Gridshell Structure

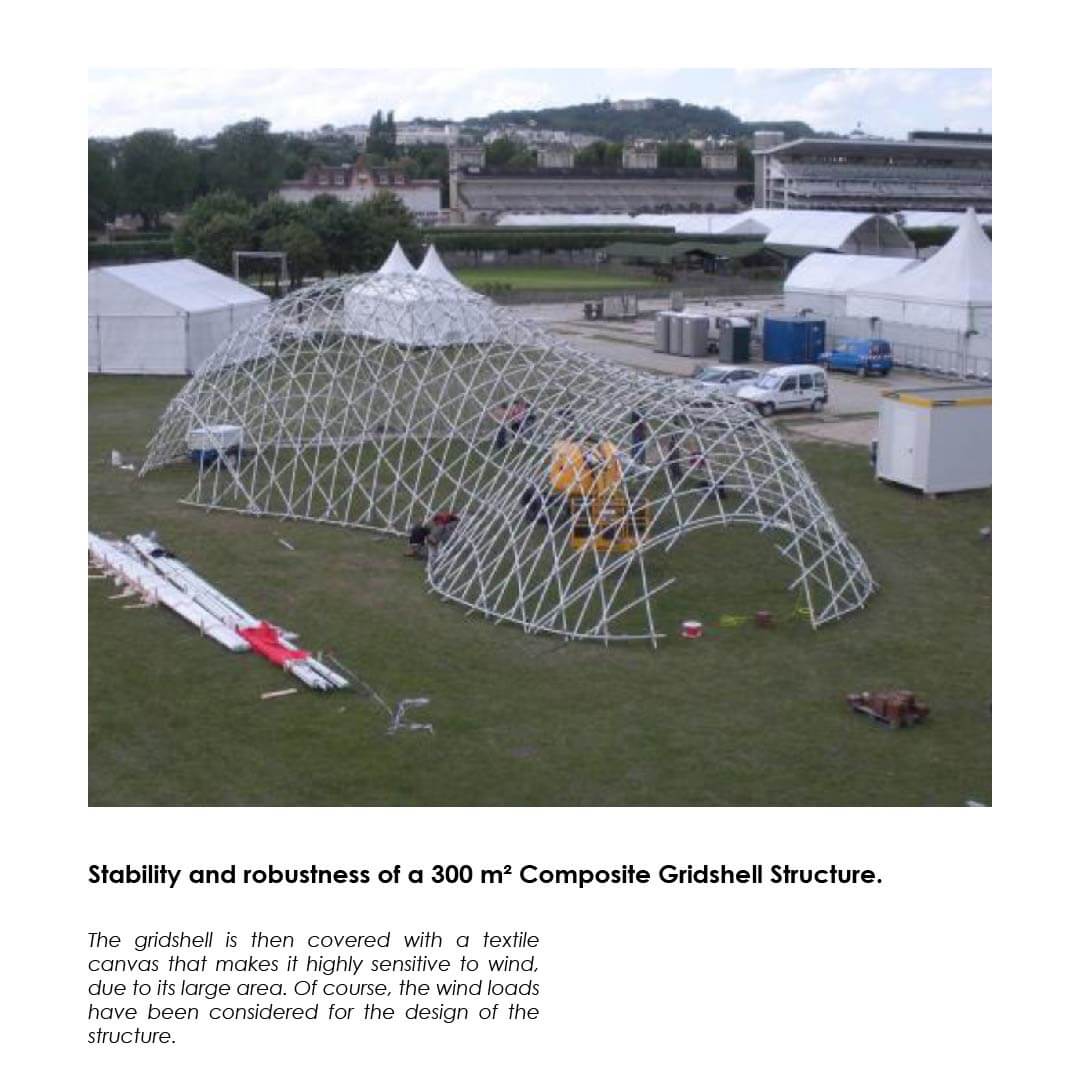

Stability and robustness of a 300 m² Composite Gridshell Structure.

F. Tayeb1, J-F. Caron1, O. Baverel1,2, L. Du Peloux1

aUR Navier, Université Paris-Est Ecole des Ponts ParisTech, 6-8 avenue Blaise Pascal, 77455 Marne la vallée cedex 2, France

bEcole Nationale Supérieure d’Architecture de Grenoble 60, rue de Constantine 38000 Grenoble, France.

In this paper, ductility aspects of a light-weight composite gridshell are developed. A gridshell is a very light structure that can support relative high loads.

For many reasons, the materials used by the Navier laboratory are glass fibre reinforced polymers (GFRP) that have elastic brittle behaviour.

To ensure the safety of people these structures have to behave in a ductile way, that is to say they must not collapse without showing signs of weakness.

To ensure the safety of people these structures have to behave in a ductile way, that is to say they must not collapse without showing signs of weakness.

This paper deals with the pseudo-ductile behaviour of the GFRP gridshells designed by the Architected Structures and Materials research unit of Navier laboratory.

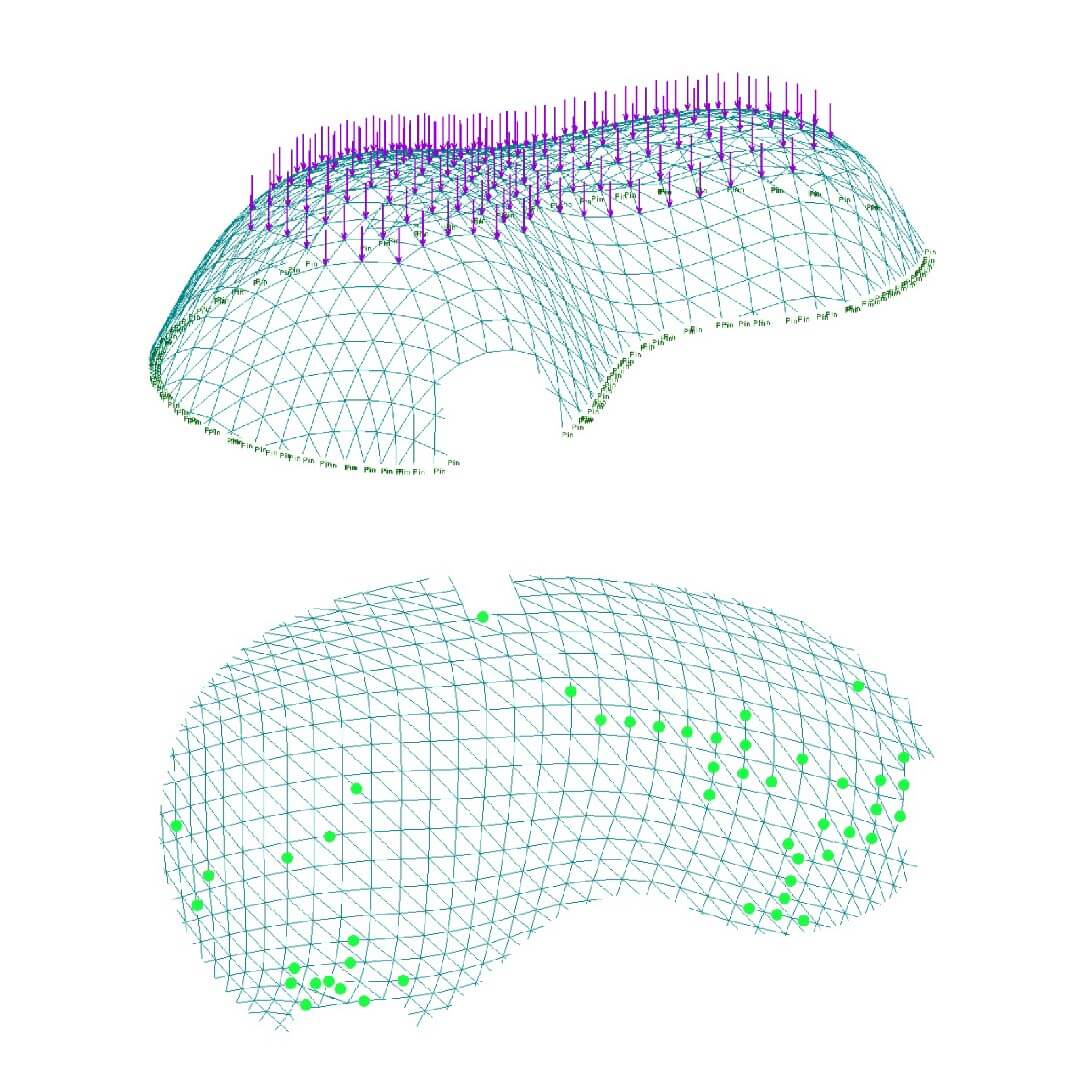

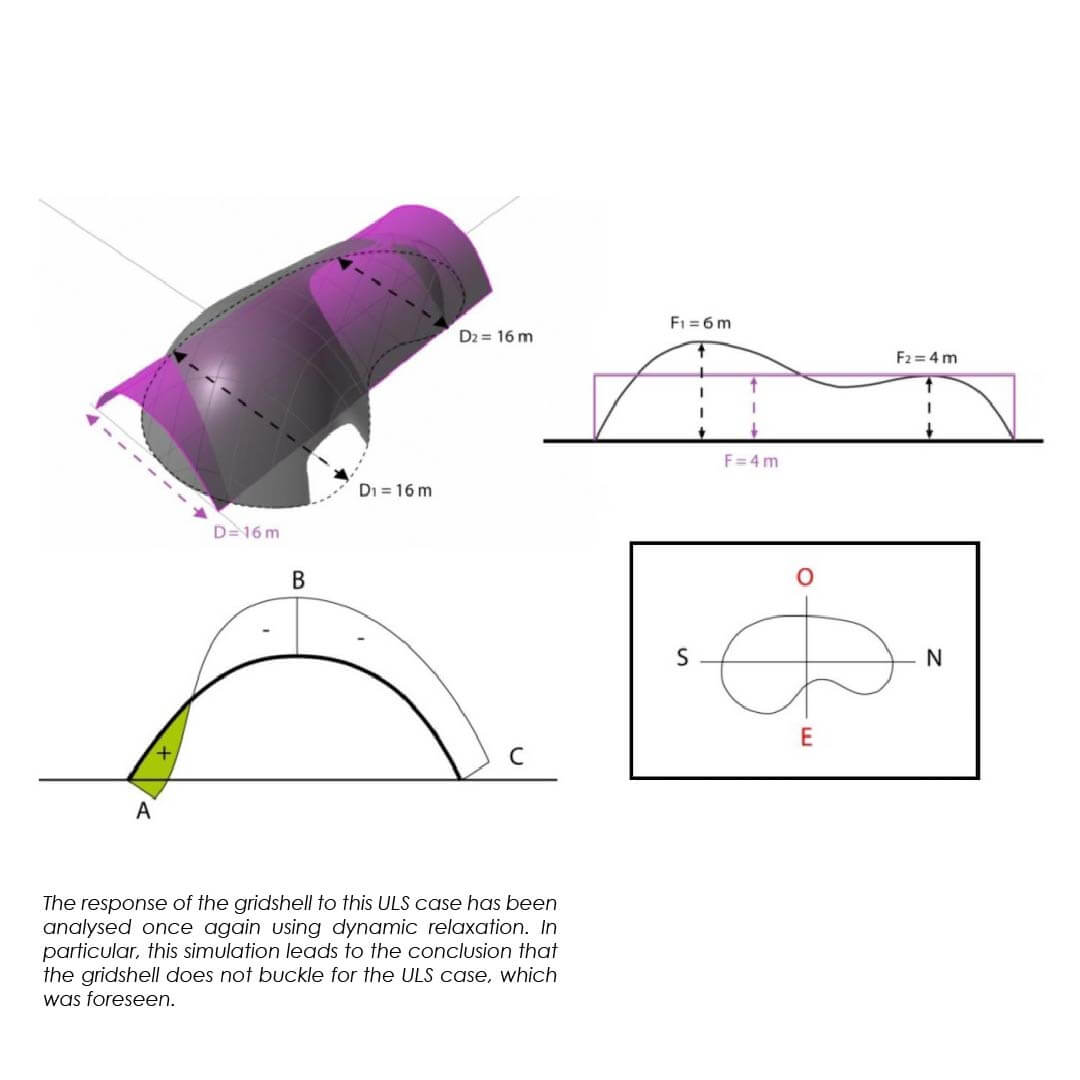

After a reminding context about gridshells, the buckling of the Solidays’ festival gridshell prototype (June 2011) is considered.

After a reminding context about gridshells, the buckling of the Solidays’ festival gridshell prototype (June 2011) is considered.

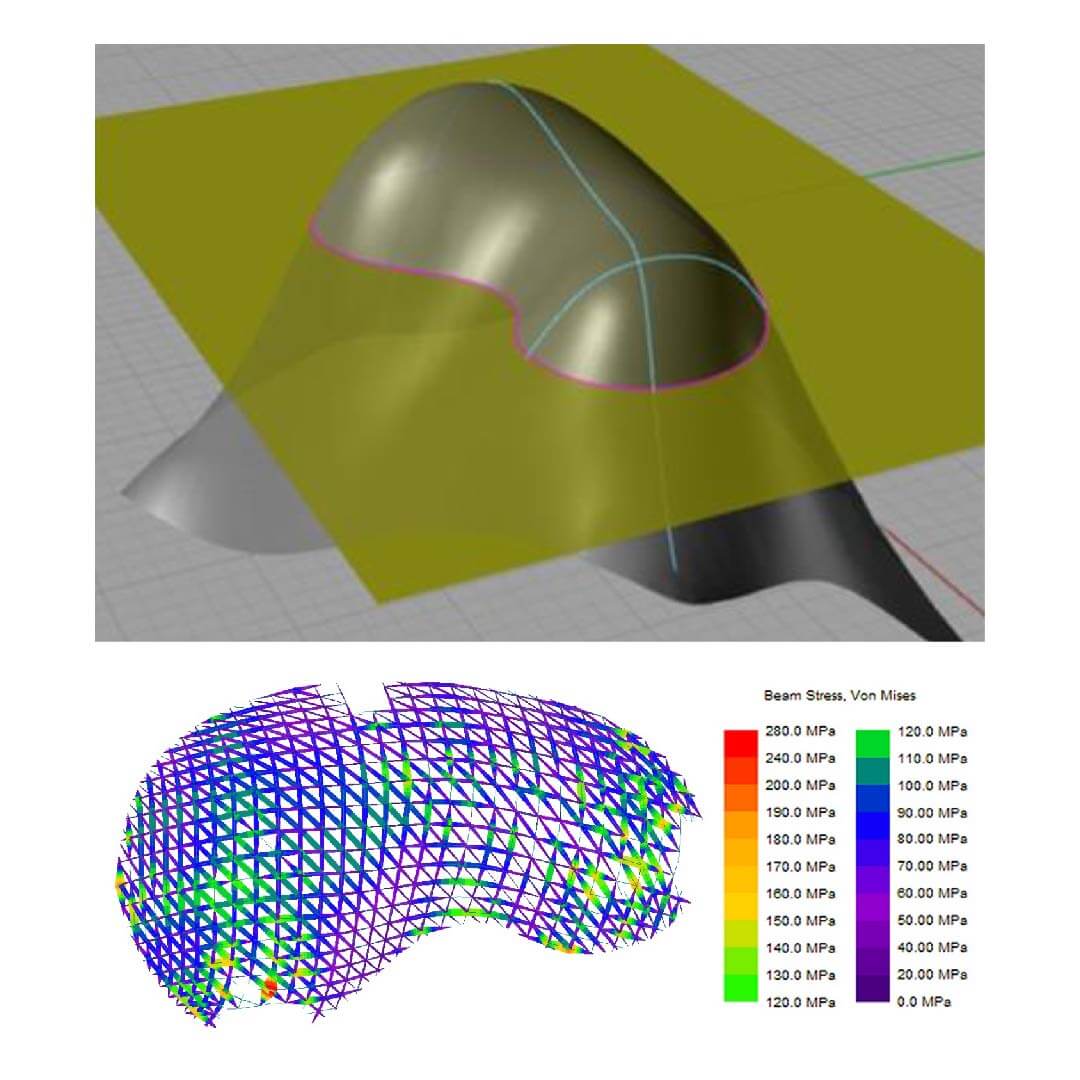

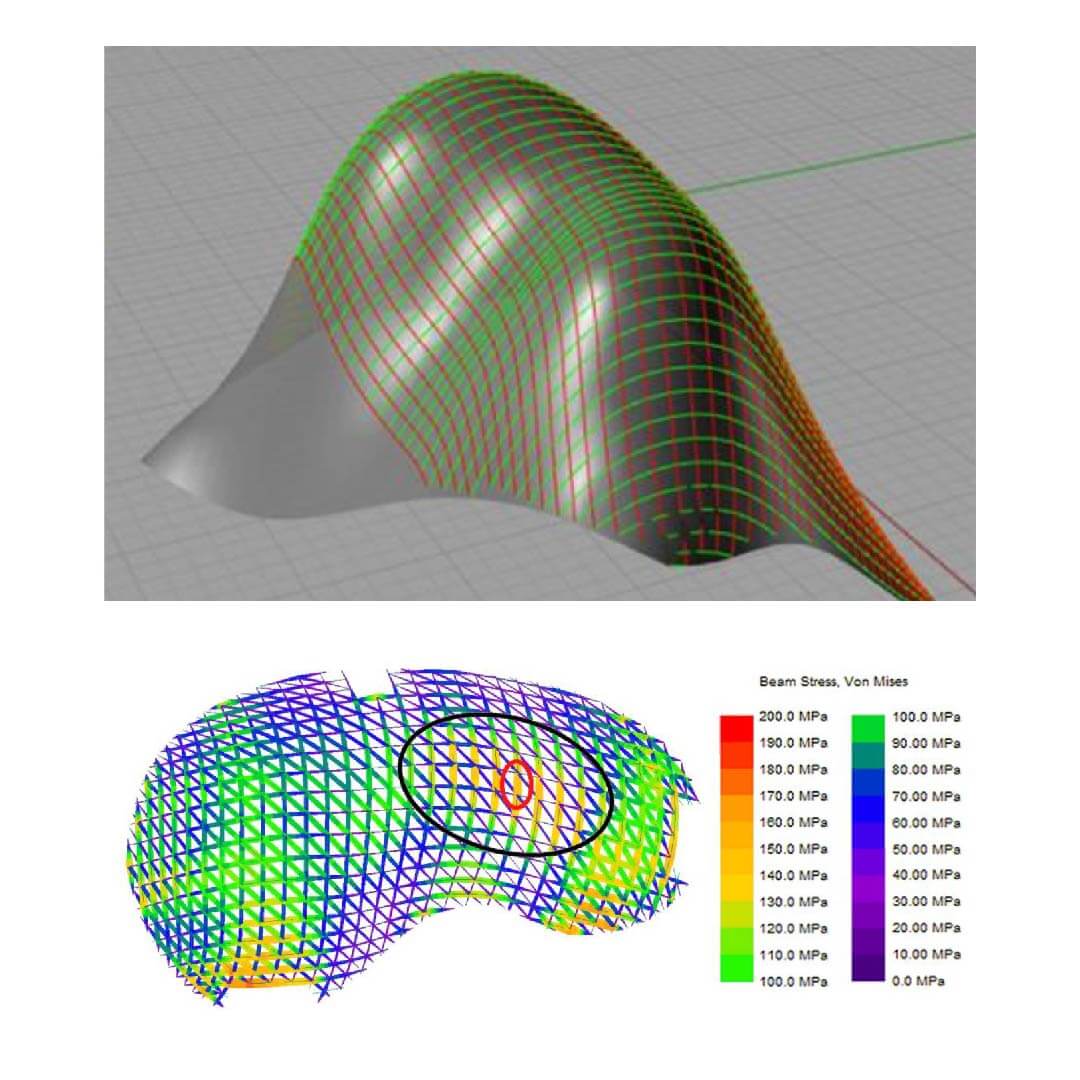

It is demonstrated that buckling has to be avoided carefully because it fosters high stresses in the beams and may lead to a brutal collapse of the structure.

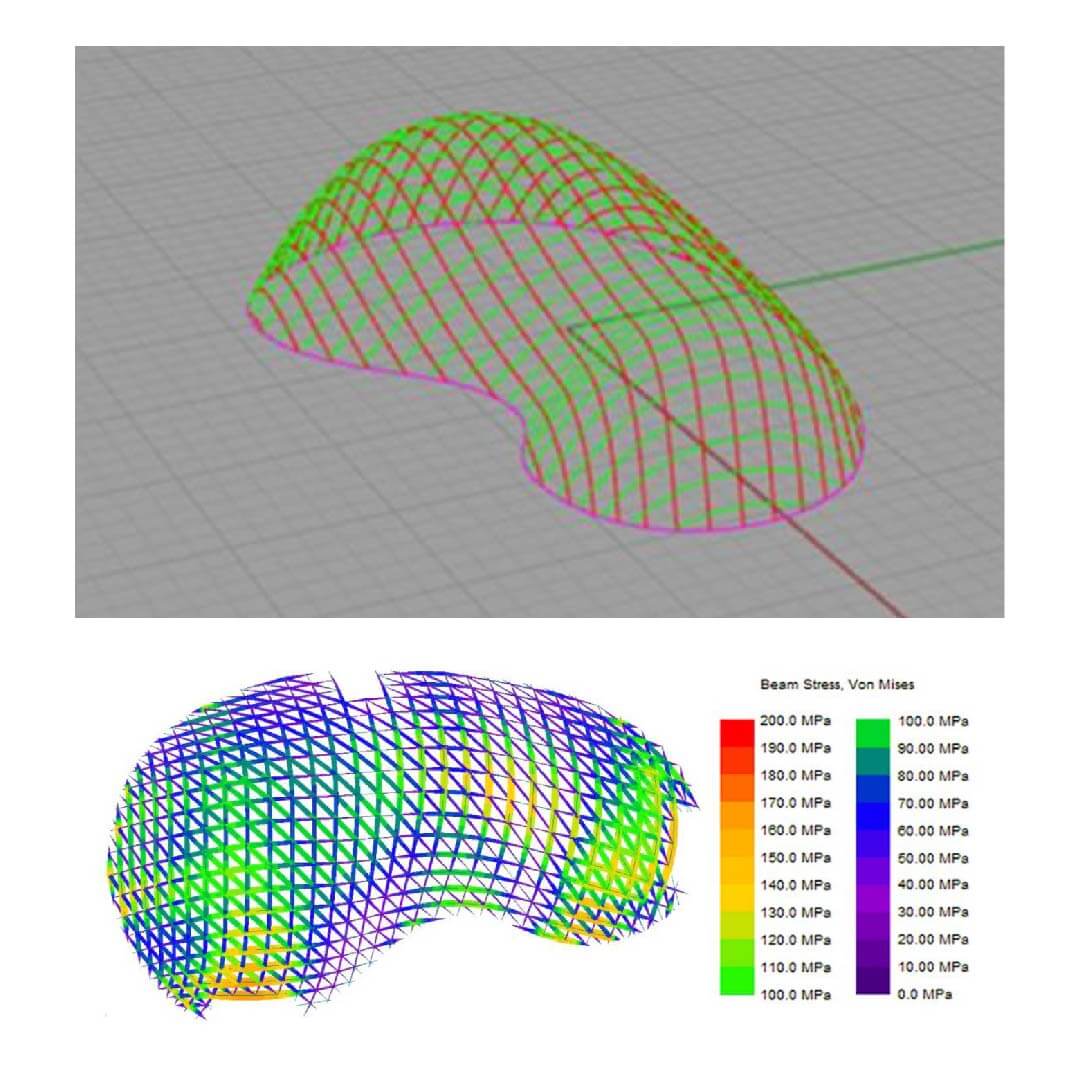

Then it is shown that, under Ultimate Limit State (ULS), the gridshell prototype is far from buckling. Finally, a simulation of accident is performed: from the ULS, several elements are broken in order to understand the behaviour of the structure in case of accident.

Then it is shown that, under Ultimate Limit State (ULS), the gridshell prototype is far from buckling. Finally, a simulation of accident is performed: from the ULS, several elements are broken in order to understand the behaviour of the structure in case of accident.

The pseudo-ductility of the structure is demonstrated thanks to the redundancy of the structural concept of the gridshell.

In the last twenty years many applications of composite materials in the construction were made. The main field of application concerns the reinforcement of concrete beams with carbon fiber plates, post tension cables or all-composite structures.

In the last twenty years many applications of composite materials in the construction were made. The main field of application concerns the reinforcement of concrete beams with carbon fiber plates, post tension cables or all-composite structures.

Nevertheless applications using composite materials as structural elements remain exceptional in comparison with concrete, steel or even wood.

Although the qualities of their mechanicals properties are obvious (low density, high strength and high resistance against corrosion and fatigue), their relatively low elastic modulus may appear as a disadvantage compared with steel.

Although the qualities of their mechanicals properties are obvious (low density, high strength and high resistance against corrosion and fatigue), their relatively low elastic modulus may appear as a disadvantage compared with steel.

Indeed most slender structures in structural engineering are designed according to their stiffness and rarely to their strength.

Indeed most slender structures in structural engineering are designed according to their stiffness and rarely to their strength.

Moreover, the elastic instabilities depend linearly on the Young modulus, so that again, having a low Young modulus can be considered as a real disadvantage when a designer tries to calculate structure based on conventional design structure.

Moreover, the elastic instabilities depend linearly on the Young modulus, so that again, having a low Young modulus can be considered as a real disadvantage when a designer tries to calculate structure based on conventional design structure.

In order to take advantages of every characteristic of composite materials, new structural concepts have to be found.

Comments

bernardusray

Can you explain the process to do beam stress simulation on gridshell structure?