Elastic Gridshell

Structural Design with Reclaimed Materials: an Elastic Gridshell out of Skis

Sofia COLABELLAa, Bernardino D’AMICOb, Endrit HOXHAa, Corentin FIVETa

aStructural Xploration Lab, École Polytechnique Fédérale de Lausanne (EPFL) & smart living lab, Passage du Cardinal 13b CH-1700 Fribourg, Switzerland

bSchool of Engineering and The Built Environment, Edinburgh Napier University

Figure 1.Third installation of the ski pavilion, EPFL, Lausanne, Switzerland.

This paper presents the design and construction of a 36m2 gridshell, the rigidity of which is achieved through the bending of an initially flat grid of 210 reclaimed skis. The generated waste for its production is near zero as it is mostly built from discarded material.

Its construction process is such that it can be disassembled and reassembled multiple times without scaffolding and by means of traditional tools only. After a brief introduction on the need for reducing embodied carbon and waste in structures through reuse, the paper sets up the constraints that have driven the definition of the pavilion, the main one being the extension of the lifetime of high-performance sport equipment by reclaiming their intrinsic mechanical properties.

Figure 2. The ski pavilion: second assembly in the courtyard of the Blue Factory, Fribourg CH, on the left; fourth assembly in La Sucrière for the “Biennale Architecture Lyon” FR, June 2017, on the right. From left to right, three ballasts replace the connecting ropes and constrain the position of the three ground edges.

The paper then details the encountered unusual aspects in the design process and how they have been overcome – i.e. sporadic material supply, categorization of mechanical properties, physical alteration of these properties, and uncertainties in the numerical modelling of both the structural analysis and the construction process.

Eventually, we conclude that reclaimed skis as a material have the potential to be as good as conventional timber when designing elastic gridshells. A series of future directions for this emerging field of research are also laid out.

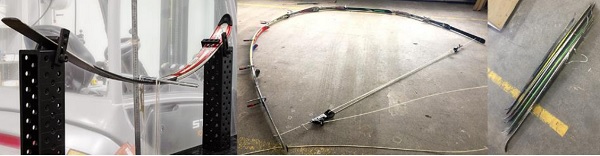

Figure 3. Bending stiffness tests on a ski (left) and on a nominal arch (centre). Folded arch (right).

To drastically reduce embodied carbon and waste production is a big challenge in the construction industry and especially in the structural design practice.

On the one hand, the manufacture, the construction, and the end-of-life of load-bearing systems is responsible for about three quarters of the embodied energy in office buildings (Kaethner & Burridge).

A share that plays an increasing role in the overall energetic impact of buildings since past and current efforts have reduced the need for operational energy – i.e. heating, cooling, lighting, airconditioning and electric appliances – to a minimum (Hoxha et al.).

On the other hand, the construction and demolition industry is responsible for the major part of waste production in terms of volume and weight (EU). Superfluous waste production in the building industry threatens earth’s eco-system regarding material exhaustion and pollution, and runs counter to the rational use of energy and workforce.

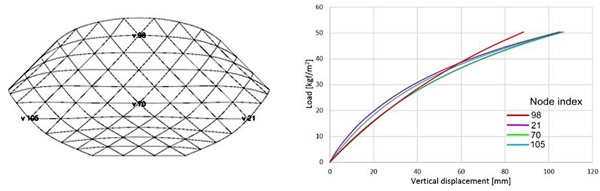

Figure 5. Reference nodes used to monitor the deformation behaviour of the gridshell during the load analysis (on the left). Nodal load-displacement curves obtained from the load analysis.

One can identify five strategies to address this double issue: reduce (the amount of resources needed), repair, reuse (or redistribute), recycle (through mechanical and chemical transformations), and restitute (to the ecological context). Circular economy is the wise application of all these strategies (EU).

Although a critical component of circular economy, the reuse approach is today seldom addressed when it comes to designing structural systems. Reuse means changing the location and/or the function of an element without significantly altering its physical features. Almost every recent implementation of reuse in the building industry concerns components that are not load-bearing – e.g. the envelope, and the indoor and outdoor finishes (Chopin & Delon).

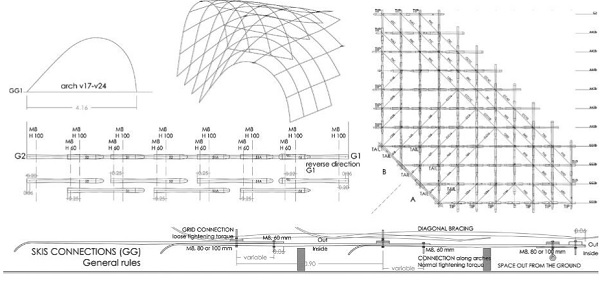

Figure 6. Ski sorting along the arch, as a consequence of the geometry stiffness of the gridshell (on the left). Bracing system (on the right). Ski assembly detail (below).

This wasn’t the case prior to the industrial revolution (Barnes). Today, rare demonstrative examples of reuse for structural purposes can be found in the work of Jean Prouvé (Chopin), Arrow Architecture & Engineering (Aubry), SSD Architecture, and Arup.

The academic world recently embraced the topic too, both in the field of design for disassembly – see for instance Paduart et al. and Durmisevic – and in the field of design from reclaimed material – see Baverel et al.

Figure 7. Plan view of the push-up method (on the left). Blocks and tackles (on the right).

The pavilion presented in this paper reclaims abandoned sport equipment for new structural purposes. Sport equipment falls in the category of high-tech products that are rapidly obsolete for purely external (understand fashion) reasons.

Therefore, it usually generates a continuous and large flow of wasted resource that is hardly recoverable. In particular, elastic and resistant products such as skis, fishing rods, and pole vaults, are generally made from different performing layers, including fibre reinforced polymers, glue, foam, etc., which meet customer’s expectations in terms of performances but also head these products towards an inglorious end-of-life.

Not only the material and the energy needed for its fabrication is wasted, but also the technology and the mechanical behaviour embedded in it. This paper shows an application that benefits from the embedded qualities of such products while extending their life span and therefore reducing the need for new manufacture. It also proves that some sport products are well suited for new large-scale structural purposes.

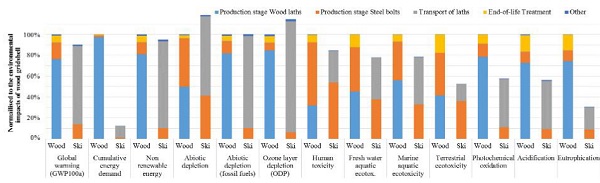

Figure 8. Environmental impacts comparison between a ski gridshell and a timber gridshell.

To design with reclaimed material is not straightforward and implies a complete redefinition of the conventional structural design process. The properties of the elements of the system (i.e. lengths, crosssectional areas and inertia, modulus of elasticity, strengths) do not result from computations but are a given.

The global geometry of the structural system is not a given, but the end result. This pavilion acts both as a methodological case-study for design and construction of a load-bearing system from dismissed engineered products and as a protocol set up to manage unclassified waste.

Comments