Vaulted Willow

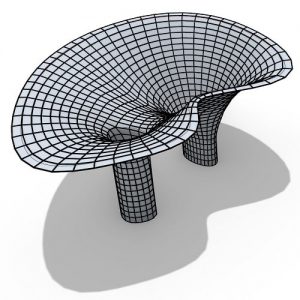

Commissioned by The Edmonton Arts Council and completed on June 18th, 2014 Design & computation: MARC FORNES & THEVERYMANY™ Engineering: Will Laufs, LaufsED, Vaulted Willow is an architectural folly exploring lightweight, self-supported shells through the development of custom computational protocols of structural form-finding and descriptive geometry. The project’s aim is to resolve and delineate structure, skin and ornamentation into a single unified system.

The overall morphology is the result of a reciprocal relationship encompassing experiments in non-linear architectural typology (multiple entries, distributed feet with branching and spiraling legs), structural differentiation (bifurcation of structural download forces, tighter radii of leg profiles for rigidity,…) and programmatic possibilities for a winding playground (hide and seek,…)

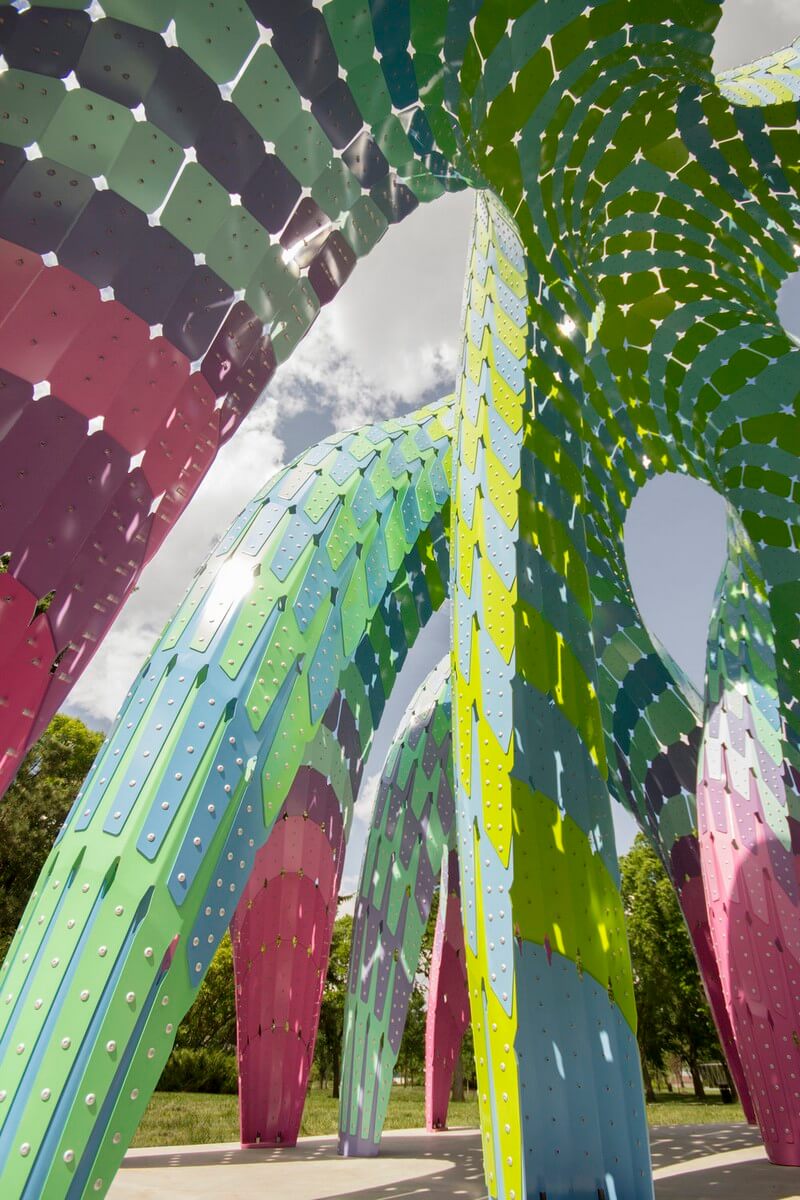

The surface is formulated through a fabrication strategy of intricate shingles assembling into a striated structural skin. The shingles are similar yet unique digitally fabricated stripes that overlap through extended tabs to double material thickness.

The surface is formulated through a fabrication strategy of intricate shingles assembling into a striated structural skin. The shingles are similar yet unique digitally fabricated stripes that overlap through extended tabs to double material thickness.

The stripe colors originate from Vaulted Willow’s surrounding environment, though for it to be an iconic destination within Borden Park, the colors are pushed toward artificiality. The greens and blues blend into a synthetic magenta, overlapping to reveal a two-way Cheshire scheme.

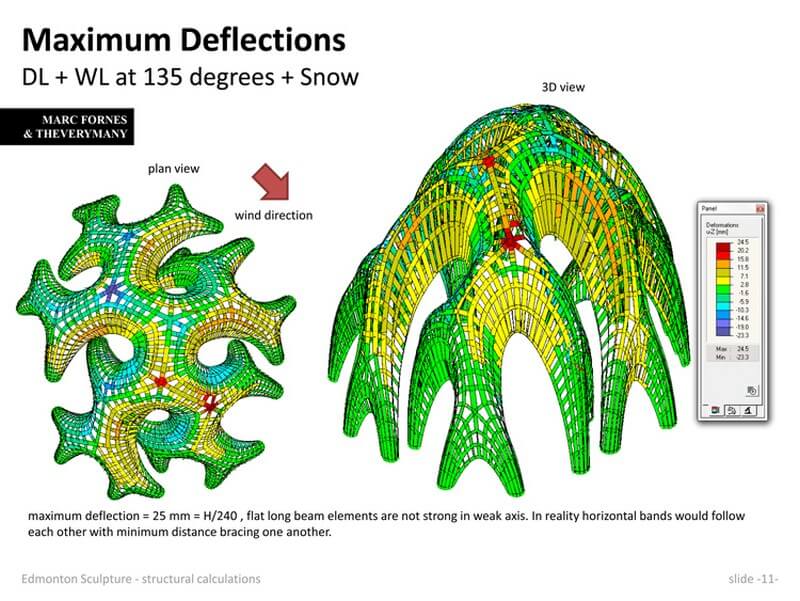

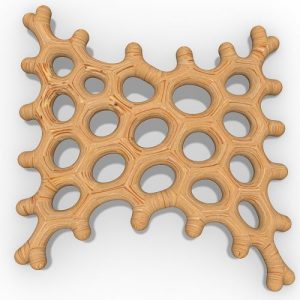

The project builds on the studio’s long-term research into self-supported structures, lightweight monocoque shells made of a series of thin, planar elements proliferating through tangential continuity. The approach uses form-finding protocols to generate structures with extensive double curvature, inherently creating stiffness through geometry and eliminating the need for sub-structure.

The studies elaborate on the 2D geometry of catenary curves by exploiting a computationally derived dynamic spring network with behavioral attributes. The springs come in various types (tensioners, straighteners,..), associated with multiple parameters (rest length, angle constraint, strength,..).

The catenary network is first inflated normal to the ground plane and as a secondary process inflated outward, normal to the surface in order to achieve double curvature. The network inflation stagnates as forces equalize, resolving into an optimized structure. Tessellation considerations therefore have to be embedded within the topology of the system prior to the inflation process.

The catenary network is first inflated normal to the ground plane and as a secondary process inflated outward, normal to the surface in order to achieve double curvature. The network inflation stagnates as forces equalize, resolving into an optimized structure. Tessellation considerations therefore have to be embedded within the topology of the system prior to the inflation process.

Stripes located at the edge of the surface increase tab overlap to help transfer additional loads through lamination and increased connectivity. Porosity increases with height as the structural needs diminish, allowing more light to permeate the space. Running bonds split the stripes, shortening them to ease fabrication, assembly, and decrease material usage through more efficient nesting.

Rivet density is also resolved relative to structural needs, with higher densities and varying configurations at bifurcation points, along the edges, and towards the base of the structure. The extensive, computationally driven, descriptive geometry protocol developed for the project embeds axis of bending, angle measurements, part nomenclature, and color information for each stripe.

Rivet density is also resolved relative to structural needs, with higher densities and varying configurations at bifurcation points, along the edges, and towards the base of the structure. The extensive, computationally driven, descriptive geometry protocol developed for the project embeds axis of bending, angle measurements, part nomenclature, and color information for each stripe.

Comments