Curved Mass Timber

Smart Manufacturing of Curved Mass Timber Components By Self-Shaping

Philippe Grönquist

MSc ETH Civil Eng

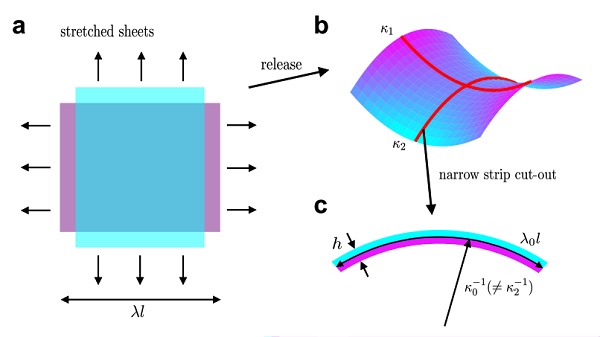

Figure 2.3: Shaping of stretched, bonded, and released sheets to a saddle-like surface. a: Imaginary isotropic sheets of initial length l are uni-axially stretched by a factor of λ. b: Upon release, the composite self-shapes into a saddle-like shell. c: A strip of infinitesimal width theoretically cut out from the saddle shell displays natural curvature κ0 and natural stretch λ0 of the mid-plane, which do not coincide with curvatures and stretches from the saddle configuration.

With the rise of complex and free-form timber architecture enabled by digital design and fabrication, timber manufacturing companies increasingly need to produce curved components.In this thesis, a novel approach for the manufacturing of curved timber building components is proposed and analyzed.

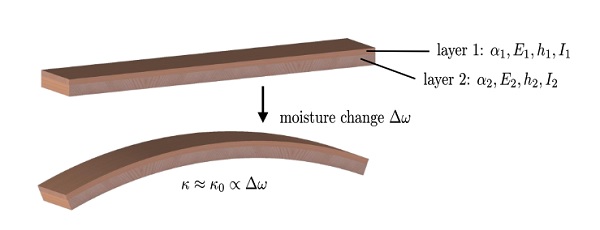

Figure 2.5: Narrow wood bilayer strip. Two bonded layers, layer 1 and layer 2, with respective parameters as in Eq. 2.7, self-shape by a change in wood MC ∆ω to a configuration with curvature κ ≈ κ0.

Following biological role models such as the bending of pine cone scales, a smart way to curve wood at large-scale is given by the biomimetic concept of bi-layered laminated wood. This principle enables large programmed material deformations upon controlled moisture content change.

The main objectives of this thesis are the in-depth understanding of the mechanics of self-shaping wood bilayers and the up-scaling of the already known principle from the laboratory to the industrial scale in order to enable an application as form-stable curved elements in architecture.

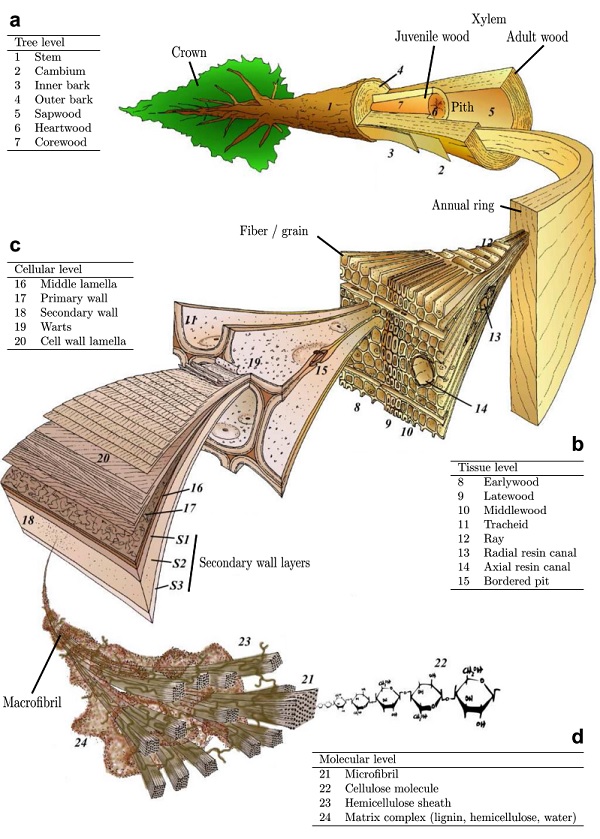

Figure 3.1: Wood hierarchical structure (softwood) and terminology. a: Macroscopic level. b: Tissue level. c: Cellular level. d: Molecular level. Adapted from, based on artwork from M. Harrington.

Hereby, the main challenges addressed are the accurate prediction of shape-change in terms of the natural variability in wood material parameters, the scale-dependent impact of moisture gradients on mechanical behavior, and the influence of wood-specific time- and moisture-dependent deformation mechanisms such as creep or mechano-sorption in the shaping process.

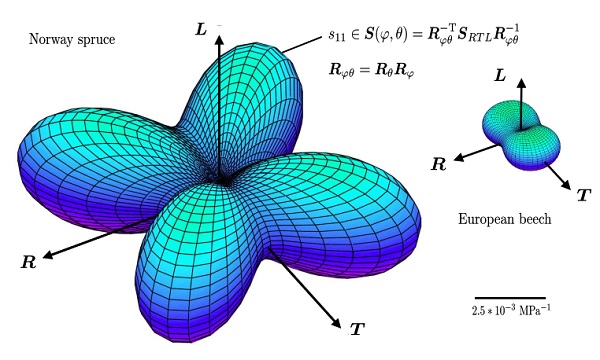

Figure 3.7: Elastic deformation body (compliance) for Norway spruce and European beech under uniaxial loading. 3D representation of the inverse elastic stiffness tensor S = C −1 at normal climate where the diagonal element s11 is plotted in function of a rotation of the tensor by two angles ϕ and θ (polar coordinates). The matrix S (in Voigt notation) can be rotated by two 6×6 rotation matrices Rϕ and Rθ (quaternion-derived). For Norway spruce, the effect of rolling shear (contained in S) is impressively visualized at 45◦ between the R and T directions. Figure modified from and.

Major impacts of these aspects on the shaping behavior could be demonstrated by the use of continuum-mechanical material models adapted to wood, both in the form of analytical and numerical models.

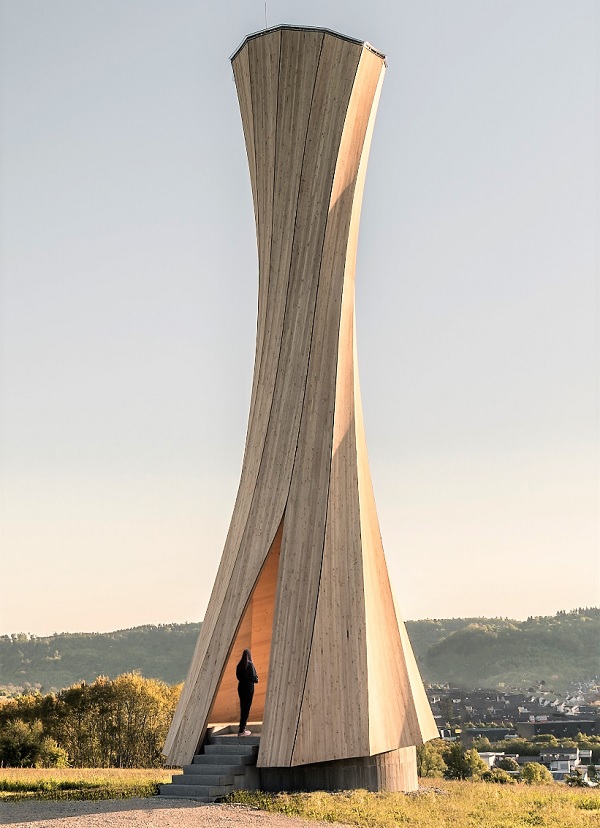

Based on the gained insight, the up-scaling process to industrial manufacturing was successfully made possible. A collaborative project realized in 2019, the 14 m high Urbach tower, is presented as a proof of concept for application and competitiveness of the novel biomimetic method for production of curved mass timber components.

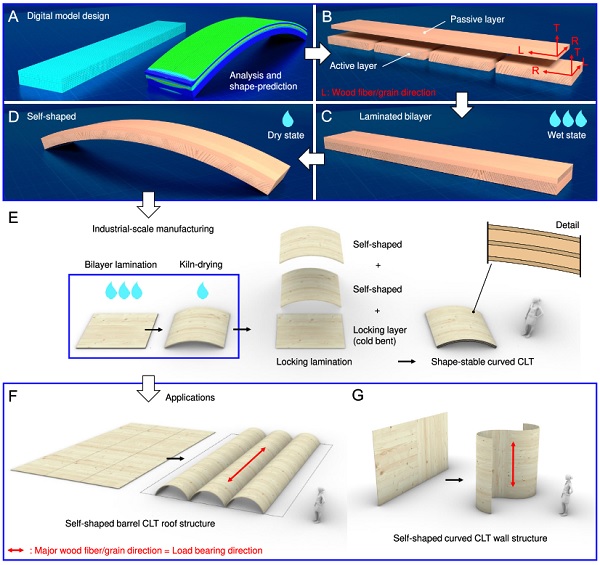

Figure 5.1: Self-shaping wood bilayer application at large-scale. A-D: Analysis and design process at laboratory scale. E-G: Industrial scale, same thickness but increased length and width of bilayers towards plate geometries. A: Parametric digital model and FE analysis for shape-prediction of arbitrary configuration. B: Example bilayer strip configuration (here, European beech wood) with passive and active layer components with wood anatomical directions radial (R), tangential (T), and longitudinal (L). C: Laminated wooden bilayer strip in initial, wet, and flat shape. D: Curved self-shaped bilayer after drying. E: Industrial-scale manufacturing (here, Norway spruce wood) in plate and shell configurations. Plates can be air-dried or kiln-dried to achieve self-shaping. Multiple shaped bilayer plates can be stack-laminated and in addition with a thin cold bent locking layer (with same thickness as a passive layer) to form shape-stable curved CLT. F: Application example as barrel vaulted CLT roof structure with wood fiber direction of thick lamellas (active layers) in load bearing direction. G: Application example as curved CLT wall with wood fiber direction of thick lamellas (active layers) in vertical direction.

Furthermore, next to self-shaping by bending to single-curved components, possibilities and limitations for achieving double-curved structures using wood bilayers in a gridshell configuration are analyzed and discussed.

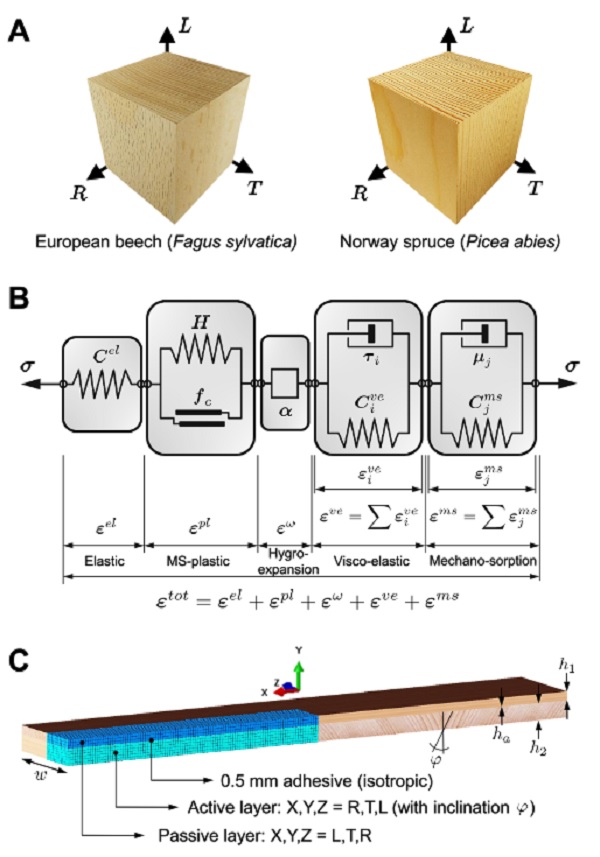

Figure 5.2: Simulation model. A: REV for wood material model (beech and spruce wood) with anatomical growth directions R, T, and L. B: Schematic rheological model for bulk wood as in. C: Setup and BC for the FE bilayer models (quarter model with XY and YZ symmetry). Symbols: C: Stiffness matrices of springs for respective deformation modes, H: Hardening moduli, f c : Yield functions, α: Differential swelling coefficients, τi : Characteristic retardation times, µj : Moisture analogous to τi , σ and ε: Stress and strain tensors.

Timber and wood products are common materials used in the building sector where they have a long tradition. The availability, machinability, and excellent mechanical properties with respect to density make wood a lightweight structural material perfectly fitted to the needs of the construction sector.

As for today, wood still represents the only truly sustainable material in this vast sector. In fact, wood, the biomass produced by trees following the photosynthesis reaction, serves as natural carbon storage.

Figure 5.5: Video Caption. Shape-change of a large-scale Norway spruce bilayer plate with total thickness of 31.5 mm (passive and active layer thicknesses of 6.5 and 25 mm), length of 1.5 m, and width of 0.5 m. A: Production in initial flat shape with wood conditioned at 85% RH. B: Self-shaping in 35% RH and room temperature over 270 hours.

If stored in large amount over periods of time surpassing the natural life-expectancy of trees, and preferably in the functional form of structural building components, wood represents a significant carbon sink in view of atmospheric CO2 reduction.

Figure 6.1: The Urbach tower. Worldwide first built application of form-stable self-shaping wood in Urbach, Germany, at the occasion of the Remstal Gartenschau 2019. (Photo credit (©): ICD/ITKE University of Stuttgart)

Nowadays, the use of mass timber products in construction, especially cross-laminated timber (CLT), represents one of the few effective methods for the modern building sector to address climate change.

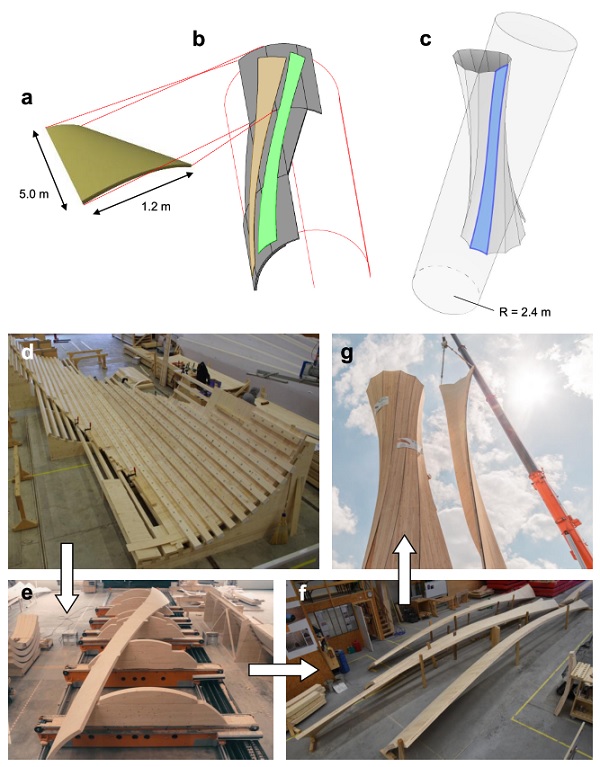

Figure 6.2: Urbach tower production process and assembly. a Self-shaped 5.0 m x 1.2 m wood bilayer plates as basic elements. b Assembly of basic elements to a half-cylinder for stacking-lamination. c Concept of diagonal lamella cutting along a single-curved cylinder. d Stacking-lamination by screw pressing. e Cut-out lamella before CNC milling. f Single lamellas after CNC milling. g On-site assembly. (Images credit (©): Empa, ICD/ITKE University of Stuttgart, Blumer-Lehmann AG)

Competitiveness among building materials is nowadays not only a question of costs, availability, structural performance, and sustainability, but also of aesthetics and freedom in form and design space.

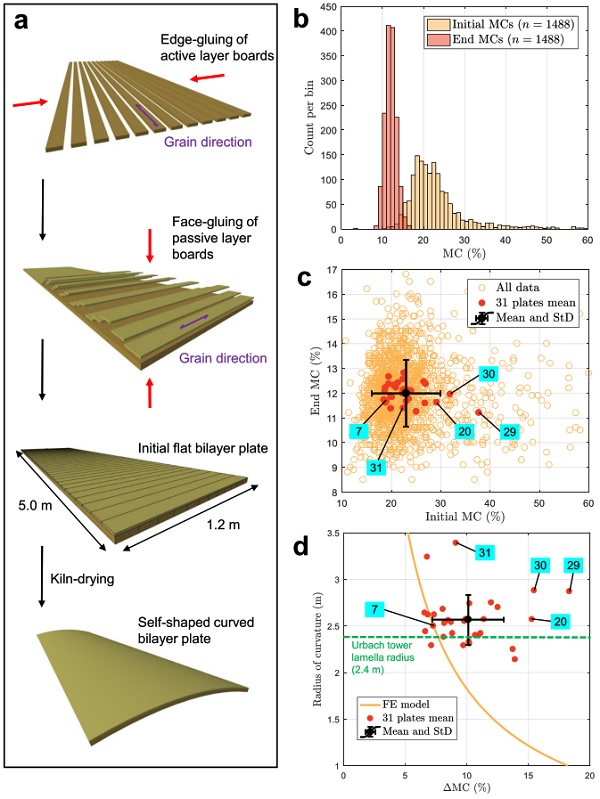

Figure 6.3: Self-shaping manufacturing process and monitoring. a: Schematic bilayer plate manufacturing. b: Distribution of MC-data of the active layers before and after kiln-drying. c: Start and end MCs of each single MC-measurement. d: MC-difference (corrected) plotted against radius of curvature, compared to FE model simulation. (Numbers in cyan boxes represent single plates shown in Fig. 6.4)

Contemporary architecture often favors curved and complex-shaped building elements. And wood can increasingly fulfill these demands. However, compared to casting materials, this often comes with the inherent drawback of high production costs due to the complexity of free-form shape-giving.

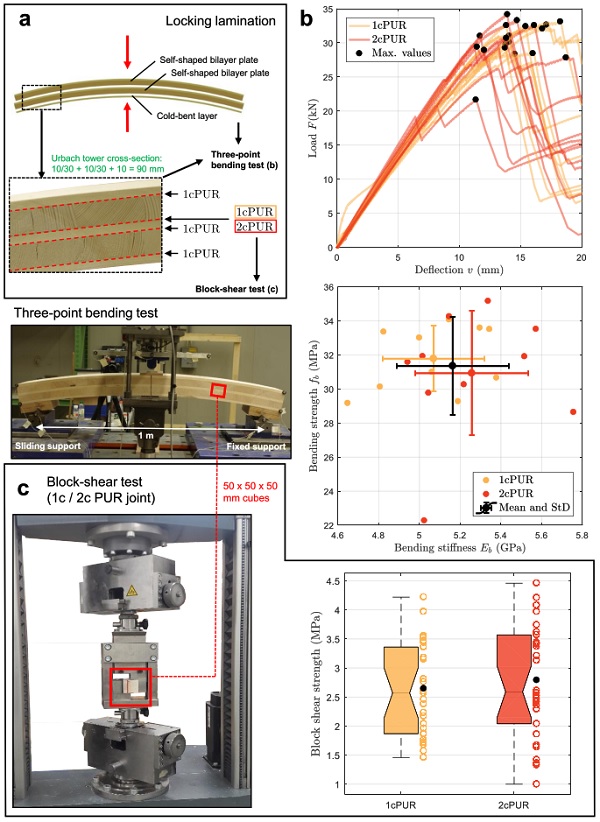

Figure 6.6: Structural testing of self-shaped CLT. a: Setup of locking- or stackinglamination procedure and overview of used adhesives per glue joint. b: Image of three-point bending test setup and results: Load-deflection graph and global bending strength-stiffness graph. c: Image of block-shear test setup and results (black dots represent mean values and circles are single data points).

Current manufacturing standards involve techniques such as subtractive milling-to-shape or extensive formwork and machines to bend, press, and glue thin timber lamellas to the desired curved shapes.

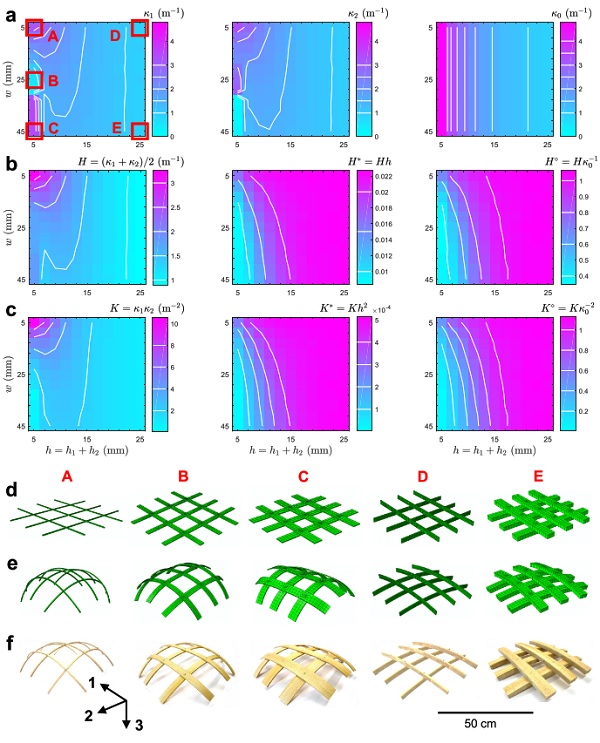

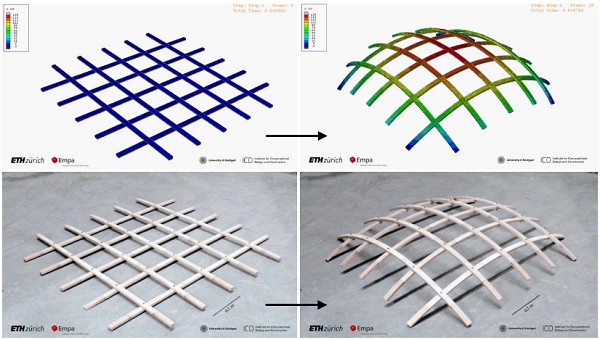

Figure 7.3: Phase space of gridshell curvatures after self-shaping in dependence of width w and thickness h for 121 (11×11) Finite Element model solutions. a: Curvatures along middle strips in directions 1 and 2 (κ1 and κ2) and natural curvatures κ0. A, B, C, D, E denote configurations at extremities of analyzed phase space. b: Mean curvatures H, and mean dimensionless curvatures H∗ and H . c: Gaussian curvatures K, and dimensionless Gaussian curvatures K ∗ and K. d: Configurations A, B, C, D, E in initial state (wet). e: Configurations after self-shaping (dry). f: Experimental configurations, 1:1 physical model rebuilds of the FE models using beech wood.

The motivation of this work is to contribute towards the establishment of a new and alternative manufacturing technique for complex-shaped wood components with reduced costs. The new method builds on principles of the prominent biomimetics field in science and engineering of the last two decades.

Specifically, wood can be programmed to act as a hygromorphic self-shaping bi-layered composite, which e.g. is mimicking the bending of pine cone scales upon drying. With wood, this concept has the unique potential to be applied at a large-scale for the manufacturing of curved mass timber products such as curved CLT.

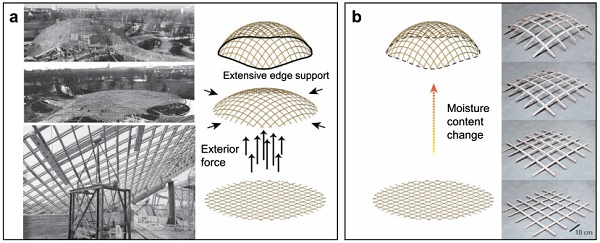

Figure 7.4: Gridshell shaping procedures. a: Conventional procedure by shaping the gridshell via exterior forces for active elastic bending; Extensive edge support is needed in the assembled configuration (Photo credit: Institute for lightweight structures and conceptual design, University of Stuttgart). b: Novel proposed procedure by hygromorphic selfshaping of the single strips; No exterior forces and lighter edge support.

Hereby, the required form-stability with respect to further changes in moisture content of the wood shall be given by applying a stack-lamination of multiple, previously self-shaped, wood bilayer components.

This novel concept removes the mechanical compatibility of the curved composite to further self-shape by creating a multi-layer component with a number of layers equal or greater than four.

Figure 7.5: Movie S1: Caption: Exemplary gridshell self-shaping process in computational and physical model. FE simulation of self-shaping process of a 5×5 gridshell made out of beech wood and physical reconstruction. U3: Out of plane displacements in mm. Parameters: Strip geometry: 600 mm length, 12 mm width, 2 mm passive layer thickness (radial orientation), 5 mm active layer thickness (longitudinal orientation). Boundary conditions: Change in moisture content from 14% to 21%, physical sample relocation from 65% to 95% relative humidity climate at 20◦C.

The one-time actuation by moisture-content change and the subsequent shape-freezing by stack-lamination foresee a more efficient and completely revolutionary use of the material wood, and with this, its further promotion in the construction sector.

Comments