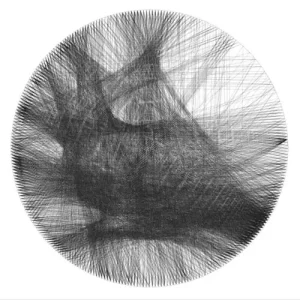

String Art Generator

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

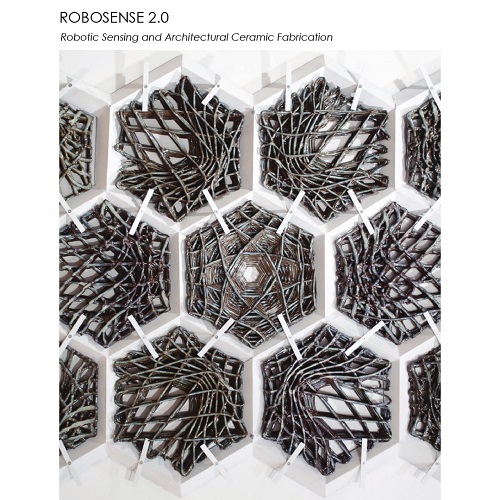

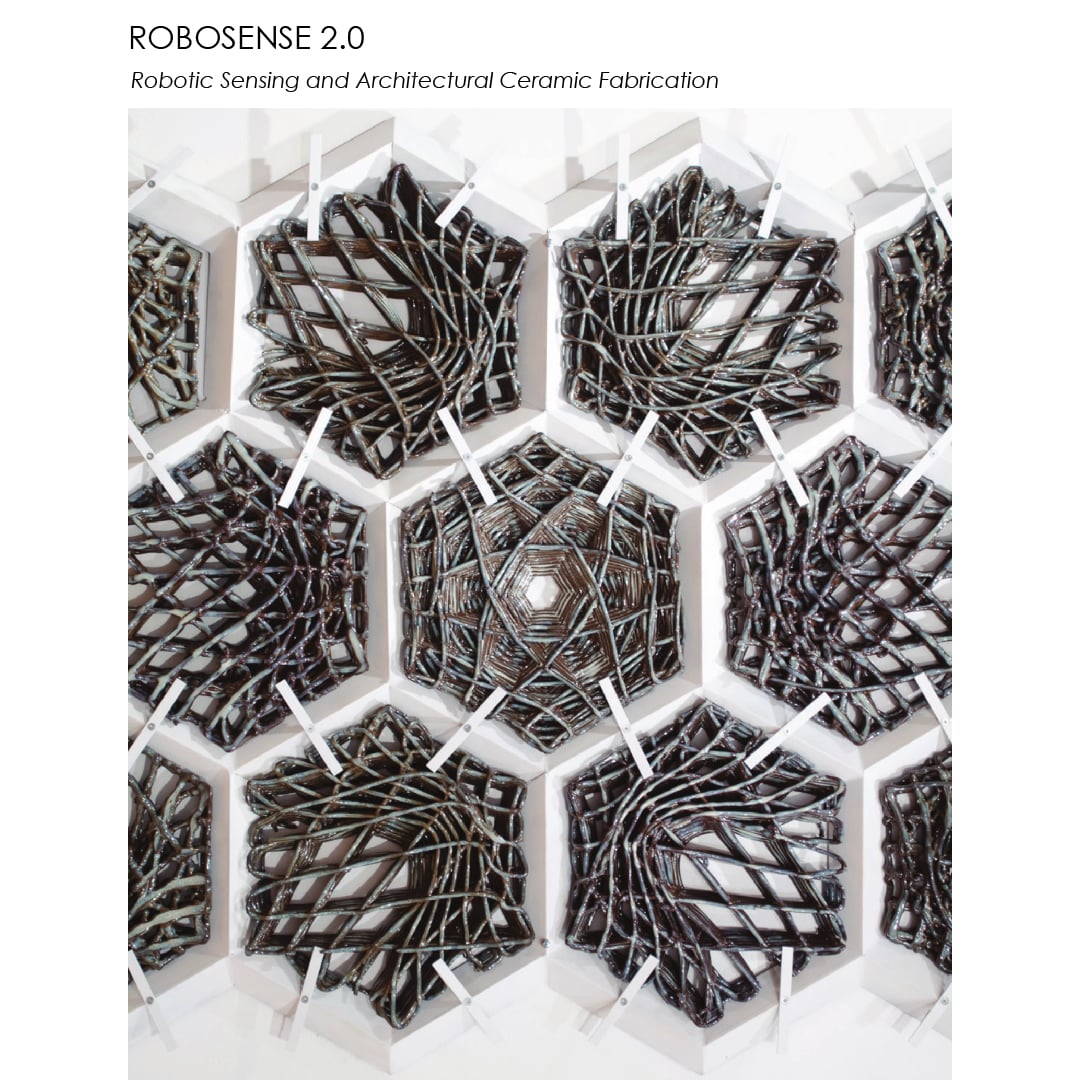

ROBOSENSE 2.0

“Robosense 2.0: Robotic Sensing and Architectural Ceramic Fabrication” demonstrates a generative design process based on collaboration between designers, robotic tools, advanced software, and nuanced material behavior.

The project employs fabrication tools that are typically used in highly precise and predetermined applications, but uniquely thematizes the unpredictable aspects of these processes as applied to architectural component design.

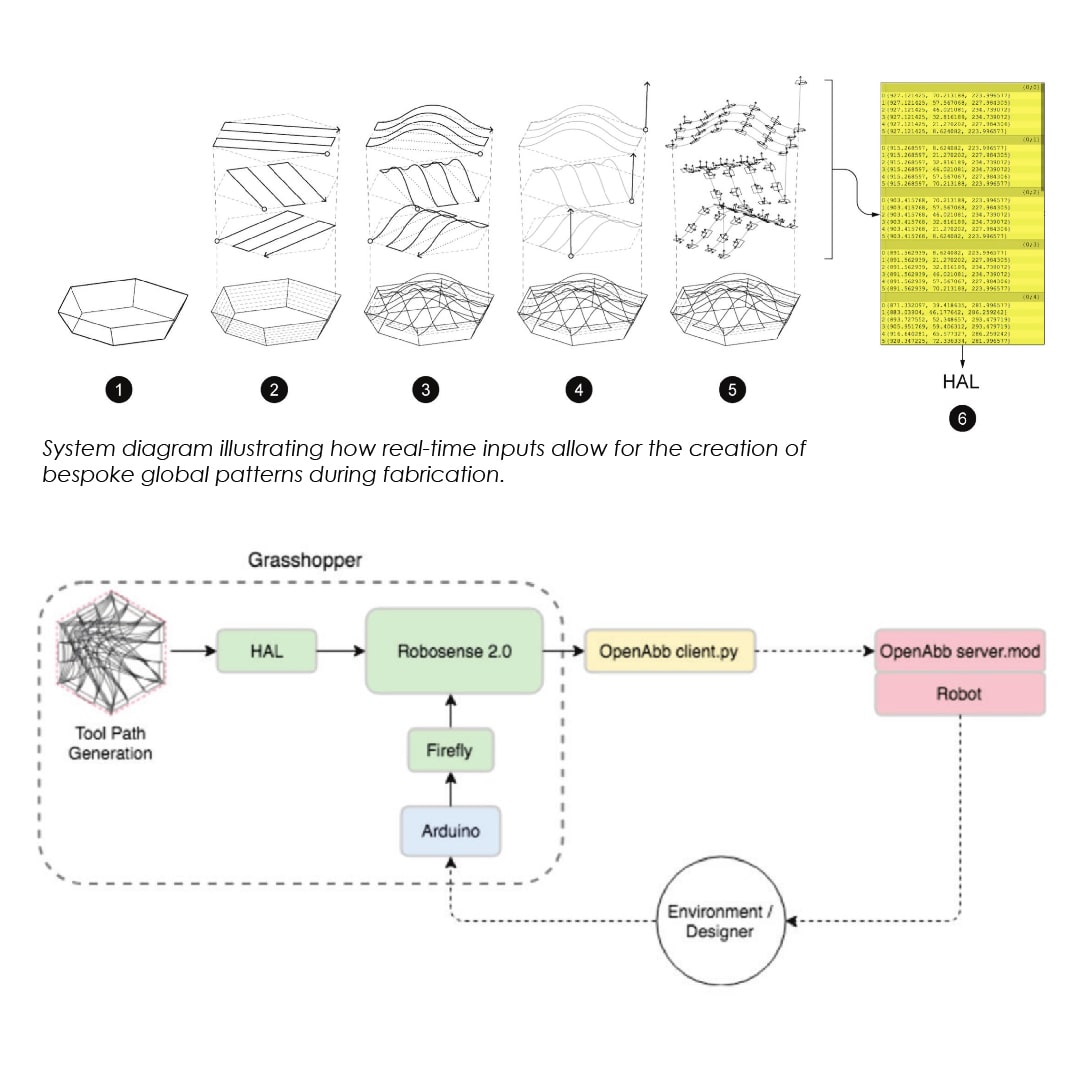

By integrating responsive sensing systems, this paper demonstrates real-time feedback loops that consider the spontaneous agency and intuition of the architect (or craftsperson) rather than the execution of static or predetermined designs.

This paper includes new developments in robotics software for architectural design applications, ceramic-deposition 3D printing, sensing systems, materially driven pattern design, and techniques with roots in the arts and crafts.

Considering the increasing accessibility and advancement of 3D printing and robotic technologies, this project seeks to challenge the erasure of materiality: when mistakes or accidents caused by inconsistencies in natural material are avoided or intentionally hidden.

Instead, the incorporation of material and user-input data yields designs that are imbued with more nuanced traces of making. This paper suggests the potential for architects and craftspeople to maintain a more direct and active relationship with the production of their designs.

Unlike robots in industry, which execute predefned and repetitive tasks in a controlled environment, robotics in design and architecture are becoming increasingly involved with uncertain tasks within more complex and dynamic contexts.

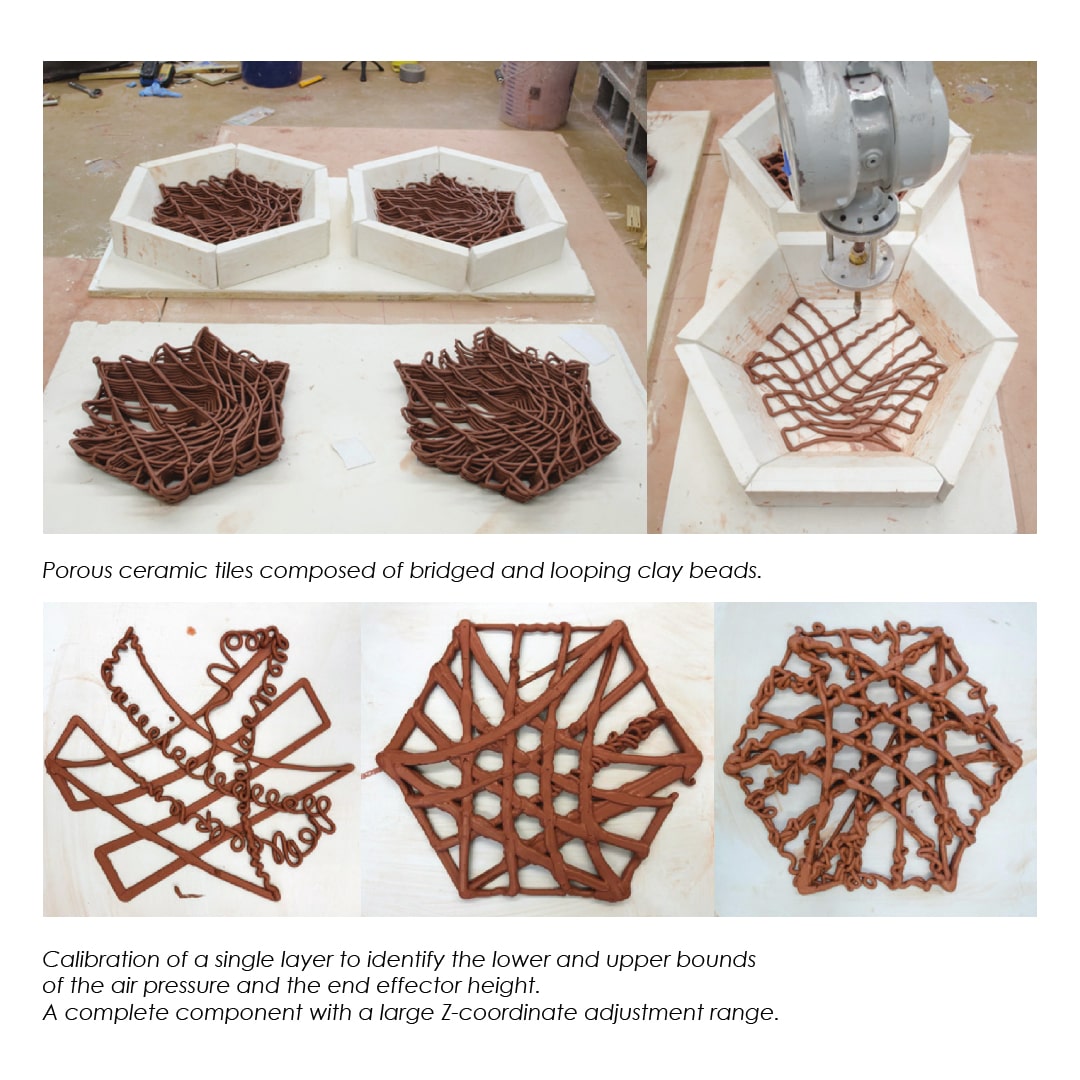

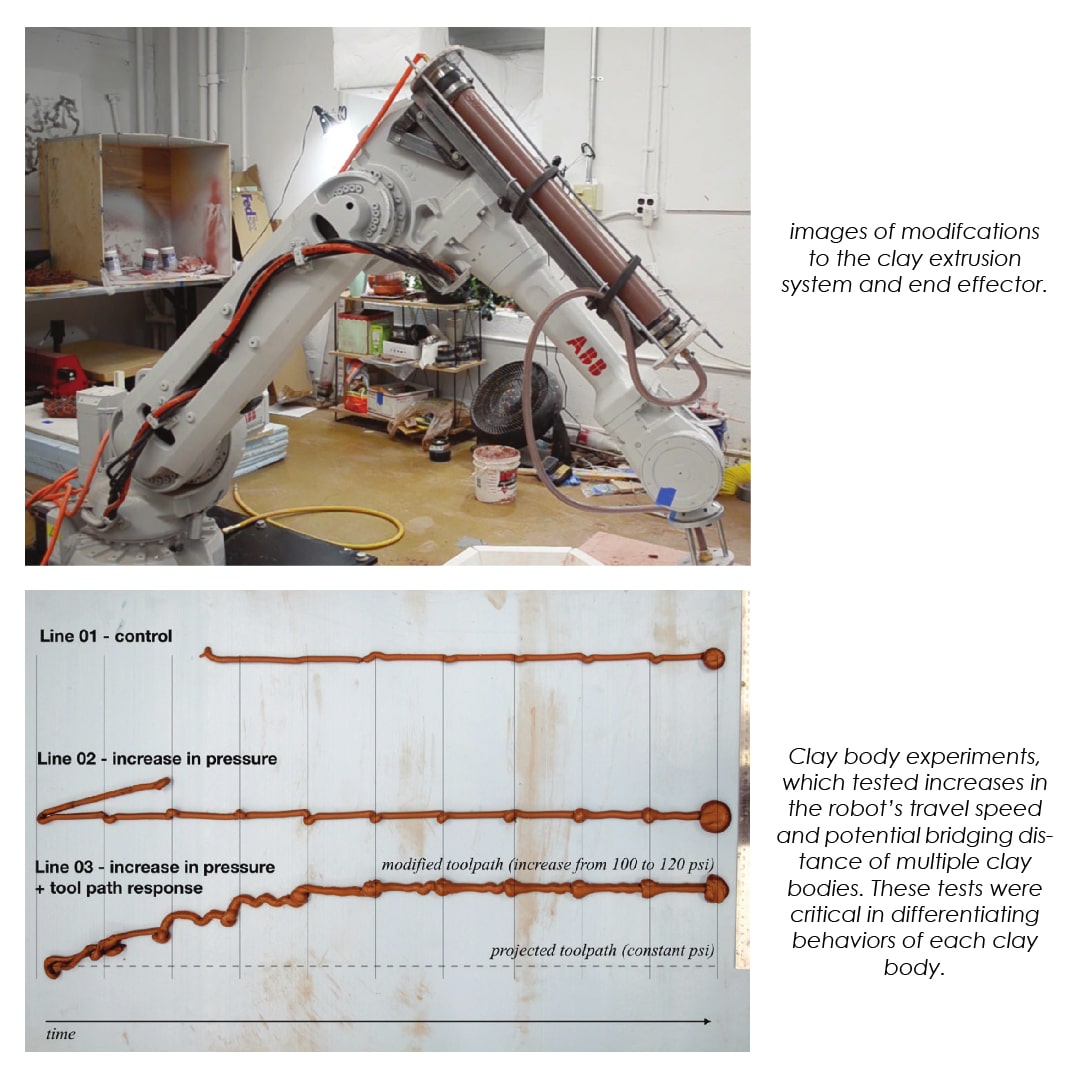

Manufacturing machines and robots have now started to gain intelligence—actively communicating, monitoring, and sensing—and with this, the ability to react (Menges 2014). To facilitate the feedback between design and robotic fabrication, a Python-based interface, encapsulating communication protocols and robotic manipulation libraries, was created in Robosense 1.0.

The interface seamlessly bridges the gap between physical and digital environments and allows for a feedback-oriented robotic fabrication paradigm. Building upon Robosense 1.0, Robosense 2.0 steps forward and integrates the interface into design software Rhinoceros 3D and Grasshopper.

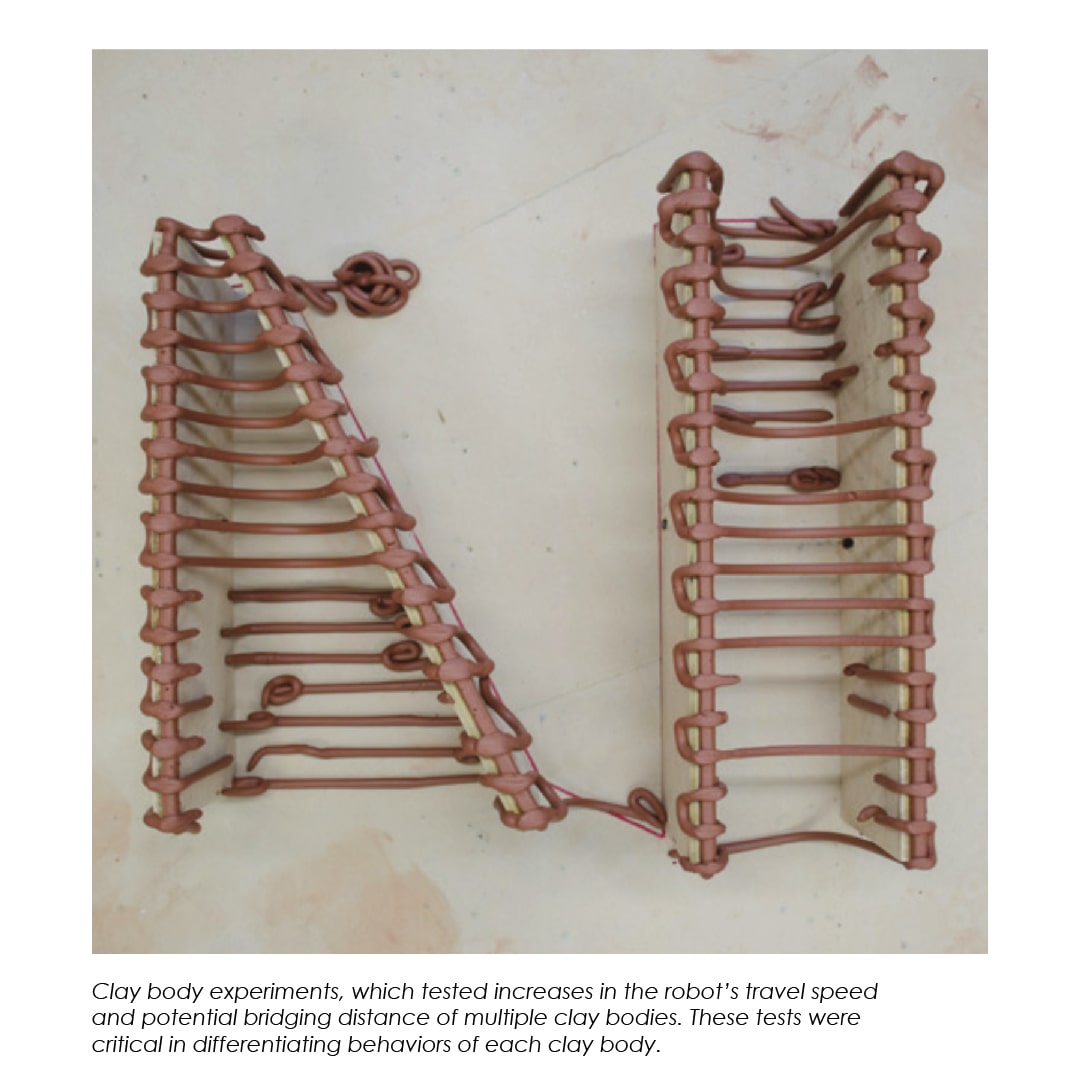

They propose the development of a responsive feedback system that provides the designer/maker with information about the material, allowing for intuitive, on-the-fy modifcations to the design process during the course of fabrication.

Reciprocally, the designer’s choices and changes are registered, and the software responds in real time to create a fuid workfow that informs and unlocks the potential for more a nuanced understanding of 3D-printed clay as an architectural fabrication technique.

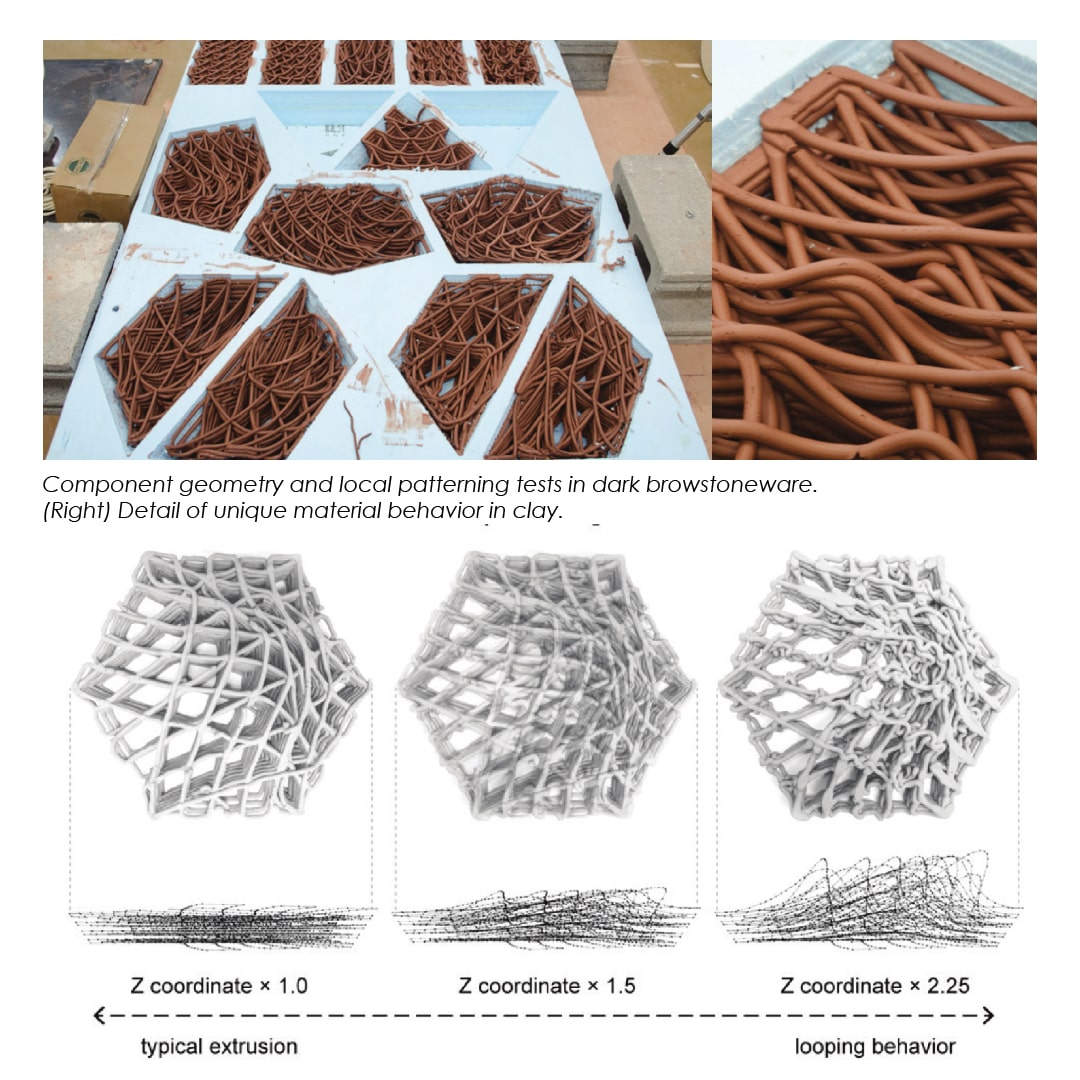

Robosense 2.0 uses the material language of clay deposition 3D printing, the extruded clay bead, as a medium for developing physical case studies.

Existing precedents that investigate clay deposition printing tend to use a technique borrowed from other forms of 3D printing: predetermined extruder motions create fne stacked layers to produce volumetric forms, similarly to how coil pots have traditionally been constructed, and to how low-cost plastic deposition 3D printers are able to produce objects with high efficiency.

The Institute for Advanced Architecture Catalonia (IAAC) is innovating the use of robotically fabricated clay components for largescale applications with exceptional results for the purpose of creating architectural enclosures.

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

This paper by Alessandro Liuti, Sofia Colabella, and Alberto Pugnale, presents the construction of Airshell, a small timber gridshell prototype erected by employing a pneumatic formwork.

In this paper by Gregory Charles Quinn, Chris J K Williams, and Christoph Gengnagel, a detailed comparison is carried out between established as well as novel erection methods for strained grid shells by means of FE simulations and a 3D-scanned scaled physical model in order to evaluate key performance criteria such as bending stresses during erection and the distance between shell nodes and their spatial target geometry.

In this paper by Frederic Tayeb, Olivier Baverel, Jean-François Caron, Lionel du Peloux, ductility aspects of a light-weight composite gridshell are developed.

Parametric Ideas for Architects @2025