Thin Folded Members

Design and Fabrication of Thin Folded Members with Digital

Concrete Processes

ANNA SZABÓ

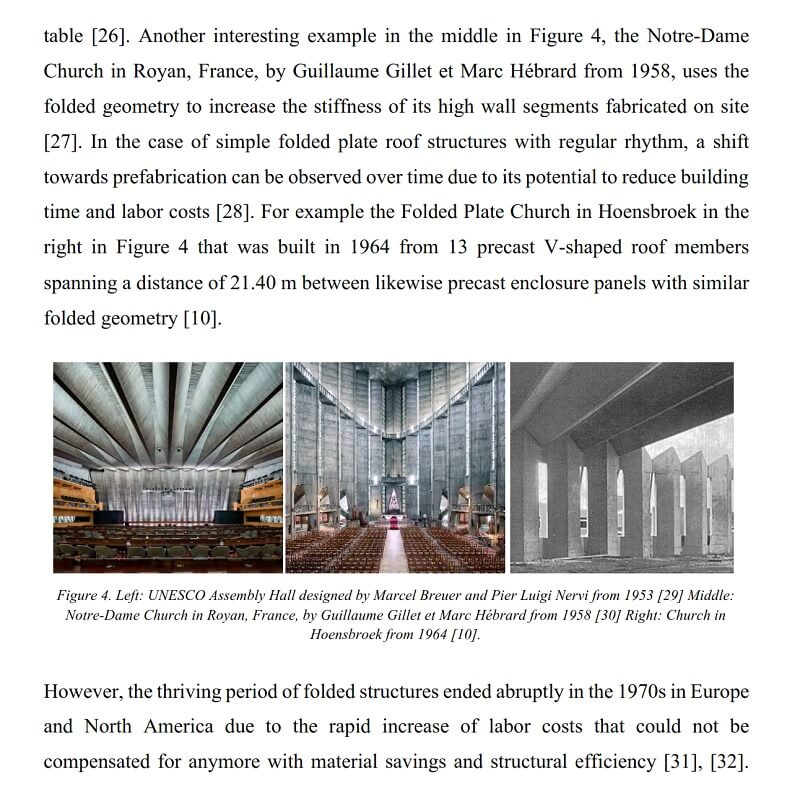

A thesis submitted to attain the degree of

DOCTOR OF SCIENCES of ETH ZÜRICH

2020

Concrete is the most widely used man-made building material in the world. It is traditionally cast in a fluid state to formworks where it hardens to a strong and durable material. However, the vast quantities of concrete are responsible for a substantial proportion of global CO2 emissions and the heavy-duty formworks that shape concrete in conventional construction are the major contributors to the overall costs and waste.

Thus, over the history of concrete different approaches evolved to increase the ecological and economical sustainability of concrete structures and this research aims to join this effort. The topic of this research by Anna Szabo is thin folded concrete structures that provide a material-efficient solution for spanning large distances due to the increased load-bearing capacity of their folded form.

Thus, over the history of concrete different approaches evolved to increase the ecological and economical sustainability of concrete structures and this research aims to join this effort. The topic of this research by Anna Szabo is thin folded concrete structures that provide a material-efficient solution for spanning large distances due to the increased load-bearing capacity of their folded form.

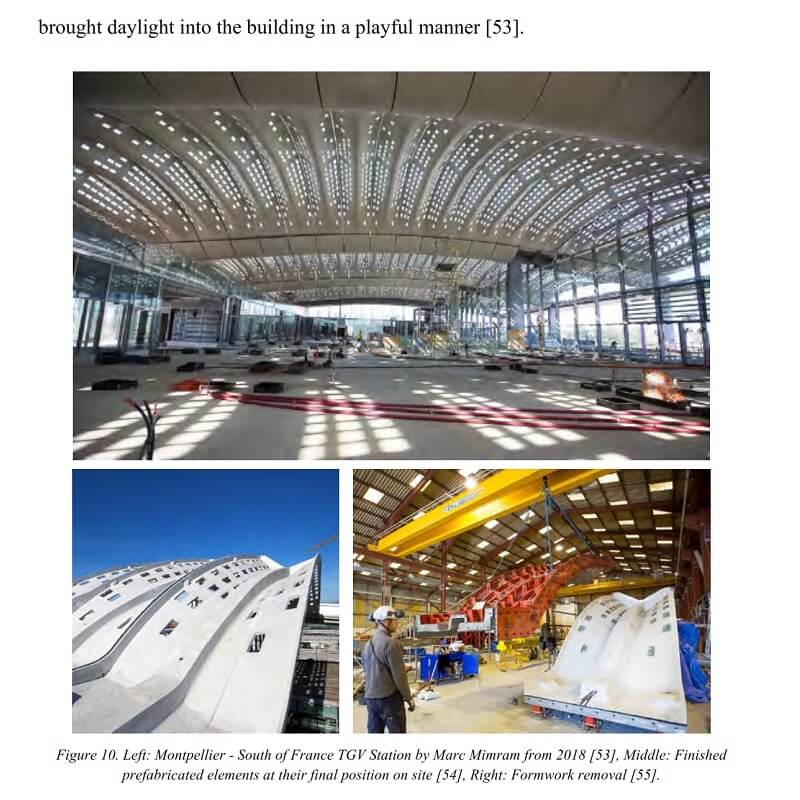

Today, the number of these projects decreased significantly due to their complicated formworks and labour-intensive realization, while their advantages remained relevant. Therefore, this thesis aims to provide efficient production methods for folded structures by using digital fabrication processes with concrete and allow for their widespread use again.

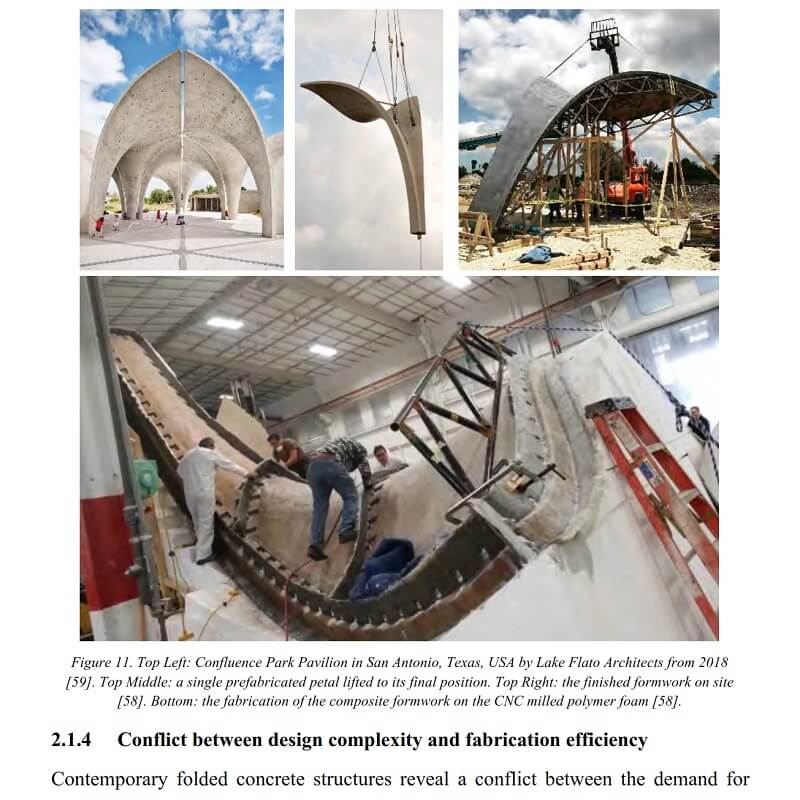

Today, the number of these projects decreased significantly due to their complicated formworks and labour-intensive realization, while their advantages remained relevant. Therefore, this thesis aims to provide efficient production methods for folded structures by using digital fabrication processes with concrete and allow for their widespread use again.

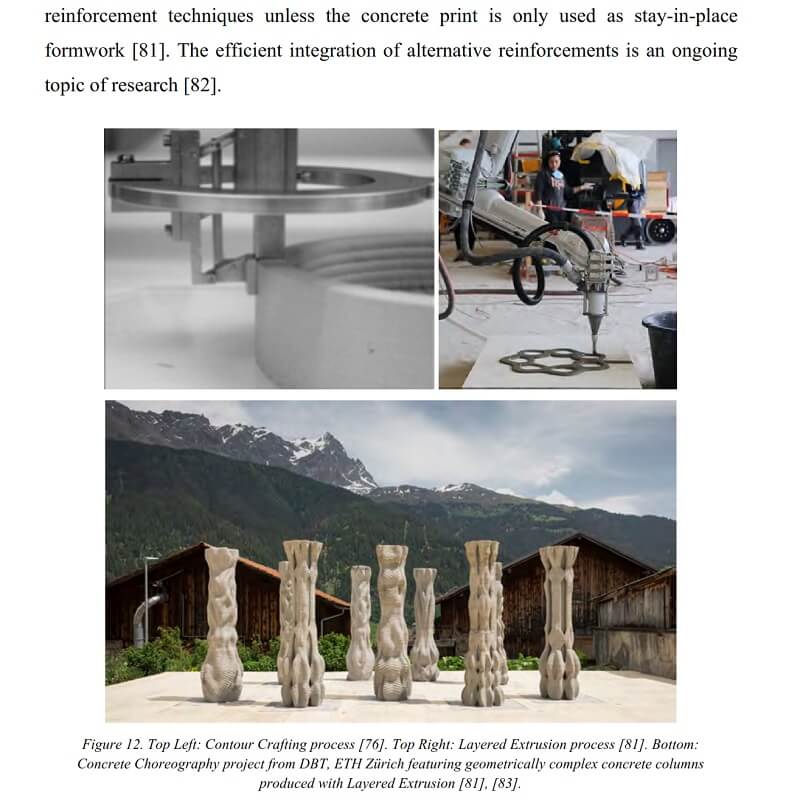

To achieve this goal, a robotic slipcasting process called Smart Dynamic Casting (SDC) was selected and studied with both empirical and analytical methodology. The empirical investigation showed that it was more difficult to produce thin folded prototypes with SDC than columns or mullions and the analysis provided an explanation with a theoretical process model.

To achieve this goal, a robotic slipcasting process called Smart Dynamic Casting (SDC) was selected and studied with both empirical and analytical methodology. The empirical investigation showed that it was more difficult to produce thin folded prototypes with SDC than columns or mullions and the analysis provided an explanation with a theoretical process model.

This model of SDC showed that the friction between the concrete and the moving formwork affects the slipping process more in relative terms with the small hydrodynamic radius (volume to surface ratio) of the thin folded formwork than previously.

This model of SDC showed that the friction between the concrete and the moving formwork affects the slipping process more in relative terms with the small hydrodynamic radius (volume to surface ratio) of the thin folded formwork than previously.

Although the model provided guidelines for material adjustments for the production of thin folded prototypes, the height and the geometries stayed limited. Thus, further research was conducted to improve the set on demand material system used in SDC with a custom dual acceleration method leading to a novel process coined as Admixture Controlled Digital Casting (ACDC).

Although the model provided guidelines for material adjustments for the production of thin folded prototypes, the height and the geometries stayed limited. Thus, further research was conducted to improve the set on demand material system used in SDC with a custom dual acceleration method leading to a novel process coined as Admixture Controlled Digital Casting (ACDC).

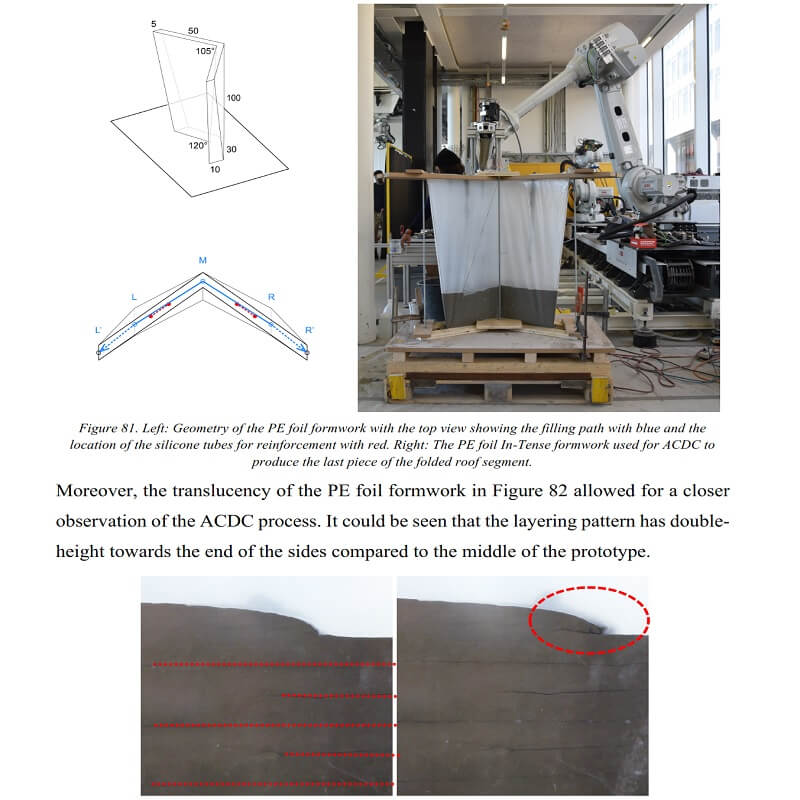

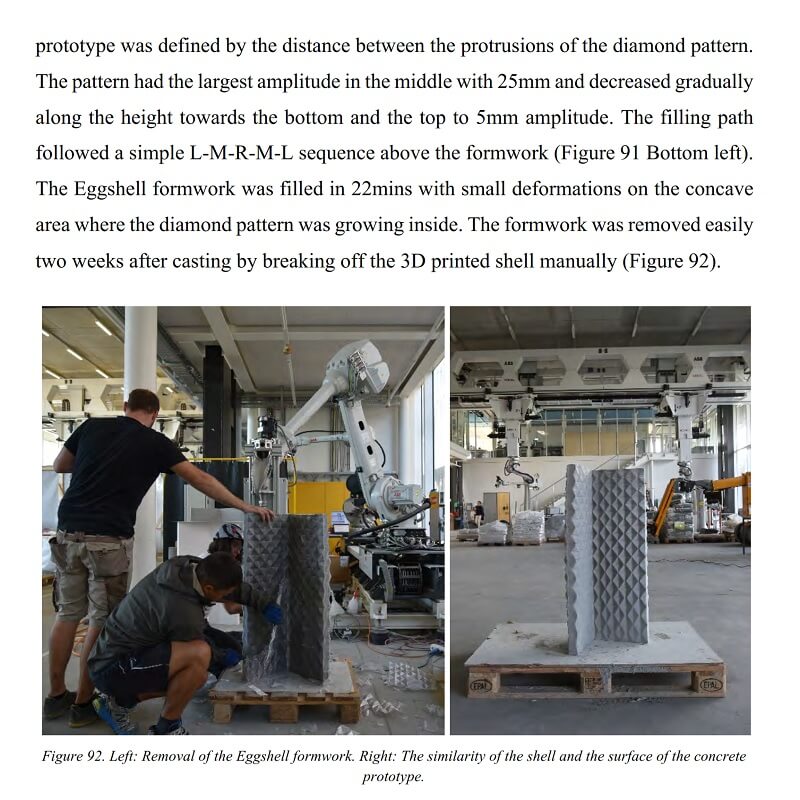

In ACDC, stationary weak formworks are filled robotically with a fast-hardening set on demand concrete to reduce the pressure from casting. The robust production of thin folded structures with ACDC was demonstrated with various cheap and simple formworks, such as the In-Tense system where thin materials are held by rigid frames, the 3D printed Eggshell formwork or the curved folded paper board formwork.

In ACDC, stationary weak formworks are filled robotically with a fast-hardening set on demand concrete to reduce the pressure from casting. The robust production of thin folded structures with ACDC was demonstrated with various cheap and simple formworks, such as the In-Tense system where thin materials are held by rigid frames, the 3D printed Eggshell formwork or the curved folded paper board formwork.

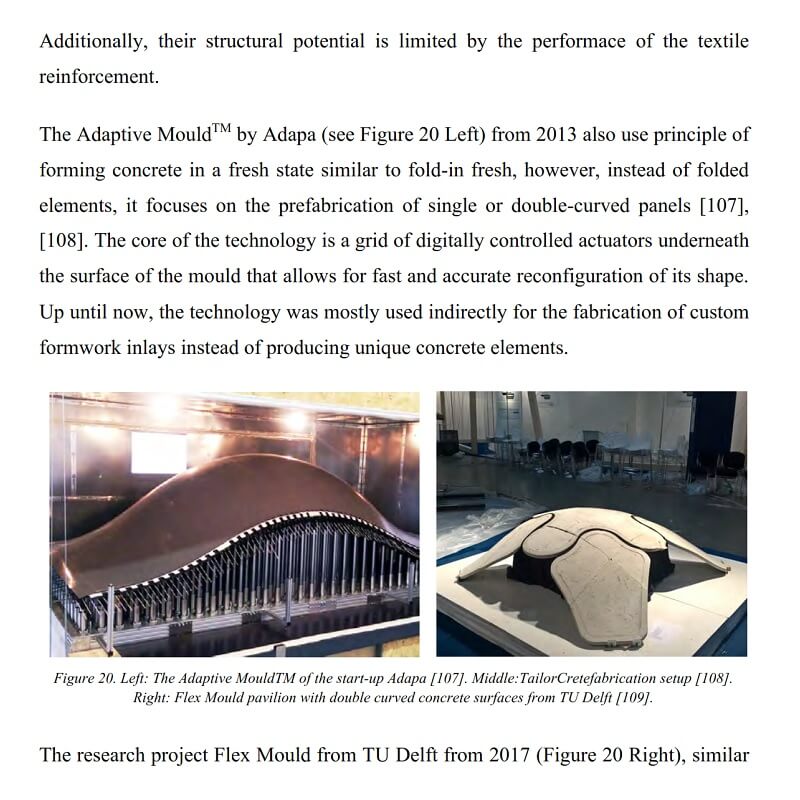

Finally, the assembly of three prototypes to a post-tensioned roof segment proved the viability of the ACDC method for thin folded concrete structures at an architectural scale.

Finally, the assembly of three prototypes to a post-tensioned roof segment proved the viability of the ACDC method for thin folded concrete structures at an architectural scale.

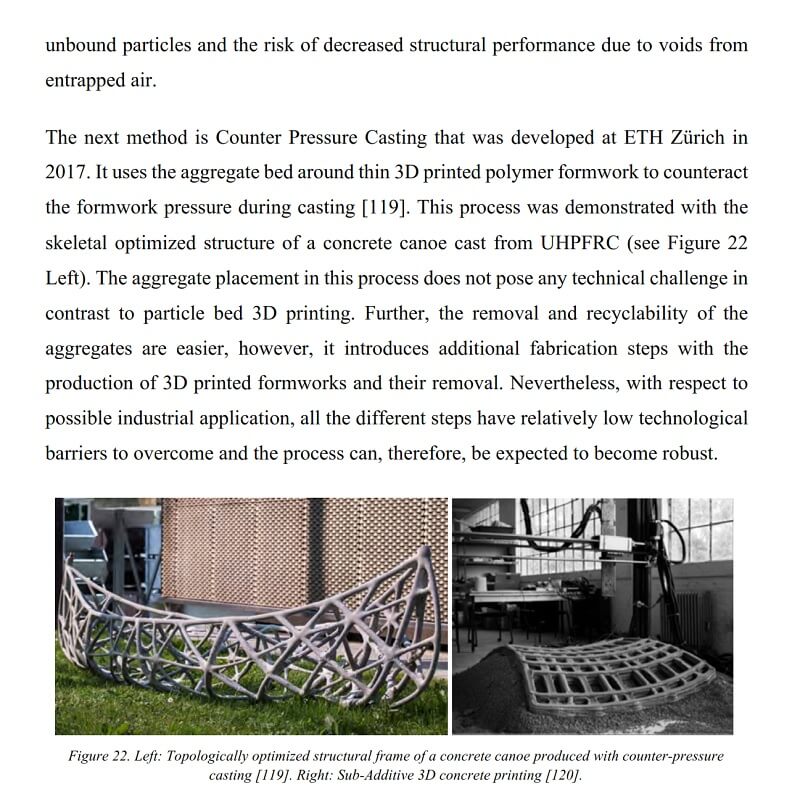

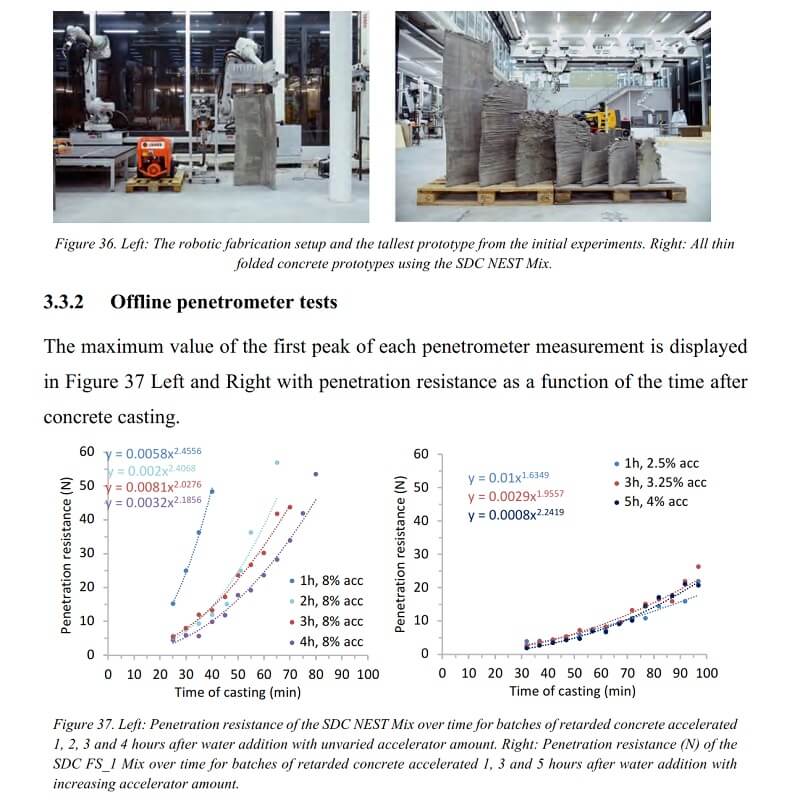

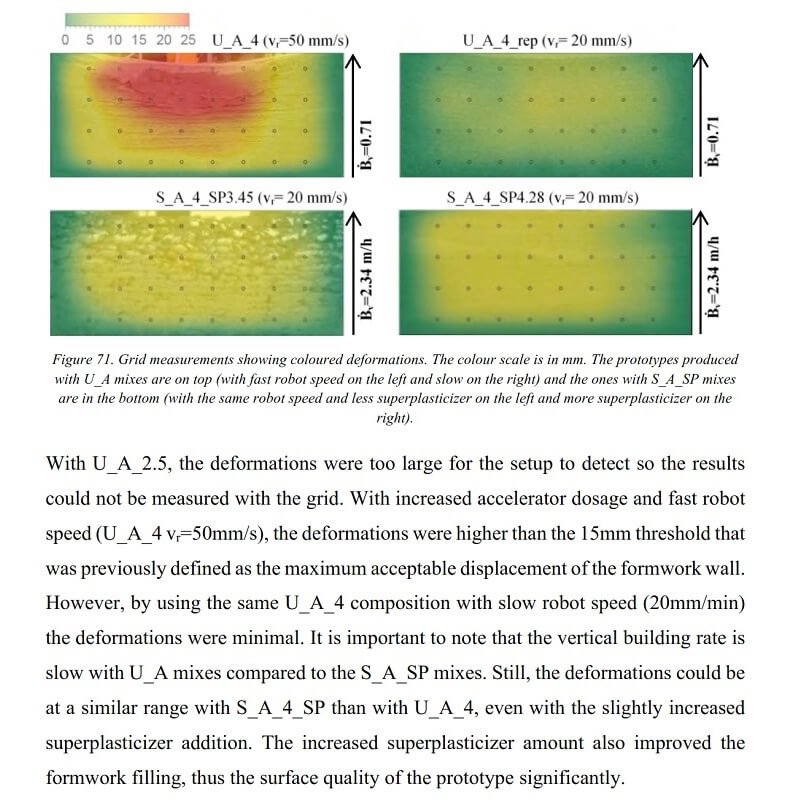

Comments