Metal Facade

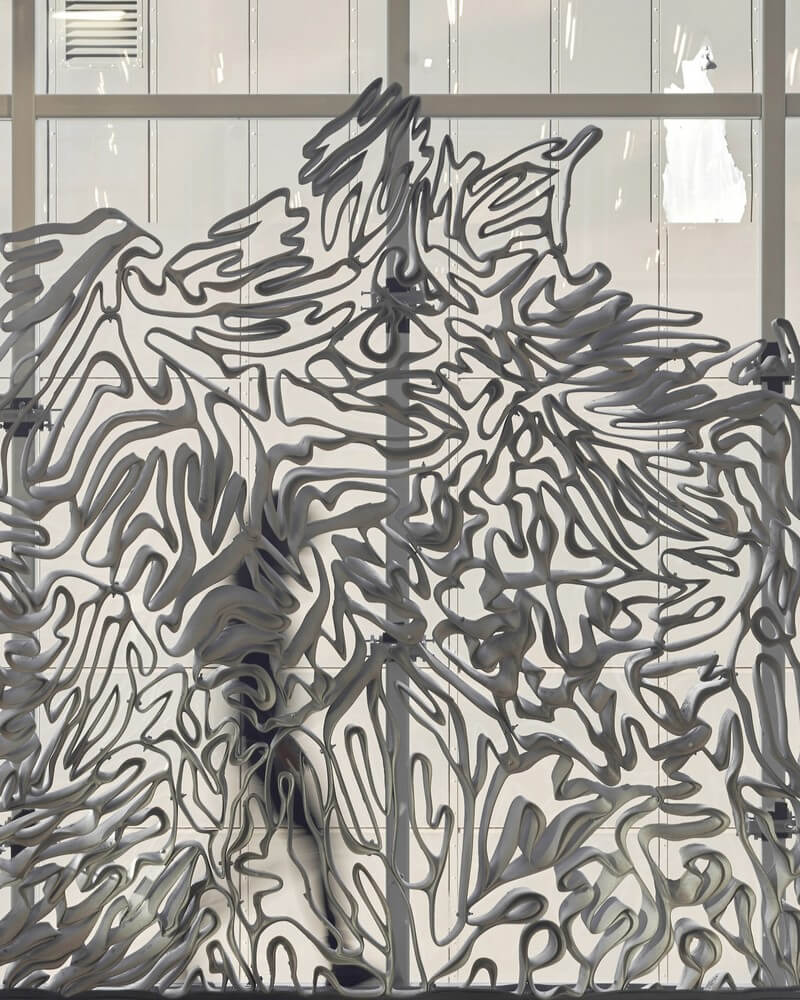

Students from ETH Zurich have pioneered a method of casting complex, one-off architectural structures from metal in a 3D-printed mould. Deep Facade, a six-metre-high aluminium structure with ribbons of metal looped in an organic fashion that recalls the folds of the brain’s cerebral cortex, is the first metal facade cast in a 3D-printed mould.

The facade was created by students of the Digital Fabrication course working with senior ETH Zurich researcher Mania Aghaei Meibodi, whose research explores how 3D printing can be used to create bespoke metal building elements.

Deep Facade follows on from another innovative work created by last year’s students – the Digital Metal Pavilion, which Aghaei Meibodi says was the first metal architectural structure of any kind to make use of a 3D-printed mould. The use of 3D printing in this way is significant as it provides a quicker, more cost-effective way to manufacture complex forms for custom architecture.

While metal can be 3D-printed directly, it is only useful to do so in some cases. Otherwise, Aghaei Meibodi says the process can be expensive, and only applies to a limited range of printable metal, with limited material properties. The Digital Building Technologies group instead 3D-printed moulds from sand and cast molten metal in the traditional way.

The Deep Facade is made of 26 articulated panels, combined into a structure that’s six metres high and four metres wide. Its ornamental design is produced by a differential growth algorithm, meaning it mimics the development of certain living organisms.

The design is meant to highlight the “liquidity and strength” of metal — some sections could not have been rendered in other traditional materials like sandstone or concrete as they would have been too fragile.

Comments