Bespoke Timber Frame

Robotic Fabrication of Bespoke Timber Frame Modules

Andreas Thoma1, Arash Adel1, Matthias Helmreich1, Thomas Wehrle2, Fabio Gramazio1, and Matthias Kohler1

1ETH Zurich, Zurich, Switzerland

1ERNE AG Holzbau, Stein, Switzerland

This paper presents methods and techniques to robotically prefabricate timber frame modules. The key challenge of this research lies in enabling the digitally informed and fabricated spatial assembly of timber beams into prefabricated timber frame modules.

The project combines the fabrication and the spatial assembly of timber beams into one fully integrated robotic fabrication process.A cooperative robotic construction procedure that minimises the need for scaffolding and allows for the informed assembly of spatial structures with non-planar geometries was developed.

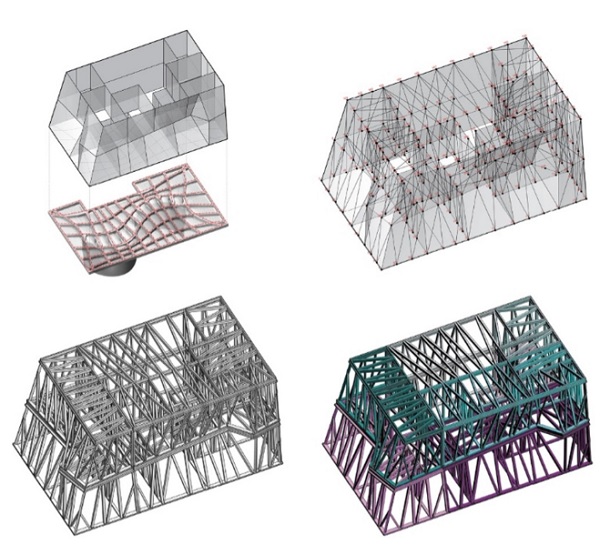

Fig. 1. Illustration of the computational design process/feedback. Diagrams: a. Architectural Inputs: the loadbearing ribs of the lower floor, programmatic organisation, and the exterior envelope b. Structure topology generation (Network graph) c. Generation of Beam class instances d. Modules.

This required the examination of suitable timber joining methods, assembly sequencing, as well developing appropriate and novel strategies to register and handle material deviations and construction tolerances.

The physical implementation of the research in multiple experiments and finally, a full-scale building project validates the approach.

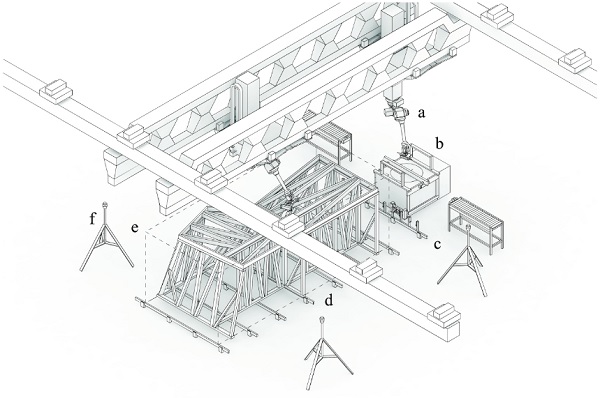

Fig. 2. Multi-Robotic Prefabrication Setup: a. Industrial robotic arm attached to a gantry system. b. CNC saw and fixing station. c. Robot end-effector storage. d. Assembly stand. e. Maximum cooperative building envelope of 3.75 m * 3.50 m * 8.20 m. f. Tracking system.

The implementation of digital fabrication technology in timber construction dates back to the 1980s. Inventions of specialised digital joinery machines and CNC milling machines (Schindler 2009) enabled the digital production of complex timber parts and are well established in the construction industry.

However, the actual assembly of these parts predominantly is still done manually (Willmann et al. 2016), requiring extensive logistics.

Timber modules, typically being assembled flat on the ground in various steps and comprising of standardised planar geometry are mostly assembled by hand however, there are a handful of machines which can automatically assemble simple standardised timber frames: exceptions such as window or door frames are still added manually.

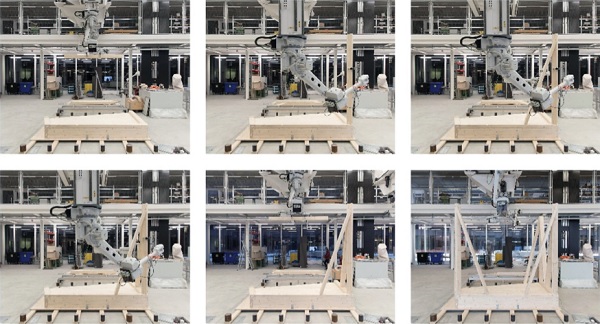

Fig. 3. Cooperative assembly sequence

The implementation of industrial robots into the fabrication loop, performing a variety of programmed tasks, allows not only the production of individual parts but also the digital assembly of them. The Sequential Roof project (Apolinarska et al. 2016), developed by Gramazio Kohler Research at the ETH Zurich and roboticallyconstructed by ERNE AG Holzbau, marked the first step into the digital fabrication of a non-standard timber assembly at a building-scale.

Fig. 5. In Place Milling: The robot mills the required façade detailing into the already assembled structure.

By shifting the fabrication scenario from The Sequential Roof’s layer-based assembly method to a method of spatial assembly, this research expands the possible timber architecture repertoires and applies it at a building-scale to the typology of the timber module: a prefabricated volumetric unit of timber framing which is subsequently assembled on-site.

The spatial assembly method builds upon previous work demonstrating the construction of stable spatial structures without the need for any scaffolding by means of a cooperative robotic sequencing (Mirjan 2016; Parascho et al. 2017) by shifting from an assembly logic that constantly requires the robotic support of parts during assembly to one where parts only require support at specific steps of the assembly process.

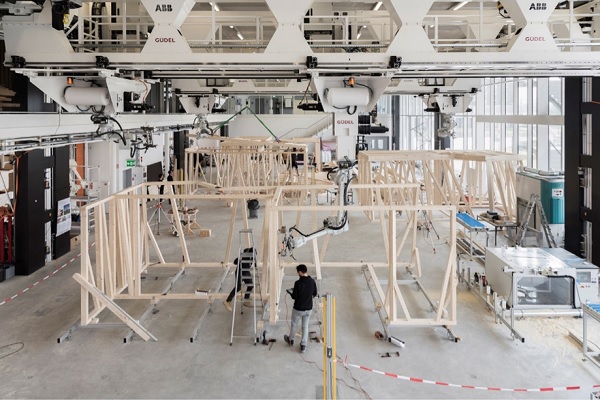

Fig. 6. Photo of the RFL during the production of DFAB HOUSE timber modules.

The DFAB HOUSE (NCCR Digital Fabrication 2018), a three-story building project initiated by the Swiss National Centre of Competence in Research (NCCR) Digital Fabrication, allows for the transfer of this research to its building-scale application.

The timber modules have to reach outside the research setting and are subjected to multiple real building challenges such as fire code, engineering code, acoustics, transport logistics, interfaces with neighbouring building components and finally the test of time while being used and exposed to the elements.

Comments