Form and Function

Reconciling Form and Function through Generative Design

Axel Nordin

DOCTORAL DISSERTATION

by due permission of the Faculty of Engineering LTH, Lund University, Sweden.

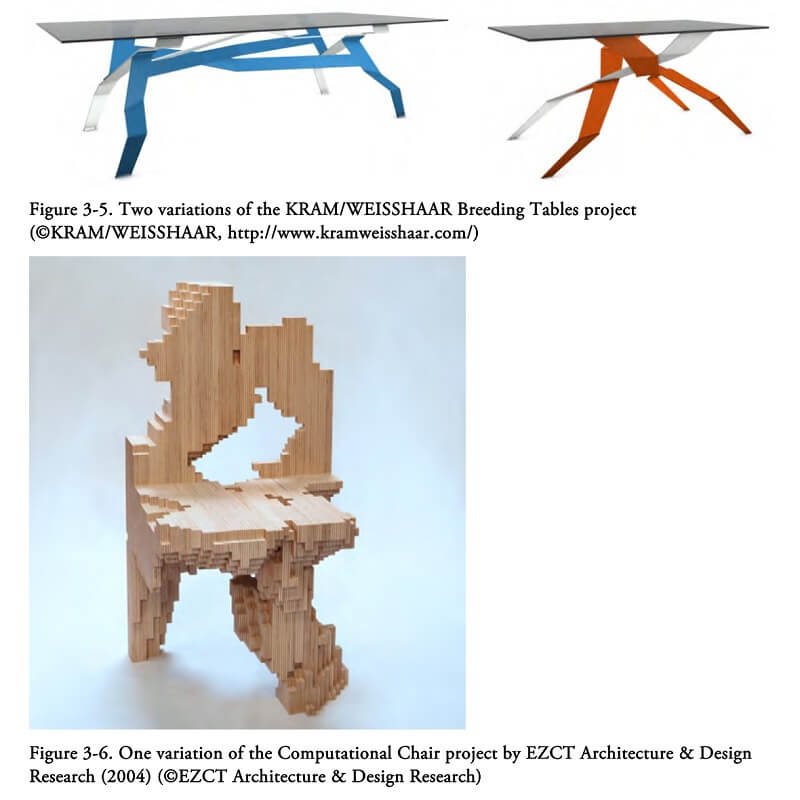

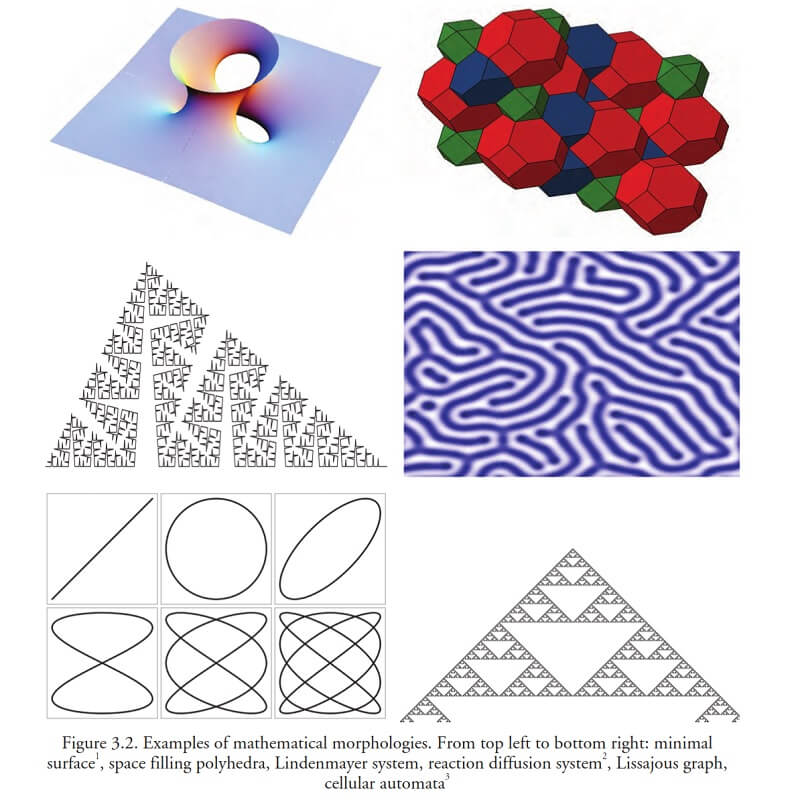

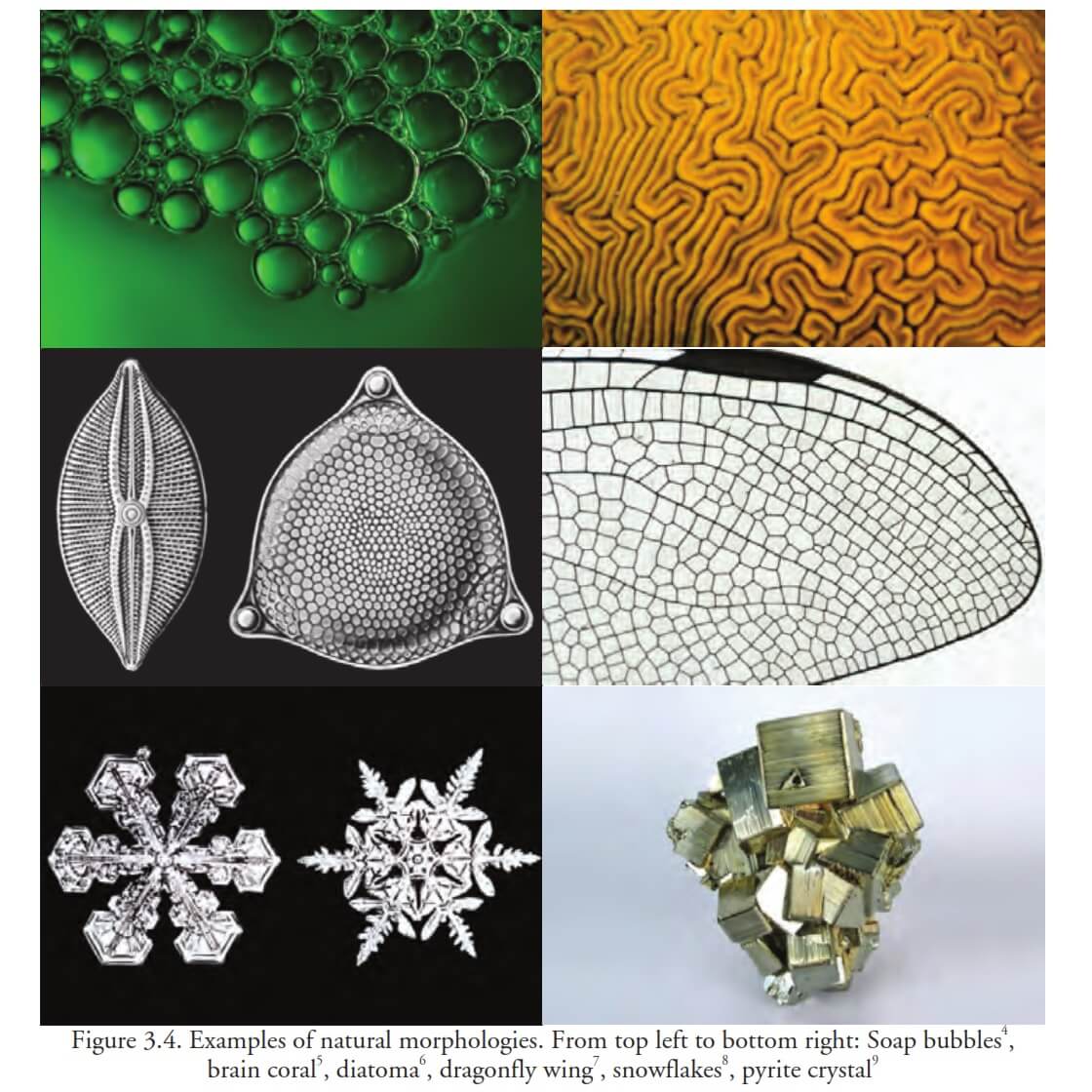

The current form-giving activity in industrial design is characterized by explorations that depend on the individual capability to mentally manipulate a solution space from which to select and express the intended result. Industrial designers frequently rely on artistic experimentation, aesthetic inspiration, or design briefs. These points of departure often result in satisfactory results, but they could be augmented by algorithmic form generation, optimization, and complex morphologies.

By adopting this approach, the industrial designer would also be able to efficiently use forms that have previously been too complex to handle and evaluate manually, thereby gaining new ways of expanding his or her morphological repertoire. This development has been seen in other creative professions such as architecture, fine arts, modern music, and contemporary dance, but because of a different set of constraints linked to physical products, the progress has not been as rapid in industrial design.

The difficulty of fulfilling these constraints is evident, as many iterations in the product development process are necessary between the different activities such as industrial design, engineering design, and production before a satisfactory design has been achieved. Additionally, if form is algorithmically generated and engineering and production demands are integrated in the process, partial or full transfer of the design activity to customers becomes a concrete option.

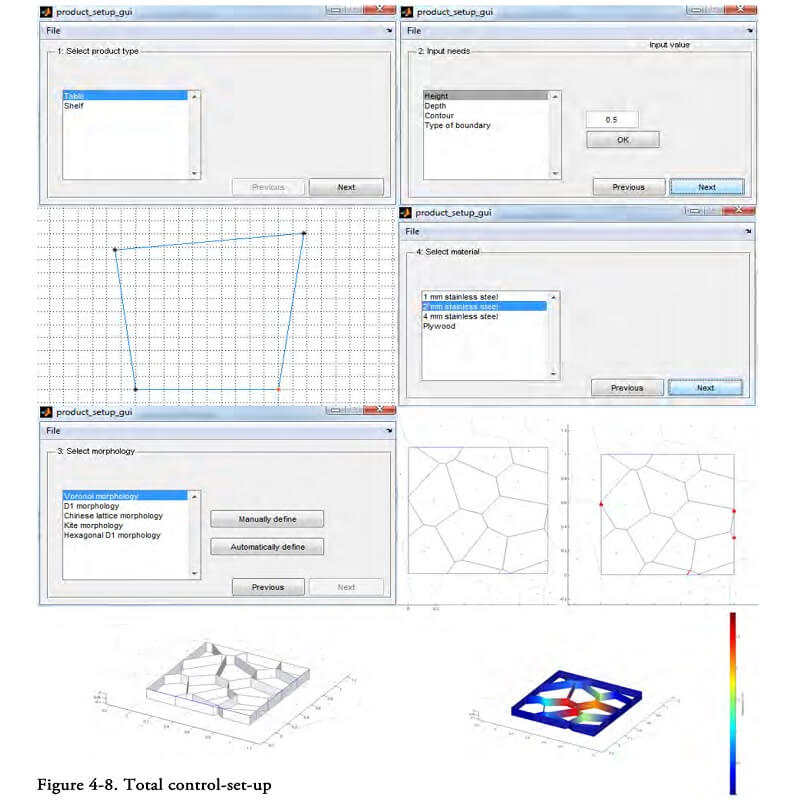

The possible results of achieving these goals are that designers gain a larger repertoire of morphologies to work from, the product development time can be reduced, the design concepts can stay true to the vision of the industrial designer, and the customers can tailor products to their needs. To achieve these goals, an approach is suggested that entails developing generative design tools that allow a user to design products with complex forms, while assisting them in ensuring the products’ producibility and function.

The focus is on increasing the integration between the industrial design activity and the other product development activities, more specifically engineering design and production. The purpose of this thesis is to investigate this approach, and to develop and test its technical feasibility and acceptance among designers and consumers.

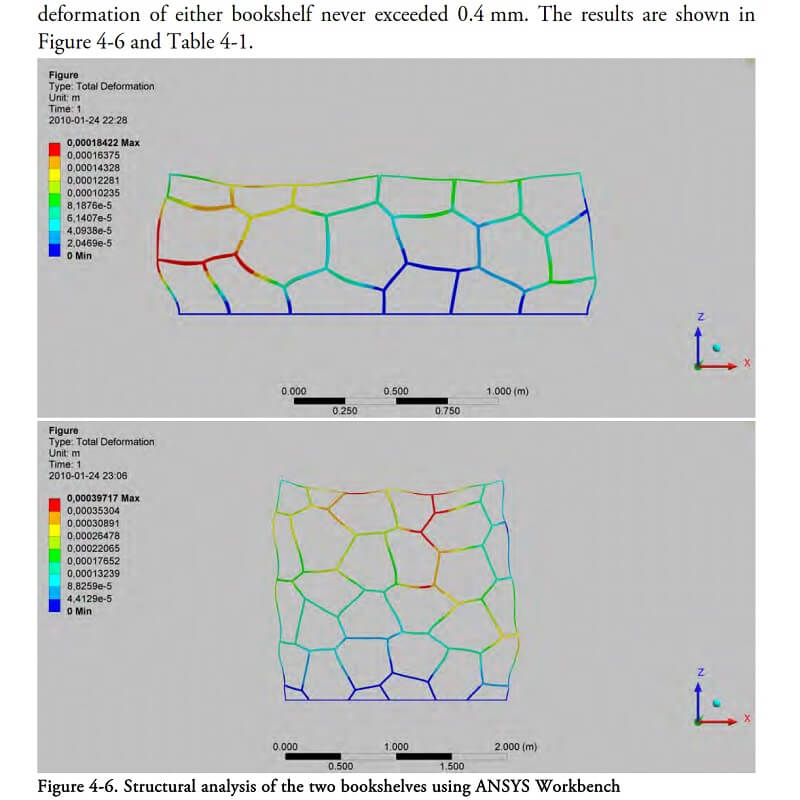

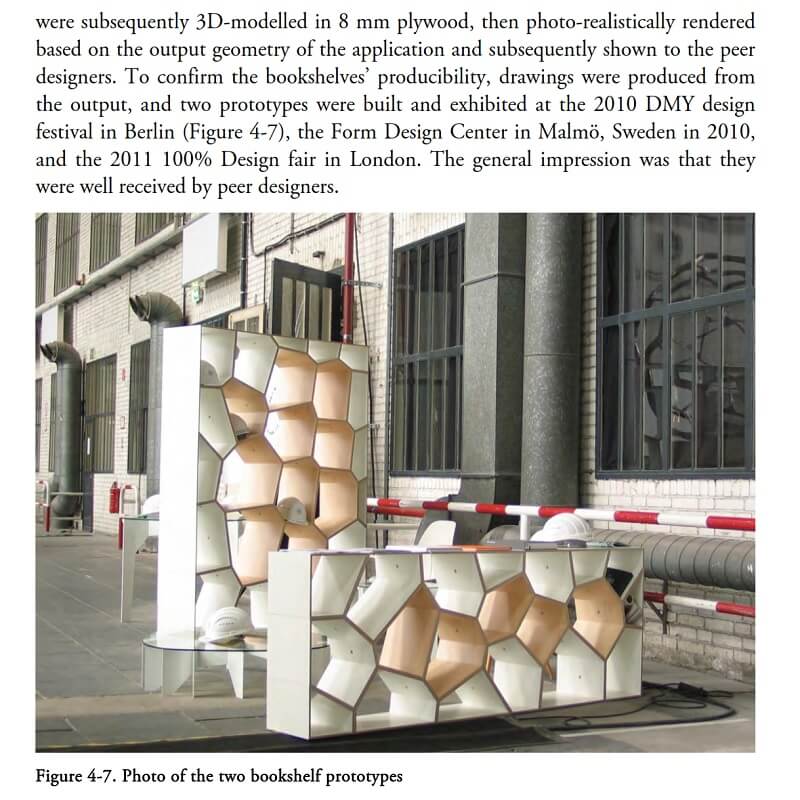

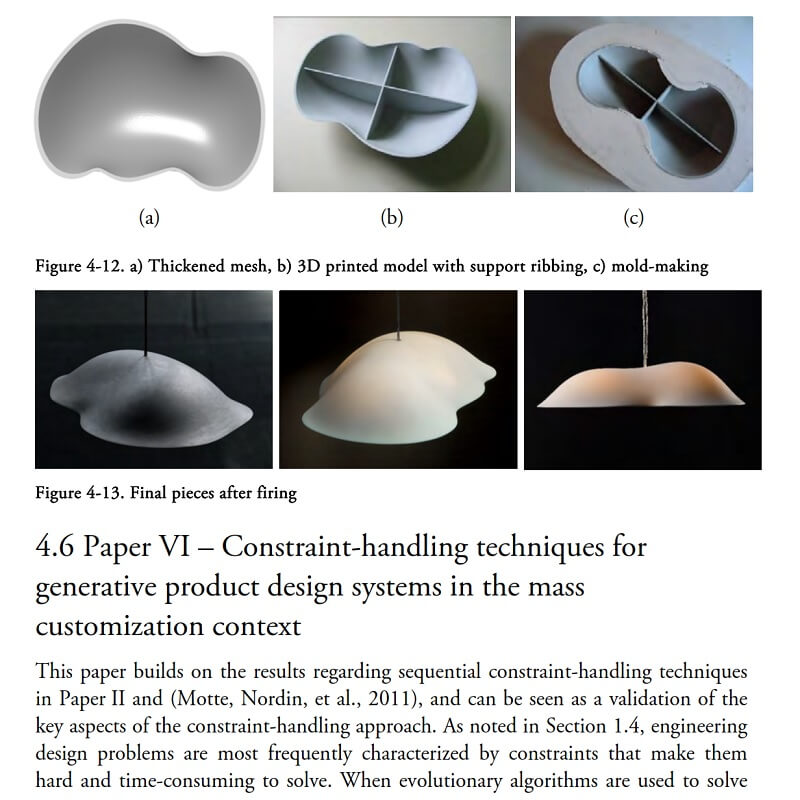

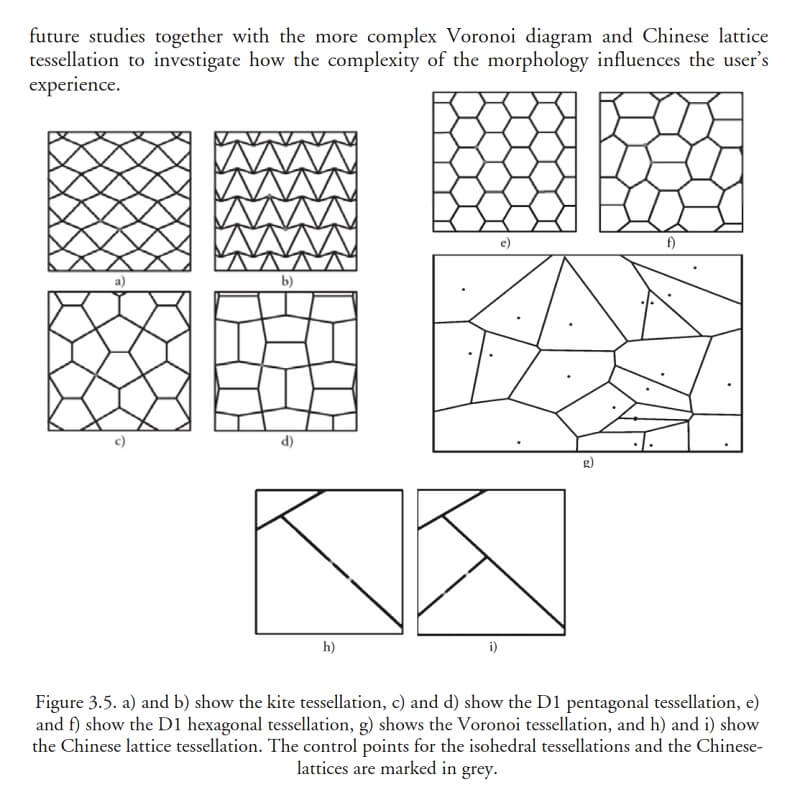

This has involved compiling an inventory of suitable morphologies, production systems and products, implementing and testing several generative design tools in industrial projects, looking into challenges concerning user manipulation of complex morphologies and industrial implementation, developing techniques for handling engineering constraints and objectives, testing the acceptance of the generative design tools with industrial designers and customers, and producing physical objects based on the output from the tools.

The results of this work show that this approach is feasible and is even already useful to the industry: the studies establish that there exists a feasible domain of application; they confirm that there are computational methods for handling engineering and user constraints and objectives; in the performed project the design process could be made to fit the needs of both consumers and designers; finally, physical products have been produced and have received acceptance by peers in international design fairs, thereby verifying and validating the output of the tools.

Comments