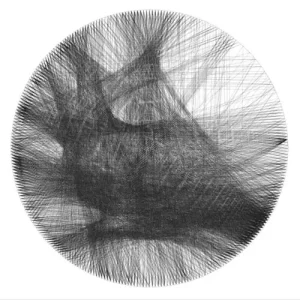

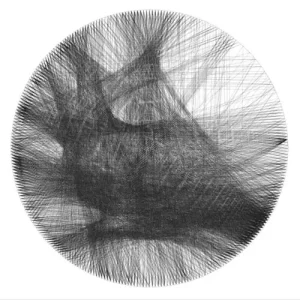

String Art Generator

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

Kerf bending: ruled double curved surfaces Manufacturing

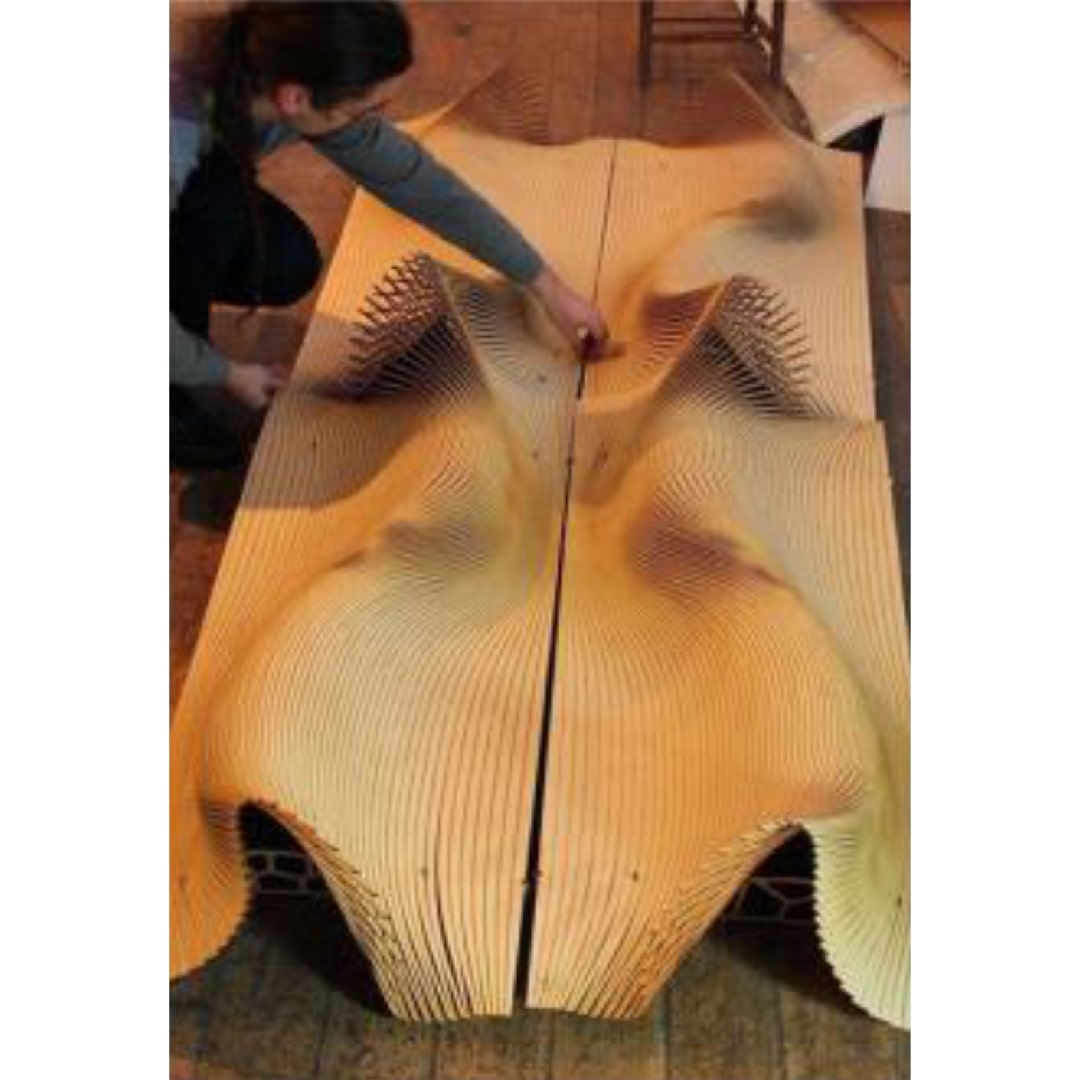

Knowledge of geometric properties of surfaces is crucial for the resolution of many manufacturing problems. Developability is an important intrinsic property of a surface, because it allows its manufacture starting from a flat “strip” of a “flexible” and “non-deformable” material.

Digital fabrication technologies are evolving and becoming more and more widespread. Knowledge of fabrication methods available and parametric design tools, based on geometry, are changing the designer way to think.

Advances in this field promotes the experimental use of new materials but also the innovative use of traditional materials, such as wood. Our research, in the field of wooden curved surfaces fabrication, move from developable surface manufacturing and from “paneling” to “kerfing”.

Advances in this field promotes the experimental use of new materials but also the innovative use of traditional materials, such as wood. Our research, in the field of wooden curved surfaces fabrication, move from developable surface manufacturing and from “paneling” to “kerfing”.

This technique consists in transforming a rigid material in a flexible one and the problem to solve is how to cut the flat shape to obtain the design surface. This is a quite simple question to solve for a developable surface but it is a very complex problems to address for double curvature surface manufacturing.

Geometric genesis of surfaces and knowledge of their properties are crucial for solving many problems, both constructive and measurement. A developable surface can be manufactured starting from a flat “strip”, using a flexible and non-deformable material.

Geometric genesis of surfaces and knowledge of their properties are crucial for solving many problems, both constructive and measurement. A developable surface can be manufactured starting from a flat “strip”, using a flexible and non-deformable material.

This is a very important feature of the surface. Geometry studies the properties that don’t change and, therefore, the shape of the “strip” to obtain a certain configuration, after a series of rigid movements.

Differential classification of surfaces, introduced by Leonhard Euler and subsequently used by Monge, allows us to group surfaces according to the definition of curvature, which will be precisely defined by Carl Friedrich Gauss in 1902, in four categories: surfaces with zero curvature, surfaces with positive curvature, surfaces with negative curvature and surfaces with variable curvature.

Differential classification of surfaces, introduced by Leonhard Euler and subsequently used by Monge, allows us to group surfaces according to the definition of curvature, which will be precisely defined by Carl Friedrich Gauss in 1902, in four categories: surfaces with zero curvature, surfaces with positive curvature, surfaces with negative curvature and surfaces with variable curvature.

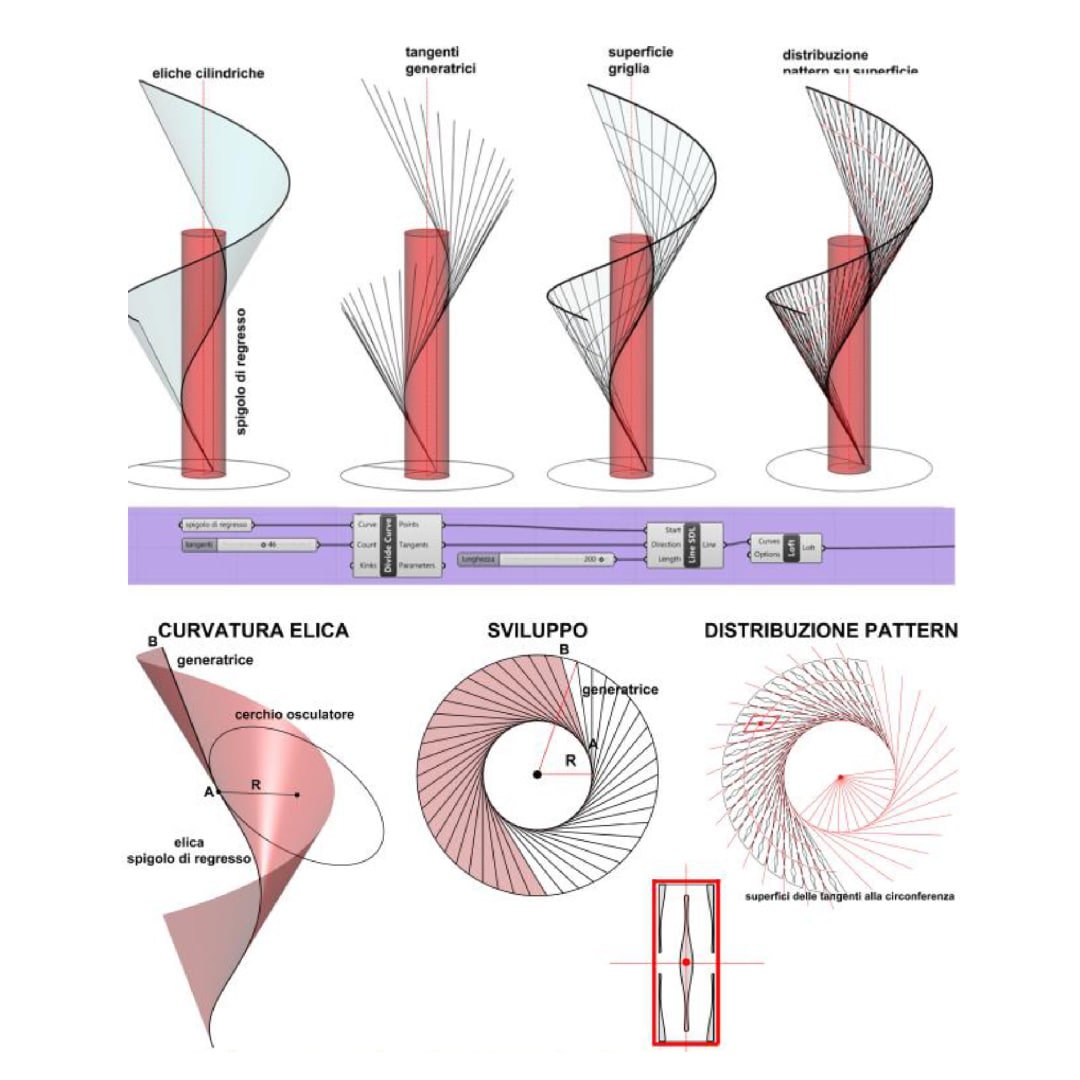

A developable surface is a surface for which every generatrix intersects the generatrix infinitely close, then: – when they intersect on curve c (edge of regression), we have tangent developable; – when they intersect in a point V (the edge of regression is a point), we have a conic surface; – when they intersect at infinity, we have a cylindrical surface.

A developable surface is a surface for which every generatrix intersects the generatrix infinitely close, then: – when they intersect on curve c (edge of regression), we have tangent developable; – when they intersect in a point V (the edge of regression is a point), we have a conic surface; – when they intersect at infinity, we have a cylindrical surface.

The case of the developable helicoid is the simplest, in fact, if the edge of regression is a cylindrical helix, in order to generate the surface we can construct the tangent at a point P and then make it move along the helix.

There are two different approaches to define approximate develop of non-developable surface: first we can design the surface and then we can find the flat shape to manufacture it, or we can design 3D surface morphing a planar surface.

There are two different approaches to define approximate develop of non-developable surface: first we can design the surface and then we can find the flat shape to manufacture it, or we can design 3D surface morphing a planar surface.

We can divide and approximate the 3D surface in order to cover a complex shape by developable strips, which can be unfolded to the plane in an isometric way, without stretching or tearing. In this way we can fabricate 3D complex shape using materials that can be bent in one direction or rigid material with no possibility of being bent at all.

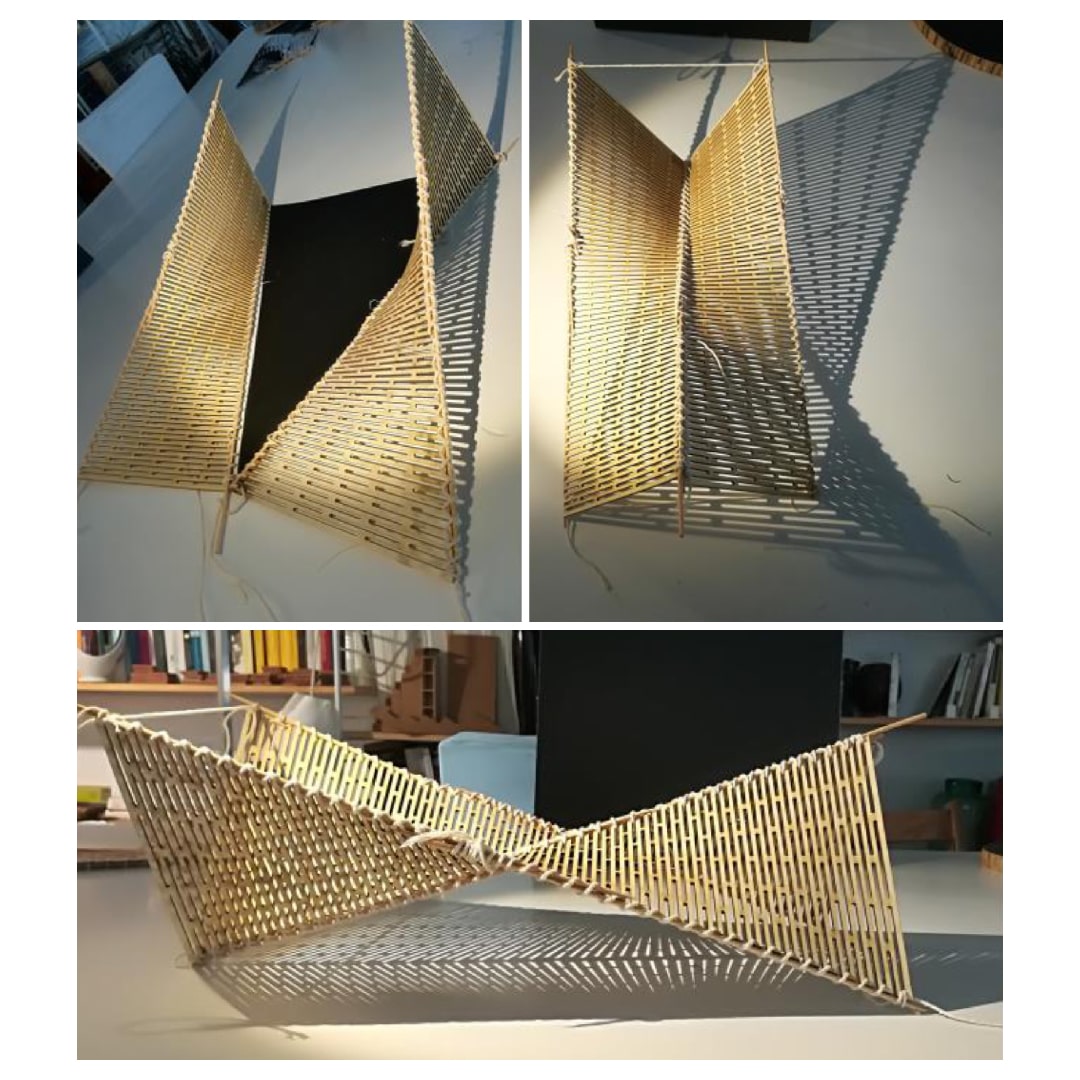

In our research we have considered materials and manufacturing techniques that can solve approximation problems allowing non isometric transformation of the panel thanks to “cuts”, kerfing, or “overlapping”, bending.

In our research we have considered materials and manufacturing techniques that can solve approximation problems allowing non isometric transformation of the panel thanks to “cuts”, kerfing, or “overlapping”, bending.

The kerfing technique consists in subtracting material in some points of the panel in order to improve its flexibility. The maximum radius of curvature, that the panel can reach, depends on the material, the panel thickness, the type of kerf and the different distribution ways on the panel in relation to the curvature of the design surface.

The kerfing technique consists in subtracting material in some points of the panel in order to improve its flexibility. The maximum radius of curvature, that the panel can reach, depends on the material, the panel thickness, the type of kerf and the different distribution ways on the panel in relation to the curvature of the design surface.

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

This paper by Alessandro Liuti, Sofia Colabella, and Alberto Pugnale, presents the construction of Airshell, a small timber gridshell prototype erected by employing a pneumatic formwork.

In this paper by Gregory Charles Quinn, Chris J K Williams, and Christoph Gengnagel, a detailed comparison is carried out between established as well as novel erection methods for strained grid shells by means of FE simulations and a 3D-scanned scaled physical model in order to evaluate key performance criteria such as bending stresses during erection and the distance between shell nodes and their spatial target geometry.

In this paper by Frederic Tayeb, Olivier Baverel, Jean-François Caron, Lionel du Peloux, ductility aspects of a light-weight composite gridshell are developed.

Parametric Ideas for Architects @2025

This tutorial or example file is exclusive to Paracourse Members.

Paracourse is an extensive library of video tutorials and example files, designed to guide you through your parametric design journey. With over 1,500 open example files & 600 Video Tutorials, you can freely edit and adapt them for your projects—no credit required.

Learn parametric design from scratch with over 100 hours of step-by-step tutorials, covering beginner to intermediate levels. Master components and their use in the design process.

Explore our open-to-edit .gh files to see how each subject is designed parametrically using Grasshopper3D. Freely adapt them for your projects—no credit required.

Delve into complete algorithms with our advanced tutorials. Learn the logic behind each step, understand how the parts work together, and see how to apply them effectively in your designs.

Grasshopper empowers architects and designers to create sophisticated, customizable designs with ease.

Architects, industrial designers, artists, and anyone passionate about parametric design will find value in this course.

With diverse tutorials and open example files, you’ll have everything you need to tackle any design challenge.

Mastering Grasshopper with Paracourse can significantly enhance your career prospects.