Efficient Shell Structures

Design, Analysis and Fabrication of Expressive, Efficient Shell Structures: A Prototype exploring synergy between `architecture, engineering and manufacture

Alicia NAHMAD VAZQUEZ*, Shajay BHOOSHANa, Asbjorn SONDERGAARDb, Chikara INAMURAc, Joshua ZABELd, Mustafa EL–SAYEDa

*Populous, London17 Majestic Court, Portland Rise N4 2UT, London, UK.

aZaha Hadid Architects, London

bAarhus University, Aarhus

cSasaki and Partners, Tokyo

dKreysler & Associates, San Francisco

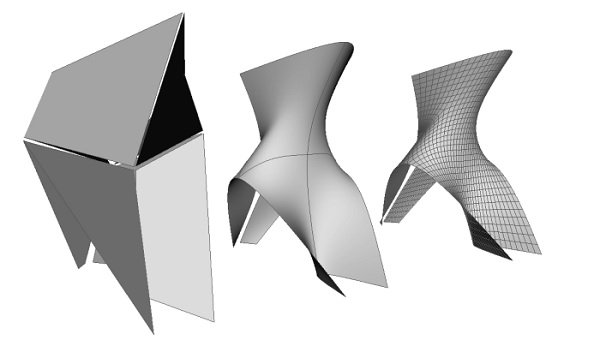

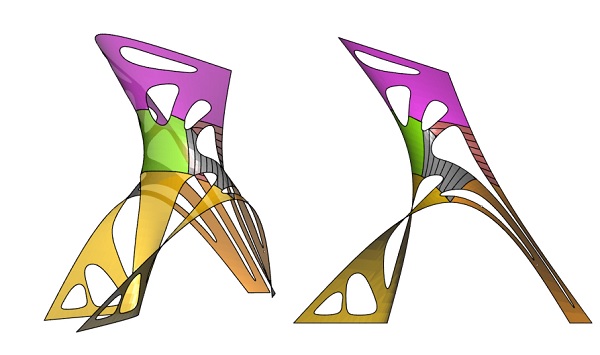

Figure 1: Multiple resolutions of design mesh, showing relatively low number of faces (6 faces) used to create complex surface.

The prototype and this ensuing paper aim to extend the rich legacy of form-finding to adequately represent the complexities of scale, digital design systems and delivery mechanisms of contemporary architectural practice. They explore synergies in early design between architecture, structural engineering, and manufacturing.

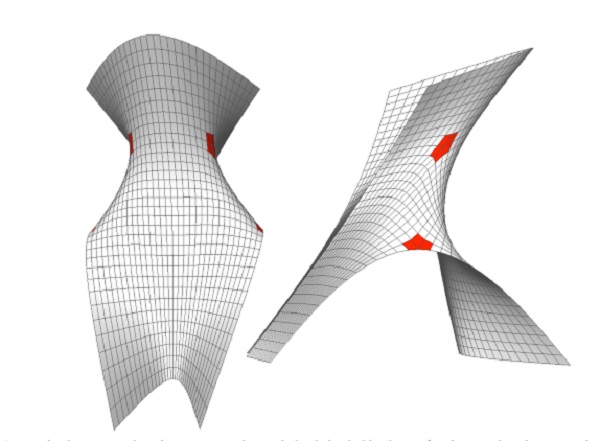

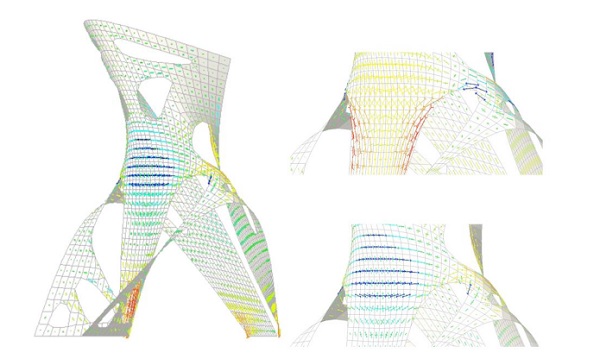

Figure 2: High-resolution mesh with highlighted singularity points

Contemporary architectural design and construction, operates under extreme pressures of time and resource management.

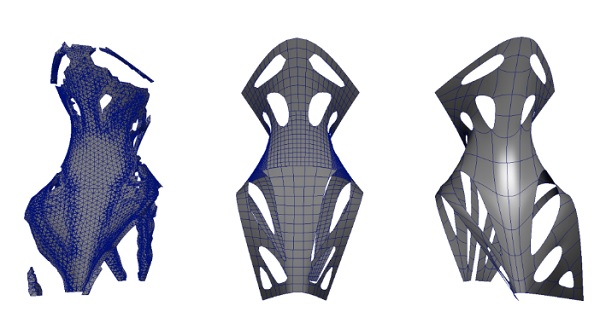

Figure 3: Left to Right : High resolution mesh FEM mesh ~50000 vertices ; multi-patch, medium resolution mesh ~6200 vertices ; low resolution, predominantly-quad, mesh ~ 275 vertices;

Design-development times are progressively being reduced while the complexity of spatial, structural and manufacturing parameters – are constantly increasing.

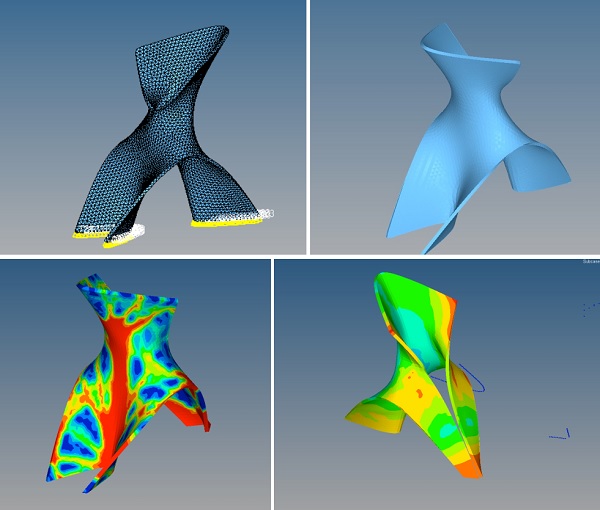

Figure 4: Shell design space FE model (top left), Shell design space FE model (top right), Material density distribution after topology optimization (bottom left), displacements of post-optimized concrete body (bottom right)

Significantly, a majority of design decisions with regard to the overall geometry of the project are made within a compacted early-design phase.

Figure 6: Remodelled geometry in McNeel Rhinoceros

Subsequently, down-stream production and delivery processes post-rationalize such geometries whilst attempting to retain the design intentions from the early-phases. Such a process comes at a high premium of resources – time and personnel.

Figure 9: Principal moment vector field.

Thus, there is increasingly a need to inform architectural design with critical aspects of structural design and fabrication processes from the early stages.

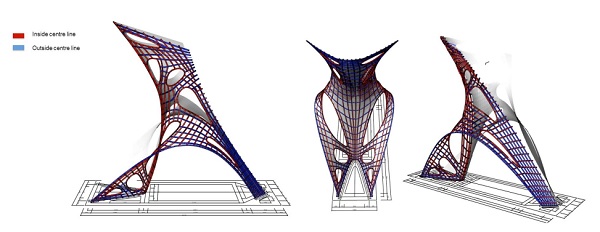

Figure 10: Reinforcement distribution diagram

Following an iterative process of structural analysis and design refinement, the optimization result was remodelled in Rhinoceros for achieving a final topology optimized geometry that satisfied all the conditions of the seismically active environment of Mexico City and with the adequate size to be built in 10 days using manual labour.

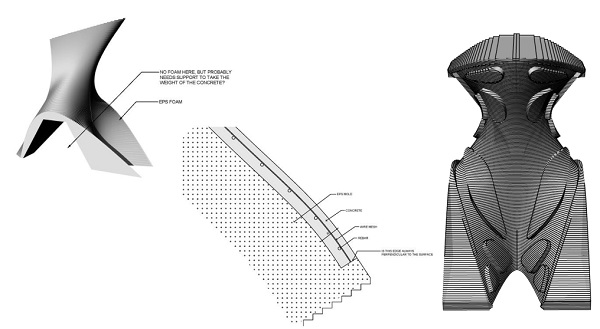

Figure 21: Typical section of the formwork guide (left) and contoured negative model of the geometry (right)

This paper presents the specifics of one such time-bound collaboration, including: an examination of computational geometry and design tools and their use in a multi-stage, collaborative design phase, application of topology optimisation methods for design and form-finding of concrete shell structures; incorporation of structural design in early-design; and strategies to describe complex geometry (i.e. form-work and steel reinforcement layout) onsite in a labour intensive economy and the teaching thereof.

Figure 15: Topology optimized shell prototype 4 x 5 x 2m, 8 cm thick

We presented the specifics of a time-bound design collaboration, including computational geometry and design tools and their use in multi-stage collaborative design phase, incorporation of structural design in early-design, strategies to describe complex geometry – form-work and steel layout – onsite in a labour intensive economy.

Comments