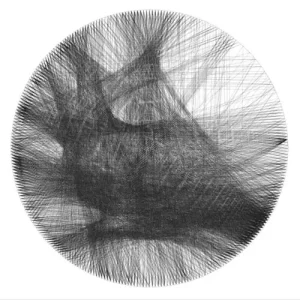

String Art Generator

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

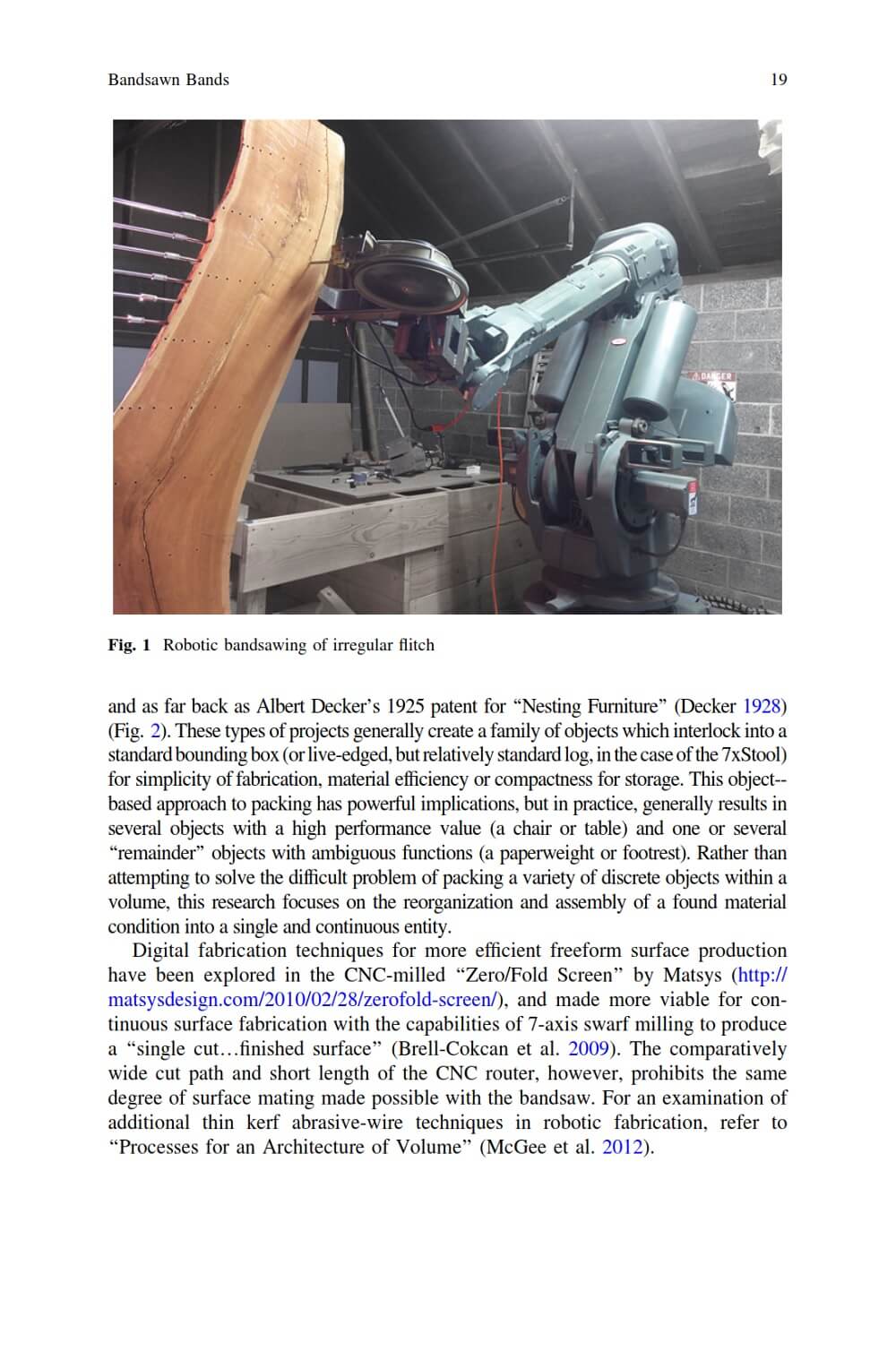

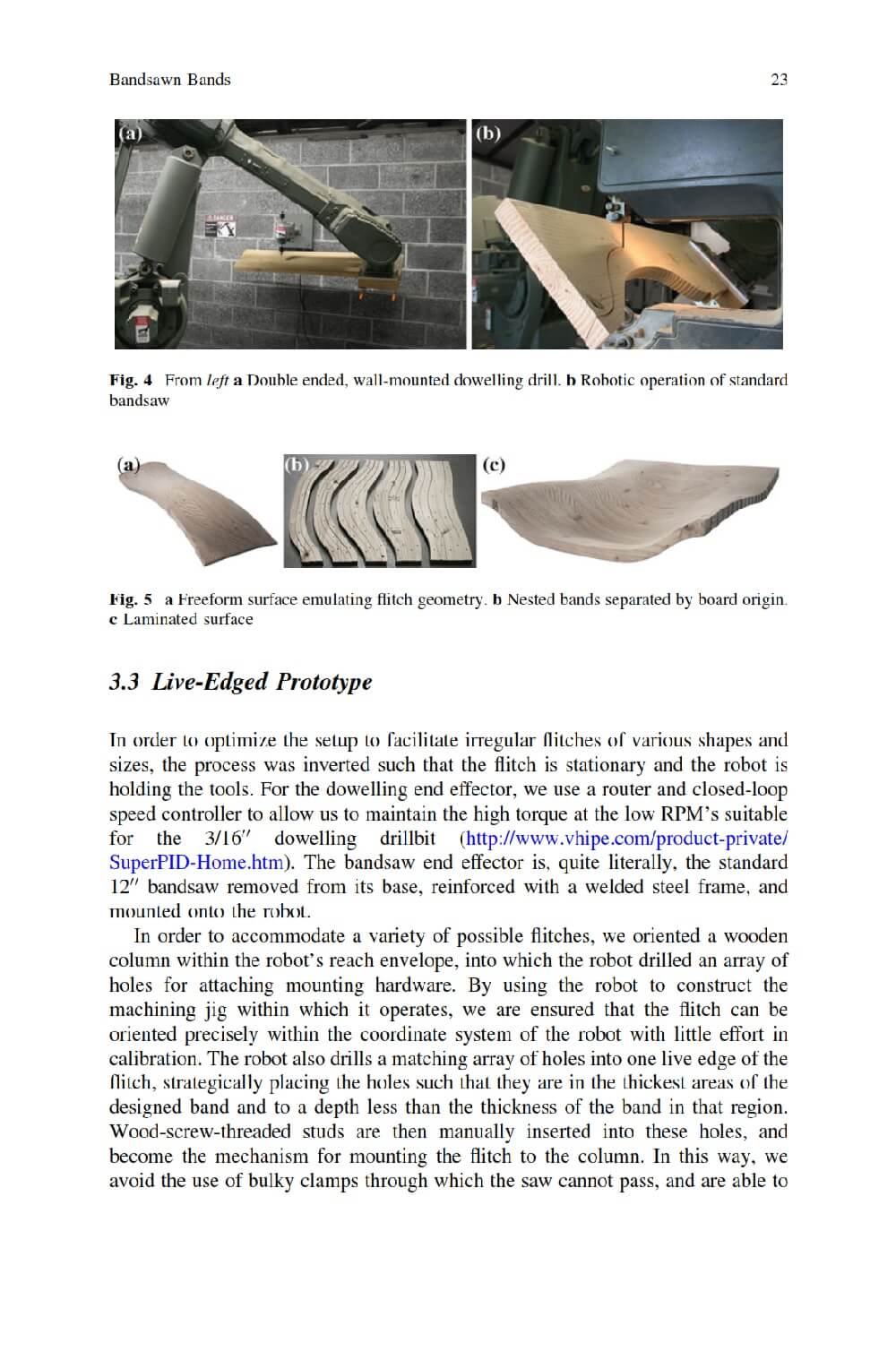

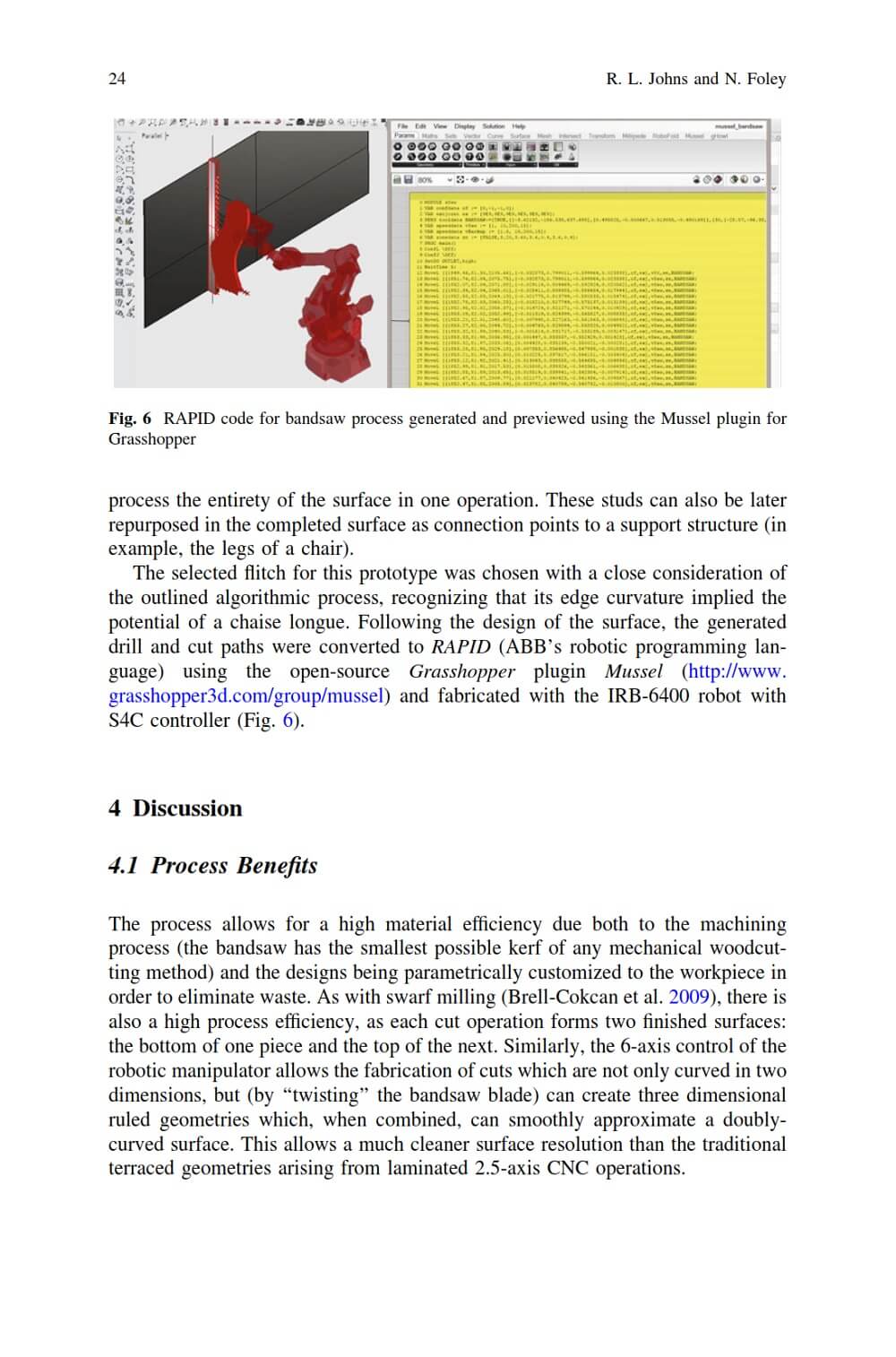

While the rising trend of research in robotic fabrication has furthered the development of parametric or mass-customization concepts in architecture, the majority of these projects are still cut or assembled from standardized blocks of material. Although the use of nonstandard, ‘found’ components provides an additional layer of complexity and constraint to the design/fabrication process, it can compensate for these challenges by enabling more sustainable material practices and the production of unique objects that cannot be reproduced.

This article by Ryan Luke Johns and Nicholas Foley, illustrates a materially efficient technique for designing and fabricating freeform surfaces within the constraints of irregular wood flitches. The process utilizes a robotically operated bandsaw to cut a series of curved strips which, when rotated and laminated, can approximate doubly-curved and digitally defined geometry. By delimiting the design space by both the ‘machinic morphospace’ (Menges in Rob|Arch 2012: Robotic Fabrication in Architecture, Art and Industrial Design, Springer, Vienna, pp. 28–47, 2012) of the fabrication technique and the naturally defined curvatures and constraints of the flitch, the customized control software and machining processes confer the capabilities of digital fabrication onto materially tailored and operator-informed woodcraft.

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

This paper by Alessandro Liuti, Sofia Colabella, and Alberto Pugnale, presents the construction of Airshell, a small timber gridshell prototype erected by employing a pneumatic formwork.

In this paper by Gregory Charles Quinn, Chris J K Williams, and Christoph Gengnagel, a detailed comparison is carried out between established as well as novel erection methods for strained grid shells by means of FE simulations and a 3D-scanned scaled physical model in order to evaluate key performance criteria such as bending stresses during erection and the distance between shell nodes and their spatial target geometry.

In this paper by Frederic Tayeb, Olivier Baverel, Jean-François Caron, Lionel du Peloux, ductility aspects of a light-weight composite gridshell are developed.

Parametric Ideas for Architects @2025