String Art Generator

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

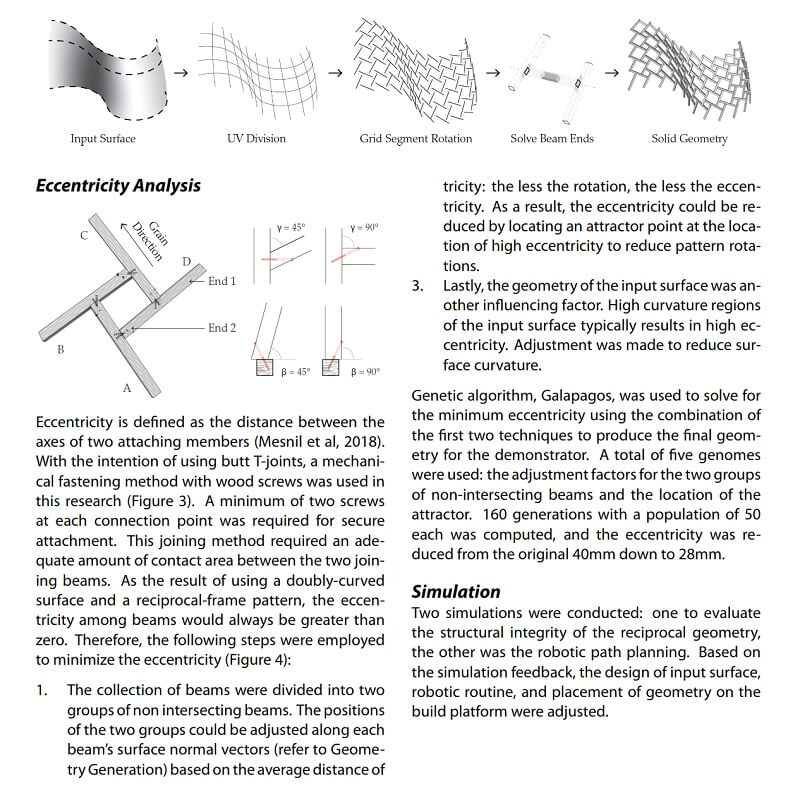

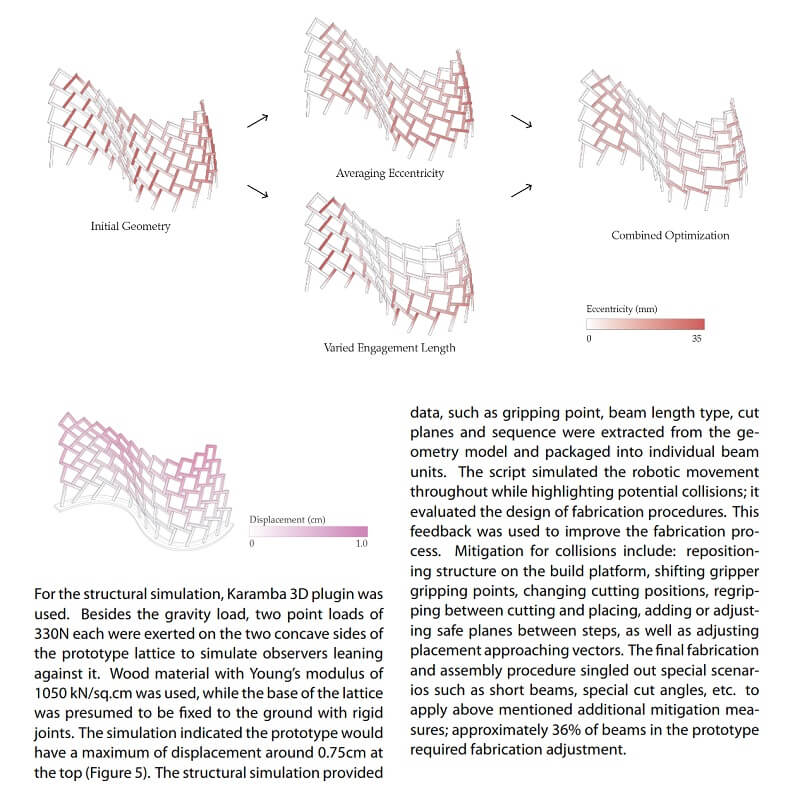

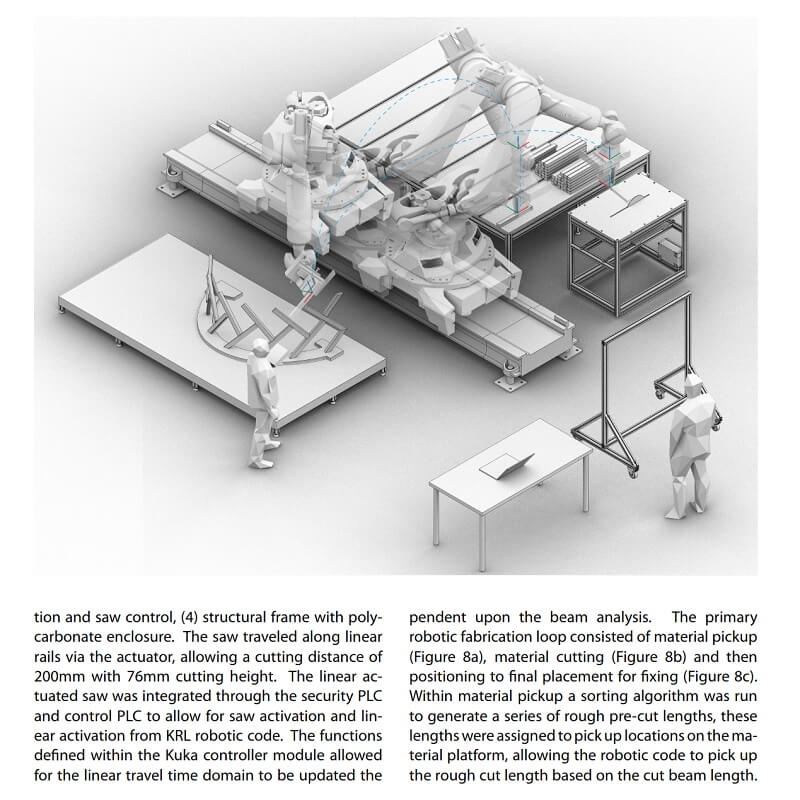

Though highly robust and economical, traditional lamella and reciprocal structural systems cannot adapt to surfaces with complex double curvature; as the timber members are standardized with no variation. Recent research has explored the use of computation for design, structural optimization, and use of robotic systems for the automated fabrication of timber joints.

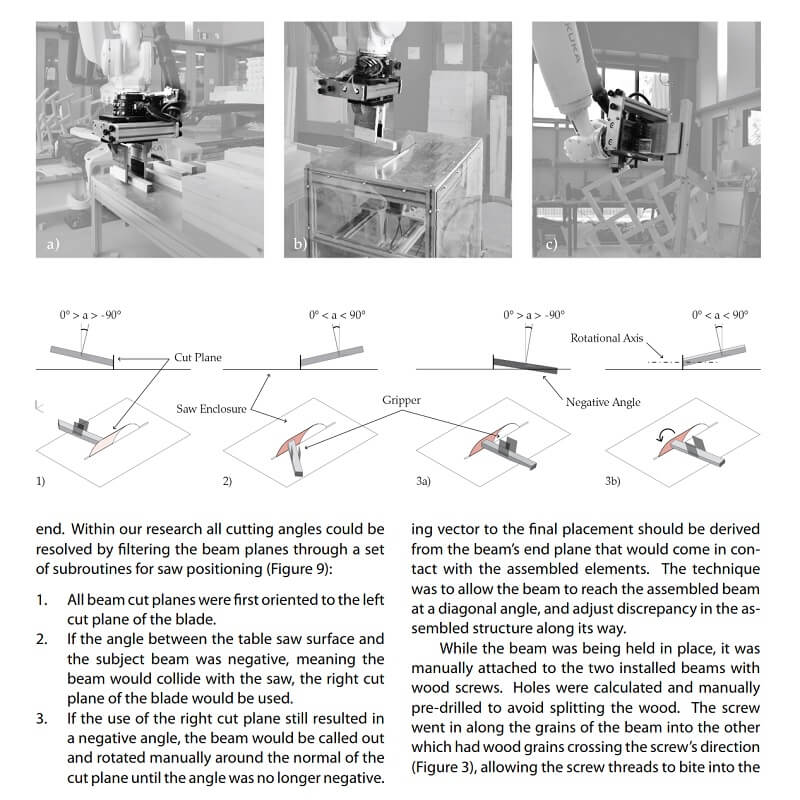

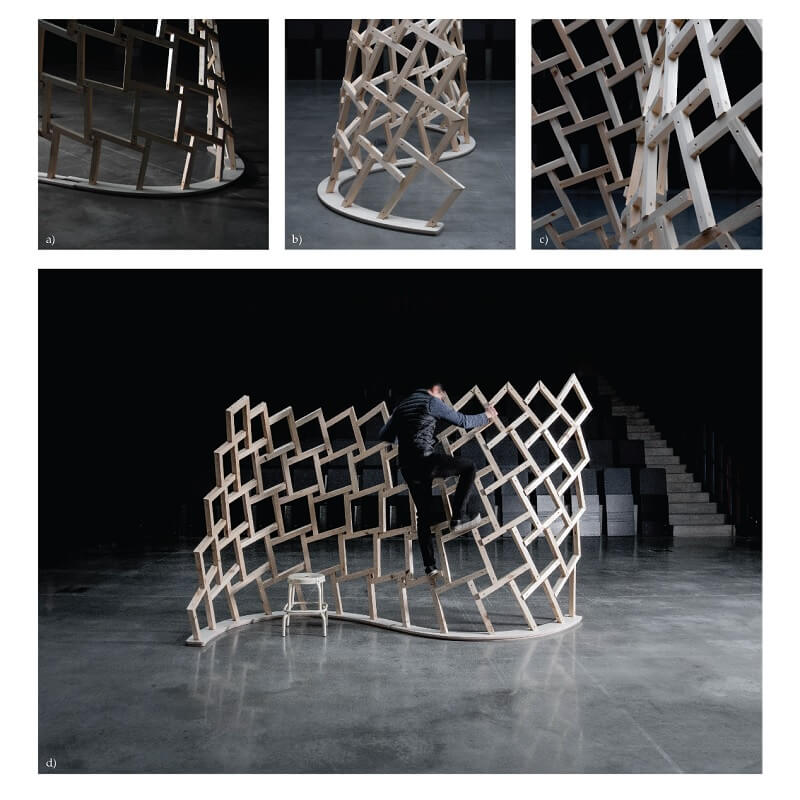

The disconnection between fabrication and assembly makes the construction of non-uniform double-curved reciprocal frames challenging, due to the required precise placement of discrete members with compound angle butt joints. This project investigates the use of robotic fabrication to cut and assemble a timber reciprocal frame assembly.

The disconnection between fabrication and assembly makes the construction of non-uniform double-curved reciprocal frames challenging, due to the required precise placement of discrete members with compound angle butt joints. This project investigates the use of robotic fabrication to cut and assemble a timber reciprocal frame assembly.

A computational model was created to generate the double-curved reciprocal frame geometry. Within this computational framework, joint analysis, fabrication, and assembly were monitored and adjusted to meet limiting factors. An industrial robot was implemented as a bridge between the computational model and the physical construction.

A computational model was created to generate the double-curved reciprocal frame geometry. Within this computational framework, joint analysis, fabrication, and assembly were monitored and adjusted to meet limiting factors. An industrial robot was implemented as a bridge between the computational model and the physical construction.

This paper by Ziju Xian, Nicholas Hoban and Brady Peters, presents a number of novel computational and robotic fabrication techniques in designing, cutting, and positioning. These techniques were explored through the robotic fabrication and assembly of a demonstrator – a double-curved reciprocal frame wall.

This paper by Ziju Xian, Nicholas Hoban and Brady Peters, presents a number of novel computational and robotic fabrication techniques in designing, cutting, and positioning. These techniques were explored through the robotic fabrication and assembly of a demonstrator – a double-curved reciprocal frame wall.

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

This paper by Alessandro Liuti, Sofia Colabella, and Alberto Pugnale, presents the construction of Airshell, a small timber gridshell prototype erected by employing a pneumatic formwork.

In this paper by Gregory Charles Quinn, Chris J K Williams, and Christoph Gengnagel, a detailed comparison is carried out between established as well as novel erection methods for strained grid shells by means of FE simulations and a 3D-scanned scaled physical model in order to evaluate key performance criteria such as bending stresses during erection and the distance between shell nodes and their spatial target geometry.

In this paper by Frederic Tayeb, Olivier Baverel, Jean-François Caron, Lionel du Peloux, ductility aspects of a light-weight composite gridshell are developed.

Parametric Ideas for Architects @2025