String Art Generator

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

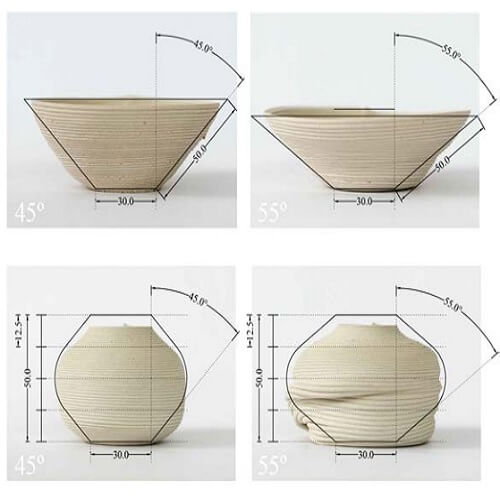

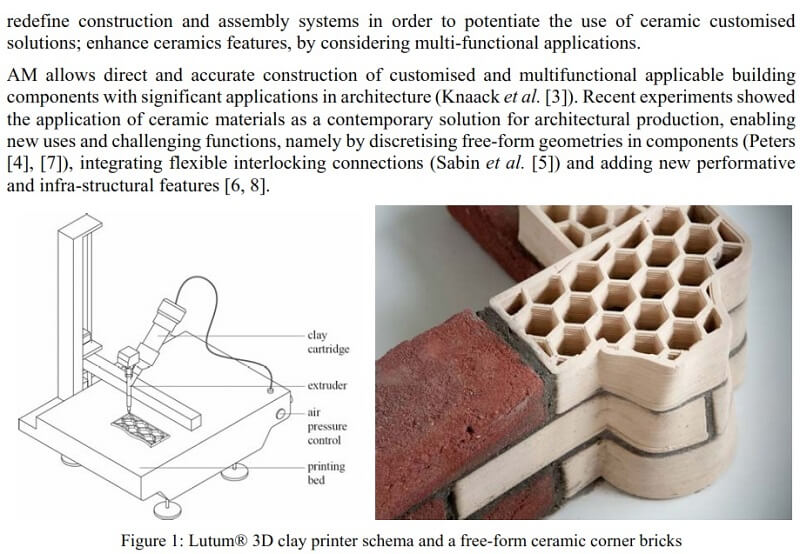

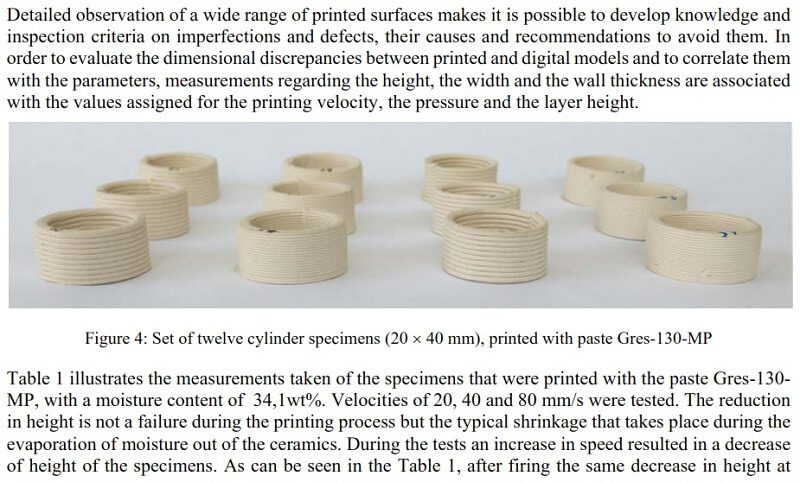

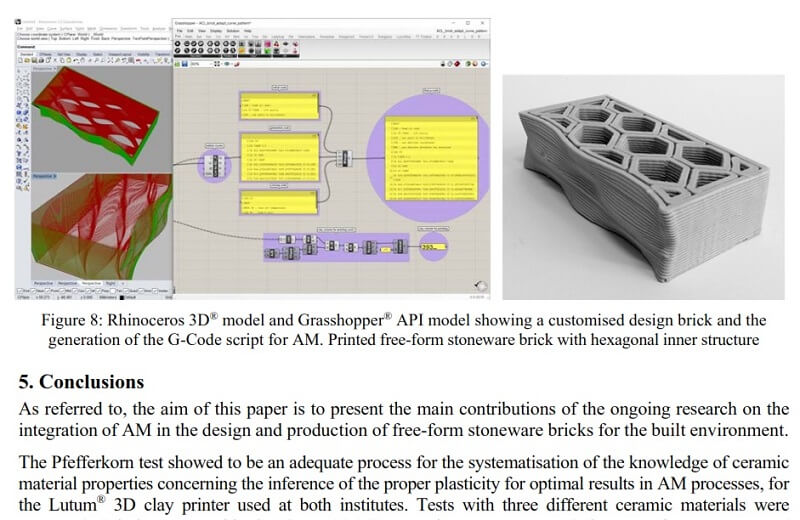

The advent of Additive Manufacturing (AM) of ceramic, brought unprecedented possibilities for the building industry while exploring and incorporating components with specific design requirements. It definitively reshaped and expanded the boundaries of what’s possible to achieve with masonry construction and opened new domains, with multiple angles of study and experimentation and with a large industrial potential.

This paper by Paulo J.S. CRUZ, Ulrich KNAACK, Bruno FIGUEIREDO and Dennis de WITTE presents the main challenges and outcomes of an ongoing research project aiming to explore the integration of digital additive manufacturing techniques in the architectural design and production processes of free-form stoneware bricks for building envelopes. The project uses a clay extruding printer, Lutum®, built by the company Vormvrij available at the Advanced Ceramics R&D Lab, at the Design Institute of Guimarães and at Technische Universität Darmstadt.

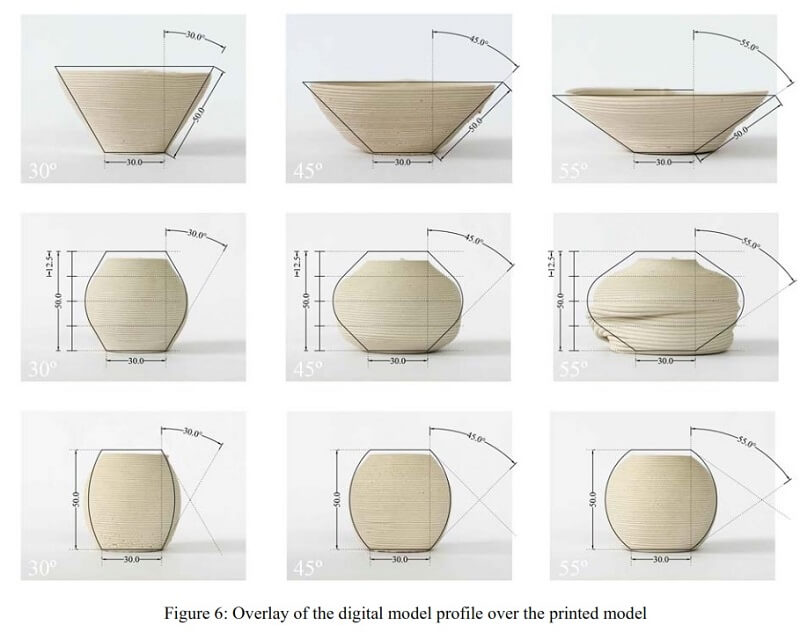

The path, material flow and printing speed of the printing process are defined digitally. The movement speed, extrusion flow and the air pressure can be controlled manually to adapt the specific printing process to the characteristics of the clay during the printing process itself. The widely accepted Pfefferkorn method has been extensively used to evaluate and control the plasticity of the stoneware used.

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

This paper by Alessandro Liuti, Sofia Colabella, and Alberto Pugnale, presents the construction of Airshell, a small timber gridshell prototype erected by employing a pneumatic formwork.

In this paper by Gregory Charles Quinn, Chris J K Williams, and Christoph Gengnagel, a detailed comparison is carried out between established as well as novel erection methods for strained grid shells by means of FE simulations and a 3D-scanned scaled physical model in order to evaluate key performance criteria such as bending stresses during erection and the distance between shell nodes and their spatial target geometry.

In this paper by Frederic Tayeb, Olivier Baverel, Jean-François Caron, Lionel du Peloux, ductility aspects of a light-weight composite gridshell are developed.

Parametric Ideas for Architects @2025