Biohybrid Components

Programming Material Intelligence: An Additive Fabrication Strategy for Self-shaping Biohybrid Components

Tiffany Cheng1, Dylan Wood1, Xian Wang2

1Stuttgart University, Germany

2Tongji University, China

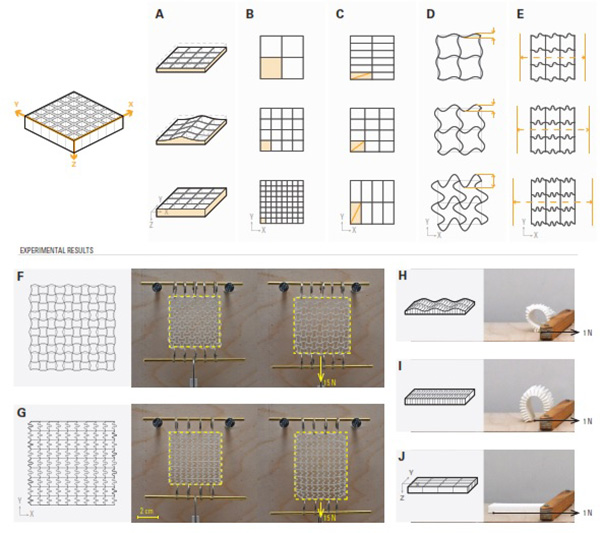

Fig. 1. Functional parameters include (A) pattern height, (B) resolution, (C) grid distribution, (D) amplitude, and (E) frequency. Shown here are the designed behaviors of(F) an isotropic pattern, deforming equally in the X and Y axes, and (G) an anisotropic pattern, deforming only in the Y axis, under a 15 N tension force. Bending bias can be tuned via anisotropy and thickness, as exhibited by testing coupons with one edge on a pin joint and string pulling from the free edge (allowing rotational freedom in the XZ plane): patterns having (H) variable height and anisotropy in the Y direction and(I) anisotropy in the Y direction buckle under a 1 N force, while (J) a pattern with anisotropy in the X direction resists bending of up to 5 N forces.

This paper presents an integrative approach to adaptive structures, which harnesses the scale and strength of natural material actuators such as wood as well as the functional physical programming of material properties enabled by 3D-printing.

Passively actuated adaptive systems represent a growing field within architecture, and wood’s innate capacity for hygroscopic responsiveness can be instrumentalized for use as a natural actuator; however, the internal compositions of wood cannot be fully customized.

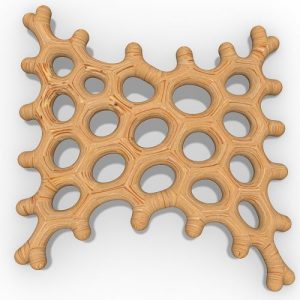

With 3D-printing, it is possible to tailor the internal substructure of physical objects. We introduce a material programming and additive fabrication method for designing macro-scale objects with anisotropic stiffness and elasticity of varying magnitudes using functional patterns, and embedding natural wood actuators into the synthetic 3D-printed structures.

In place of electronics and digital control, movement is encoded in the physical material and fabrication logic—demonstrating how self-shaping biohybrid components can emerge from a synergy of natural and synthetic materials.

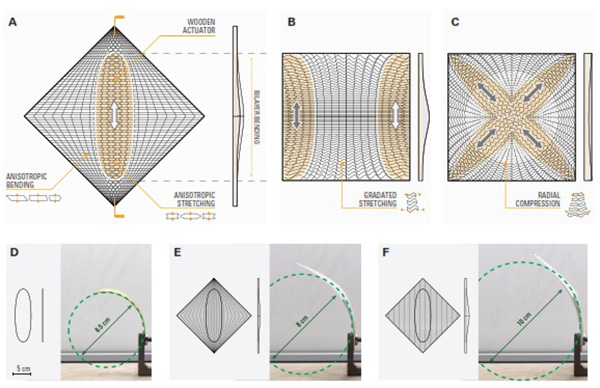

Fig. 2. Integrating natural and synthetic materials necessitates the mediation between discrete parts to work together as one entity. A biohybrid component containing one wood bilayer actuator (A) can display multiple functionalities across areas, transitioning from patterns for anisotropic bending to stretching. Material properties for wood-plastic integration and the interface of their associated patterns can be assigned using a number of strategies; illustrated are designs with (B) two wood actuators of opposing bending orientations and (C) four actuators arranged in radial symmetry. Captured at 40% RH, shown here are (D) the control sample, (E) an integrated sample with strategic patterning, and (F) an integrated sample with non-differentiated patterning.

Passively actuated adaptive systems represent a growing field in architecture and engineering. Many bio-based materials have the capacity to change shape based on external environmental stimuli such as heat or humidity. Wood is a sustainable, readily available, easily machinable, and high-performance construction material with a natural capacity for moisture-induced and direction-dependent swelling and shrinking.

By accessing this inherent hygroscopic and orthotropic behavior in a bilayer configuration, wood becomes a natural actuator that can produce shape changes in curvature through bending. This adaptiveness alludes to the potential for buildings to be more in tune with the fluctuating climate by automatically self-shading, self-ventilating, and self-stiffening in response to environmental changes.

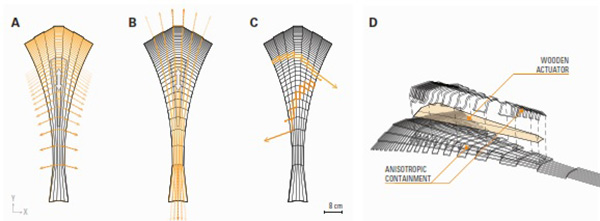

At the same time, when used at increased size and thickness, wood can be employed as a self-shaping mechanism for the manufacture of curved timber components and larger structures.

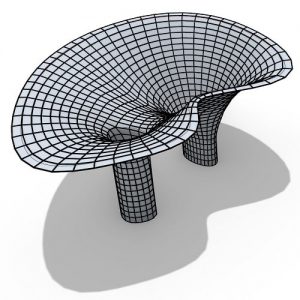

Fig. 3. The additive fabrication strategy was transferred to full scale using robotic extrusion. The production of a biohybrid leg required (A) enough flexibility in the di-rection of bending, but also (B) high stiffness to transfer loads and support self-weight. Extrusion paths were kept as continuous as possible, (C) following an alternating layer-by-layer logic of diagonal cross-hatching to maximize mechanical performance. The fabrication sequence involved creating containers (D) which indicate the placement of wood actuators as well as provide for them a secure enclosure.

The structural properties of wood specific to shrinking and swelling can be adjusted through densification, delignification, or chemical treatment. As a natural material, however, its stark anisotropic behavior within a sheet stock can not be fully customized. Tailoring the direction of hygroscopic actuation can be achieved by combining multiple boards into larger parts, but there are limits due to the existing structure of the material.

Meanwhile, 3D-printing has enabled the tuning of material properties and functionalities through the manufacture of compliant mechanisms with tailored internal substructures.

3D-printed mechanical metamaterials with a range of functions, from elastic patterns to double curvature to thermally actuated mechanisms, have been researched; but existing literature shows that these laboratory prototypes lack the scale, high swelling force, and actuation speed necessary for some building applications.

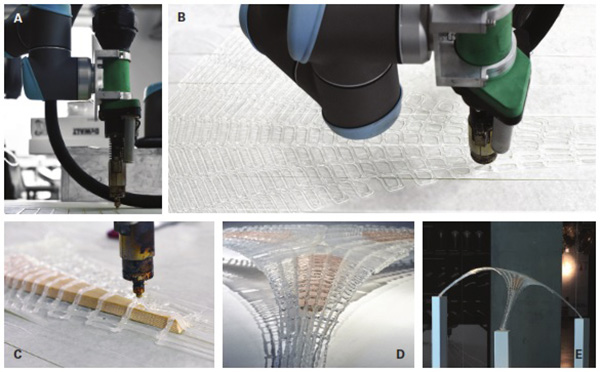

Fig. 4. The biohybrid leg was fabricated with a robotic arm (A) equipped with an end effector for large format extrusion (B). At 10% WMC, the wood bilayer actuator is flat and thus can be embedded (C). Three biohybrid legs were assembled to forma shape-changing tripod (D); exposure to higher humidity environments activates the wood bilayers, shown here curving at 20% WMC and shaping the entire structure (E).

Biohybrid parts which move in response to the changing weather without electrical power can potentially serve as a solution to energy-efficient indoor climate control. Although we have shown self-shaping at a range of spatial scales, the adoption of biohybrid components in buildings will require further exploration of the additional functionalities which are enabled by this material programming and additive fabrication approach.

For the application of responsive facades that can manage the indoor climate, it will be necessary to overcome the poro elastic time scale. In the case of irreversible self-shaping such as in deployable structures and shells, safety mechanisms for locking the desired shape change will need to be investigated.

Beyond the use of wood, other combinations of natural material actuators and synthetic material programming could be particularly interesting for large-scale self-shaping systems.

Comments