Generative Reciprocity

Generative Reciprocity: A Computational Approach for Performance-Based and Fabrication-Aware Design of Reciprocal Systems

Omid Oliyan Torghabehi

University of Michigan 2020

In the traditional sense, reciprocal structures combine the advantages of timber as a renewable source of construction material and low-energy production with the modular fabrication, fabrication efficiency, structural capacities, and elegance of reciprocal interconnection of members.

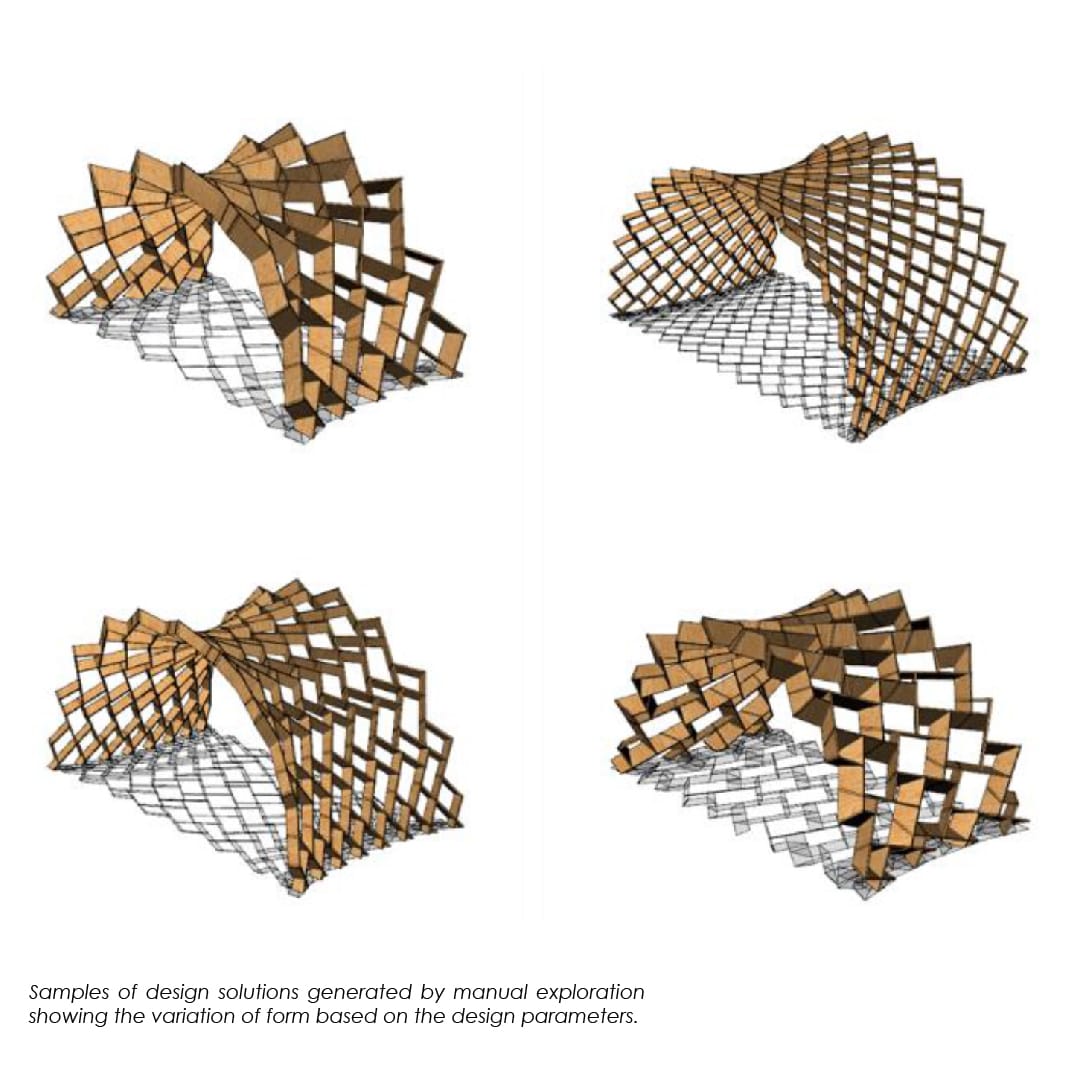

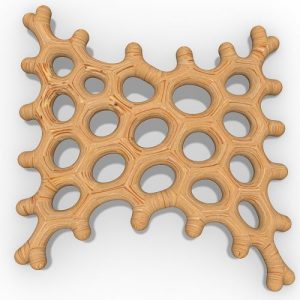

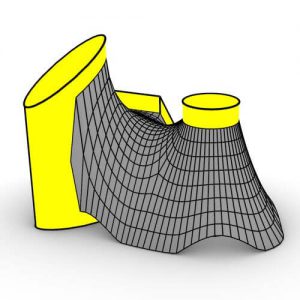

The unique benefits of reciprocal systems come from their discrete geometry, which simplifies the connection detailing and provides freedom for local and global variations in the system.

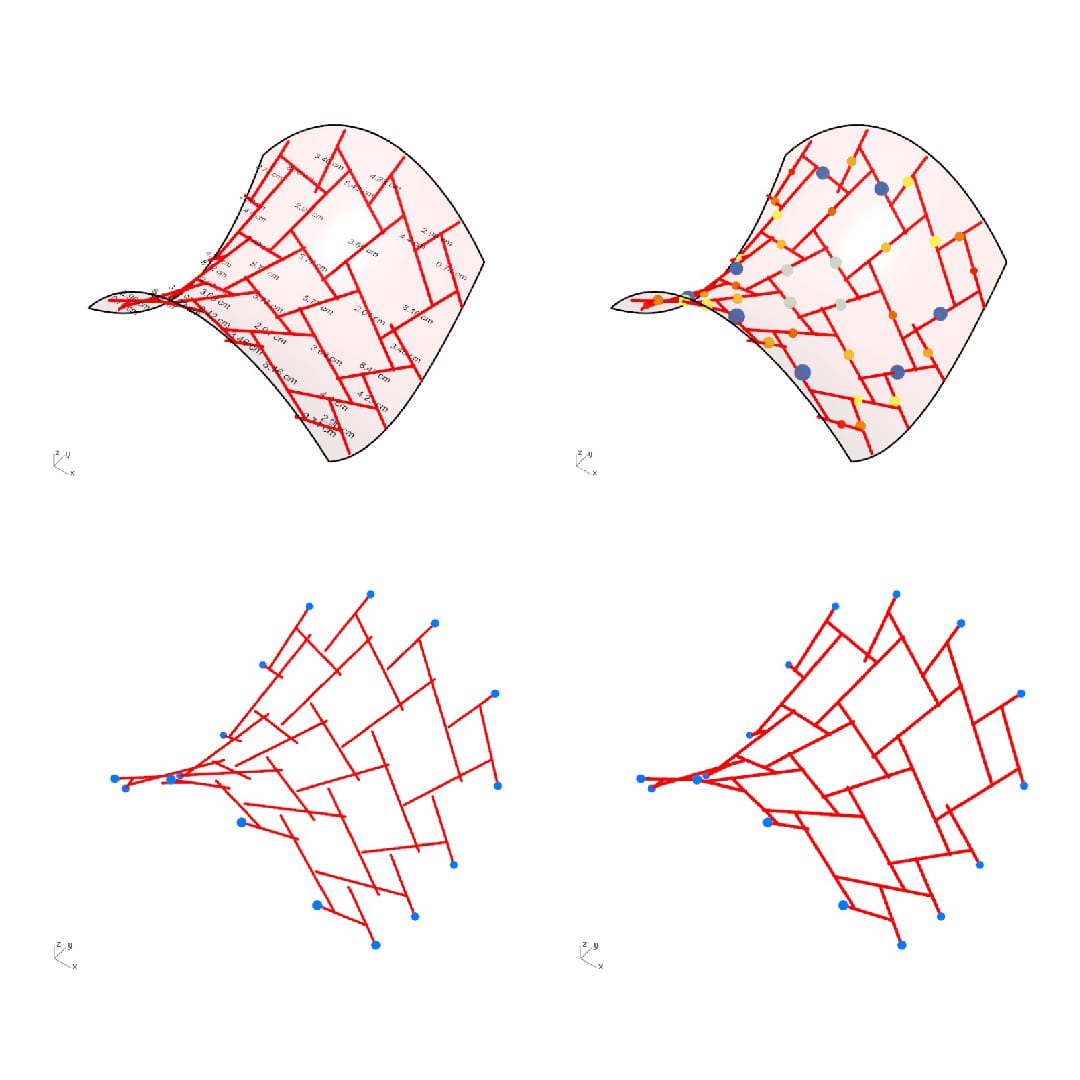

However, this reduction in construction complexity and flexibility of local variation is replaced with geometrical complexity due to numerous compatibility constraints coupled with the structural behavior of the system.

However, this reduction in construction complexity and flexibility of local variation is replaced with geometrical complexity due to numerous compatibility constraints coupled with the structural behavior of the system.

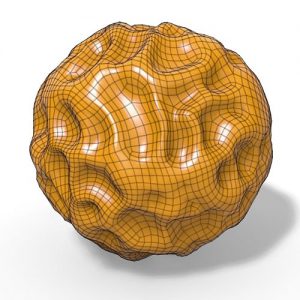

This research therefore identifies the key design parameters and design constraints of reciprocal systems. The results demonstrate the complex coupling of geometry, structural performance and fabrication in these systems, hence an essential need for application of an integrative design process.

Through the application of computation, simulation, and digital fabrication this research proposes an integrative computational design process which can effectively address the coupling of design, analysis and fabrication of reciprocal systems and accommodate design exploration and optimization.

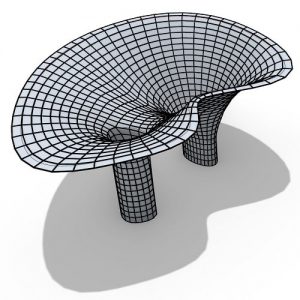

The principle of structural reciprocity is based on the 3-D assembly of loadbearing members that mutually support each other along their span and create a self-supporting spatial configuration without any structural hierarchy and which can span multiple times the length of members.

The principle of structural reciprocity is based on the 3-D assembly of loadbearing members that mutually support each other along their span and create a self-supporting spatial configuration without any structural hierarchy and which can span multiple times the length of members.

The primitive concept initially emerged in the East, in the Song dynasty in China, at least 900 years ago as a bridge construction system to span longer than the length of available timbers and became a practical approach for construction in different parts of the world.

The simplicity of connection detailing and use of relatively short members to cover a large area are some of the construction benefits of these systems.

The simplicity of connection detailing and use of relatively short members to cover a large area are some of the construction benefits of these systems.

Using the capacities of computation and digital fabrication this dissertation provides a basis for a novel process of design to fabrication for reciprocal systems.

Using the capacities of computation and digital fabrication this dissertation provides a basis for a novel process of design to fabrication for reciprocal systems.

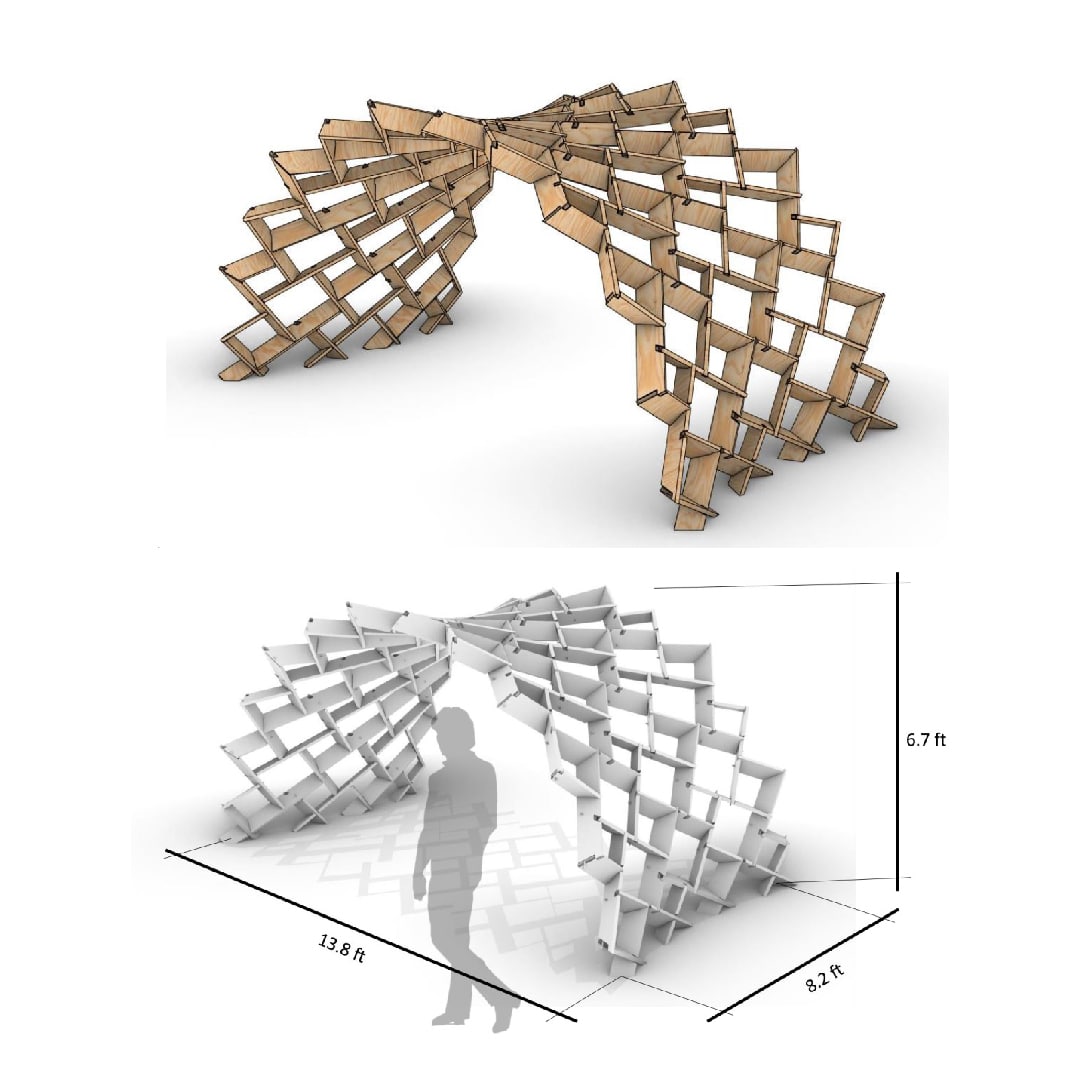

Specifically, the focus lies in self-supporting systems based on planar elements which have a high fabrication efficiency from sheet materials.

This research demonstrates the essential need for the application of an integrative design process to address the complex coupling of geometry, structural performance and fabrication and presents a novel computational process for design to fabrication of these systems.

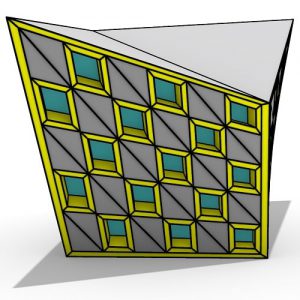

The proposed computational design process is developed by rethinking and replacing the conventional direct incremental development by a modular integrative computational process using multi-directional dataflow between modeling, analysis and fabrication modules.

The proposed computational design process is developed by rethinking and replacing the conventional direct incremental development by a modular integrative computational process using multi-directional dataflow between modeling, analysis and fabrication modules.

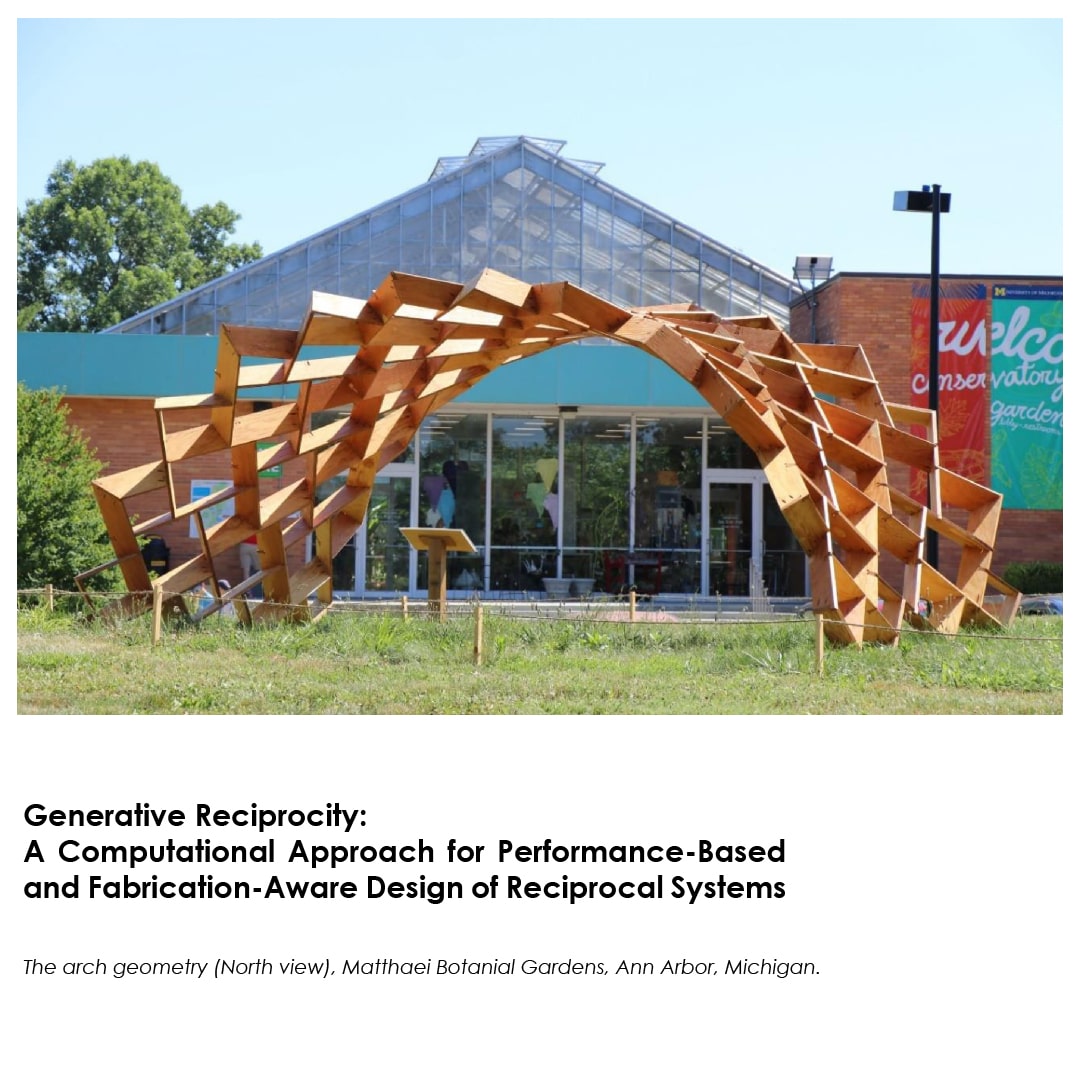

Finally, the proposed framework is used for a full-scale design to fabrication case study to validate the applicability of the design process.

In addressing different design aspects of reciprocal systems, new design methods and tools are required. This dissertation identifies the main limitations of the existing methods and proposes practical solutions for an efficient design development, including modelling, analysis and fabrication.

In addressing different design aspects of reciprocal systems, new design methods and tools are required. This dissertation identifies the main limitations of the existing methods and proposes practical solutions for an efficient design development, including modelling, analysis and fabrication.

The results demonstrate the complex coupling of geometry, structural performance and fabrication in these systems, hence an essential need for application of an integrative design process.

The results demonstrate the complex coupling of geometry, structural performance and fabrication in these systems, hence an essential need for application of an integrative design process.

Though application of computation, simulation, and digital fabrication this research proposes an integrative computational design process which can effectively address the coupling of design, analysis and fabrication of reciprocal systems and accommodate design exploration and optimization.

Comments