String Art Generator

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

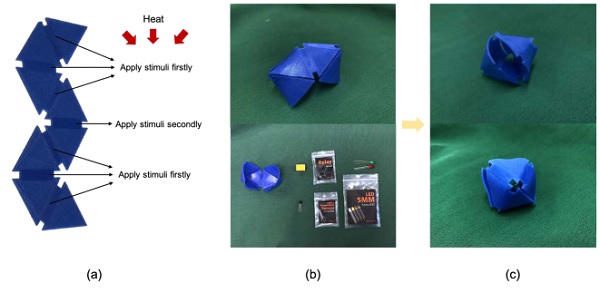

Origami-based design for 4D printing of deployable structures

Additive manufacturing (AM) technology (also known as 3D printing) has been recognized globally as one of the leading forms of manufacturing process for advanced components, providing great prospects for complex part manufacturing, rapid prototyping and distributed digital manufacturing.

Starting from a computer-aided design (CAD) model, materials are added layer by layer to build complex 3D solid components without using other auxiliary resources and special tools for parts, which greatly reduces the geometric complexity and the constraints of topology optimization imposed by the conventional manufacturing.

Unlike traditional manufacturing methods, AM has the potential to revolutionize the manufacturing industry with their unique capabilities. It has indeed the ability to build complex shapes and geometries which are not compatible to any other conventional manufacturing technologies.

Nowadays, with the support of high-performance materials and increased efficient AM processes, the freeform building capacity plays a quite relevant role in the production of complex geometries for products of several domains, such as medical industry, tooling industry, automotive and aerospace industry, among others, where conventional manufacturing approaches are not technically feasible due to geometrical complexity.

Of course, conventional applications such as special tools, low production parts, biomedical devices and implants, aerospace components, and rapid prototyping will all benefit from the flexibility provided by AM.

The unique features of AM give this new technology the potential to completely change the manufacturing industry and the way many parts are made.

In addition, AM can now be seen as an emerging shape forming technology in the last three decades, it has received great attention from academia and industry and has great potential to promote transformative manufacturing and product design in many fields in a wide range of engineering and materials science fields.

Their advantages have attracted the imagination of the public and have been called “the fourth industrial revolution” by recent mainstream publications. From the Industry 4.0 mission in Germany to the Made in China 2025, AM is being promoted in the world’s major industrial countries as the technological basis for future manufacturing.

At present, high levels of manufacturing automation, incorporating AM equipment as well as smart factories are emerging, the standardization for materials, material testing and manufacturing processes is beginning to establish breakthrough standards to harmonize the use of worldwide AM technologies. Now, we can foresee the bright future of additive manufacturing technology in the new decade.

3D printing has been developed toward high accuracy, high speed, diverse and robust material properties, and low cost. Meeting these demanding goals requires interdisciplinary collaborations involving mechanical engineering, material science and processes, data processing, and even art designing.

While facing challenges and opportunities in many aspects, the lack of high-performance printable materials is a common and perhaps the biggest barrier confronting various 3D printing technologies. Several leading 3D printing commercial companies have established their dedicated material Research & Development teams.

At the same time, some traditional material suppliers have also begun to launch printable materials adaptable for various printing processes.

Right now, the most advanced commercial printable materials are mainly formulated to be tough, flexible, transparent, colorful or recyclable to meet various end applications. There is no doubt that material development will be the main focus in the foreseeable future.

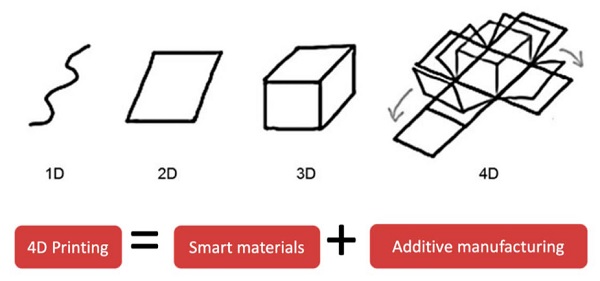

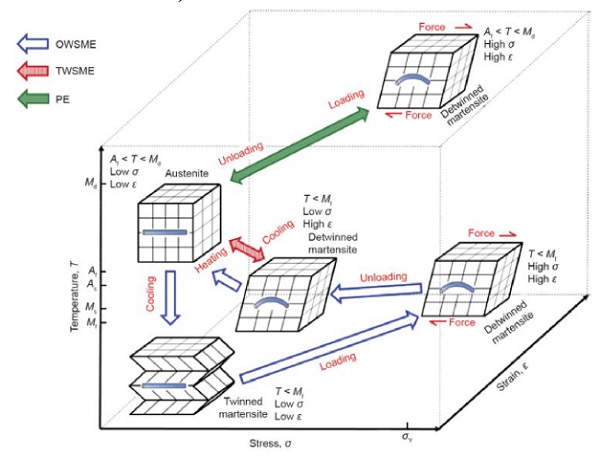

The development of AM advanced materials is a continuous process, which provides a new competitive edge to AM technologies. With the in-depth exploration of smart materials, a revolutionary breakthrough — 4D printing has emerged.

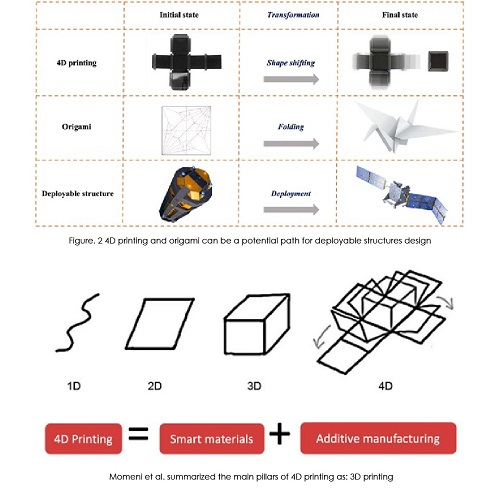

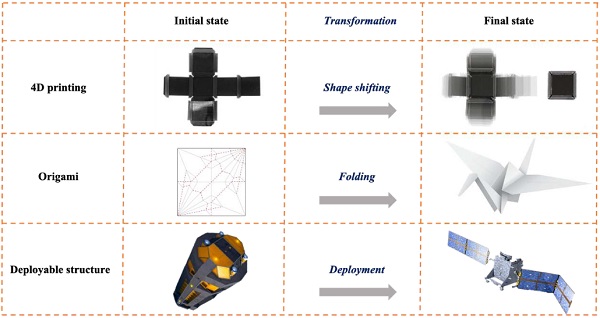

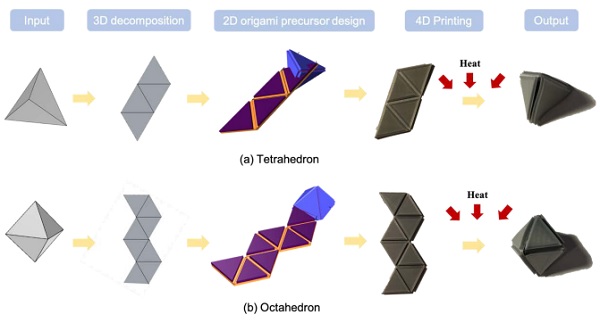

At the 2013 TED Talks, Skylar Tibbits demonstrated how the printed static objects could change their shape over time. This marked the start of the 4D printing concept, where the fourth dimension is time.

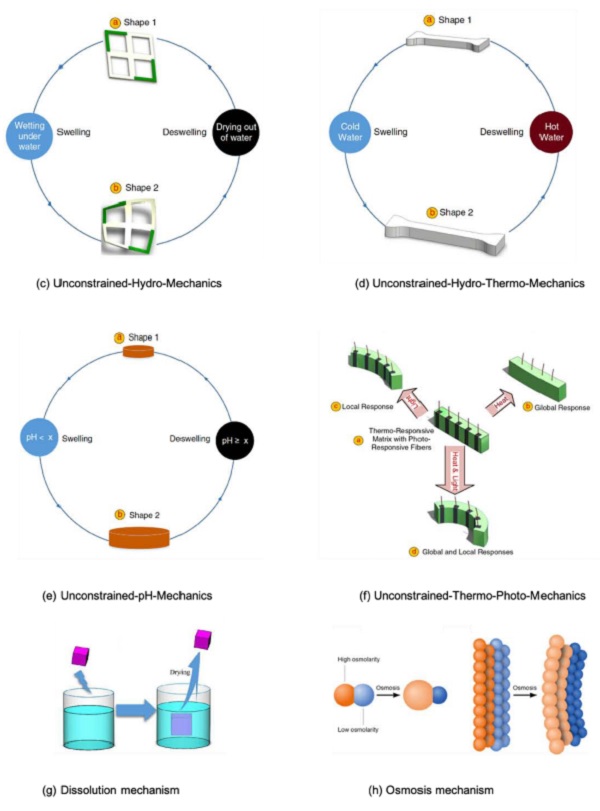

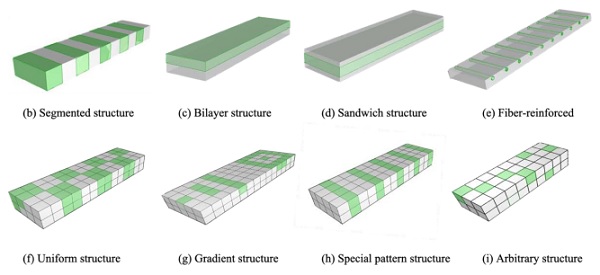

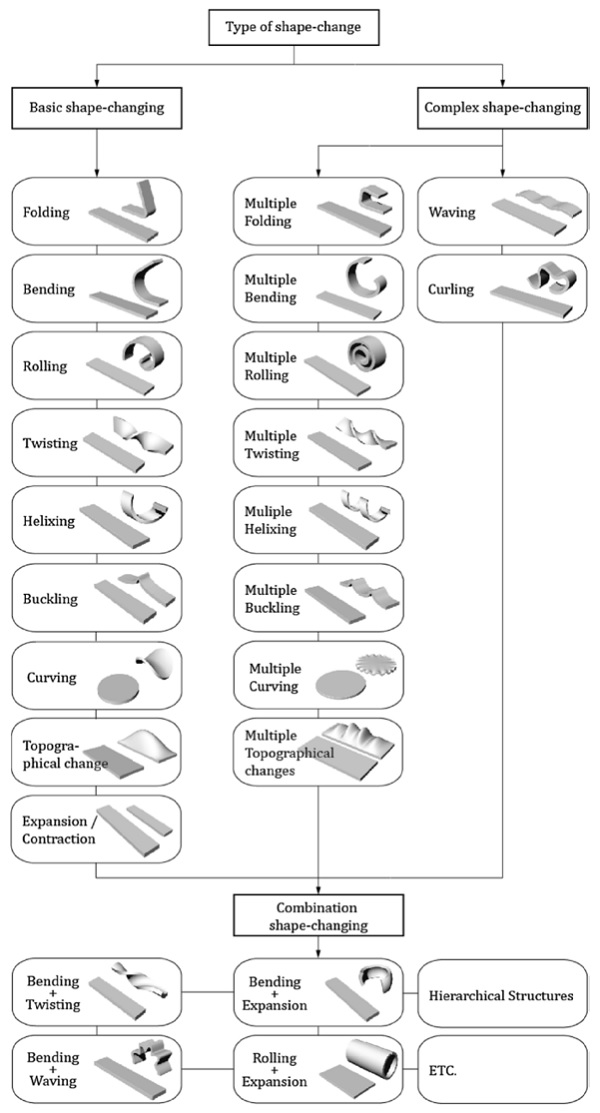

Since then, as a combination of the AM and smart materials, 4D printing has become a new and exciting branch of 3D printing, increasingly gaining substantial attention from scientists and engineers of multiple disciplines since the obtained structure can be transformed in a pre-programmed way.

Currently, due to the exploration and rise of commercial printers marketed as “multi-material printing”, like ProJet MJP series by 3D systems and PolyJet Connex series by Stratasys, also give a restricted chance for the development of 4D printing to which additional efforts are dedicated towards the development of more flexible and customized multi-material 3D printers. Figure. 1 shows the development of 3D printing towards 4D printing.

Due to unique advantages and complex design freedom, many fields have shown a strong interest in 4D printing. The self-assembly characteristics of 4D printing will reduce manufacturing time and labor, which is beneficial to the packaging and transportation industry.

Another potential opportunity is that this new technology is expected to be used in deployable solar arrays or antenna arrays in space.

In fact, the application of 4D printing has been reported in various fields, such as electronic devices, biomedical devices, organ and tissue engineering, optics and soft actuators, smart valves, regenerative design, electromechanical switches and smart clothing. It is believed that this revolutionary technology may influence various other mature applications in the near future.

Despite the rapid development of materials AM machines, the research progress of 4D printing is still in its infancy. Since there are many potential applications of 4D printing in renewable energy, the printed soft actuators and soft robotics, bioprinting for healthcare, material handling and transportation, defense applications and even in fashion domain, we cannot ignore that it is a rapidly developing and exciting research field.

4D printing prospects for the next decade will definitively impact business and industrial production models, and even daily life. Therefore, the comprehensive investigation of 4D printing has great significance, especially in the global context of smart manufacturing and Industry 4.0.

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

This paper by Alessandro Liuti, Sofia Colabella, and Alberto Pugnale, presents the construction of Airshell, a small timber gridshell prototype erected by employing a pneumatic formwork.

In this paper by Gregory Charles Quinn, Chris J K Williams, and Christoph Gengnagel, a detailed comparison is carried out between established as well as novel erection methods for strained grid shells by means of FE simulations and a 3D-scanned scaled physical model in order to evaluate key performance criteria such as bending stresses during erection and the distance between shell nodes and their spatial target geometry.

In this paper by Frederic Tayeb, Olivier Baverel, Jean-François Caron, Lionel du Peloux, ductility aspects of a light-weight composite gridshell are developed.

Parametric Ideas for Architects @2025