String Art Generator

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

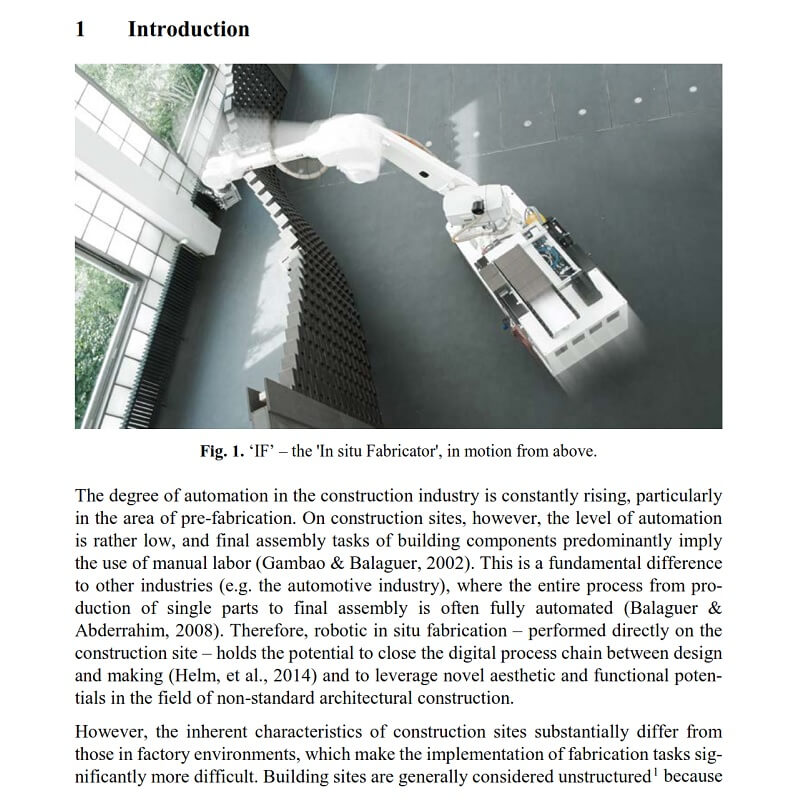

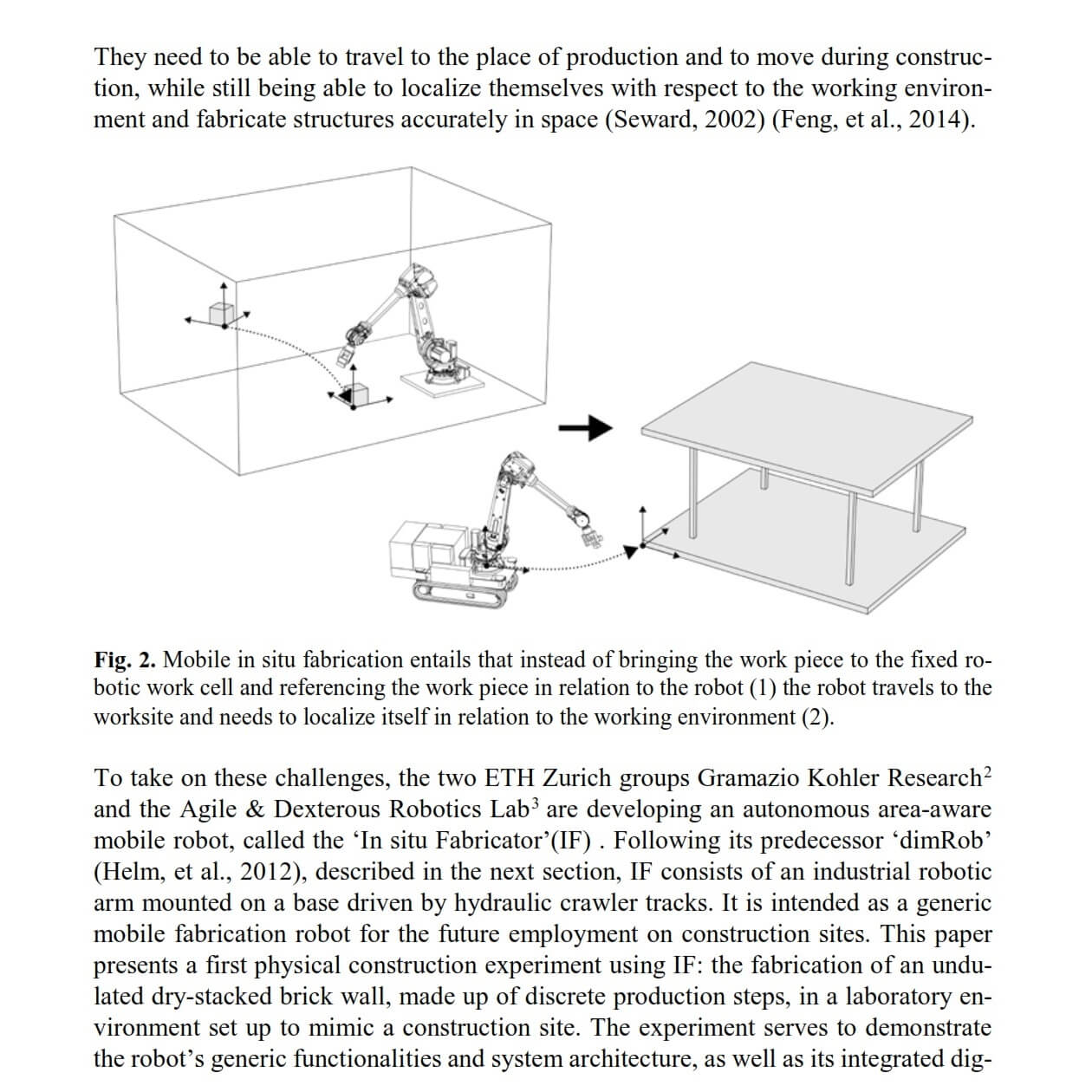

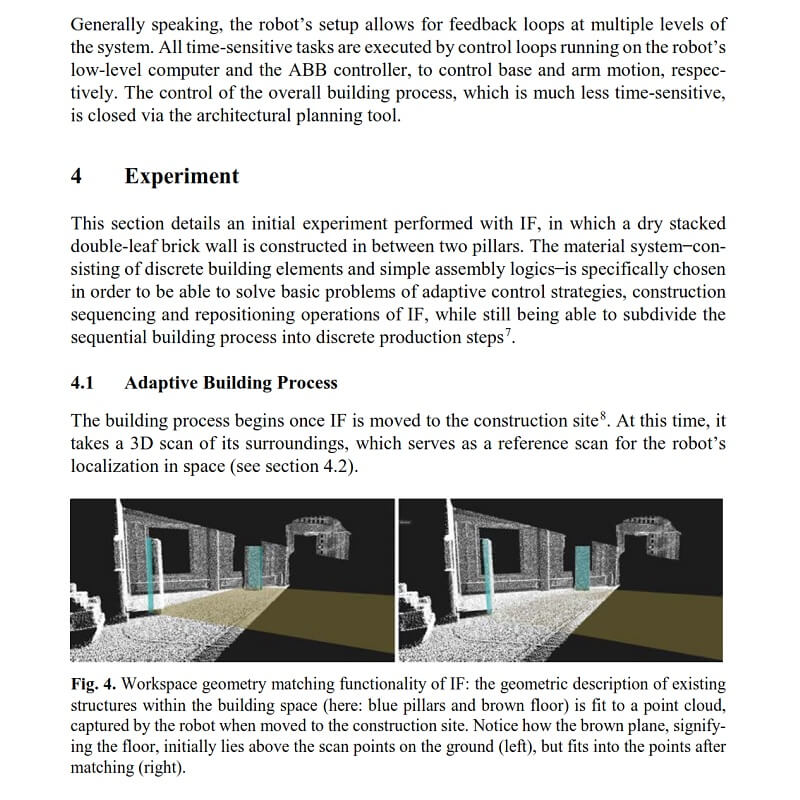

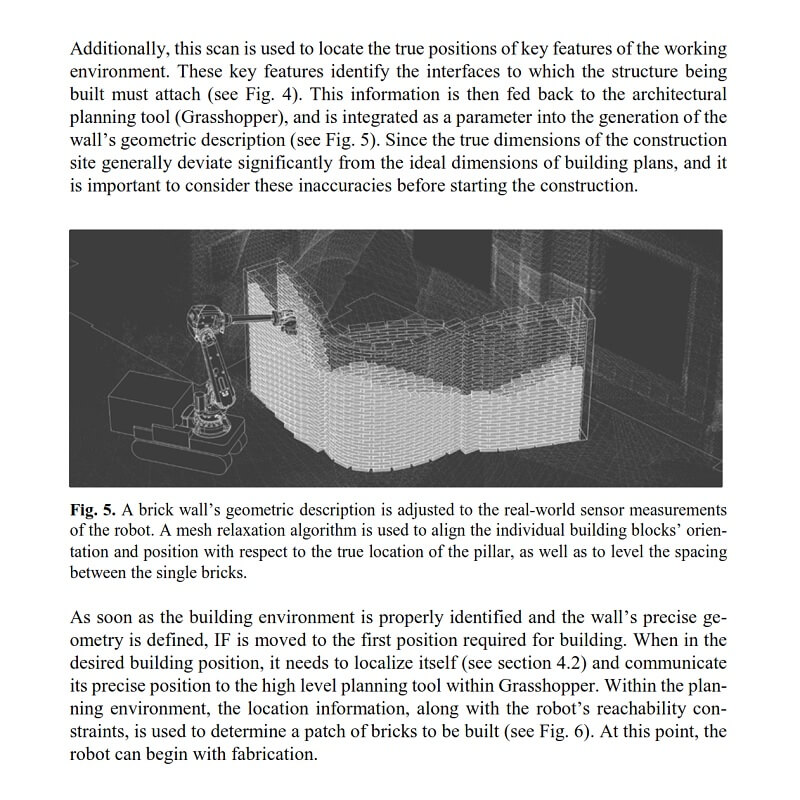

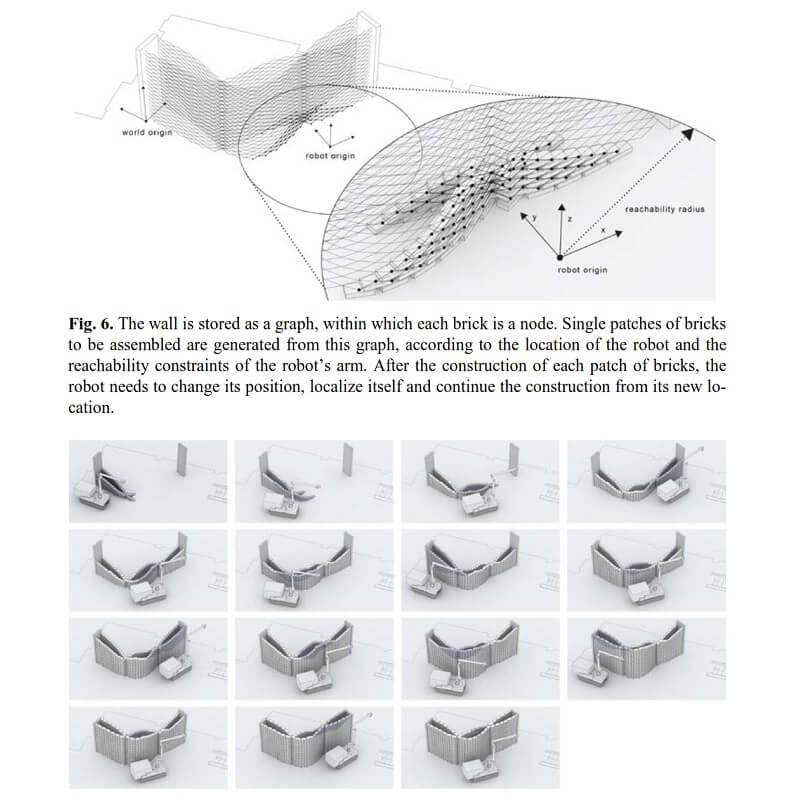

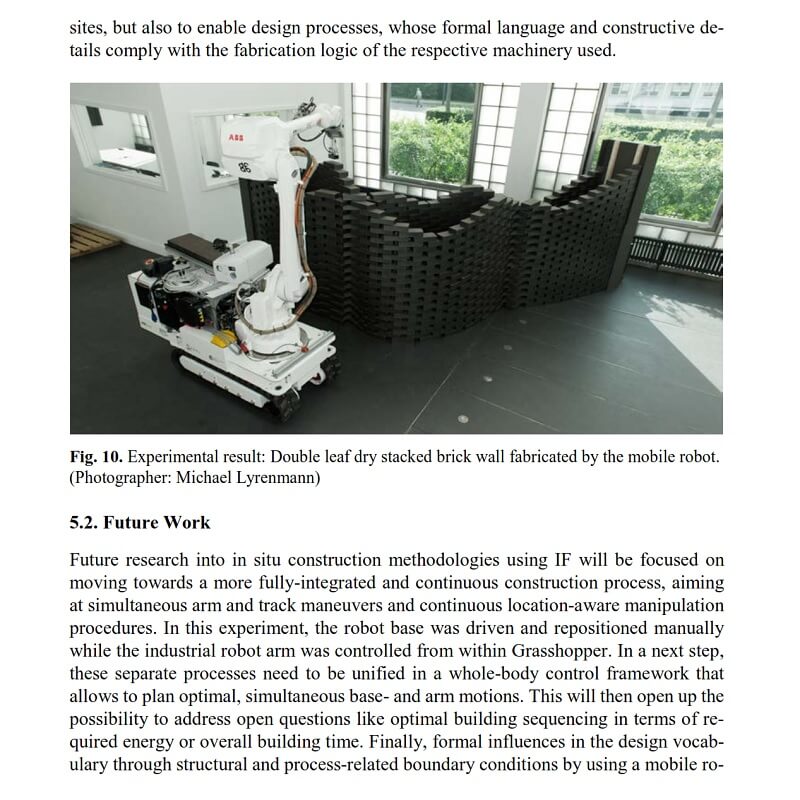

This paper by Kathrin Dörfler, Timothy Sandy, Markus Giftthaler, Fabio Gramazio, Matthias Kohler and Jonas Buchli, describes the implementation of a discrete in situ construction process using a location-aware mobile robot. An undulating dry brick wall is semi-autonomously fabricated in a laboratory environment set up to mimic a construction site.

On the basis of this experiment, the following generic functionalities of the mobile robot and its developed software for mobile in situ robotic construction are presented: 1) its localization capabilities using solely on-board sensor equipment and computing, 2) its capability to assemble building components accurately in space including the ability to align the structure with existing components on site, and 3) the adaptability of computational models to dimensional tolerances as well as to process-related uncertainties during construction.

On the basis of this experiment, the following generic functionalities of the mobile robot and its developed software for mobile in situ robotic construction are presented: 1) its localization capabilities using solely on-board sensor equipment and computing, 2) its capability to assemble building components accurately in space including the ability to align the structure with existing components on site, and 3) the adaptability of computational models to dimensional tolerances as well as to process-related uncertainties during construction.

As such, this research advances additive non-standard fabrication technology and fosters new forms of flexible, adaptable and robust building strategies in the new emerging field of autonomous robotic in situ production for the final assembly of building components directly on construction sites.

As such, this research advances additive non-standard fabrication technology and fosters new forms of flexible, adaptable and robust building strategies in the new emerging field of autonomous robotic in situ production for the final assembly of building components directly on construction sites.

While this paper highlights the challenges of the current state of research and experimentation, it also provides an outlook to the implications for future robotic construction and the new possibilities the proposed approaches open up: the high-accuracy fabrication of large-scale building structures outside of structured factory settings, which could radically expand the application space of automated building construction in architecture.

While this paper highlights the challenges of the current state of research and experimentation, it also provides an outlook to the implications for future robotic construction and the new possibilities the proposed approaches open up: the high-accuracy fabrication of large-scale building structures outside of structured factory settings, which could radically expand the application space of automated building construction in architecture.

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

This paper by Alessandro Liuti, Sofia Colabella, and Alberto Pugnale, presents the construction of Airshell, a small timber gridshell prototype erected by employing a pneumatic formwork.

In this paper by Gregory Charles Quinn, Chris J K Williams, and Christoph Gengnagel, a detailed comparison is carried out between established as well as novel erection methods for strained grid shells by means of FE simulations and a 3D-scanned scaled physical model in order to evaluate key performance criteria such as bending stresses during erection and the distance between shell nodes and their spatial target geometry.

In this paper by Frederic Tayeb, Olivier Baverel, Jean-François Caron, Lionel du Peloux, ductility aspects of a light-weight composite gridshell are developed.

Parametric Ideas for Architects @2025