String Art Generator

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

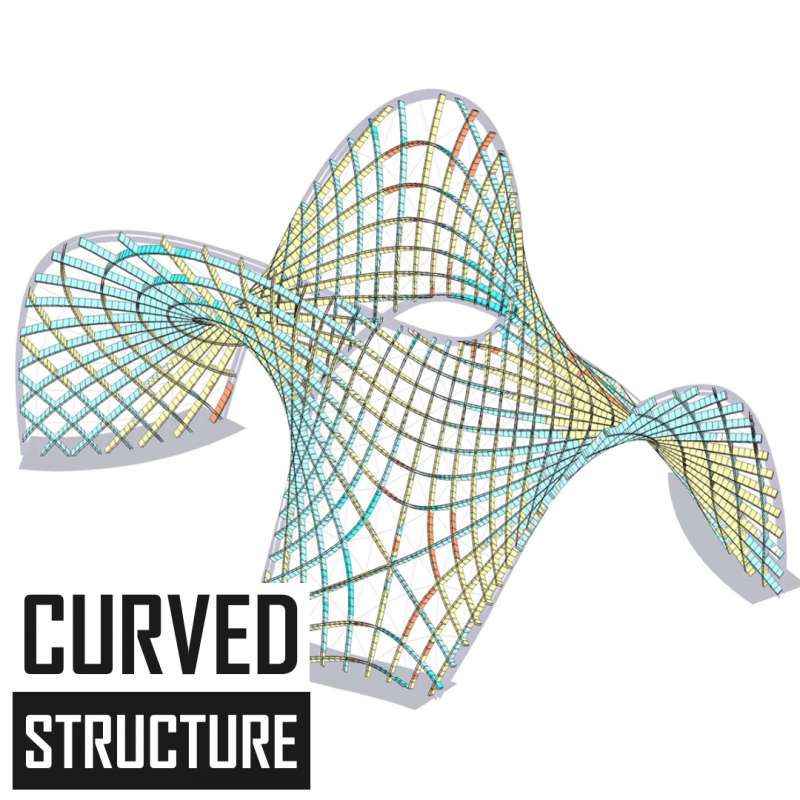

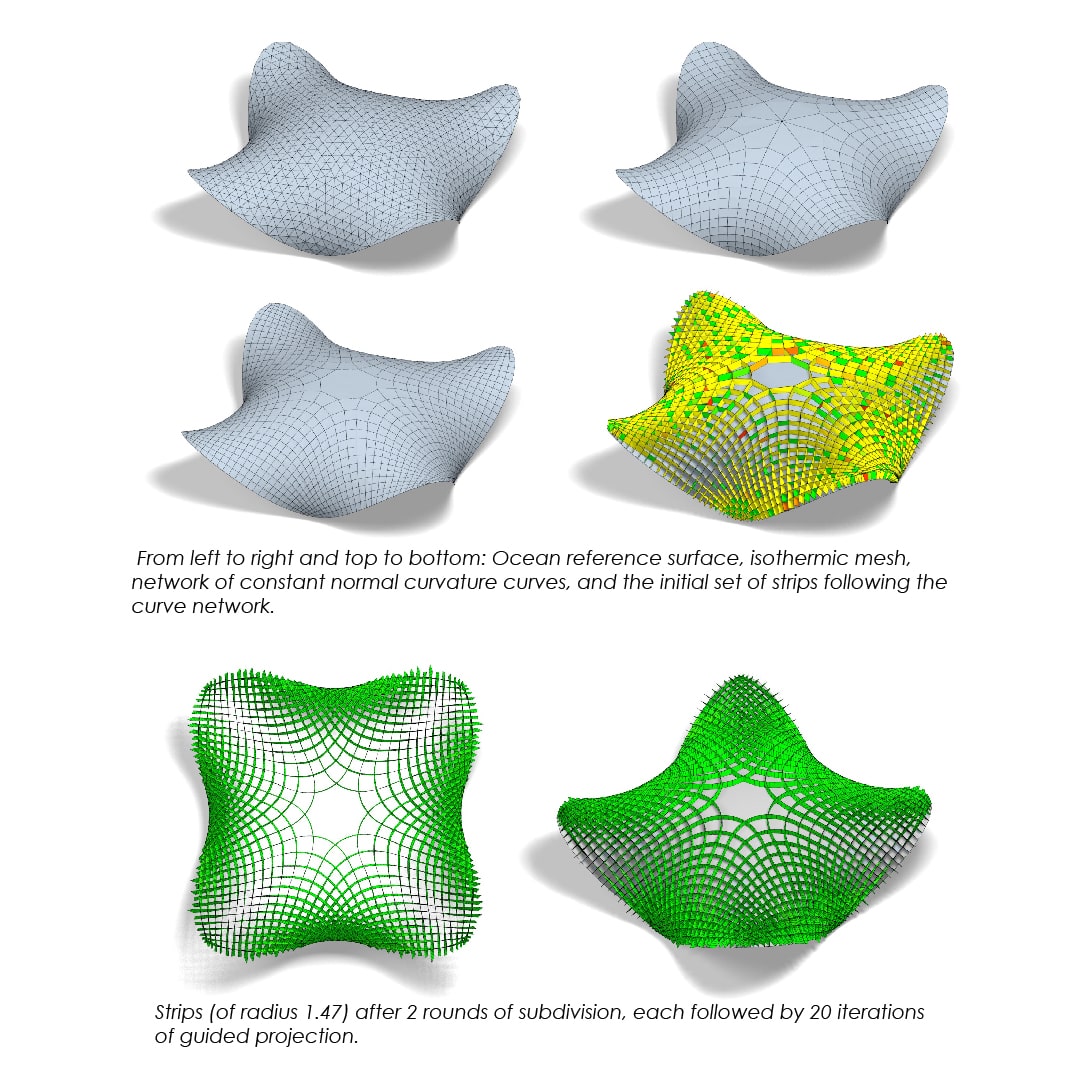

Design and Construction of Curved Support Structures with Repetitive Parameters

The fabrication and construction of curved beams along freeform skins pose many challenges related to their individual and complex geometry.

One strategy to simplify the fabrication process uses elastic deformation to construct curved beams from flat elements. Controlling the curvature of the design surface and beams has the additional potential to create repetitive building parts with beneficial beam orientation.

They aim for strained gridshells built entirely from straight or circular lamellas of the same radius and with orthogonal nodes. The lamellas are aligned normal to a reference surface enabling an elastic assembly via their weak axis and a local transfer of loads via their strong axis.

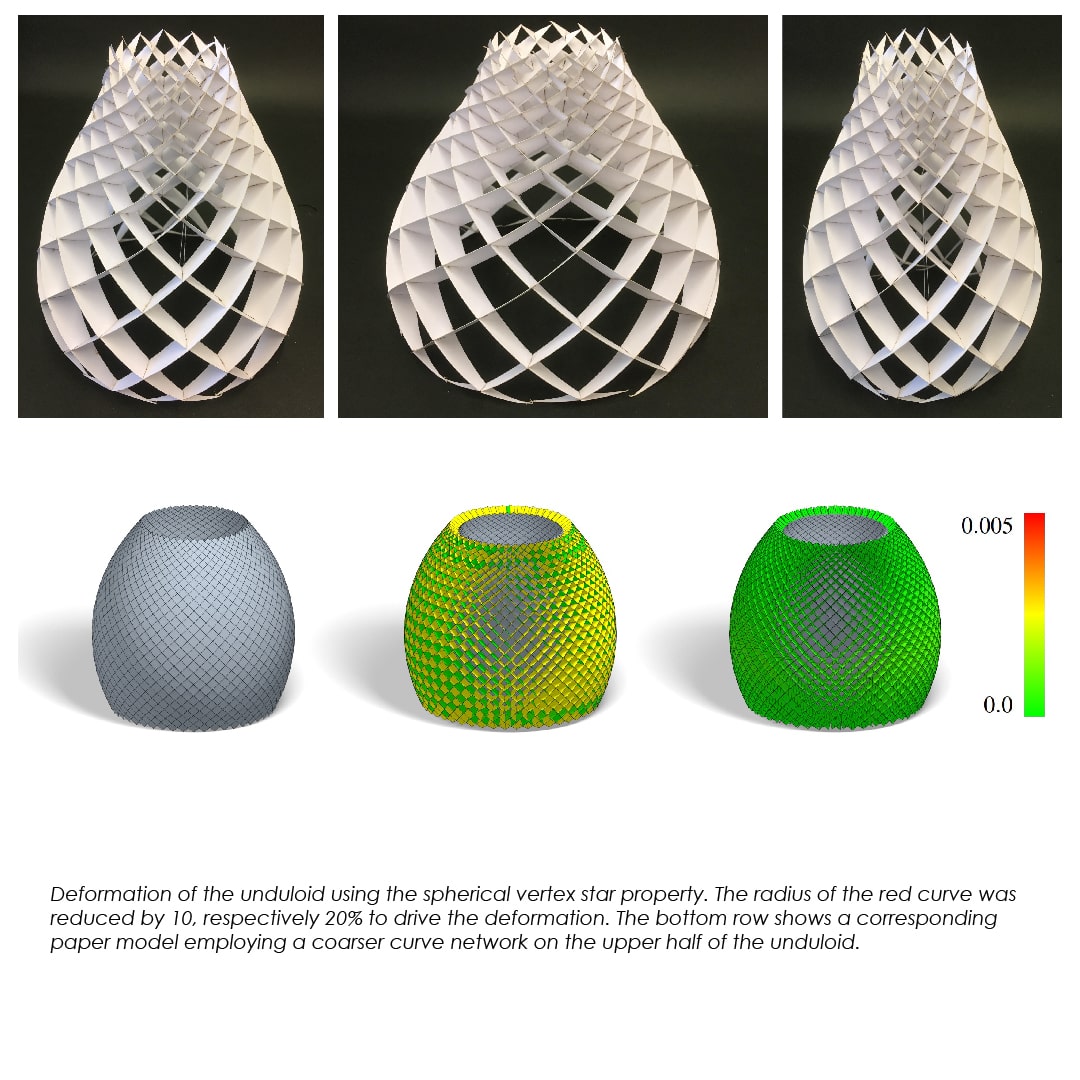

They aim for strained gridshells built entirely from straight or circular lamellas of the same radius and with orthogonal nodes. The lamellas are aligned normal to a reference surface enabling an elastic assembly via their weak axis and a local transfer of loads via their strong axis.

They show that the corresponding reference surfaces are of constant mean curvature and that the network of beams bisects principal curvature directions.

They introduce a new discretization of these networks as quadrilateral meshes with spherical vertex stars and present a computational workflow for the design of such structures.

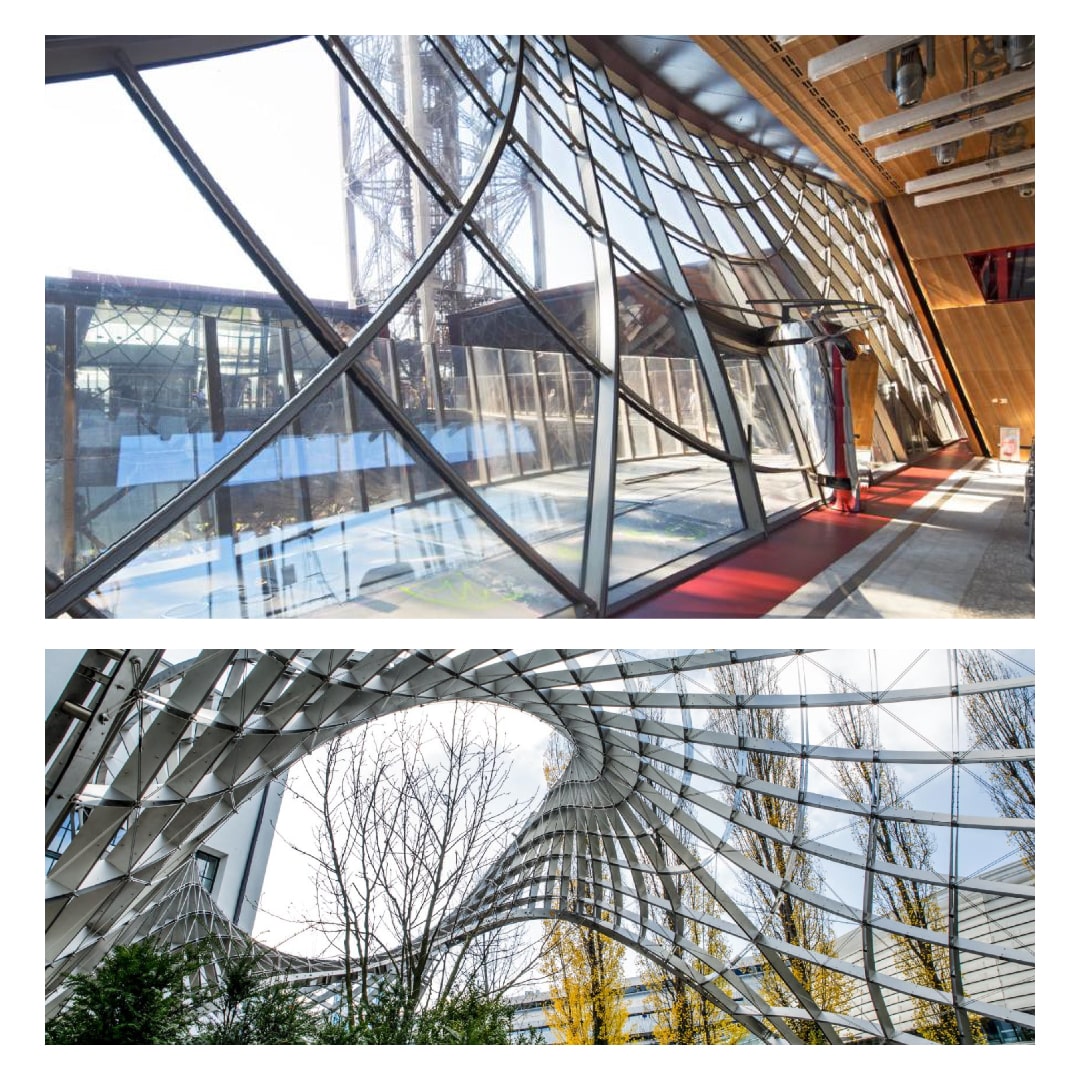

The geometric advantages of these networks were key for the fabrication and assembly of a prototype structure, the Asymptotic Gridshell.

The geometric advantages of these networks were key for the fabrication and assembly of a prototype structure, the Asymptotic Gridshell.

They describe the complete process from design to construction, presenting further insights on the symbiosis of geometry, fabrication and load-bearing behavior.

Gridshells are highly efficient structures because they carry loads through their curved shape with very little material. Their construction however, poses great challenges related to their complex geometry.

Gridshells are highly efficient structures because they carry loads through their curved shape with very little material. Their construction however, poses great challenges related to their complex geometry.

In a freeform grid every node and every beam are likely to be different and have to be fabricated individually using computer aided, 3D manufacturing tools.

Controlling the curvature parameters of design surfaces and beam networks, and using the elastic behavior of material to shape these grids opens up new strategies for fabrication-aware design.

For digital design of the structures they have in mind, it is very useful to have discrete models of the network of curves along which the strips are attached.

For digital design of the structures they have in mind, it is very useful to have discrete models of the network of curves along which the strips are attached.

This means that they have to come up with quad meshes whose mesh polylines discretize the system of curves of constant normal curvature Kn on a smooth surface.

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

This paper by Alessandro Liuti, Sofia Colabella, and Alberto Pugnale, presents the construction of Airshell, a small timber gridshell prototype erected by employing a pneumatic formwork.

In this paper by Gregory Charles Quinn, Chris J K Williams, and Christoph Gengnagel, a detailed comparison is carried out between established as well as novel erection methods for strained grid shells by means of FE simulations and a 3D-scanned scaled physical model in order to evaluate key performance criteria such as bending stresses during erection and the distance between shell nodes and their spatial target geometry.

In this paper by Frederic Tayeb, Olivier Baverel, Jean-François Caron, Lionel du Peloux, ductility aspects of a light-weight composite gridshell are developed.

Parametric Ideas for Architects @2025