GC Installation

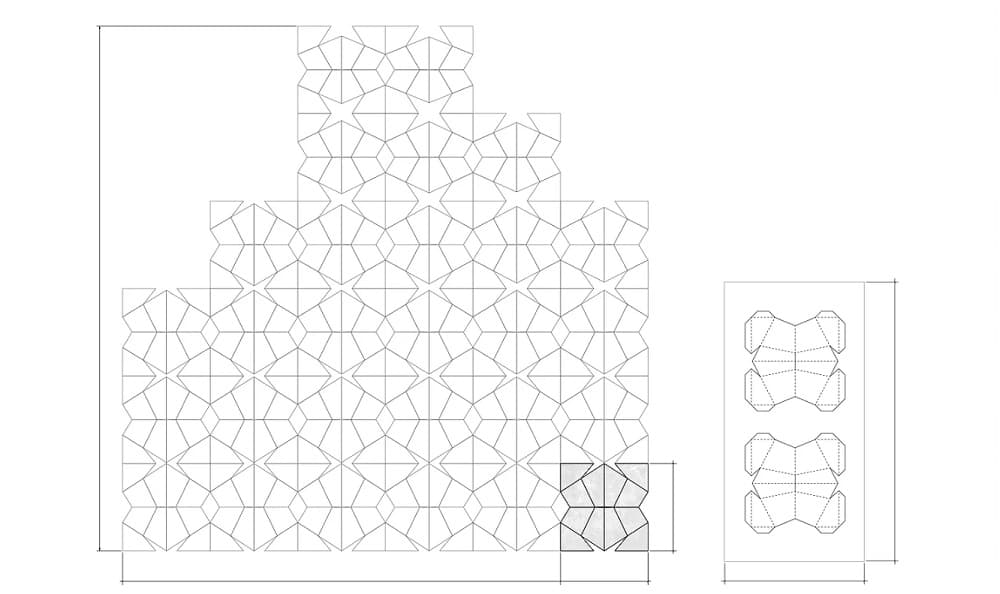

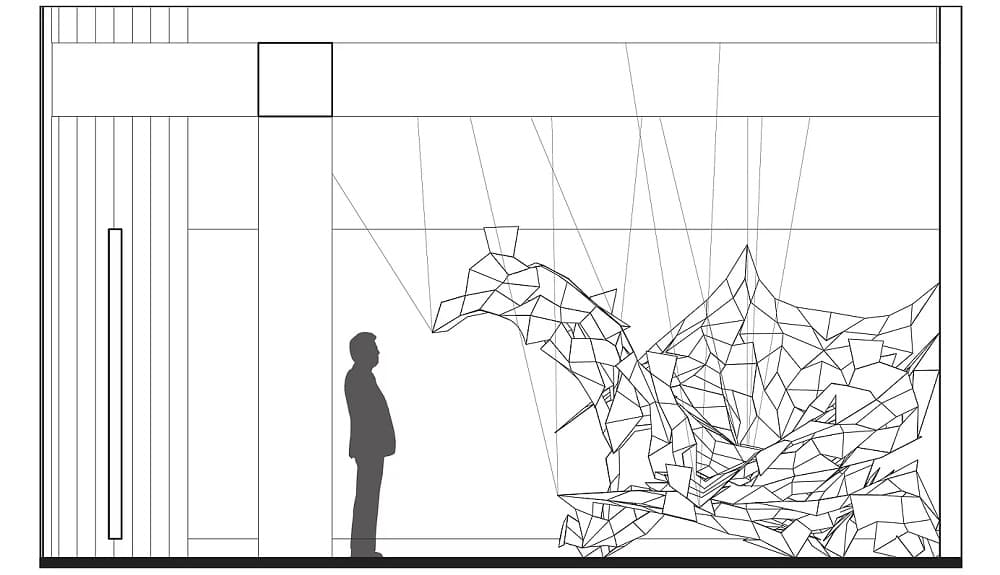

This pavilion by Milad Showkatbakhsh, Chritopher Testa, Chris Yu and Shayna Cooper explores the limits of composite aluminum panels. With the use of parametric modelling and digital fabrication, a unitized panel system was designed that aggregates to operate as a larger system of surfaces. Each panel uses an aperture to maximize its ability to fold. The strength of the composite aluminum is further utilized through a shallow scoring of the panels, allowing for the material to fold and create a three-dimensionality, while still maintaining its planarity. By exploiting the fold lines, the surfaces create a pillowing of space between the panels. These cove-like spaces allow the opposing surfaces to respond and react to one another, optimizing the tension created by the negative space.

The bends and undulations of the units translate to the larger scale of the surfaces themselves, transforming the flat aluminum panels into a three-dimensional surface that stimulates an interaction with both the viewer and the space. The negative space between the panels also gives the viewer an opportunity to observe their connections, interworking and functionality. The joints and connectivity built into the system do not go unnoticed. Parametric design allows for this type of intelligence to be built into the system, enabling the production and fabrication of these surfaces of complexity.

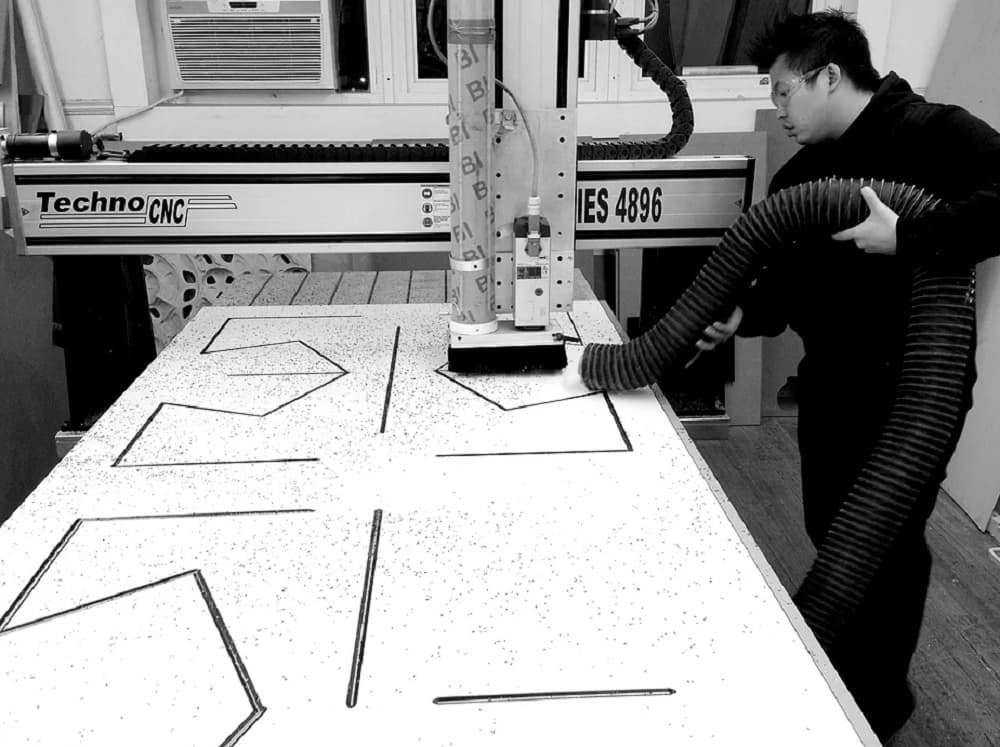

In the following picture you can see laid out panels of the installation.

Although each panel was easily deformed, it was strong enough for the assembly.

Comments