Lightweight Dismountable Structures

Hinged Folded Festival Pavilion – Membrane Bearing in Lightweight Dismountable Structures

Manfred GROHMANN*, Philipp EISENBACHa, Moritz RUMPFb, Cynthia WARDc

*Professor, CEO – School of Architecture, University of Kassel Bollinger + Grohmann Ingenieure, Germany

a, b PhD Candidate – School of Architecture, University of Kassel, Germany

c Master Candidate – School of Architecture, University of Kassel, Germany

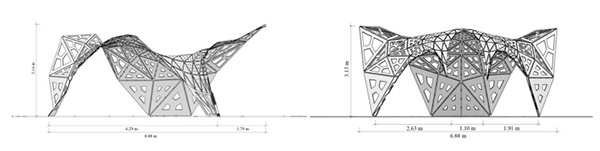

Figure 01: Visualization of the folded structure made of planar timber elements. The pavilion is designed as a meeting point and sun shelter for the German festival A Summer’s Tale.

Lightweight and dismountable structures are valuable examples in future building industry. Not only due to aesthetical reasons but also in order to use material in a resource conserving way. An increasing speed of changes of user demands of the built environment results in the exertion of temporary structures ensuring not only a quick installation but also an unpretentious de- and reassembly.

Figure 02: Sections with outline dimensions of the envisaged, slender structure.

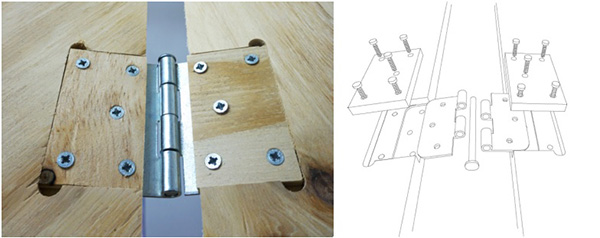

Folded structures as well as tessellated freeform structures with a load bearing behaviour reduced to membrane action allow the application of fully hinged connections at the adjacent edges of the surfaces. In consequence the construction of the joints can be simplified to modular low-tech systems with no constraints to the global geometry of the architectural design.

Figure 03: A connection detail was chosen and implemented, which is identical throughout the entire structure. It is fully hinged and therefore can take any angle. Furthermore, it allows a simple mounting by inserting bolts.

The building industry is directly affected by current global challenges of climate- and demographic changes. A significant portion of the required energy during the live cycle of our buildings is covered within the grey energy – the part of the embodied energy of each building element which is not considered in some of the commissioned certification institutes of sustainable building design. An increasing speed of changes of user demands of the build environments directs to a rethinking of design approaches and building technology.

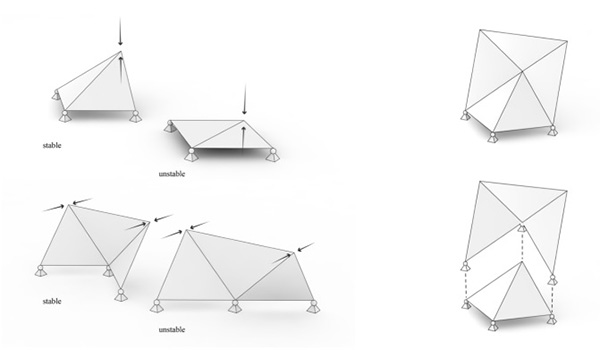

Figure 04 (left): A tessellated structure with hinged joints gains stability when no two faces are in one plane (top) AND no three adjacent supports are in one line (bottom).

The construction of lightweight and filigree structures is – beside its aesthetic benefits – one approach to utilize materials in a recourse conserving way. Enormous developments over the past decade in digitizing planning and design processes enable the analysis of complex geometries under consideration of multiple boundary conditions.

Figure 06: Exemplary structural manipulations illustrate the development of stability gained by folding.

Despite the possibilities of digital tools and fabrication methods, the way of thinking of the construction industry is dominated by the standards of industrial production and buildings are assembled of massive elements under flexural stress.

Material savings and slenderness is achieved by both, the application of high performance materials and the negotiation of the force flow by generating form active structures. The form manipulation towards a load bearing with axial-, avoiding in-plane bending stresses, leads to an activation of membrane actions with an optimized utilization of the material, as described by Eisenbach et al.

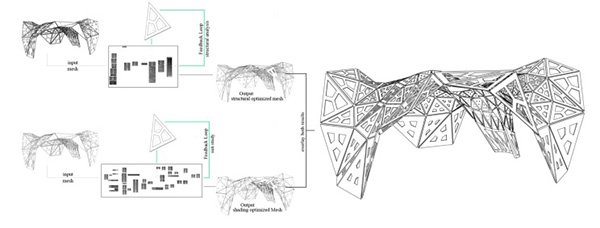

Figure 07: Multiple design parameters are implemented in the architectural layout. Openings in planar elements are derived from light- and shade analysis as well as structural analysis. Both results are overlaid.

The production of complex building elements, embedded within an integral and digital workflow postulates the prefabrication under laboratory conditions to assure a sufficient accuracy and to minimize construction times on site, especially in densified urban areas. Thus a special focus is put on the construction of jointing techniques.

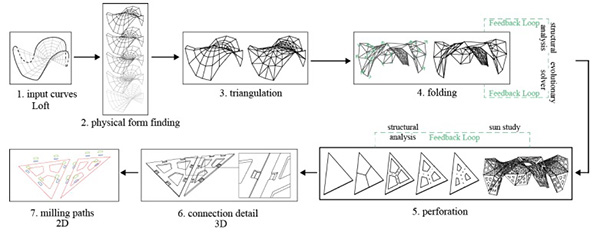

Figure 08: Workflow of the design process. A consistent digitally controlled chain from design to fabrication allowed for an efficient realization of a prototype.

Temporary structures and event architecture even emphasize the demands to efficient assembly concepts: Not only may a quick assembly, but also an unpretentious de- and reassembly be necessary. Thus a non-destructive dismounting is taken for granted.

The festival pavilion processed within a one-semester studio looked into the depicted subject. The result is a form-active structure with a stability gained through folding. A low-tech construction with fully hinged connection is developed fulfilling the requirements of a quick and easy construction on site.

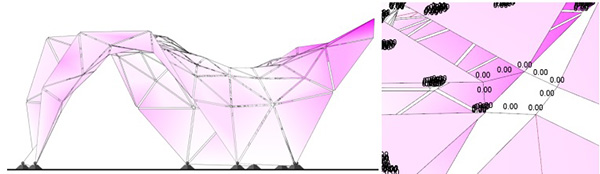

Figure 10: Structural behavior of the pavilion investigated in a live analysis within a parametric environment (left). The planar shell elements are interconnected with virtual hinges with element forces that converge to zero with the help of optimization solvers (right).

The material and machining effort to create curved or even double curved objects is exponentially higher compared to planar objects – or objects made out of planar elements. Taking the small budget into account, it was thus obvious to work with wooden sheet material (22mm plywood made of pinewood), which could be machined with our in-house facilities (3-axis CNC milling machine). Therefore, any freeform geometry has to be approximated through tessellation.

The most straight-forward approach to tessellation is to employ triangulation, since triangles are planar by default whereas the creation of planar faces with more than three corners is extremely challenging.

Figure 11: Constructing the mock-up verified the developed connection system with fully hinged joints.

A festival pavilion has been designed fulfilling architectural functions of usage as well light- and shading boundary conditions and structural integrity. The overall form has been triangulated in a way that a fabrication from planar timber plates is possible with the use of a 3-axis milling machine.

Main aspect and however design decisive is the global form finding with stabilizing folding, allowing the application of fully hinged connections. The connections developed are identical in construction throughout the entire structure regardless the angle of two adjacent plates, simplifying the mounting and construction process significantly.

Figure 12 (left): Visualization of the proposed slender festival pavilion.

Figure 13 (right): 3d printed model of final design in front of the 1:1 mock-up.

Investigations have been undertaken to implement the stabilizing manipulation of the geometry in a general approach in parametric software tools. These investigations are based on virtual spring forces converging to zero with the help of optimization solvers.

This future form finding software tool in combination with the demonstrated and tested hinged connection technique opens up a wide variety in freeform structures made of planar raw materials, especially when uncomplicated and consistent mounting and a non-destructive de- and reassembly is required.

Comments