Generative Fabrication

myTHREAD PAVILION: GENERATIVE FABRICATION IN KNITTING PROCESSES

Jenny E. Sabin

Cornell University

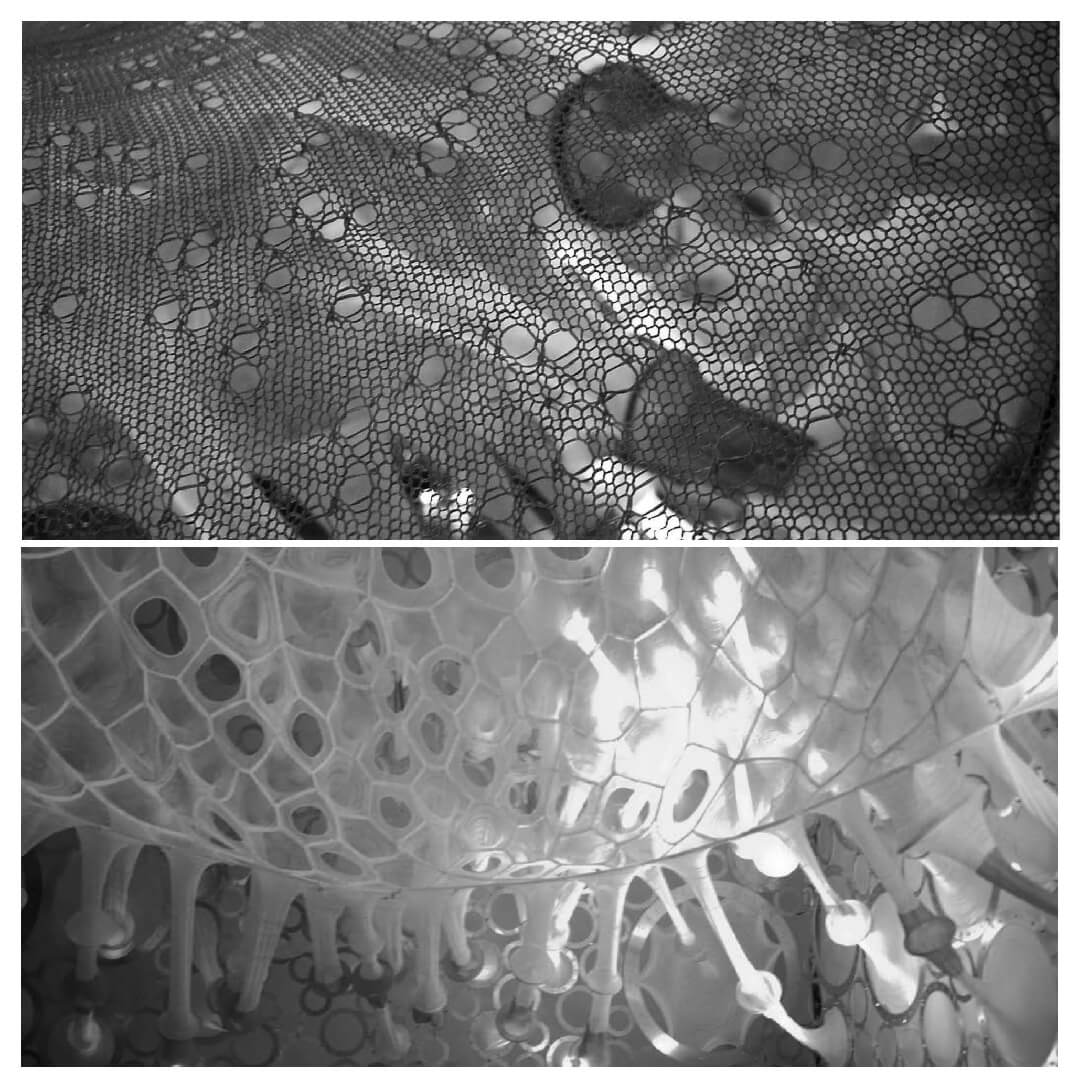

Advancements in weaving, knitting and braiding technologies have brought to surface high-tech and high-performance composite fabrics. These products have historically infiltrated the aerospace, automobile, sports and marine industries, but architecture has not yet fully benefitted from these lightweight freeform surface structures.

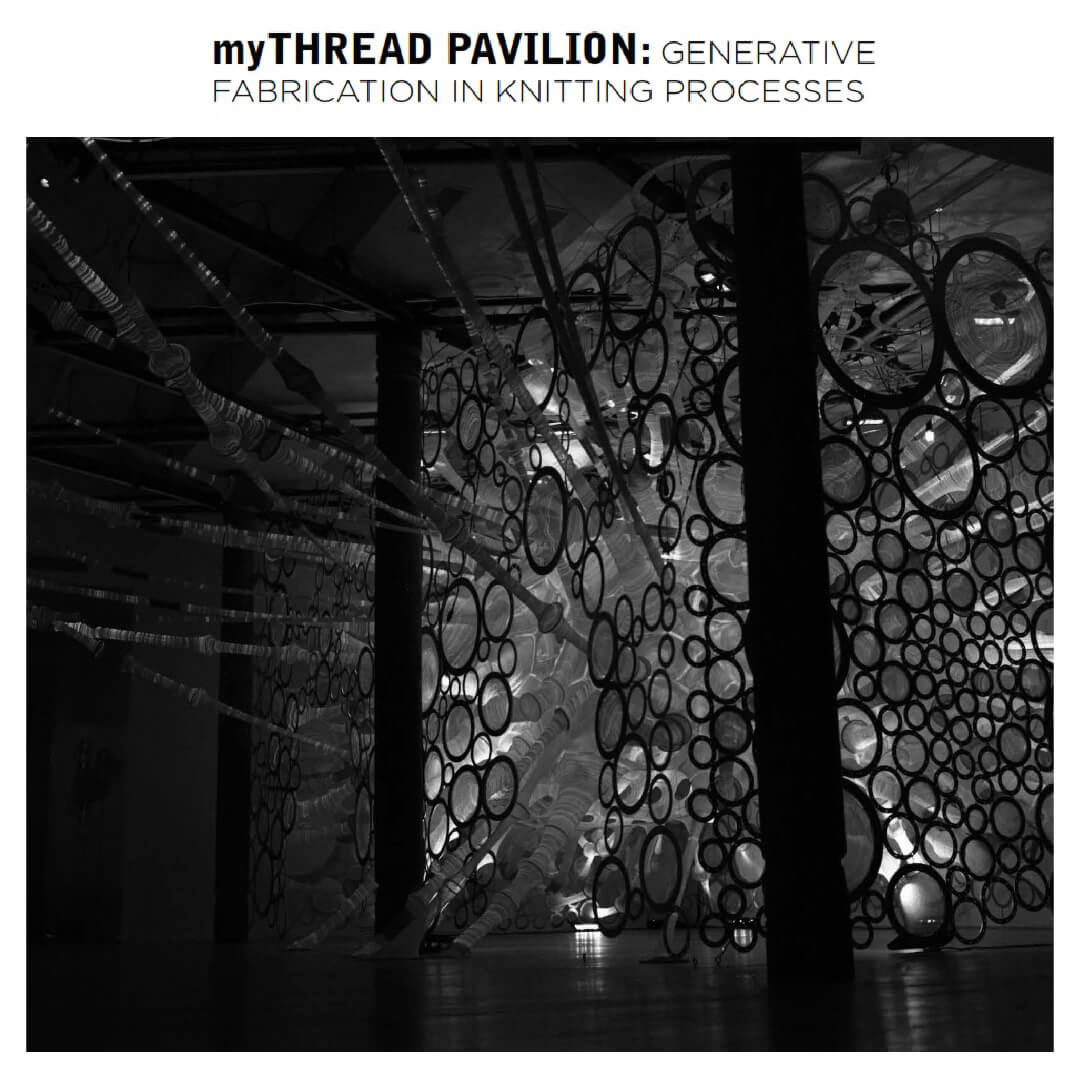

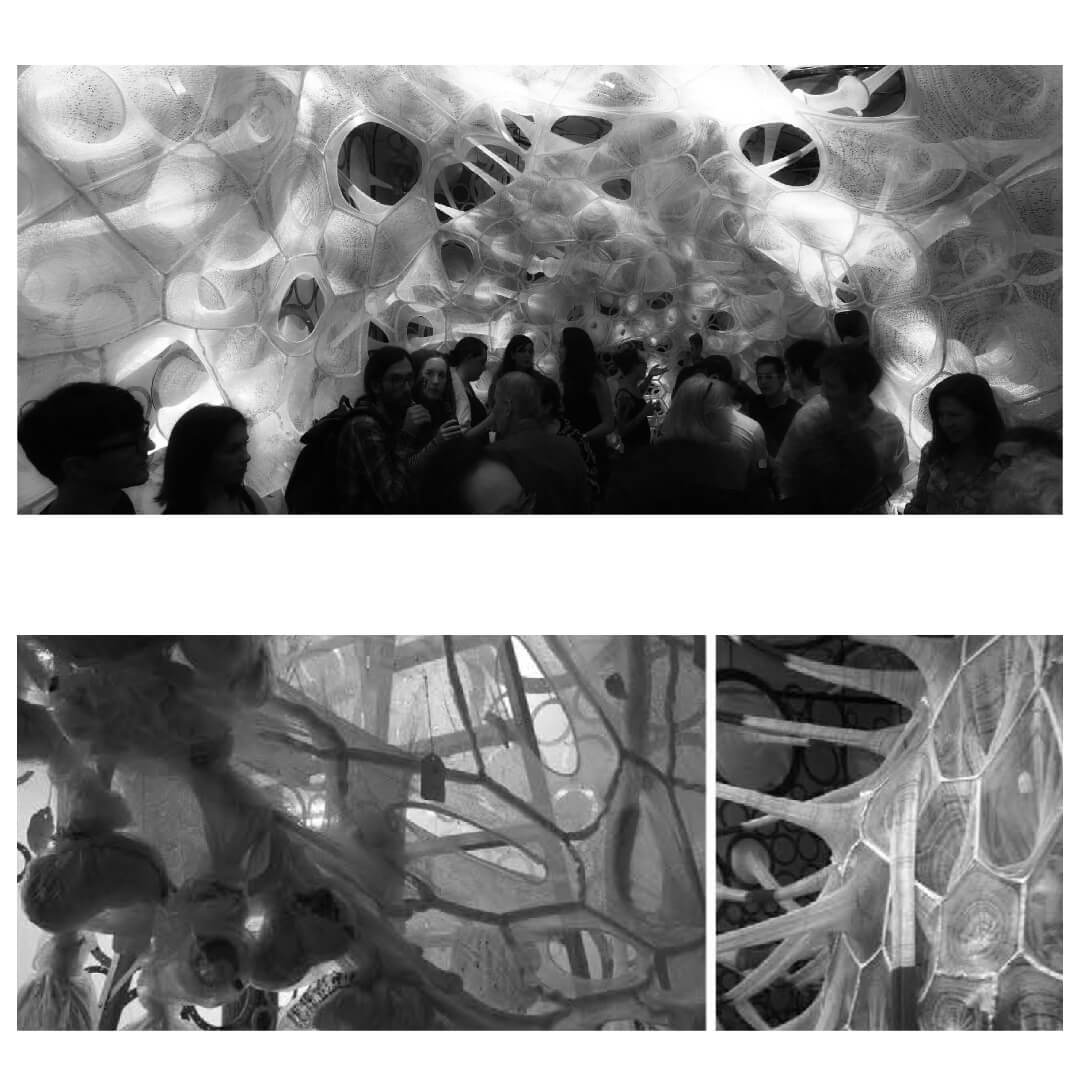

myThread, a commission from the Nike FlyKnit Collective, features knitted textile structures at the scale of a pavilion. The evolution of digital tools in architecture has prompted new techniques of fabrication alongside new understandings in the organization of material through its properties and potential for assemblage.

myThread, a commission from the Nike FlyKnit Collective, features knitted textile structures at the scale of a pavilion. The evolution of digital tools in architecture has prompted new techniques of fabrication alongside new understandings in the organization of material through its properties and potential for assemblage.

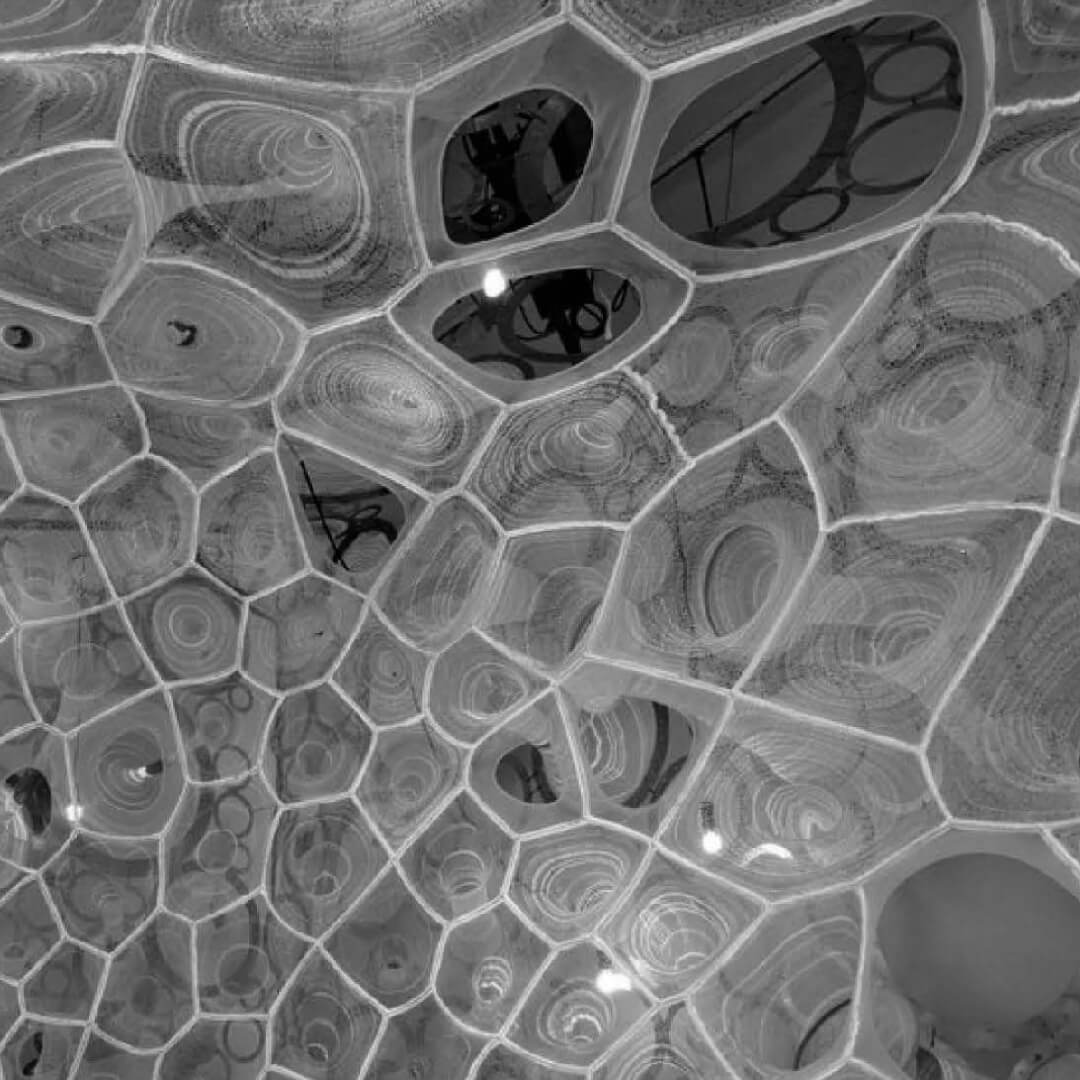

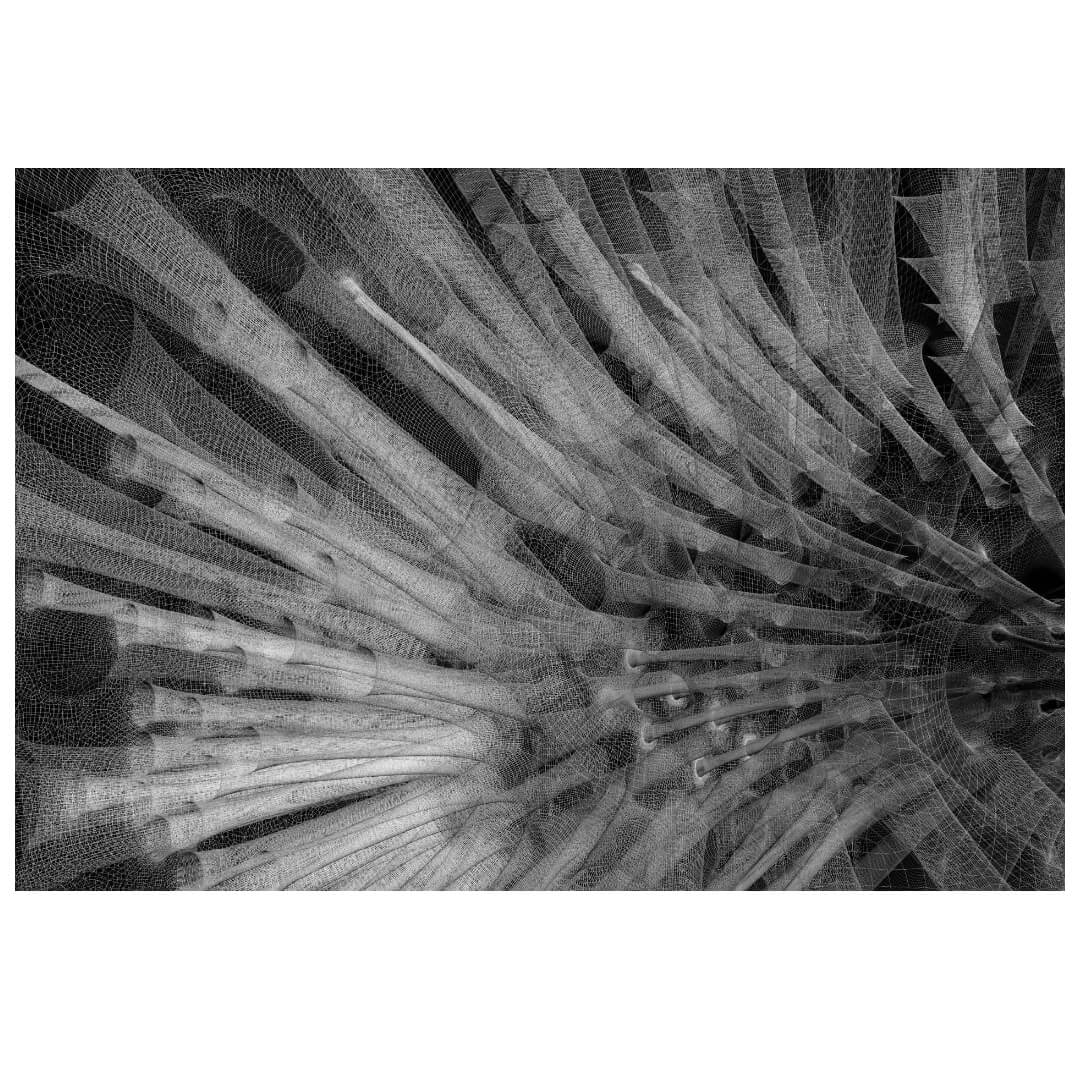

No longer privileging column, beam and arch, our definition of architectural tectonics has broadened alongside advancements made in computational design. Internal geometries inherent to natural forms, whose complexity could not be computed with the human mind alone, may now be explored synthetically through mathematics and generative systems.

No longer privileging column, beam and arch, our definition of architectural tectonics has broadened alongside advancements made in computational design. Internal geometries inherent to natural forms, whose complexity could not be computed with the human mind alone, may now be explored synthetically through mathematics and generative systems.

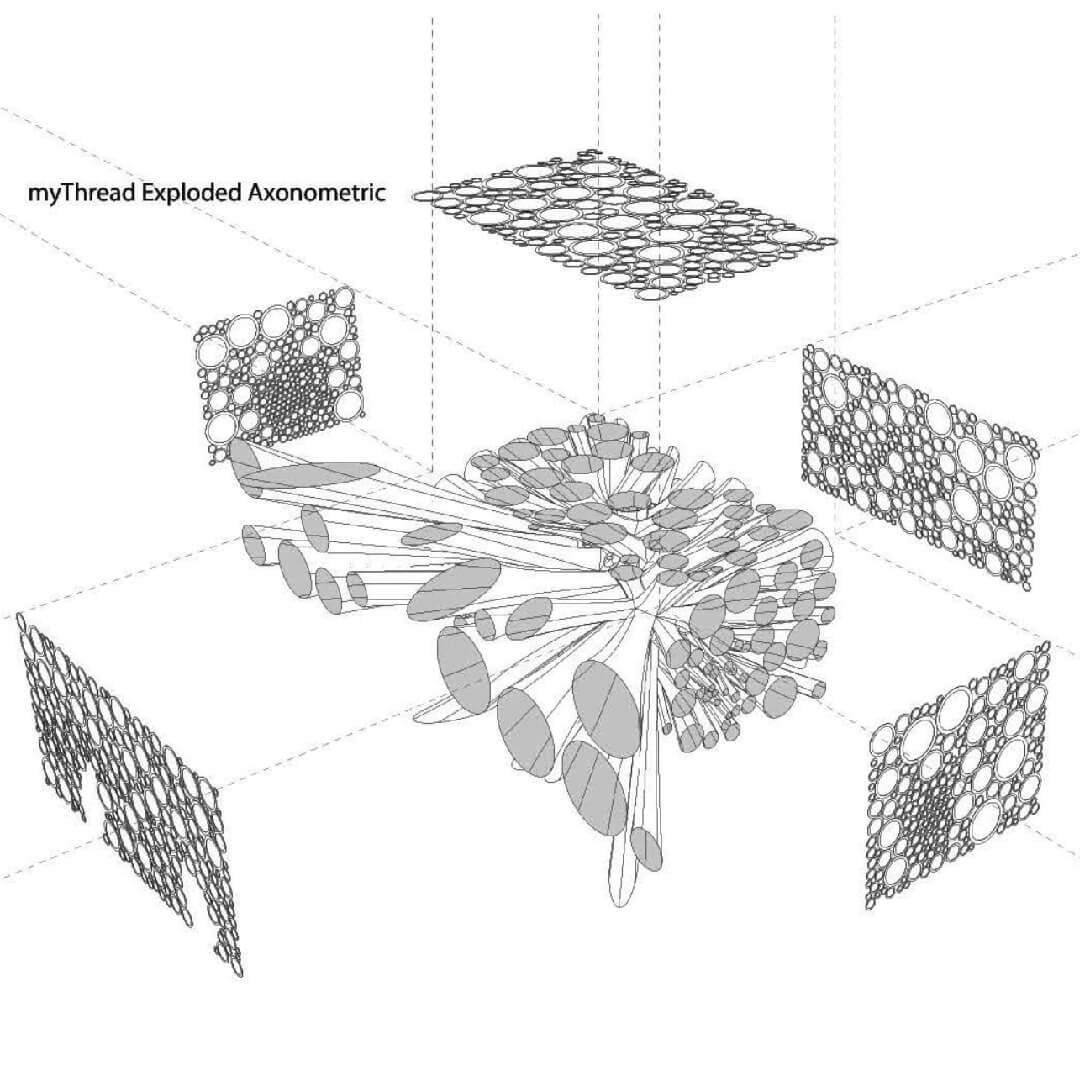

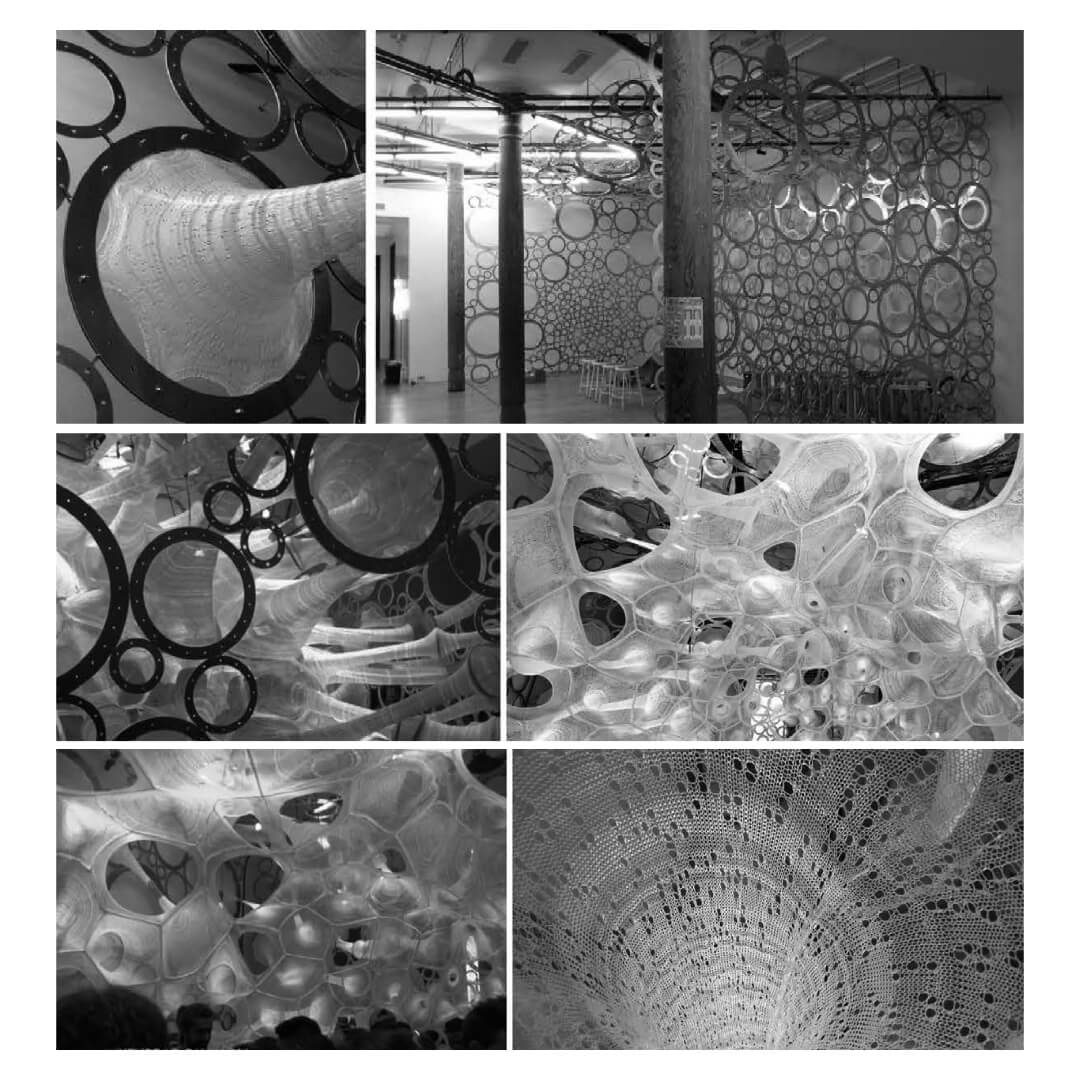

Textiles offer architecture a robust design process whereby computational techniques, pattern manipulation, material production and fabrication are explored as an interconnected loop that may feedback upon itself in no particular linear fashion.

Textiles offer architecture a robust design process whereby computational techniques, pattern manipulation, material production and fabrication are explored as an interconnected loop that may feedback upon itself in no particular linear fashion.

The myThread Pavilion integrates emerging technologies in design through the materialization of dynamic data sets generated by the human body engaged in sport and movement activities in the city.

Turning performance into structure for the Nike Flyknit Collective, Jenny Sabin works at the intersection of art, architecture, design and science. There are instant similarities in this approach to the work of Nike’s Innovation Kitchen, where disciplines from different fields are brought together with a view to re-thinking basic principles and approaches to design challenges.

Turning performance into structure for the Nike Flyknit Collective, Jenny Sabin works at the intersection of art, architecture, design and science. There are instant similarities in this approach to the work of Nike’s Innovation Kitchen, where disciplines from different fields are brought together with a view to re-thinking basic principles and approaches to design challenges.

This project aims to engage a new material practice and next steps in digital fabrication in architecture through the production of models and prototypes via cutting-edge parametric and associative software that interface fabrication technologies in related, but alternative disciplines.

This project aims to engage a new material practice and next steps in digital fabrication in architecture through the production of models and prototypes via cutting-edge parametric and associative software that interface fabrication technologies in related, but alternative disciplines.

By digitally crafting these new formfitting material systems at architectural scales, beautiful formal possibilities emerge allowing for the construction of novel spaces and immersive adaptive environments that ultimately advance textile tectonics in architecture.

Importantly, this project seeks to communicate, document and make public advances in tooling and textile fabrication towards the design and production of nonlinear systems via complex geometries. Central to this is the integration of fields and industries outside of our own with the promise of advancing the functional, adaptive and formfitting nature of knit material alongside provocative emergent forms and spaces.

Importantly, this project seeks to communicate, document and make public advances in tooling and textile fabrication towards the design and production of nonlinear systems via complex geometries. Central to this is the integration of fields and industries outside of our own with the promise of advancing the functional, adaptive and formfitting nature of knit material alongside provocative emergent forms and spaces.

This is achieved through visualization models of human bio-data — motion data from a large group of runners — transformed and realized as a new choreography of performances in the context of a fully knitted pavilion.

This is achieved through visualization models of human bio-data — motion data from a large group of runners — transformed and realized as a new choreography of performances in the context of a fully knitted pavilion.

Simply put, the generative design strategy is based on prior performances that are translated into present-tense performance through a finely tuned material assembly of knitted threads that respond and adapt to the presence or absence of light. The main goal of this project concerns the evolution of digital complexity in the built world.

The myThread Pavilion is the result of collaboration across disciplines and industries including architecture, textiles, sportswear and engineering. Linking biology and innovation, technology and tradition, this is an analog manifestation both of the benefits of Nike FlyKnit, and also the activities and performance of the individuals that went into its making.

The myThread Pavilion is the result of collaboration across disciplines and industries including architecture, textiles, sportswear and engineering. Linking biology and innovation, technology and tradition, this is an analog manifestation both of the benefits of Nike FlyKnit, and also the activities and performance of the individuals that went into its making.

This installation’s adaptable sensitivity and flexibility mirrors the human form. It is its own environment, its own community and its own energy. While interpreting and visualizing human data, the pavilion also becomes a body itself by virtue of a dynamic, spatial interiority and the presence of a multitude of actual human interactions.

Comments