Bending-Active Structures

Deployable textile hybrid structures: design and modelling of kinetic membrane-restrained bending-active structures

Stijn Brancart, Lars De Laet, Niels De Temmerman

Architectural Engineering Lab (Æ-LAB), Department of Architectural Engineering, Vrije Universiteit Brussel (VUB), Pleinlaan 2, 1050 Brussels, Belgium

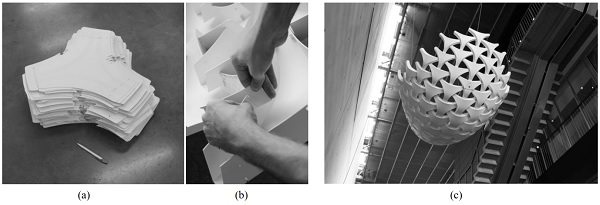

Fig. 1. The Undulatus is a bending-active assembly kit based on the principle of curved-line folding. A small stacking volume (a), easy and rapid assembly through simple connections (b) and self-interlocking of the components in a weave pattern (c) are its main characteristics.

By rapidly expanding from a compact, stowed bundle to a functional space enclosure, deployable structures can address temporary needs in a minimum amount of time. Using the intrinsic elastic behaviour of flexible elements — active bending — in the design of transformable or deployable structures leads to a wide range of kinetic concepts.

This component transformation can decrease the complexity that often comes with rigid-body mechanisms. This paper presents one principle for deployable bending-active structures, based on the interaction between a deployable grid and a restraining membrane: deployable textile hybrid structures.

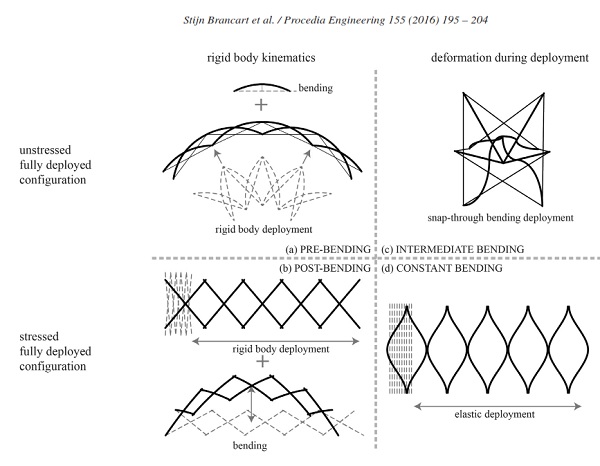

Fig. 2. Based on the implementation of bending in the deployment process — before, during or after — and the presence of residual stress in the structure, we can define four principles for deployable bending-active structures: pre-bending (a), post-bending (b), intermediate bending (c) and constant bending (d).

A case study illustrates the design concept and the deployment and assembly processes that allow multiple structural transformations. The large interdependency of the form and material behaviour of bending-active structures, contrary to conventional formactive structures, requires a specific modelling approach.

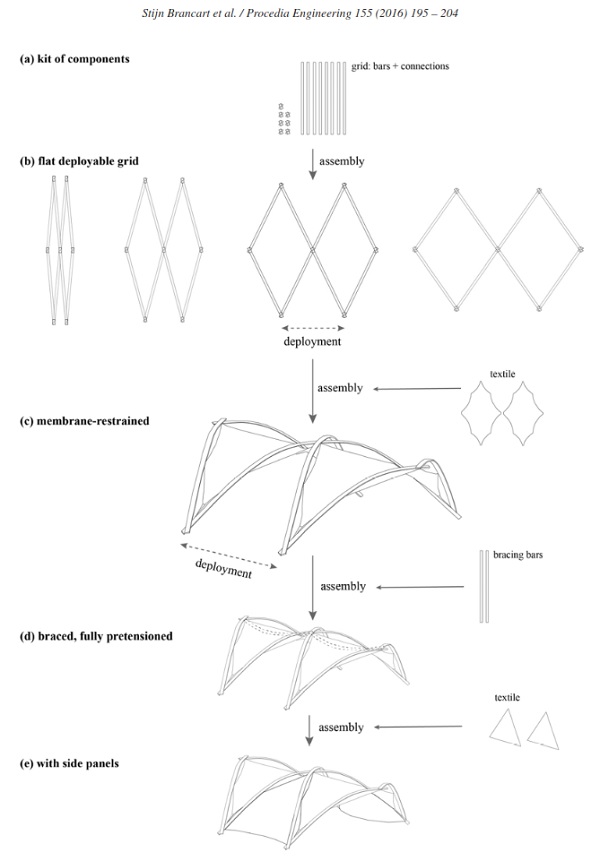

Fig. 3. The assembly of the deployable textile hybrid grid consists of multiple transformation processes, enabling multiple configurations and deployments depending on the need and available time.

The approach presented in this paper allows feedback between the parametric input of starting geometry and material characteristics, and the output geometry and internal stress. Working with a high-strain fabric without cutting pattern, balancing the stresses and strains between the bending elements and tensile fabric becomes the prime focus.

Although the preliminary results are acceptable in theory, a more detailed structural analysis and real-scale models should validate the assumptions of rapid assembly and the structural behaviour on a realistic and practical level.

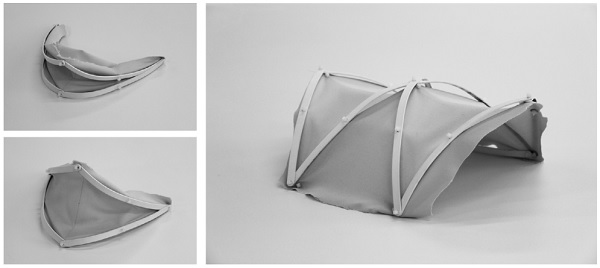

Fig. 4. Physical models allow experimental insight in the behaviour of deployable and bending-active structures, very intuitively. This allows testing the kinetic behaviour (left) and structural behaviour of the fully assembled structure (right).

The principle of transformable structures entails a wide range of deployable and rapidly assembled structures. Incorporating transformability in the design and construction of temporary structures, can greatly improve their reusability and reconfigurability and reduce their assembly time, thus not only avoiding excessive waste production, but also bettering their efficiency in responding to short-term or critical needs.

Including active bending in the assembly of these structures leads to a wide range of structural concepts that owe their kinetic behaviour to the elastic deformation of the members. This paper focuses on one principle of transformable active bending: the hybrid action of a deployable bending-active system with textile restraint.

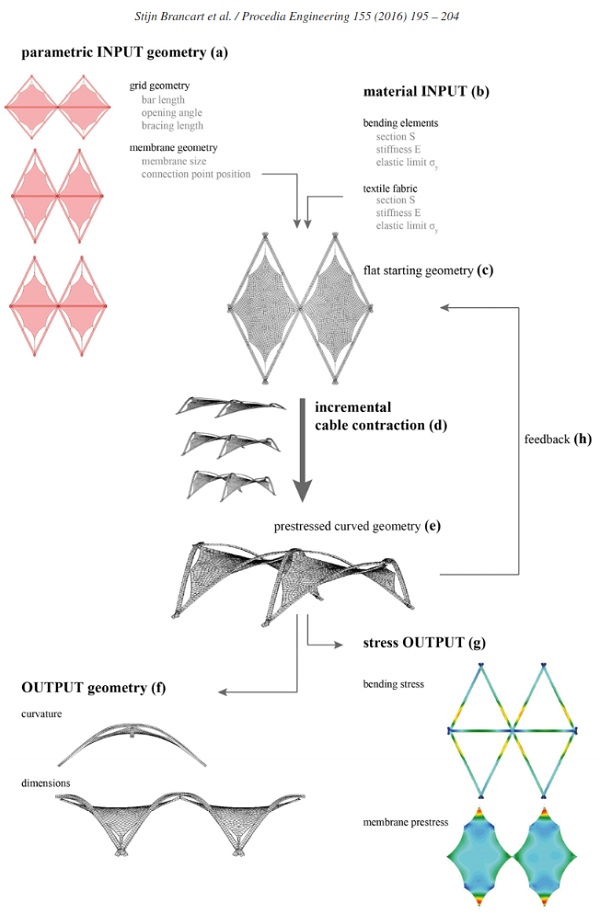

Fig. 5. The form finding from a flat input geometry to a curved, prestressed structure, starts from predefined material properties for both membrane and bending elements.

This reciprocal relation of restraint and pre-tensioning does not only improve the load-bearing behaviour, but can also be utilised during the assembly process.

Moreover, the membrane restraint action allows creating a fully self-tensioning structure without grid distortions or incompatibilities in the deployable system, facilitating unrestrained rigid-body deployment when the fabric is not attached.

Through a case study, this paper elaborates on the design and modelling of deployable textile hybrid structures. Though their conceptual design, easily supported by physical models, often occurs intuitively with a basic or experimental understanding of the bending and tensile actions, modelling these structures in a digital environment is rather complex.

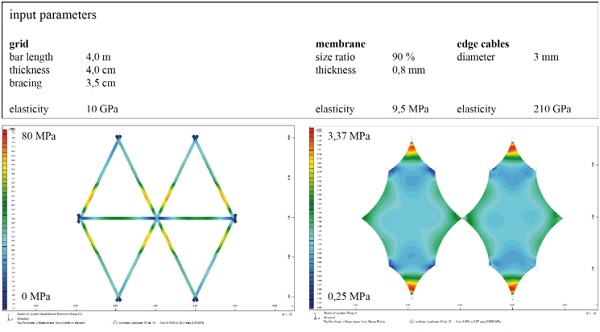

Fig. 6. After an iterative form finding process, this preliminary configuration shows an acceptable stress distribution in the membrane and gridshells. During the more detailed analysis of the structure and large-scale production, specific attention needs to be paid to the connections.

Since the form finding of bending-active structures depends largely on the starting geometry and material behaviour, the process differs noticeably from that of conventional form-active structures. Therefore, we performed the form finding of the structure in an interactive environment between a parametric model of the flat starting geometry and the elastic formation of the structure through cable contraction in a finite-element environment.

Using stretchable, high-strain fabrics eliminates the need for cutting pattern generation. Although this case study validates the approach and structural integrity of the concept, more detailed analysis and prototyping are necessary to facilitate the construction of these deployable textile hybrid structures.

Comments