String Art Generator

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

Lattice structures are frequently found in nature and engineering due to their myriad attractive properties, with applications ranging from molecular to architectural scales. Lattices have also become a key concept in additive manufacturing, which enables precise fabrication of complex lattices that would not be possible otherwise.

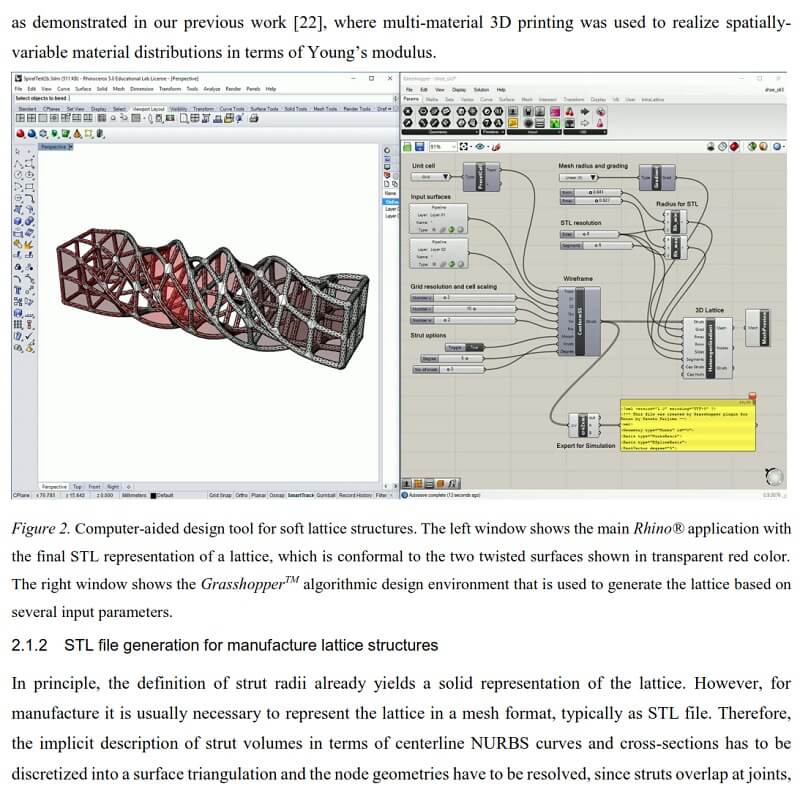

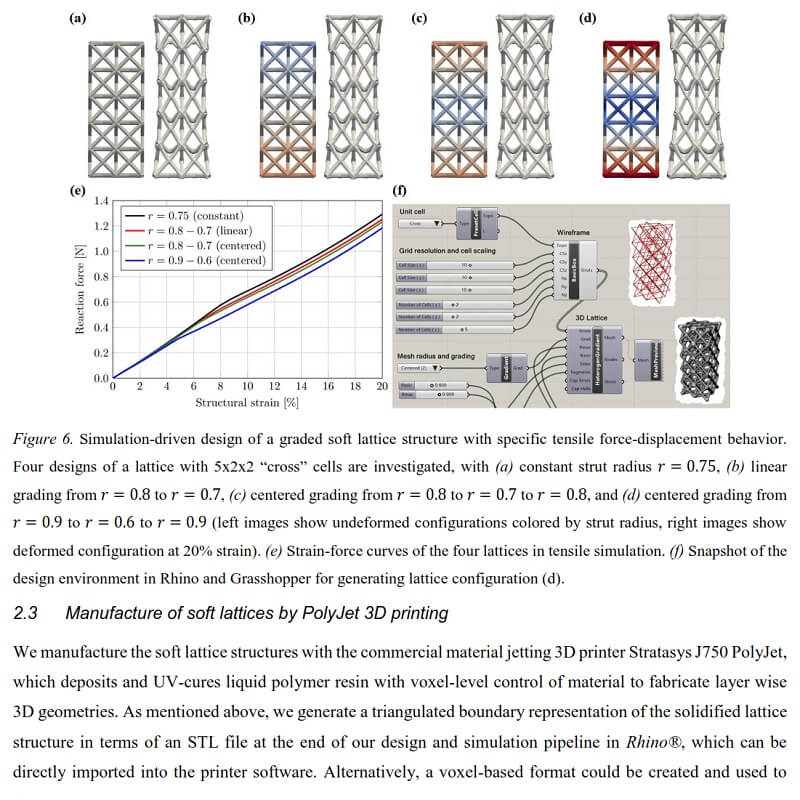

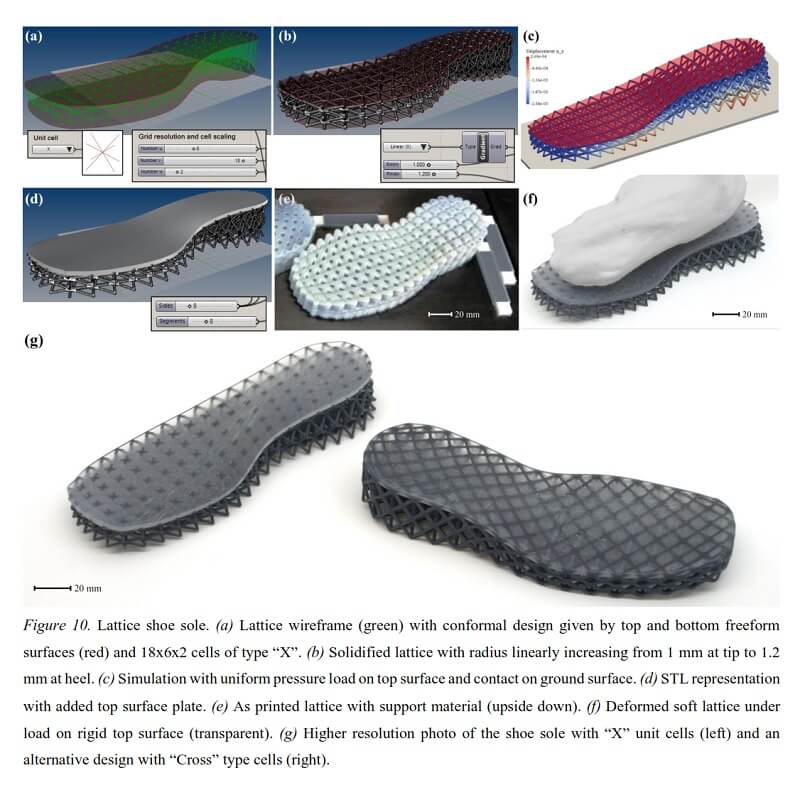

While design and simulation tools for stiff lattices are common, this article by O. Weeger, N. Boddeti, S.-K. Yeung, S. Kaijima and M. L. Dunn presents a digital design and manufacturing approach for soft lattices structures subject to large deformations and instabilities, for which applications in soft robotics, healthcare, personal protection, energy absorption, fashion and design are rapidly emerging.

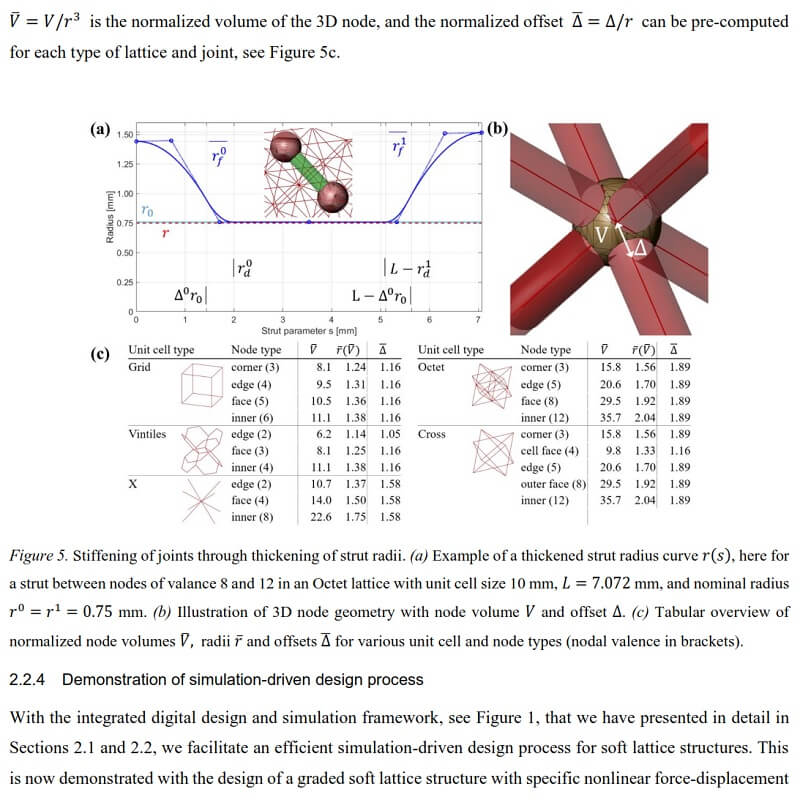

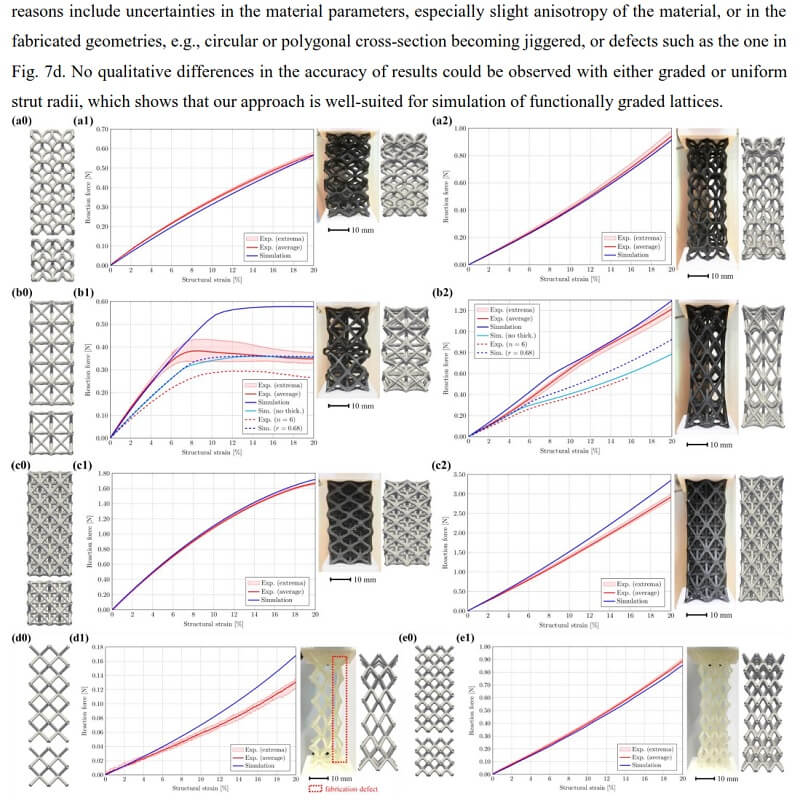

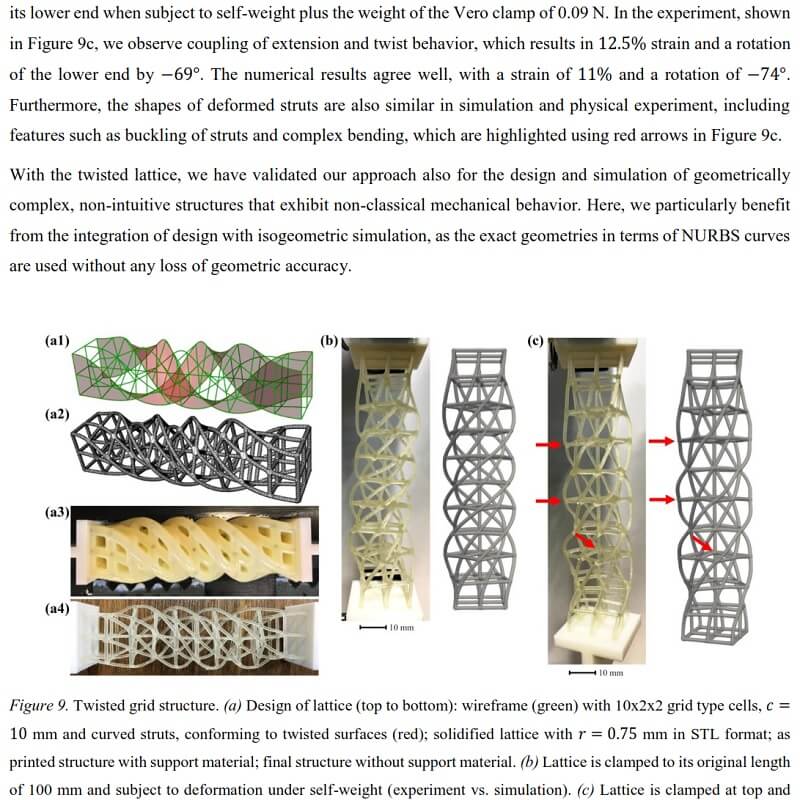

The framework admits soft lattices with curved members conforming to freeform geometries, and with variable, gradually changing member thickness and material, allowing the local control of stiffness. Authors model the lattice members as 3D curved rods and using a spline-based isogeometric method that allows the efficient simulation of nonlinear, large deformation behavior of these structures directly from the CAD geometries.

Furthermore, they enhance the formulation with a new joint stiffening approach, which is based on parameters derived from the actual node geometries. Simulation results are verified against experiments with soft lattices realized by PolyJet multi-material polymer 3D printing, highlighting the potential for design and application of non-uniform and curved soft lattice structures.

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

This paper by Alessandro Liuti, Sofia Colabella, and Alberto Pugnale, presents the construction of Airshell, a small timber gridshell prototype erected by employing a pneumatic formwork.

In this paper by Gregory Charles Quinn, Chris J K Williams, and Christoph Gengnagel, a detailed comparison is carried out between established as well as novel erection methods for strained grid shells by means of FE simulations and a 3D-scanned scaled physical model in order to evaluate key performance criteria such as bending stresses during erection and the distance between shell nodes and their spatial target geometry.

In this paper by Frederic Tayeb, Olivier Baverel, Jean-François Caron, Lionel du Peloux, ductility aspects of a light-weight composite gridshell are developed.

Parametric Ideas for Architects @2025