Slender Concrete Shells

PROCESSING OF SLENDER CONCRETE

SHELLS — FABRICATION AND INSTALLATION

Philipp Eisenbach

Faculty of Architecture – Urban and Regional Planning – Landscape

Architecture and Landscape Planning of the University of Kassel as a thesis for acquiring the academic degree of Doktor der Ingenieurwissenschaften

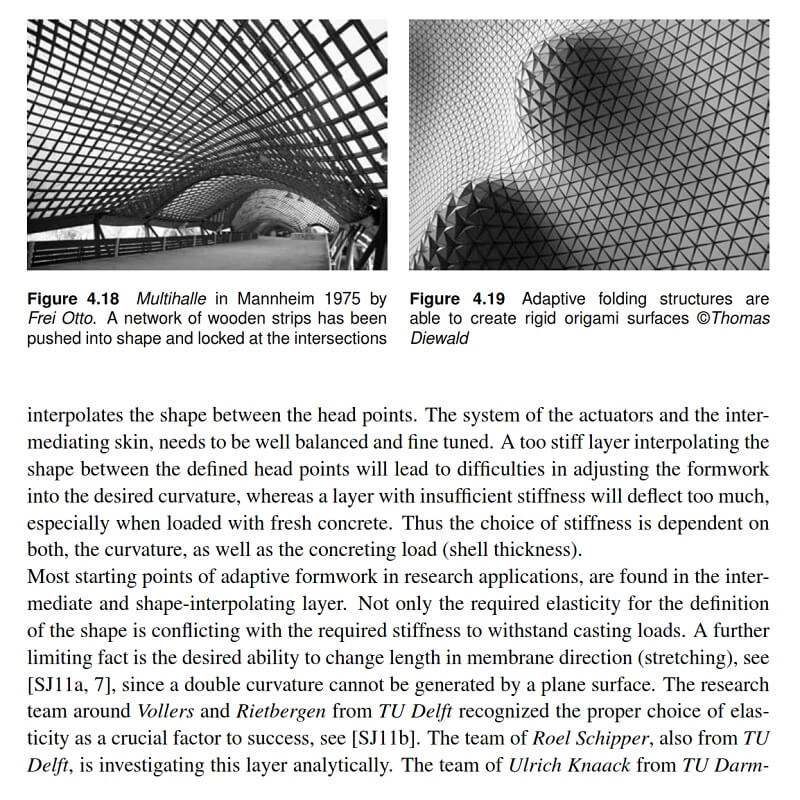

Lightweight structures and material optimized systems are the key objectives of several research efforts. This is not only for aesthetic reasons, but also to use materials in a more resource conserving way. Minimization of cross-section dimensions is achieved by two measures: Firstly the increase of strength and stiffness characteristics, secondly the directed allocation of material within a given design-space in order to create form dependent structures. For both, the material and the form-giving aspects, progresses have been made recently.

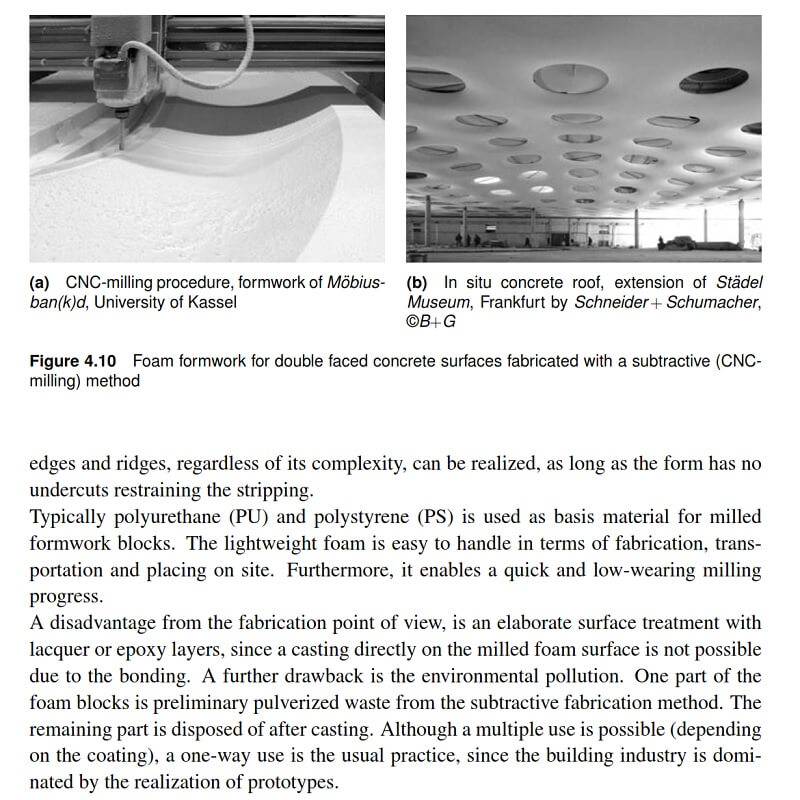

Technical advances in computation allow digitized form finding processes and the analysis of complex geometries, as well as the transfer to computer-aided manufacturing. Improvements in material science, focusing on cementitious materials, lead to high- and ultra-high performance concrete, with compressive strength characteristics, closing up with the properties of steel. In combination with respective reinforcement strategies, high tensile and bending tensile capacities and ductile material behaviour are also enabled.

Despite the possibilities at hand, it can be observed that the potential is not reflected in built architecture. One reason is a lack of experience and the consequent economical risks, but also implementation features on site: The greater the material performance, the higher the requirements of precision in manufacturing and post-treatment, necessitating a prefabrication under laboratory conditions.

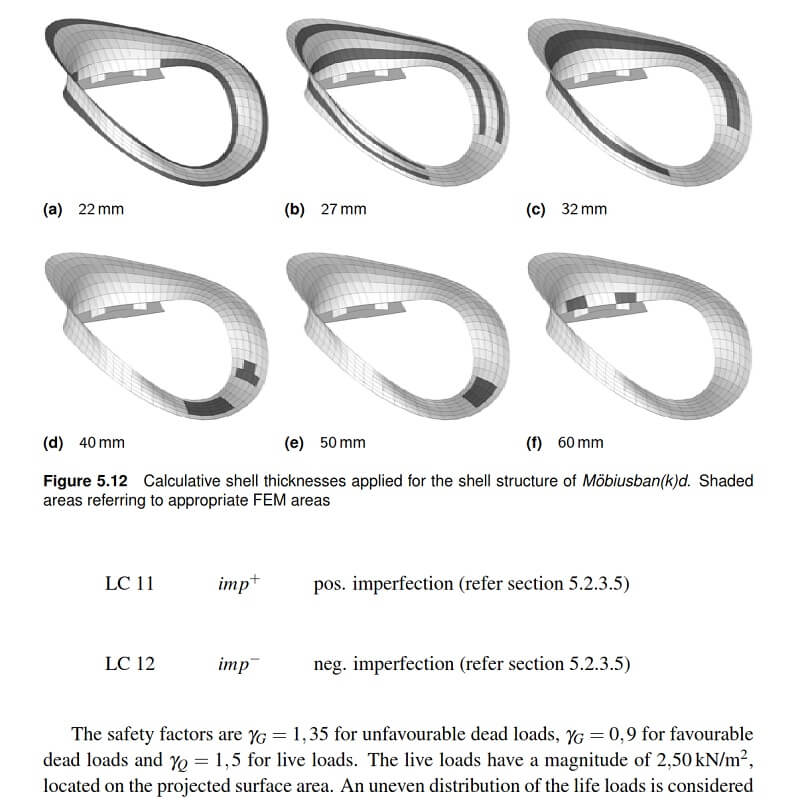

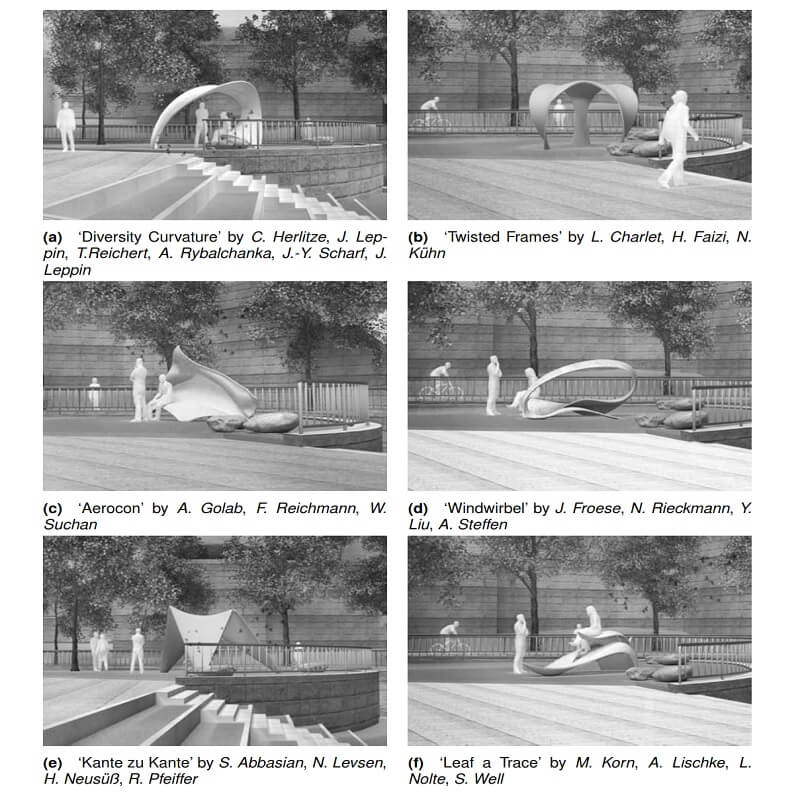

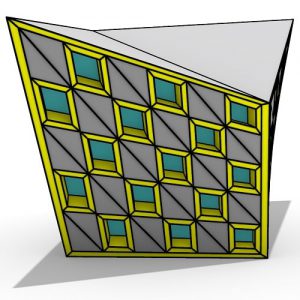

This thesis by Philipp Eisenbach examines the contradiction of the possibility to reduce cross-section dimensions, and the complexity of the discontinued homogeneity arising from segmentation. The objective is to expand the planning and the variety of contemporary concrete shells. Connection typologies are categorized according to their mechanical behaviour, to enable the development of jointing strategies. Selected case studies, all of them either exhibited or surrendered to the public, are demonstrating approaches, about how to implement pre-fabricated concrete elements on site.

Two developed connection methods are investigated in detail, and their applicability is verified by the evaluation of experimental examinations.

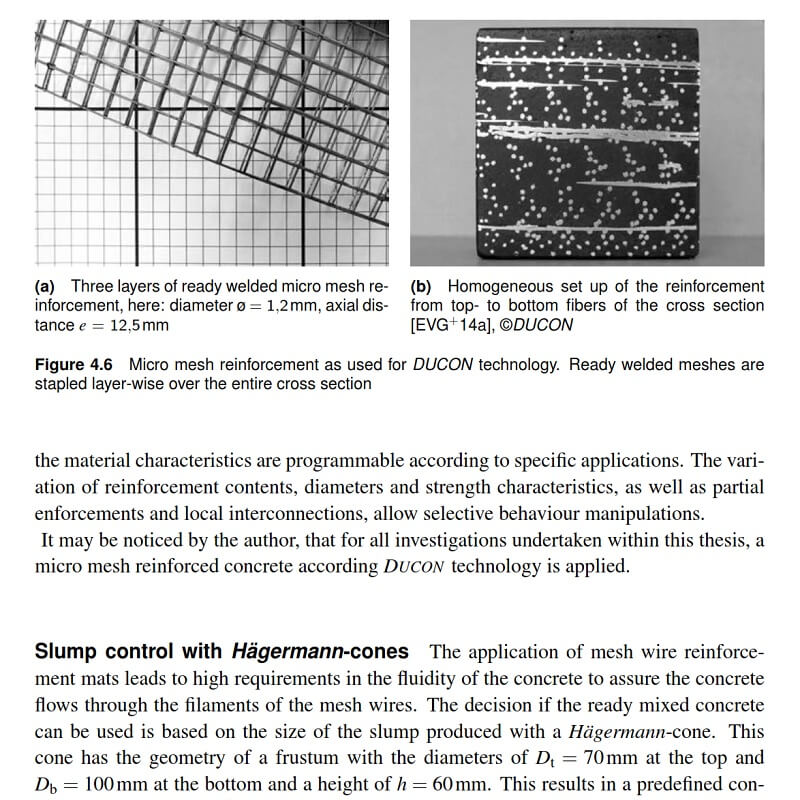

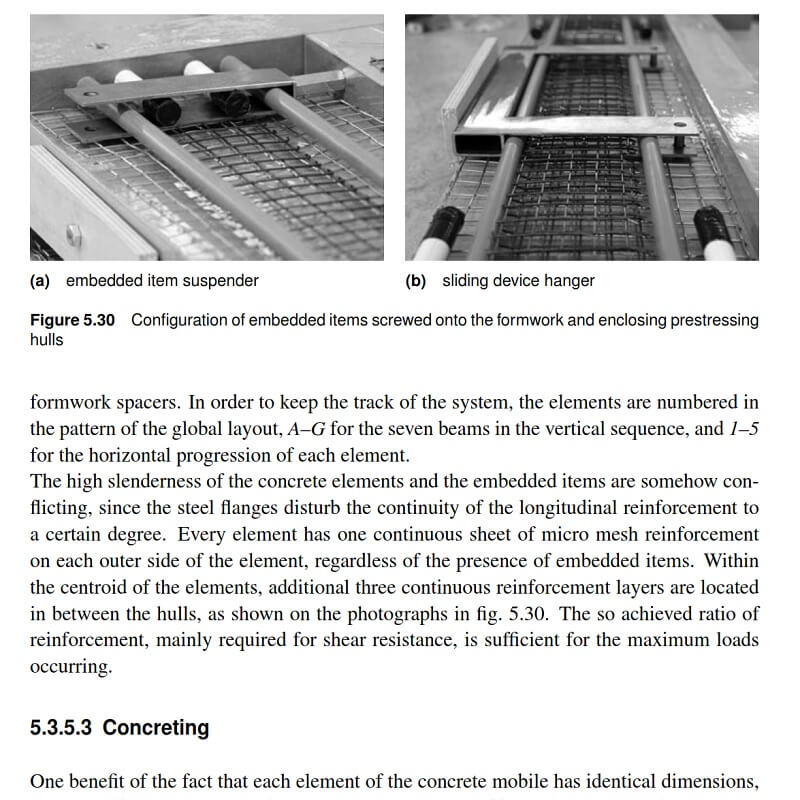

The ‘seamless rigid connection technique’ is a fully load bearing connection, in which the necessary overlapping of micro reinforcement layers within the joint zone is enabled by two subsequent casting steps and the associated invention of a stop-end technique.

The ‘micro prestressing connection technique’ is based on the idea to scale system dimensions of concrete sections. In analogy to mesh wire reinforcement, small prestressing media with small axial distances are constructed and embedded in slender concrete elements.

Comments