The Segment Lath

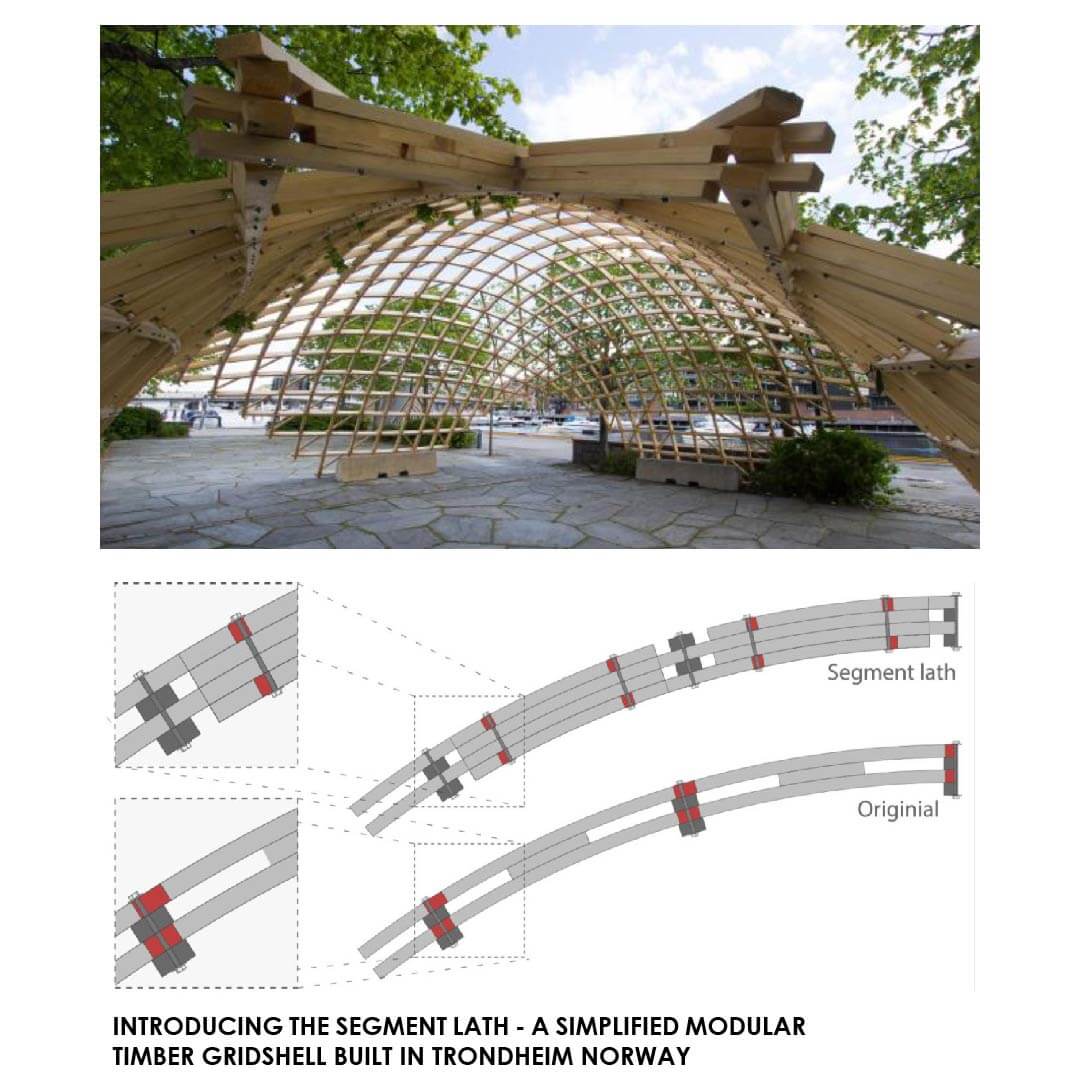

INTRODUCING THE SEGMENT LATH – A SIMPLIFIED MODULAR TIMBER GRIDSHELL BUILT IN TRONDHEIM NORWAY

John Haddal Mork1, Steinar Hillersøy Dyvik2, Bendik Manum1, Anders Rønnquist1, Nathalie Labonnote2

1Norwegian University of Science and Technology

2SINTEF

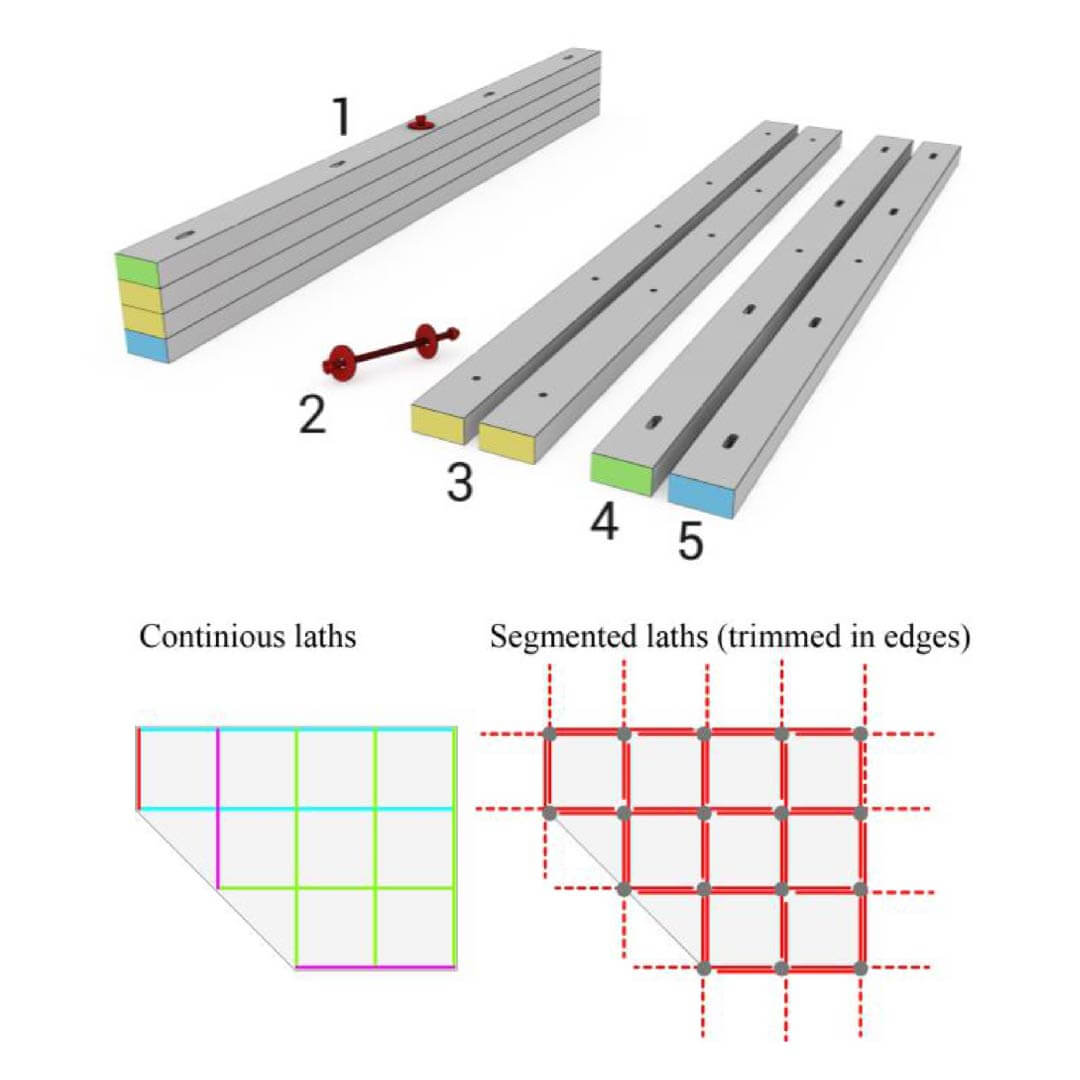

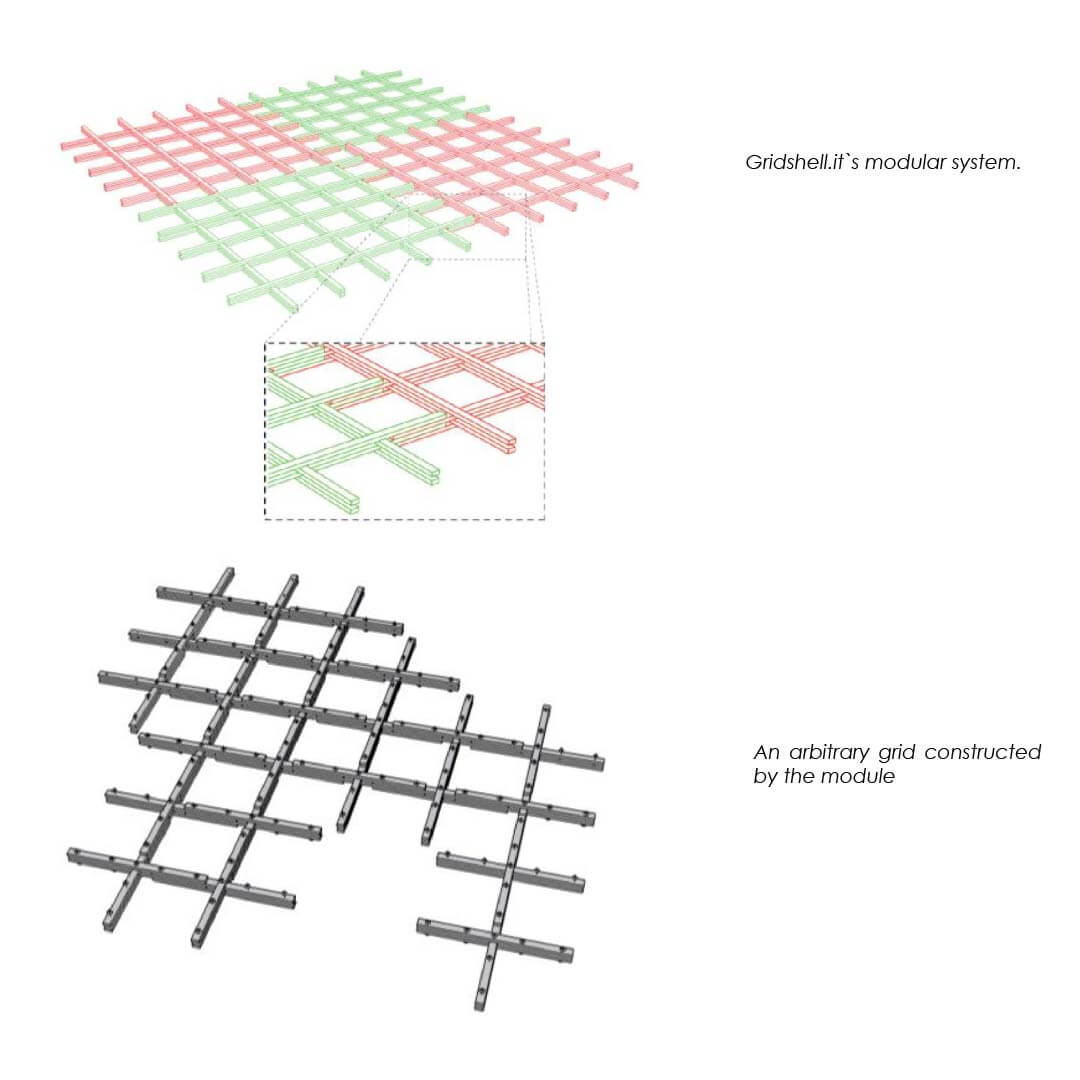

The paper introduces a kinematic gridshell principle built with the smallest possible module. The module consists of only two laths providing one node and the four connectors to adjacent nodes.

The solution is named the segment lath and the result is a system able to construct any quadratic grid shape using only one module type.

The solution is named the segment lath and the result is a system able to construct any quadratic grid shape using only one module type.

Among other assets, the system includes the function usually handled by additional shear blocks, it enables simplified manufacturing, compact transportation, fast construction and efficient use of materials.

Among other assets, the system includes the function usually handled by additional shear blocks, it enables simplified manufacturing, compact transportation, fast construction and efficient use of materials.

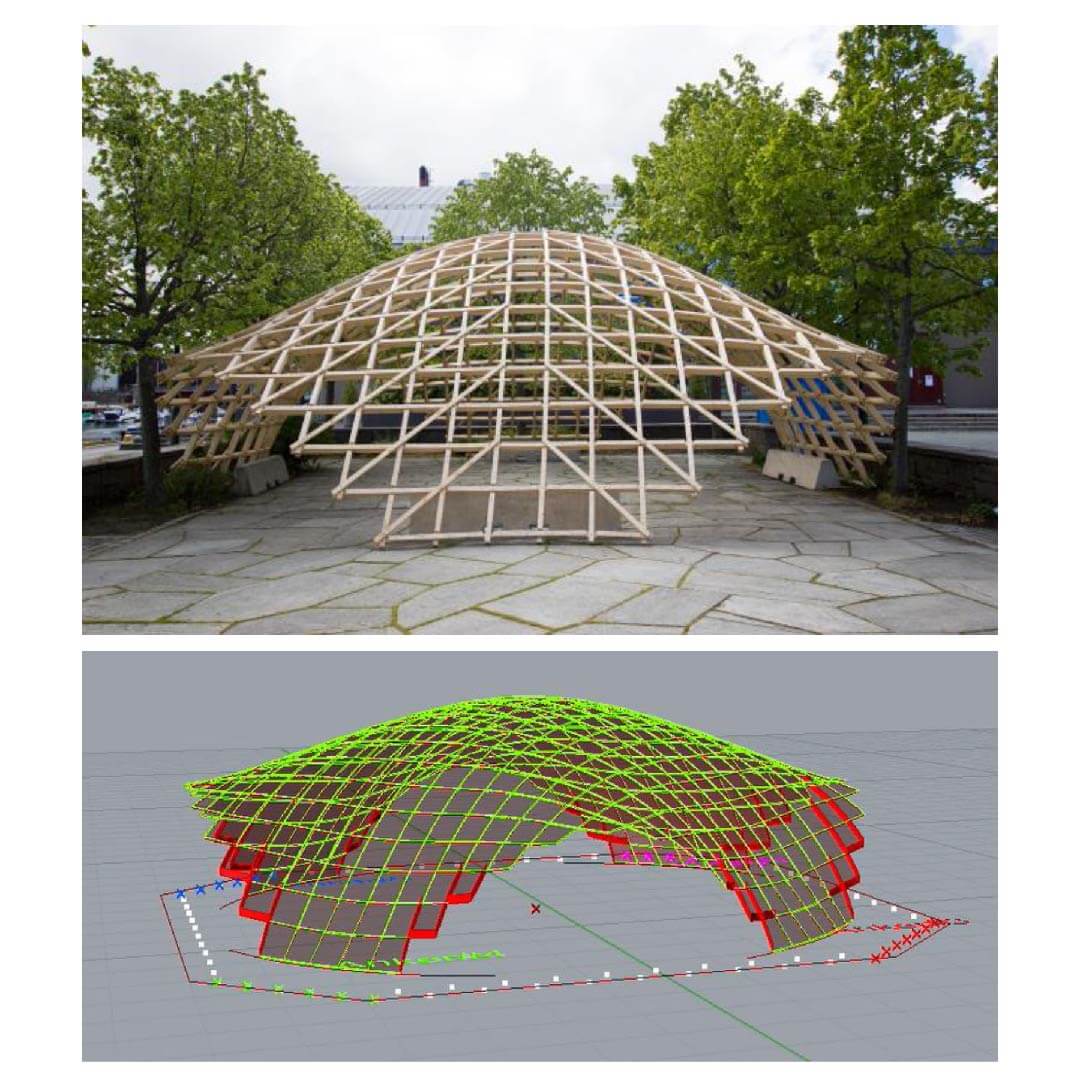

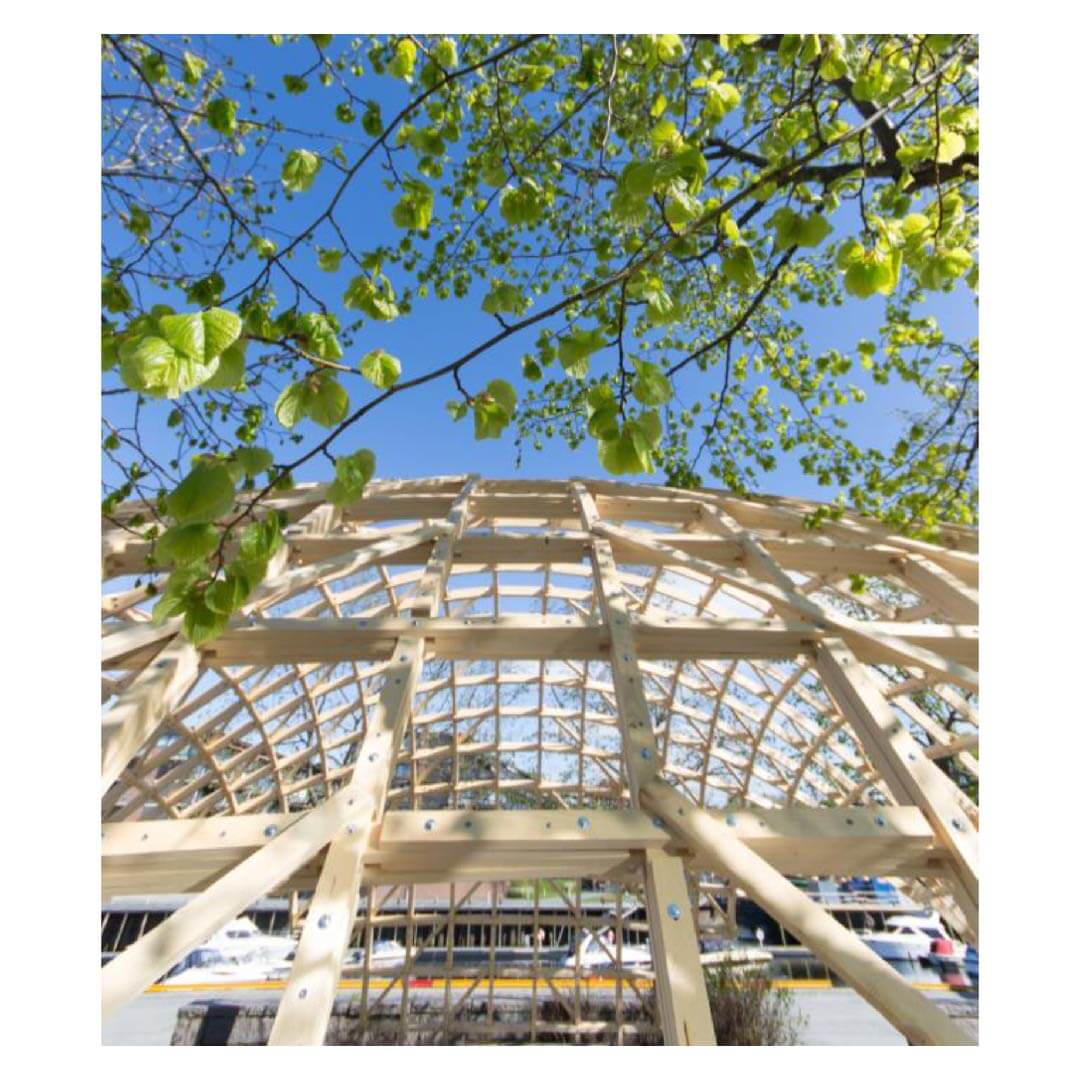

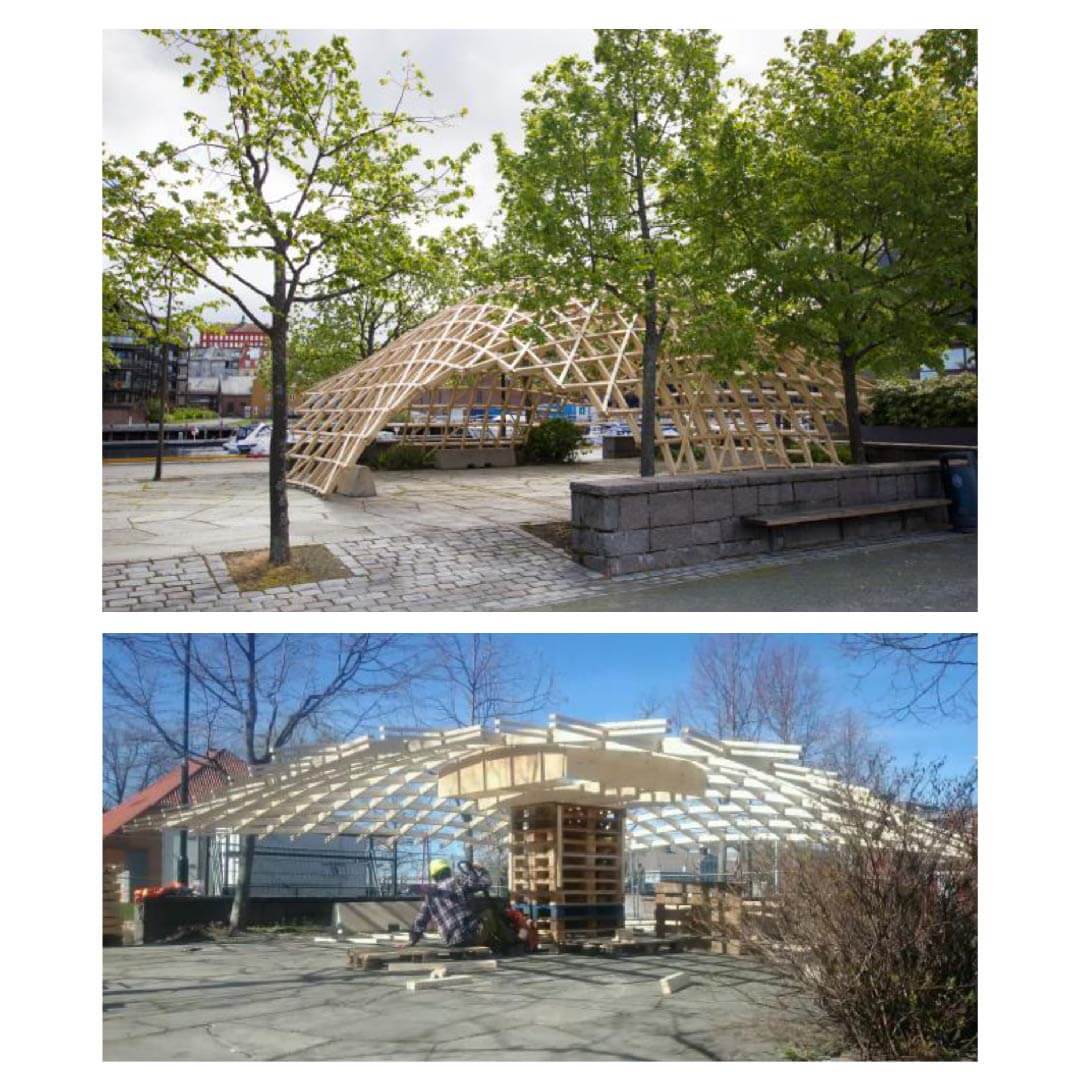

Further, the paper describes the process of designing and building a 10 meter full scale segment lath gridshell in Trondheim, Norway.

Further, the paper describes the process of designing and building a 10 meter full scale segment lath gridshell in Trondheim, Norway.

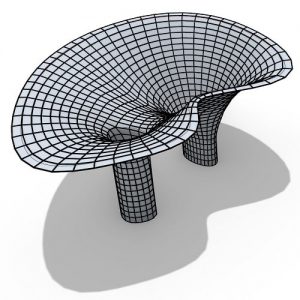

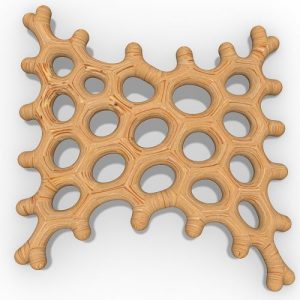

The elegance of a gridshell lies in its complex shape built up by simple elements. A kinematic gridshell, originally called timber lattice roof, is defined as a flat squared lattice that is lifted (or lowered) into a doubly curved shape.

The elegance of a gridshell lies in its complex shape built up by simple elements. A kinematic gridshell, originally called timber lattice roof, is defined as a flat squared lattice that is lifted (or lowered) into a doubly curved shape.

In principle, the same connection detail can be applied in all nodes except for the edges. In addition, the distance between the nodes are uniform.

In principle, the same connection detail can be applied in all nodes except for the edges. In addition, the distance between the nodes are uniform.

Natural limitations determine the length of laths. A high-quality timber-lath, off the shelf, can be up to six meters, but depending on chosen specie and irregularities, most laths must be trimmed to achieve the needed quality.

Natural limitations determine the length of laths. A high-quality timber-lath, off the shelf, can be up to six meters, but depending on chosen specie and irregularities, most laths must be trimmed to achieve the needed quality.

The laths are then joined by various techniques to achieve the required lengths of the laths in the complete shell.

Gridshells have been developed since 1890’s by the pioneer Vladimir Shukhov, but Frei Otto together with Edmund Happold and Ian Liddel is a main reference regarding the development of the timber based kinematic gridshell.

Gridshells have been developed since 1890’s by the pioneer Vladimir Shukhov, but Frei Otto together with Edmund Happold and Ian Liddel is a main reference regarding the development of the timber based kinematic gridshell.

In 1975, they constructed and built the Mannheim Multihalle, a 7400 m2 gridshell that spans up to 85 m. Their solution was a double layer configuration using 50x50mm hemlock laths. Extension of laths were done by finger joints.

In 1975, they constructed and built the Mannheim Multihalle, a 7400 m2 gridshell that spans up to 85 m. Their solution was a double layer configuration using 50x50mm hemlock laths. Extension of laths were done by finger joints.

Comments