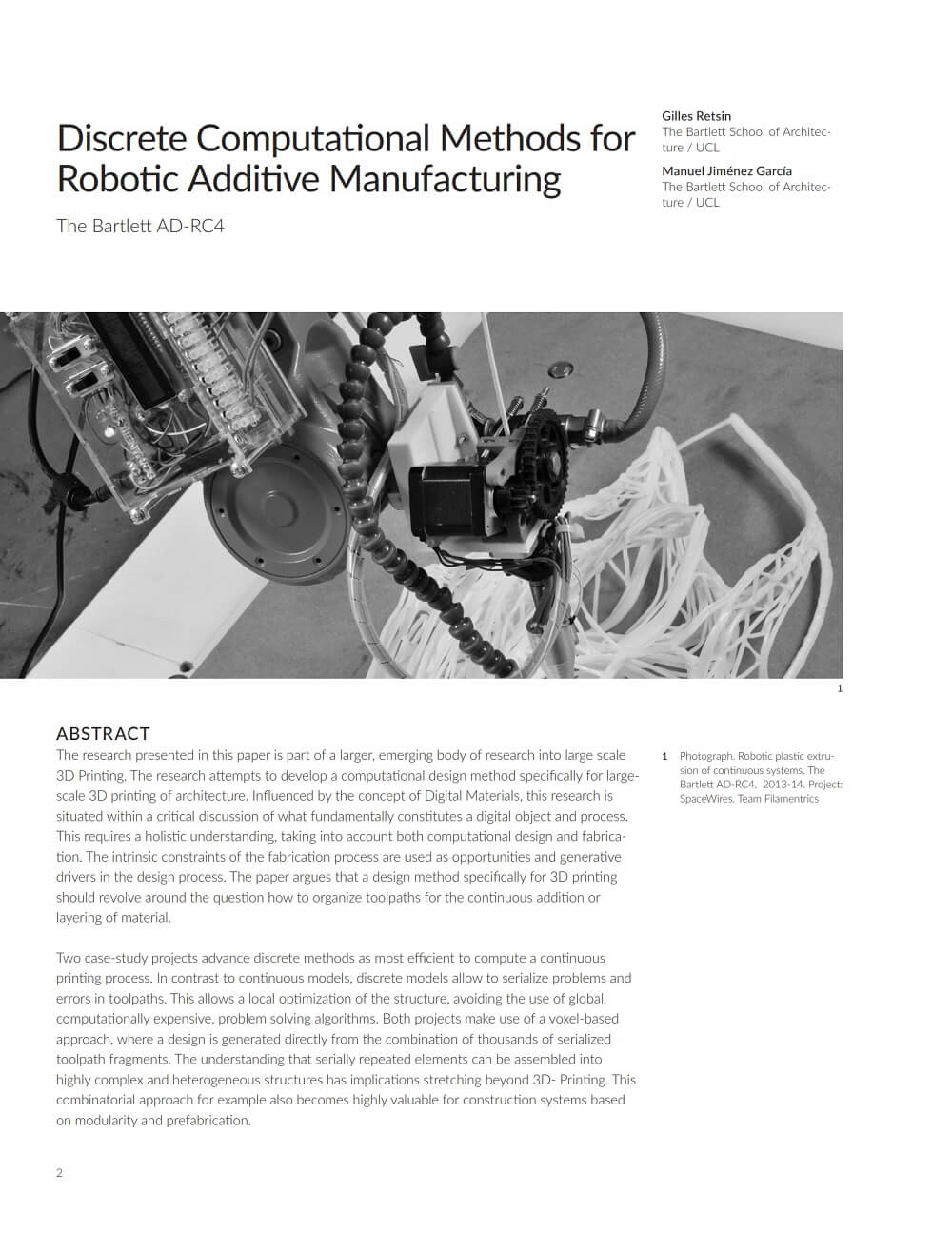

Robotic Manufacturing

The research presented in this paper by Gilles Retsin and Manuel Jiménez García is part of a larger, emerging body of research into large scale 3D Printing. The research attempts to develop a computational design method specifically for large-scale 3D printing of architecture. Influenced by the concept of Digital Materials, this research is situated within a critical discussion of what fundamentally constitutes a digital object and process. This requires a holistic understanding, taking into account both computational design and fabrication.

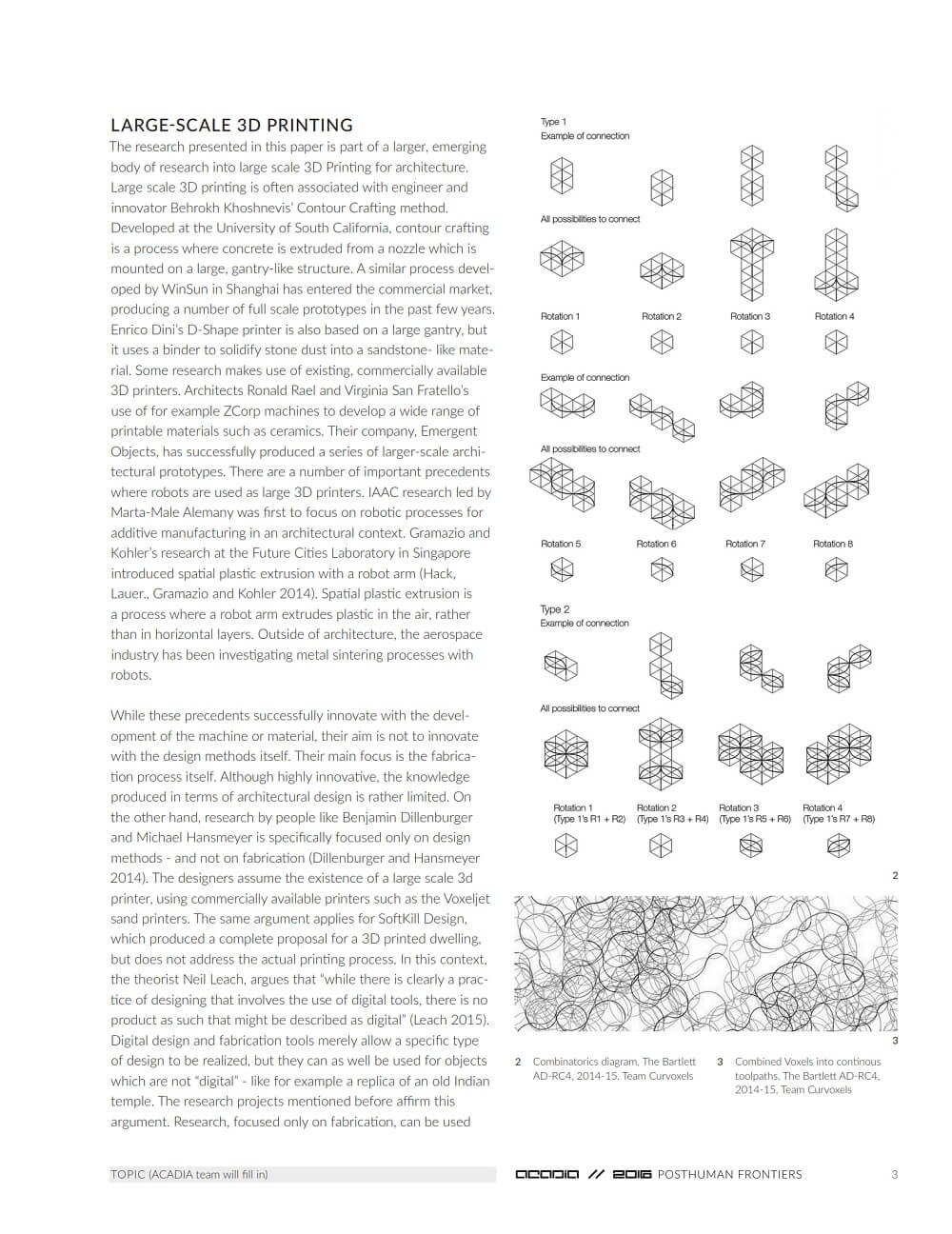

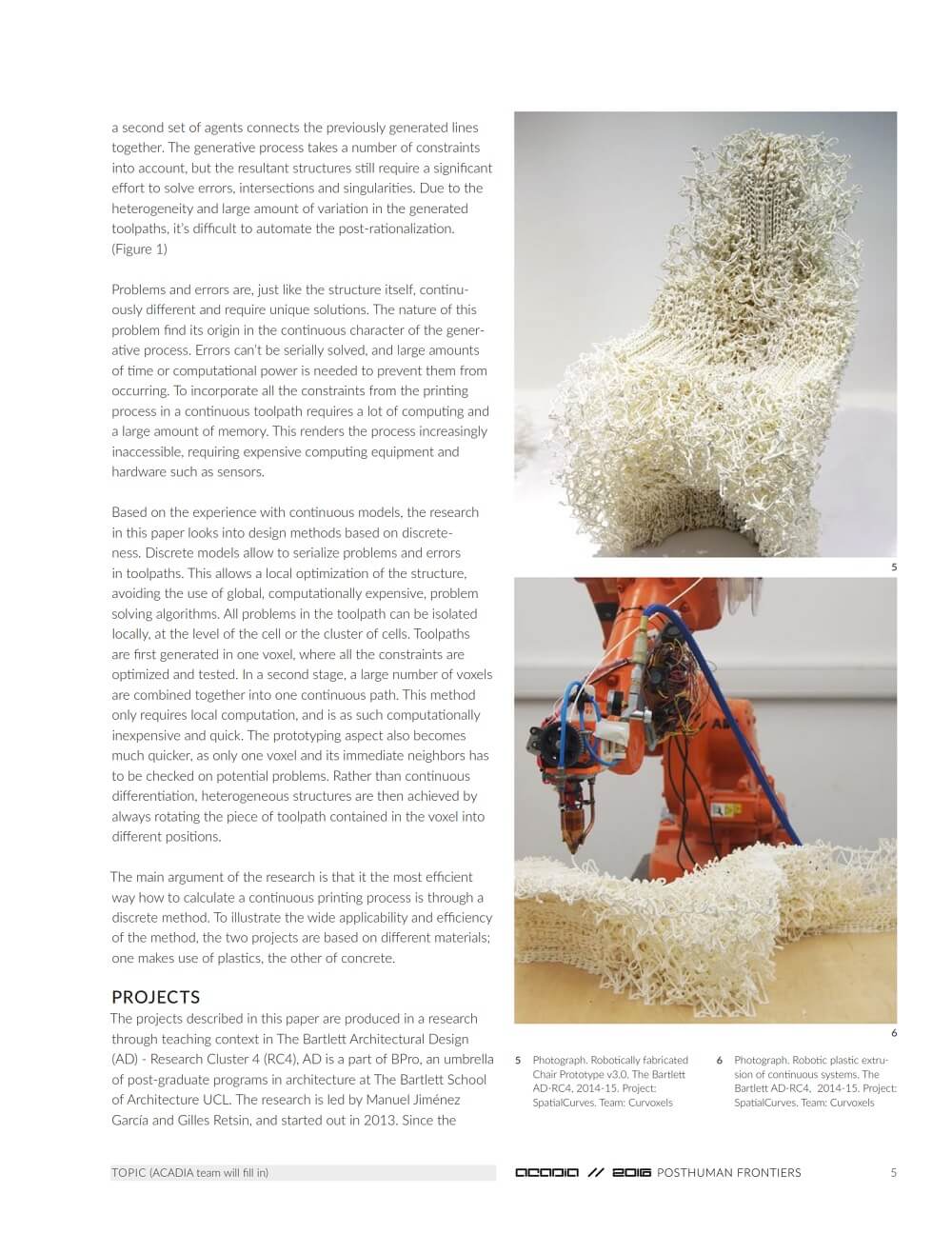

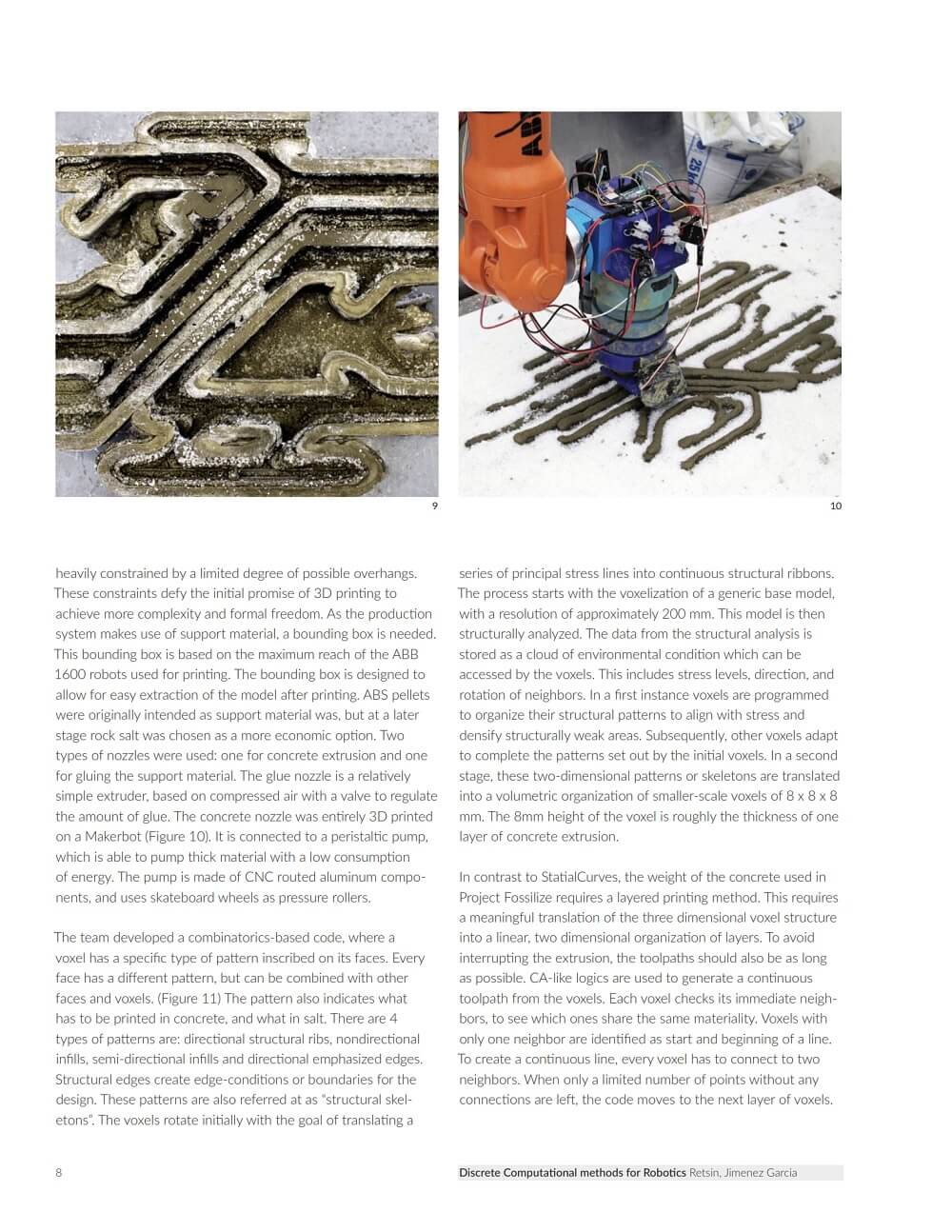

The intrinsic constraints of the fabrication process are used as opportunities and generative drivers in the design process. The paper argues that a design method specifically for 3D printing should revolve around the question how to organize toolpaths for the continuous addition or layering of material. Two case-study projects advance discrete methods as most efficient to compute a continuous printing process. In contrast to continuous models, discrete models allow to serialize problems and errors in toolpaths.

This allows a local optimization of the structure, avoiding the use of global, computationally expensive, problem solving algorithms. Both projects make use of a voxel-based approach, where a design is generated directly from the combination of thousands of serialized toolpath fragments. The understanding that serially repeated elements can be assembled into highly complex and heterogeneous structures has implications stretching beyond 3D Printing. This combinatorial approach for example also becomes highly valuable for construction systems based on modularity and prefabrication.

Comments