TECLA

TECLA Technology and Clay 3D Printed House

Mario Cucinella Architects

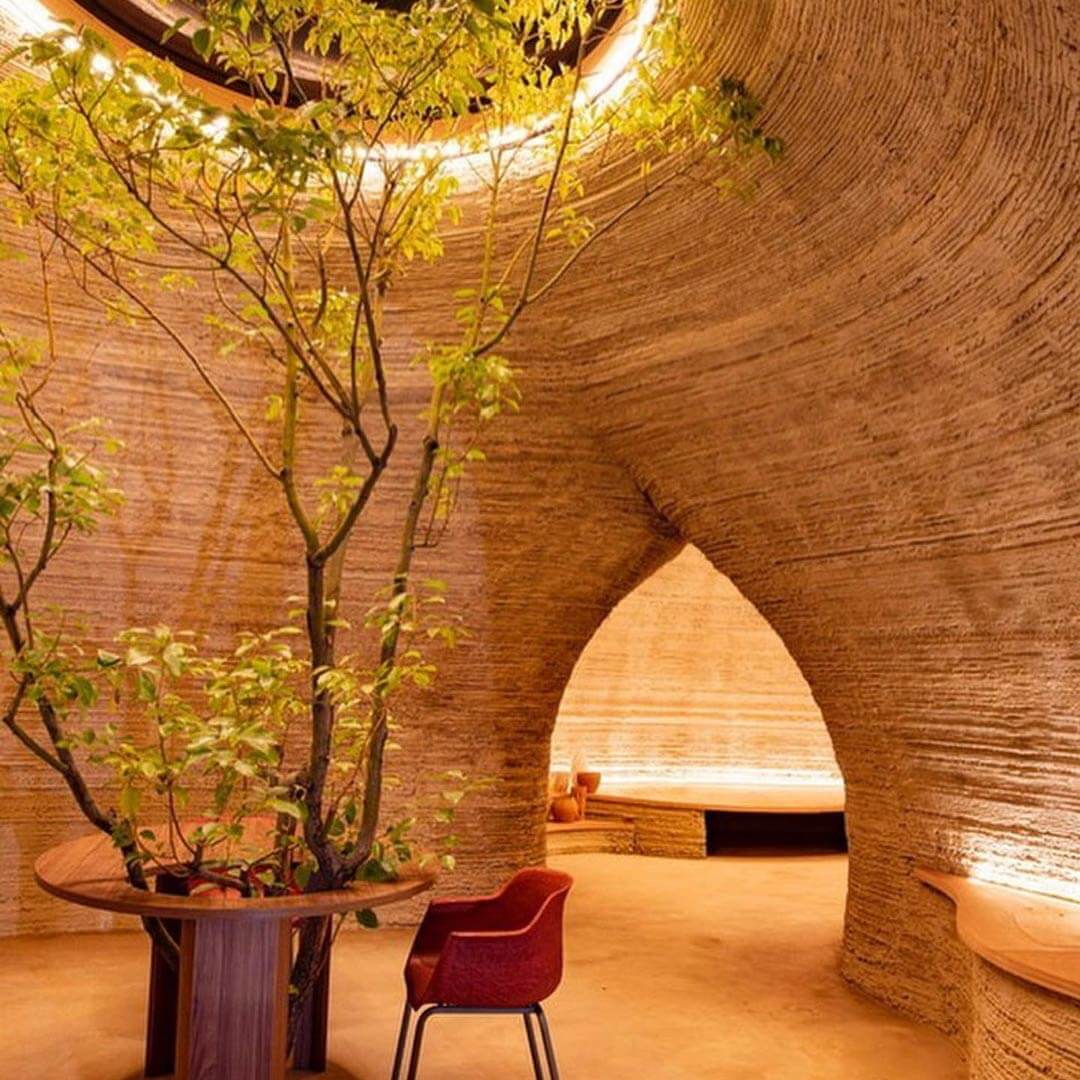

The first eco-sustainable housing model 3D printed entirely from local raw earth. This genuinely innovative and pioneering approach was conceived from the start as a joint project between the two firms, who worked closely throughout the project’s design and construction.

Metaphorically inspired by one of Italo Calvino’s ‘invisible cities’ – the city in continuous construction – the name TECLA evokes the strong link between past and future by combining the matter and spirit of timeless ancient homes with the world of 21st-century technological production.

Metaphorically inspired by one of Italo Calvino’s ‘invisible cities’ – the city in continuous construction – the name TECLA evokes the strong link between past and future by combining the matter and spirit of timeless ancient homes with the world of 21st-century technological production.

Located in Massa Lombarda (Ravenna, Italy), TECLA has become a reality thanks to the eco-sustainability research of the SOS – School of Sustainability (training center founded by Mario Cucinella), the pioneering research projects of Mario Cucinella Architects and the collaborative 3D printing technology of WASP.

Located in Massa Lombarda (Ravenna, Italy), TECLA has become a reality thanks to the eco-sustainability research of the SOS – School of Sustainability (training center founded by Mario Cucinella), the pioneering research projects of Mario Cucinella Architects and the collaborative 3D printing technology of WASP.

TECLA is an innovative circular housing model that brings together research on vernacular construction practices, the study of bioclimatic principles and the use of natural and local materials. It is a nearly zero-emission project: its casing and the use of an entirely local material allows for the reduction of waste and scraps. This and the use of raw earth make TECLA a pioneering example of low-carbon housing.

TECLA is an innovative circular housing model that brings together research on vernacular construction practices, the study of bioclimatic principles and the use of natural and local materials. It is a nearly zero-emission project: its casing and the use of an entirely local material allows for the reduction of waste and scraps. This and the use of raw earth make TECLA a pioneering example of low-carbon housing.

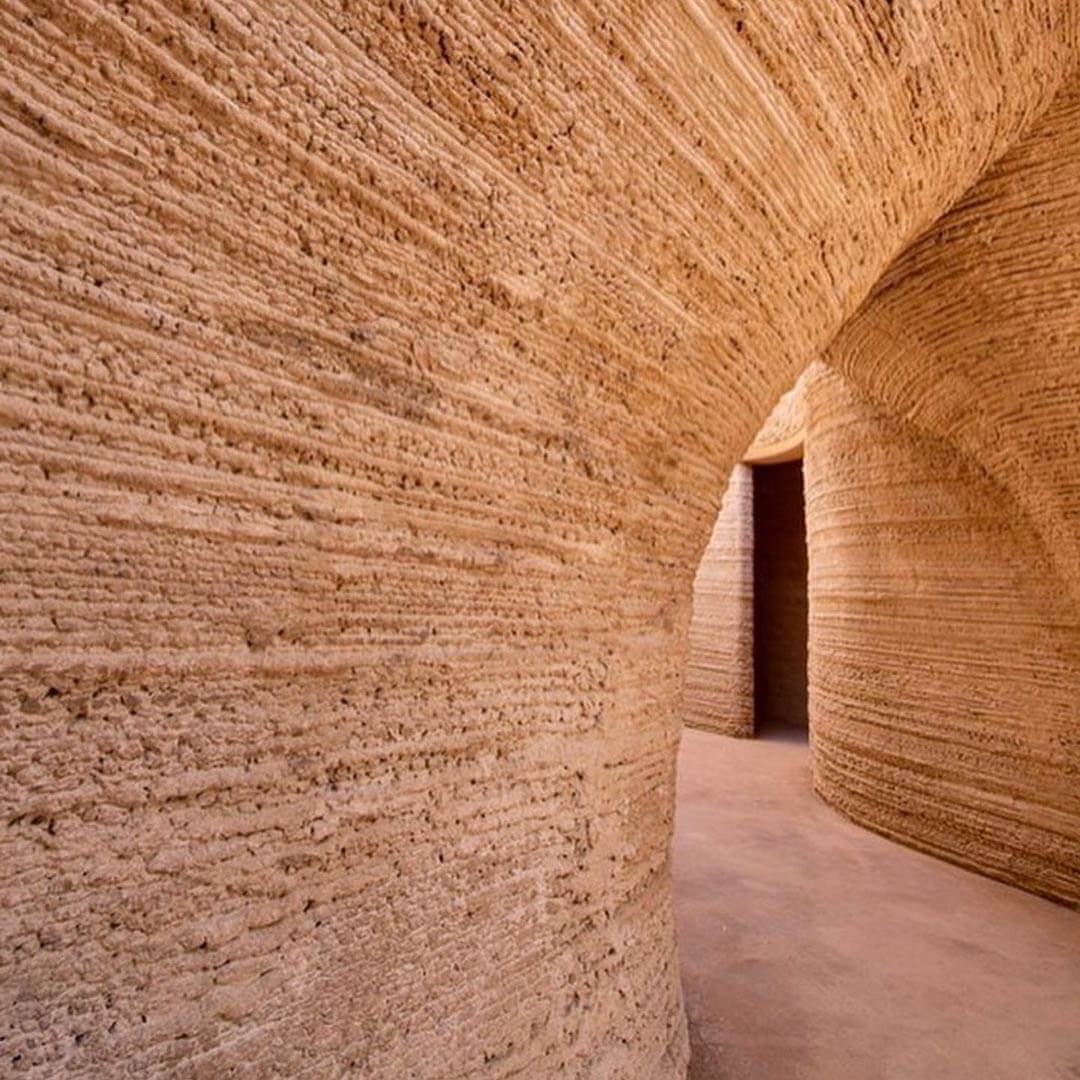

For this project, Mario Cucinella Architects not only explored housing solutions in formal aesthetic terms, it also studied the building’s shape in relation to its climate and latitude. In addition, the composition of the earth mixture responds to local climatic conditions and the filling of the envelope is parametrically optimised to balance thermal mass, insulation and ventilation according to the climate needs.

For this project, Mario Cucinella Architects not only explored housing solutions in formal aesthetic terms, it also studied the building’s shape in relation to its climate and latitude. In addition, the composition of the earth mixture responds to local climatic conditions and the filling of the envelope is parametrically optimised to balance thermal mass, insulation and ventilation according to the climate needs.

The atypical shape, from the geometry to the external ridges, has enabled the structural balance of the construction – both during the 3D printing phase of the envelope and once the covering is completed – giving life to an organic and visually coherent design.

The atypical shape, from the geometry to the external ridges, has enabled the structural balance of the construction – both during the 3D printing phase of the envelope and once the covering is completed – giving life to an organic and visually coherent design.

With an area of about 60 square meters, it comprises a living zone with a kitchen and a night zone which includes services. The furnishings – partly printed in local earth and integrated into the raw-earth structure, and partly designed to be recycled or reused – reflect the philosophy of a circular house model.

With an area of about 60 square meters, it comprises a living zone with a kitchen and a night zone which includes services. The furnishings – partly printed in local earth and integrated into the raw-earth structure, and partly designed to be recycled or reused – reflect the philosophy of a circular house model.

The technological research of WASP, specialised in Km0 3D printing from raw earth, has led to an innovative 3D printing technology called Crane WASP, the first in the world to be modular and multilevel, designed to build construction works collaboratively.

The technological research of WASP, specialised in Km0 3D printing from raw earth, has led to an innovative 3D printing technology called Crane WASP, the first in the world to be modular and multilevel, designed to build construction works collaboratively.

TECLA uses two synchronised printer arms simultaneously, thanks to software capable of optimising movements, avoiding collisions and ensuring streamlined operation. Each printer unit has a printing area of 50 square meters which therefore makes it possible to build independent housing modules in a few days.

TECLA uses two synchronised printer arms simultaneously, thanks to software capable of optimising movements, avoiding collisions and ensuring streamlined operation. Each printer unit has a printing area of 50 square meters which therefore makes it possible to build independent housing modules in a few days.

Comments