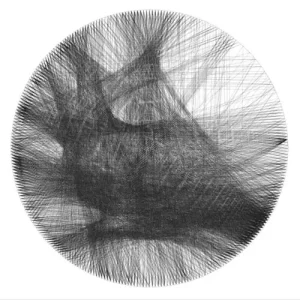

String Art Generator

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

FROM MACHINE CONTROL TO MATERIAL PROGRAMMING SELF-SHAPING WOOD MANUFACTURING OF A HIGH PERFORMANCE CURVED CLT STRUCTURE – URBACH TOWER

Computational design and digital fabrication for architecture focuses increasingly on advanced robotic machine control for the shaping and assembly of pre-engineered building materials to produce structures with complex functional geometries.

Intelligent digital planning methods and machine material feedback make processes of additive, subtractive and formative manufacturing incrementally more efficient and tuneable. However, complex shaping is still achieved by combinations of pre-shaped formwork, application of brute mechanical force, robotic manipulation, and subtractive machining from larger stock.

In the shaping process, powerful innate material behaviour that influences shape is either viewed as problematic or ignored. In the quest for infinitely more axes, and endlessly more sophisticated end effectors, it’s clear we have overlooked the useful capacities found within the structures and tissues of the materials we fabricate with.

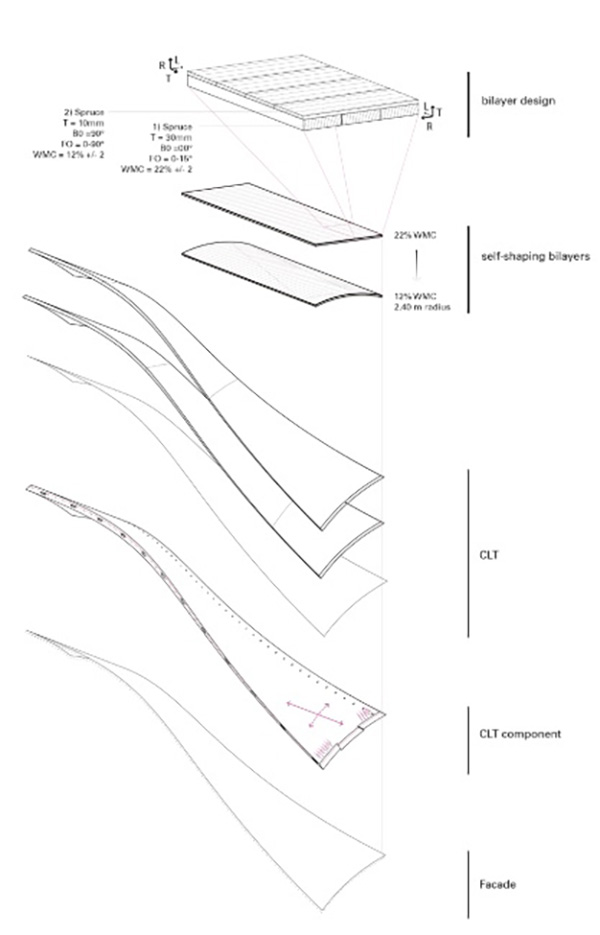

This research presents a paradigm shift towards a material-driven self-shaping fabrication method for full scale timber building components. Here the 3D geometry emerges from the designed material arrangement in flat 2D parts that are exposed to an external stimulus.

By utilising the unique capacity of the material to act as an integrated, shaping actuator and the final loadbearing structure, elaborate external forming equipment is eliminated. This simple yet informed material programming replaces typically material, energy and labour intensive shaping process.

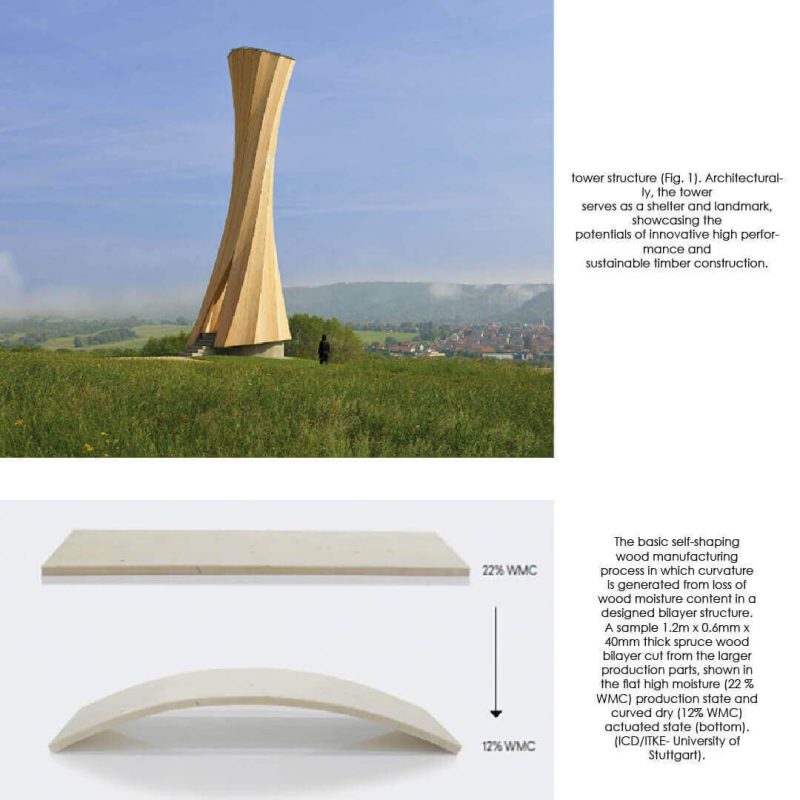

Using wood, which exhibits strong anisotropic dimensional instability in response to changes in moisture, we developed a material-specific predictive model, and a physical material programming routine that allows for a selfshaping manufacturing process for high curvature Cross Laminated Timber (CLT) building components.

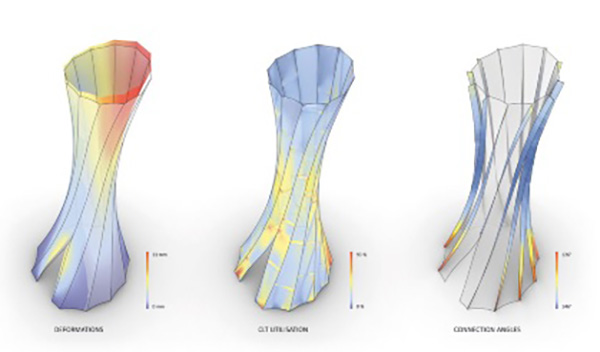

Surface active structures benefit tremendously from curvature in both the overall structural geometry and individual building components. For wooden shell structures, curvature is, however, expensive to produce in terms of costs, material, and environmental impact.

In this research, the manufacturability of high curvature CLT components enabled by self-shaping is paired with the development of performative geometry and structural analysis for folded plate cylindrical shell structures.

The concept is demonstrated with the design, engineering, manufacture, and construction of a 14m tall thin shell tower structure. Architecturally, the tower serves as a shelter and landmark, showcasing the potentials of innovative high performance and sustainable timber construction.

The challenge of applying self-shaping technologies for the building industry is how to upscale basic principles to a size that is suitable for the manufacture of building components while ensuring that both material and building structure are maintained. The fundamental research question centres on how known shape-changing properties of a building material can be used purposely to generate shape.

Programming of the shape changes requires an advanced understanding of the underlying mechanisms of deformation, which can only be gained by employing simulations based on specific material models coupled with experimental testing.

Critical to manufacturing innovation is the development of a materially-informed digital design methodology that could be used to predict and tune the final shape and translate a design geometry to the material information required for production. To be effective, the predictive model must be accurate using material input parameters and sorting ranges that can be collected and implemented in an industrial context.

The construction of the tower demonstrated self-shaping manufacturing for industry level production of curved load-bearing building components. As the same material is both the shaping mechanism and the final structure, the need of larger machines and formwork is greatly reduced.

The current process is directly applicable for the solid wood production of lightweight curved roof components, curved vertical shear walls for multi-storey timber construction and cylindrical structures such as silos or turbine towers. It presents an ecological option for performative curved geometries that are often produced with malleable yet energy intensive materials such as concrete, plastic or metals.

A designed self-shaping process is a new approach to digital fabrication at the scale of building components. Rather than outputting machine codes to communicate a position for additive or subtractive shaping, the selfshaping process means geometry is communicated through the specific characteristic and arrangement of material, providing an implicit understanding of the resulting physical transformation.

As the scale of parts increase, the self-shaping processes become inherently more valuable as the force and coordination required to bend the parts increase. Similarly, self-shaping enables adaptable and parallel manufacturing within a standard setup, which is valuable for large quantity and high variation production.

Rethinking materials’ active role in construction leads to new architectural opportunities as well as increased sustainability in the production and operation of buildings. As our understanding and control of materials become increasingly sophisticated, their symbiotic relationship with the digitally-controlled fabrication machines of the future is brought into question, productively inverting and blurring the relationship between material and machine. Perhaps in the future the materials will do the fabricating and the machines as we know them will rest.

String Art Generator by Yiran is a grasshopper plugin which generates a string art sequence based on an input image. You can

This paper by Alessandro Liuti, Sofia Colabella, and Alberto Pugnale, presents the construction of Airshell, a small timber gridshell prototype erected by employing a pneumatic formwork.

In this paper by Gregory Charles Quinn, Chris J K Williams, and Christoph Gengnagel, a detailed comparison is carried out between established as well as novel erection methods for strained grid shells by means of FE simulations and a 3D-scanned scaled physical model in order to evaluate key performance criteria such as bending stresses during erection and the distance between shell nodes and their spatial target geometry.

In this paper by Frederic Tayeb, Olivier Baverel, Jean-François Caron, Lionel du Peloux, ductility aspects of a light-weight composite gridshell are developed.

Parametric Ideas for Architects @2025

This tutorial or example file is exclusive to Paracourse Members.

Paracourse is an extensive library of video tutorials and example files, designed to guide you through your parametric design journey. With over 1,500 open example files & 600 Video Tutorials, you can freely edit and adapt them for your projects—no credit required.

Learn parametric design from scratch with over 100 hours of step-by-step tutorials, covering beginner to intermediate levels. Master components and their use in the design process.

Explore our open-to-edit .gh files to see how each subject is designed parametrically using Grasshopper3D. Freely adapt them for your projects—no credit required.

Delve into complete algorithms with our advanced tutorials. Learn the logic behind each step, understand how the parts work together, and see how to apply them effectively in your designs.

Grasshopper empowers architects and designers to create sophisticated, customizable designs with ease.

Architects, industrial designers, artists, and anyone passionate about parametric design will find value in this course.

With diverse tutorials and open example files, you’ll have everything you need to tackle any design challenge.

Mastering Grasshopper with Paracourse can significantly enhance your career prospects.