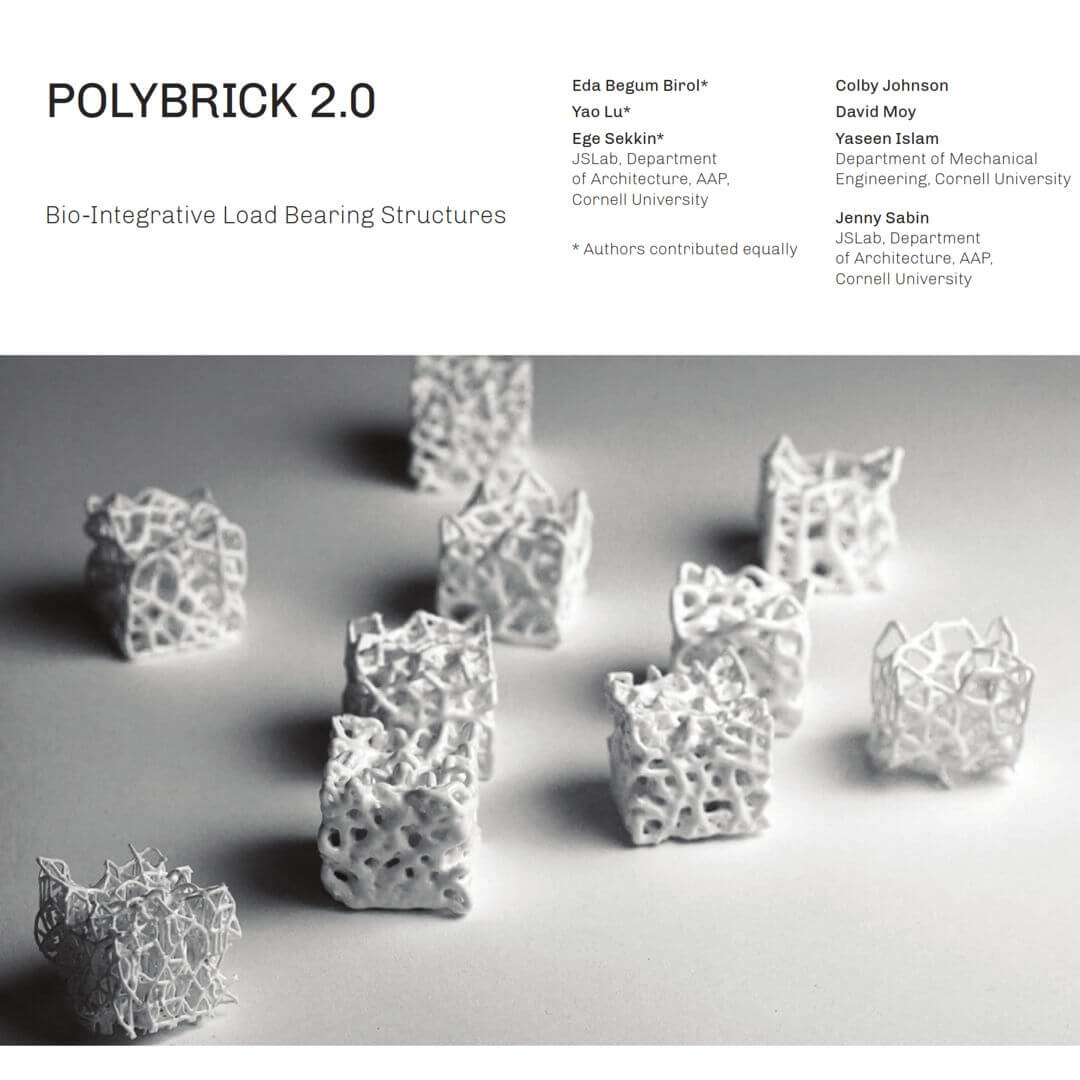

Bio-Integrative Structures

Bio-Integrative Load Bearing Structures

Eda Begum Birol1, Yao Lu1, Ege SekkiN1, Colby Johnson2, David Moy2, Yaseen Islam2, Jenny Sabin1

1JSLab, Department of Architecture, AAP, Cornell University

2Department of Mechanical Engineering, Cornell University

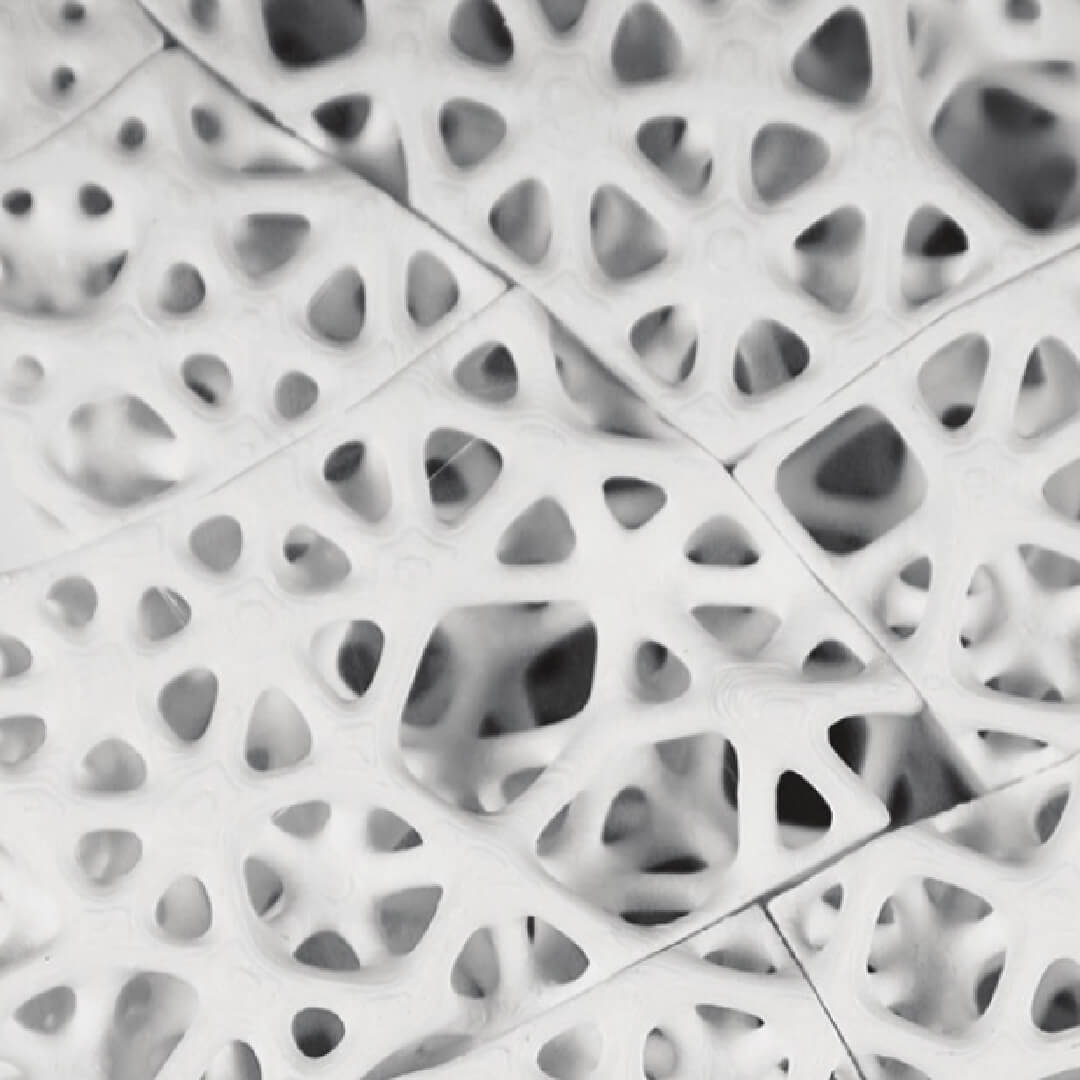

Natural load bearing structures are characterized by aspects of specialized morphology, lightweight, adaptability, and a regenerative life cycle. PolyBrick 2.0 aims to learn from and apply these characteristics in the pursuit of revitalizing ceramic load bearing structures.

For this, algorithmic design processes are employed, whose physical manifestations are realized through available clay/porcelain additive manufacturing technologies (AMTs).

By integrating specialized expertise across disciplines of architecture, engineering, and material science, our team proposes an algorithmic toolset to generate PolyBrick geometries that can be applied to various architectural typologies.

By integrating specialized expertise across disciplines of architecture, engineering, and material science, our team proposes an algorithmic toolset to generate PolyBrick geometries that can be applied to various architectural typologies.

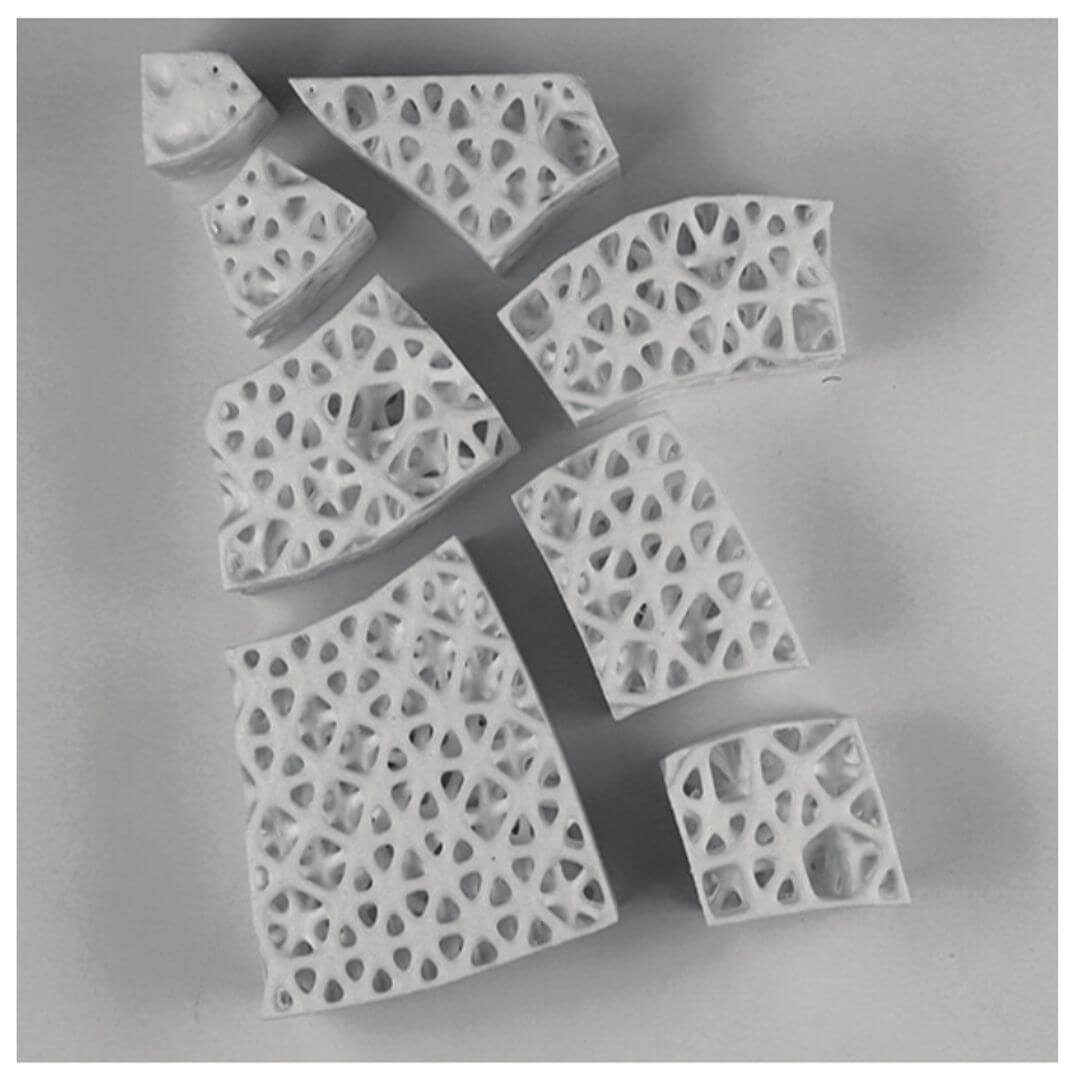

Additionally, comparative frameworks for digital and physical performance analyses are outlined. Responding to increasing urgencies of material efficiency and environmental sensibility, this project strives to provide for designers a toolset for environmentally responsive, case-specific design, characterized by the embedded control qualities derived from the bone and its adaptability to specific loading conditions. Various approaches to brick tessellation and assembly are proposed and architectural possibilities are presented.

Ceramic modules of standard measurement have been used as a building block […] for many centuries” (Sabin 2014). With rapid developments in the area of clay additive manufacturing, there is an emerging possibility to reintroduce non-standard clay building blocks in load bearing applications.

Ceramic modules of standard measurement have been used as a building block […] for many centuries” (Sabin 2014). With rapid developments in the area of clay additive manufacturing, there is an emerging possibility to reintroduce non-standard clay building blocks in load bearing applications.

The motivation for such research trajectories comprise of “a qualitative, design driven desire for novel forms, or an aspiration for the quantitative improvement of building performance metrics” (Seibold et al. 2018). However, literature outlining expansive utilization of these technologies within comprehensive processes of algorithmic generation, manufacturing, digital and physical evaluation, and architectural application remains lacking.

As part of comprehensive workflow for PolyBrick 2.0, novel algorithmic processes are developed, fabrication methods are outlined, prototype performances are evaluated, and architectural applications are envisioned.

As part of comprehensive workflow for PolyBrick 2.0, novel algorithmic processes are developed, fabrication methods are outlined, prototype performances are evaluated, and architectural applications are envisioned.

Hence, PolyBrick 2.0 suggests a complete methodology in continuing PolyBrick’s ubiquitous aim to “bridge digital processes with the production and design of nonstandard ceramic building blocks in architecture” (Sabin et al. 2014). Within this process the role of “non-standard” components in load bearing applications is addressed and the duality of solidity and porosity in relation to structural performance is explored.

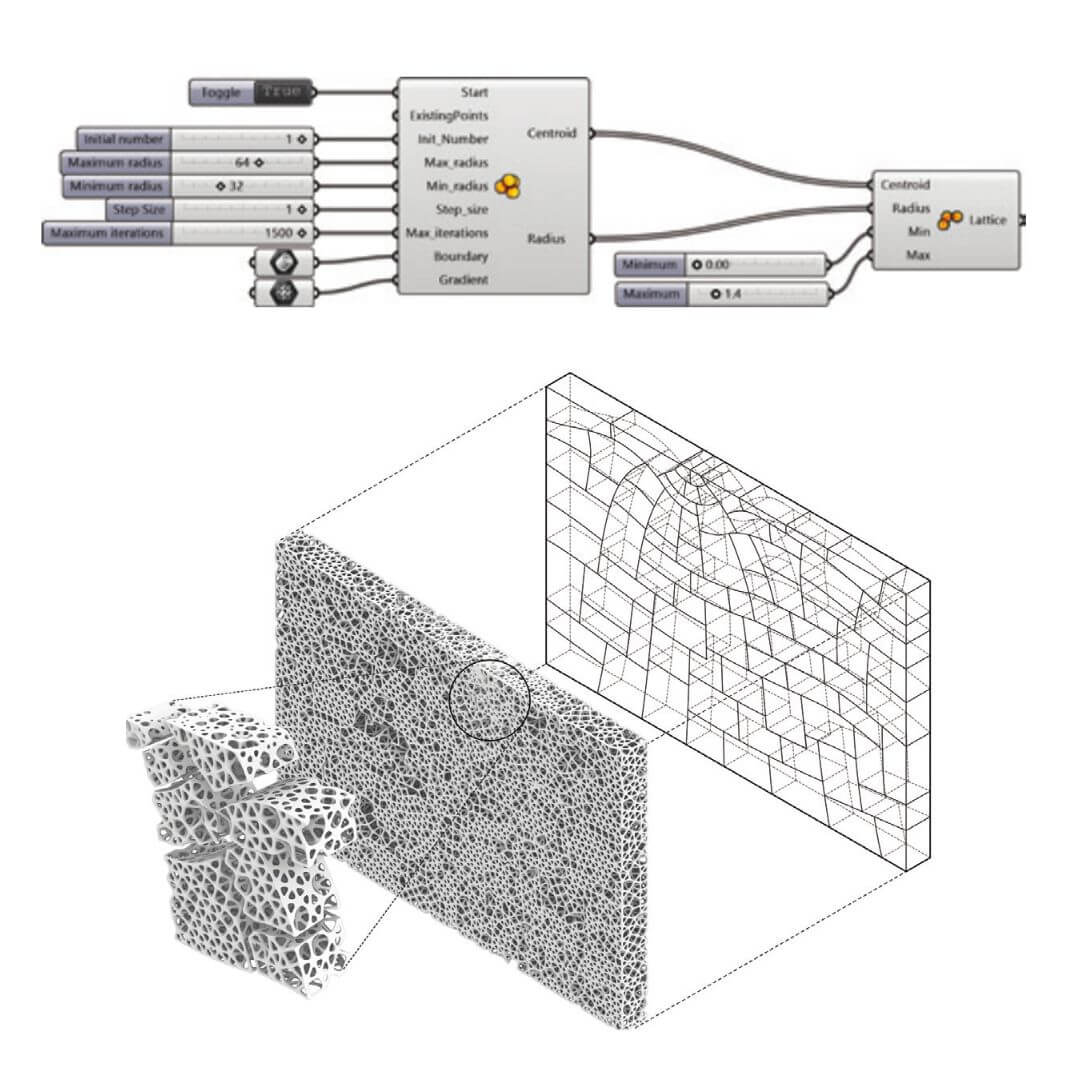

With the use of global finite element analysis, the aim is to achieve responsive lattice heterogeneity at the architecture scale according to prevalent stress magnitude and direction data. To initiate this process, a hypothetical loading condition is applied upon a speculative wall with the dimensions of 0.2 m x 2 m x 3 m.

With the use of global finite element analysis, the aim is to achieve responsive lattice heterogeneity at the architecture scale according to prevalent stress magnitude and direction data. To initiate this process, a hypothetical loading condition is applied upon a speculative wall with the dimensions of 0.2 m x 2 m x 3 m.

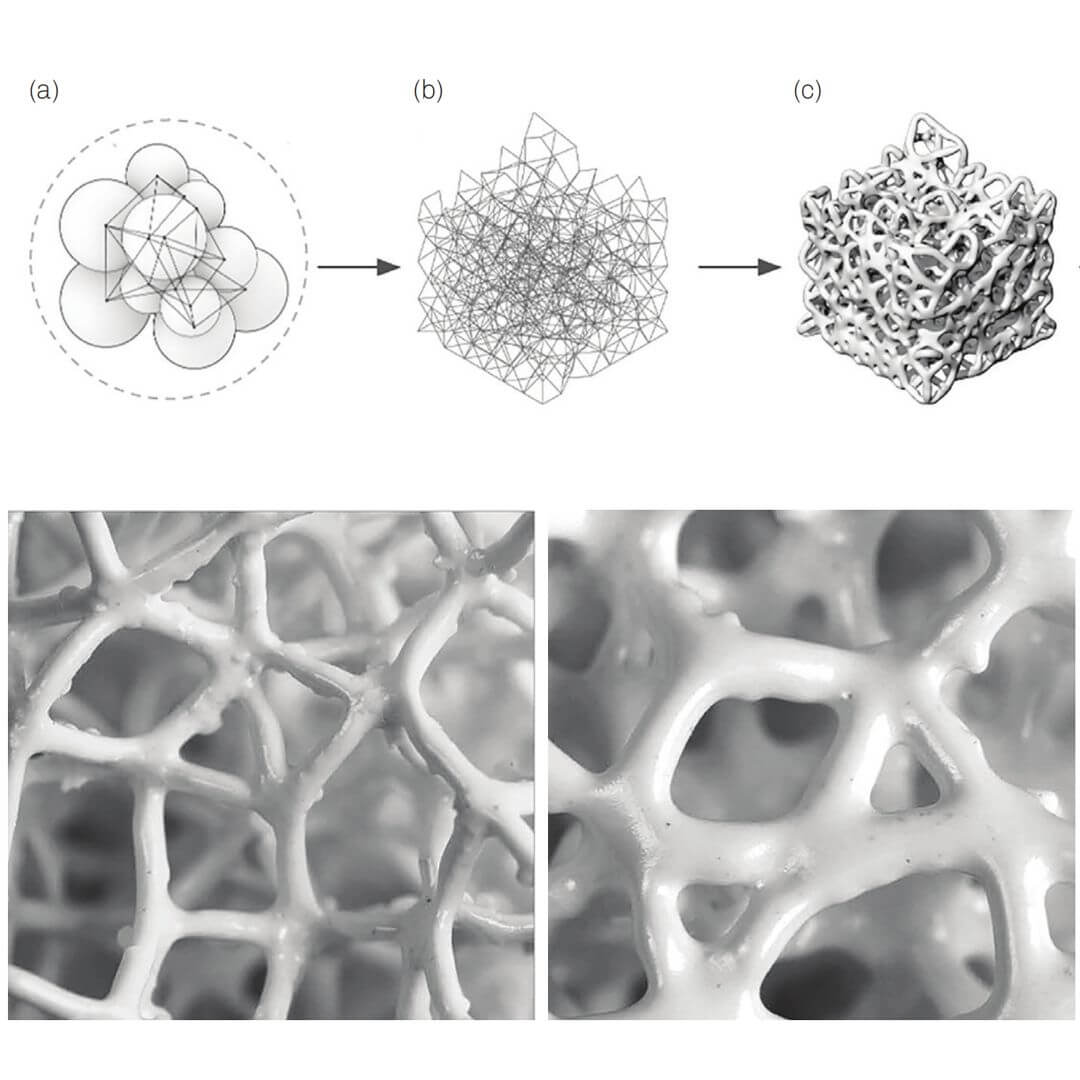

A comprehensive workflow is developed, entailing algorithmic generation of PolyBrick lattices and corresponding reevaluation and adaptations according to local and global scale stress distributions. The algorithmic process is formalized as a custom Grasshopper plug-in containing components for sphere packing, ellipsoid packing, lattice generation (kissing spheres), and thickening meshing applicable to various global geometries.

A comprehensive workflow is developed, entailing algorithmic generation of PolyBrick lattices and corresponding reevaluation and adaptations according to local and global scale stress distributions. The algorithmic process is formalized as a custom Grasshopper plug-in containing components for sphere packing, ellipsoid packing, lattice generation (kissing spheres), and thickening meshing applicable to various global geometries.

Comments

Mattar

Hi I would like to find this Plugin to download. Do you know where I can find it?