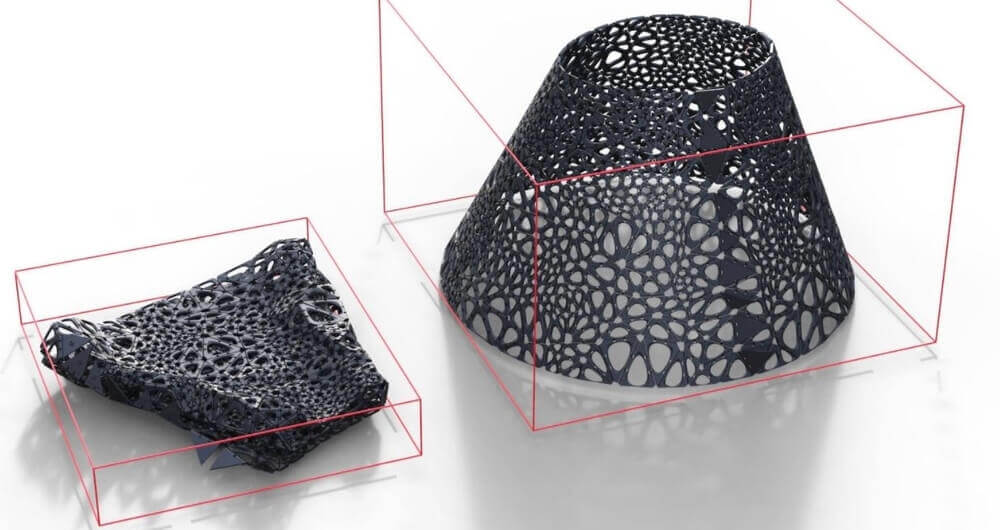

The most obvious advantage of 4D printing is that through computational folding, objects larger than printers can be printed as only one part. Since the 4D printed objects can change shape, can shrink and unfold, objects that are too large to fit a printer can be compressed for 3D printing into their secondary form. Another advantage of the 4D Printing technology is the usage of the possible applied materials. 4D printing has a vast potential to revolutionize the world of materials as we know it today. Imagine 4D printing being applied to a variety of smart materials that today we cannot even imagine!

Comments