Double-Curved Form

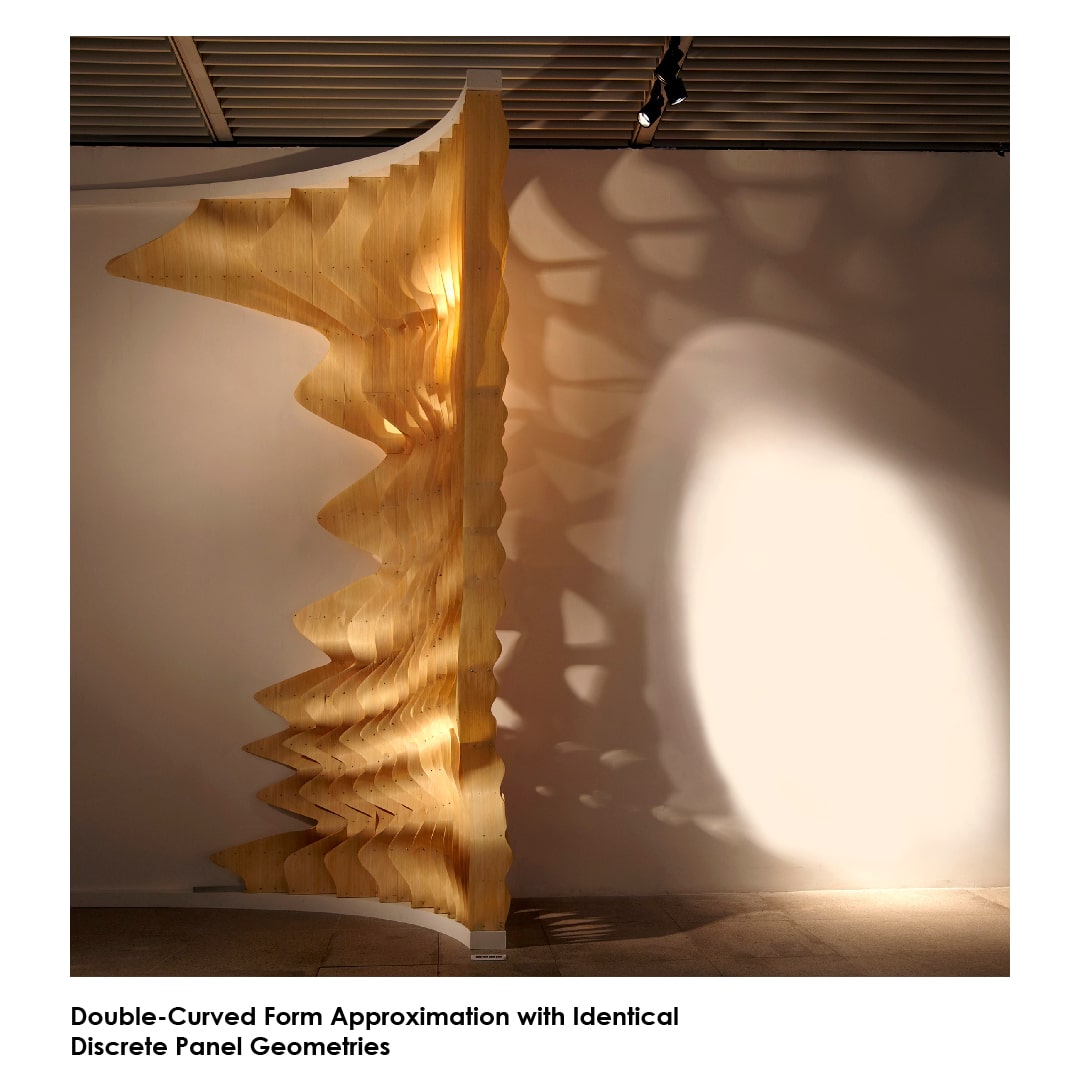

Double-Curved Form Approximation With Identical Discrete Panel Geometries

CHRISTOPH KLEMMT1 and RAJAT SODHI2

1Orproject, United Kingdom; University of Cincinnati, United States of America; University of Applied Arts Vienna, Austria

2Orproject, India

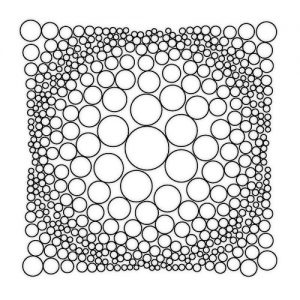

To reduce the costs of manufacturing multiple moulds for double-curved facade construction, this research suggests a method of approximating the desired envelope with identically formed panel geometries.

The panels can then be fabricated by only using two doublecurved moulds. In a second step, individual segments are cut out of the identical base geometries. The method has been successfully tested with the construction of a prototype.

The result is an intricately textured freeform geometry. The installation was built at a reasonable cost compared to other ways of fabricating double-curved geometry. The strength of the panels was utilised as the sole structural system of the prototype.

The result is an intricately textured freeform geometry. The installation was built at a reasonable cost compared to other ways of fabricating double-curved geometry. The strength of the panels was utilised as the sole structural system of the prototype.

The main challenge in the construction of double-curved facade geometry is the cost of manufacturing individual panels. Except in few cases, a seemingly double-curved facade is rarely actually constructed double-curved; more often it is rationalised into flat or single-curved elements that approximate the intended double-curvature.

The main challenge in the construction of double-curved facade geometry is the cost of manufacturing individual panels. Except in few cases, a seemingly double-curved facade is rarely actually constructed double-curved; more often it is rationalised into flat or single-curved elements that approximate the intended double-curvature.

The economic challenge lies in the costs of manufacturing moulds against which the façade panels are formed. For the fabrication of panels from various materials, such as aluminium, glass, fibre concrete or polymers, usually a separate mould needs to be manufactured for each panel. Alternatives such as Multi-Point Forming offer savings but are still relatively costly.

The economic challenge lies in the costs of manufacturing moulds against which the façade panels are formed. For the fabrication of panels from various materials, such as aluminium, glass, fibre concrete or polymers, usually a separate mould needs to be manufactured for each panel. Alternatives such as Multi-Point Forming offer savings but are still relatively costly.

In order to allow for an affordable manufacturing of complex form, architects have proposed geometries that are based on a limited amount of identical discrete components.

In order to allow for an affordable manufacturing of complex form, architects have proposed geometries that are based on a limited amount of identical discrete components.

While this may provide an answer to the economic issues of the construction, it very often leads to geometric systems that appear pixelated rather than flowing.

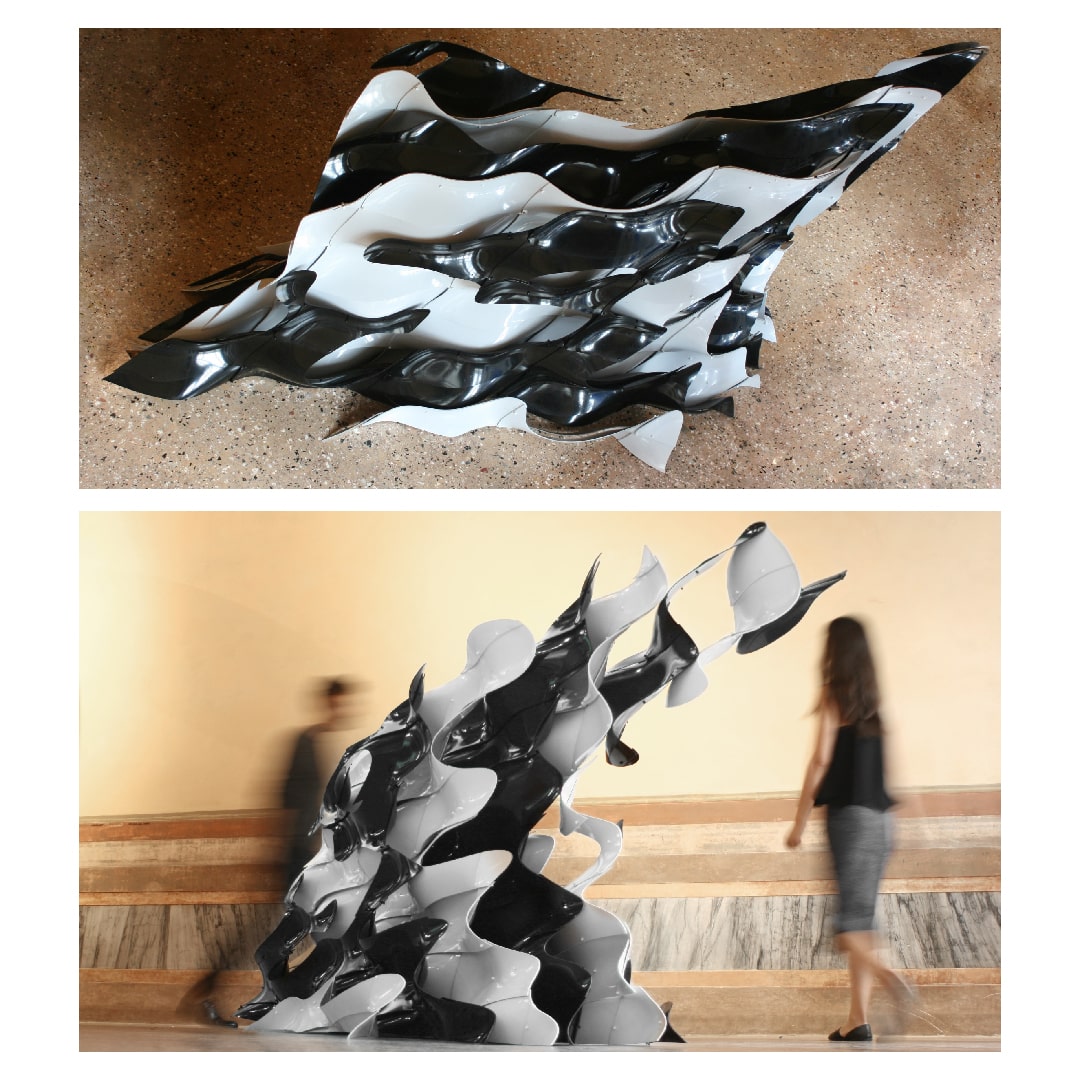

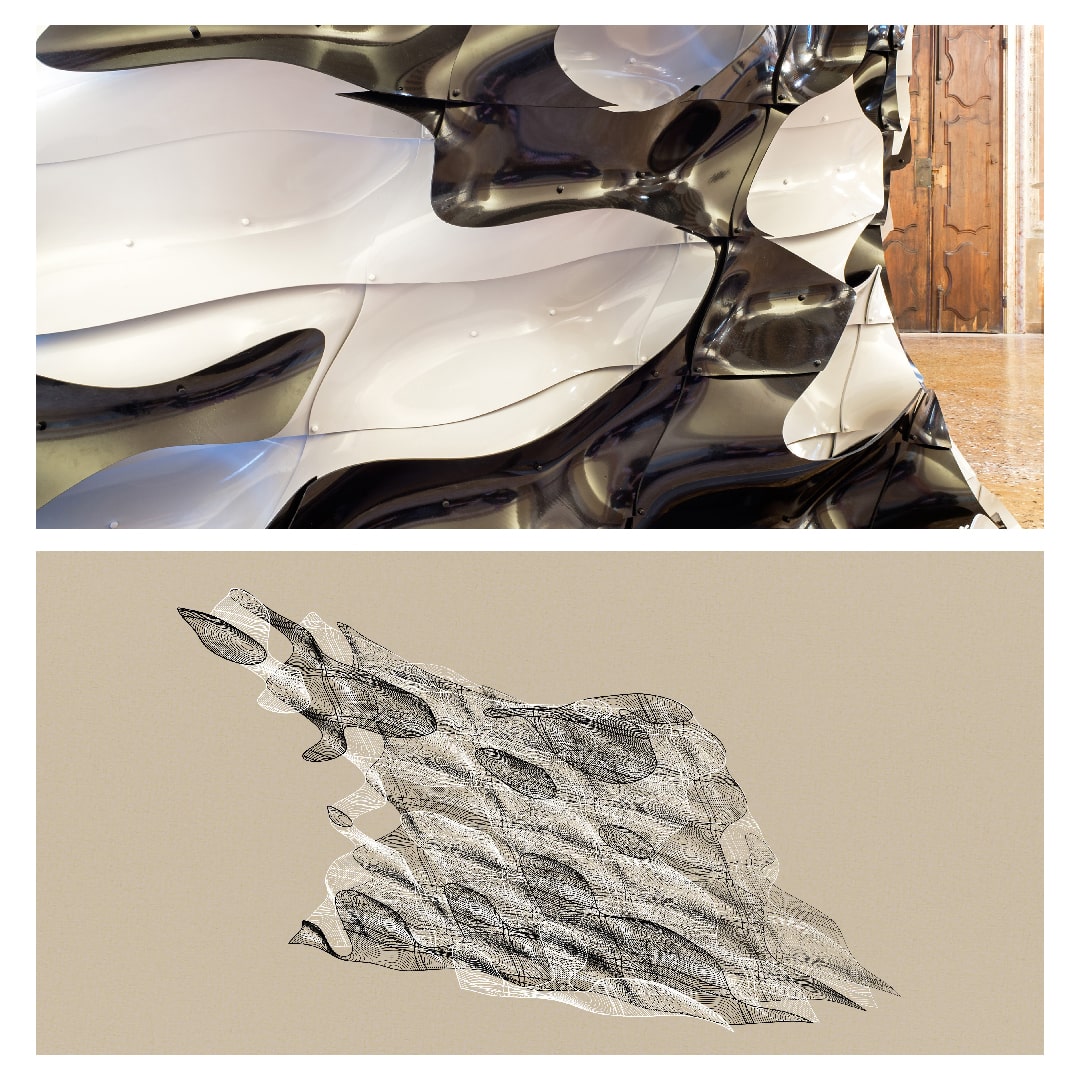

We therefore propose a method of double-curved façade construction that utilises identical discrete panels during the forming process, which are then trimmed in order to align to the desired free-form envelope.

We therefore propose a method of double-curved façade construction that utilises identical discrete panels during the forming process, which are then trimmed in order to align to the desired free-form envelope.

The method has been tested with a prototype and was evaluated for its aesthetic and economic performance. It was shown to cost significantly less than a fully double-curved construction while resulting in a dynamically flowing, textured geometry.

We propose a system similar to that of our previous research in order to approximate a desired envelope geometry, which in this case uses discrete panels that are double-curved in two repetitive shapes, rather than being singlecurved as in the previous work.

We propose a system similar to that of our previous research in order to approximate a desired envelope geometry, which in this case uses discrete panels that are double-curved in two repetitive shapes, rather than being singlecurved as in the previous work.

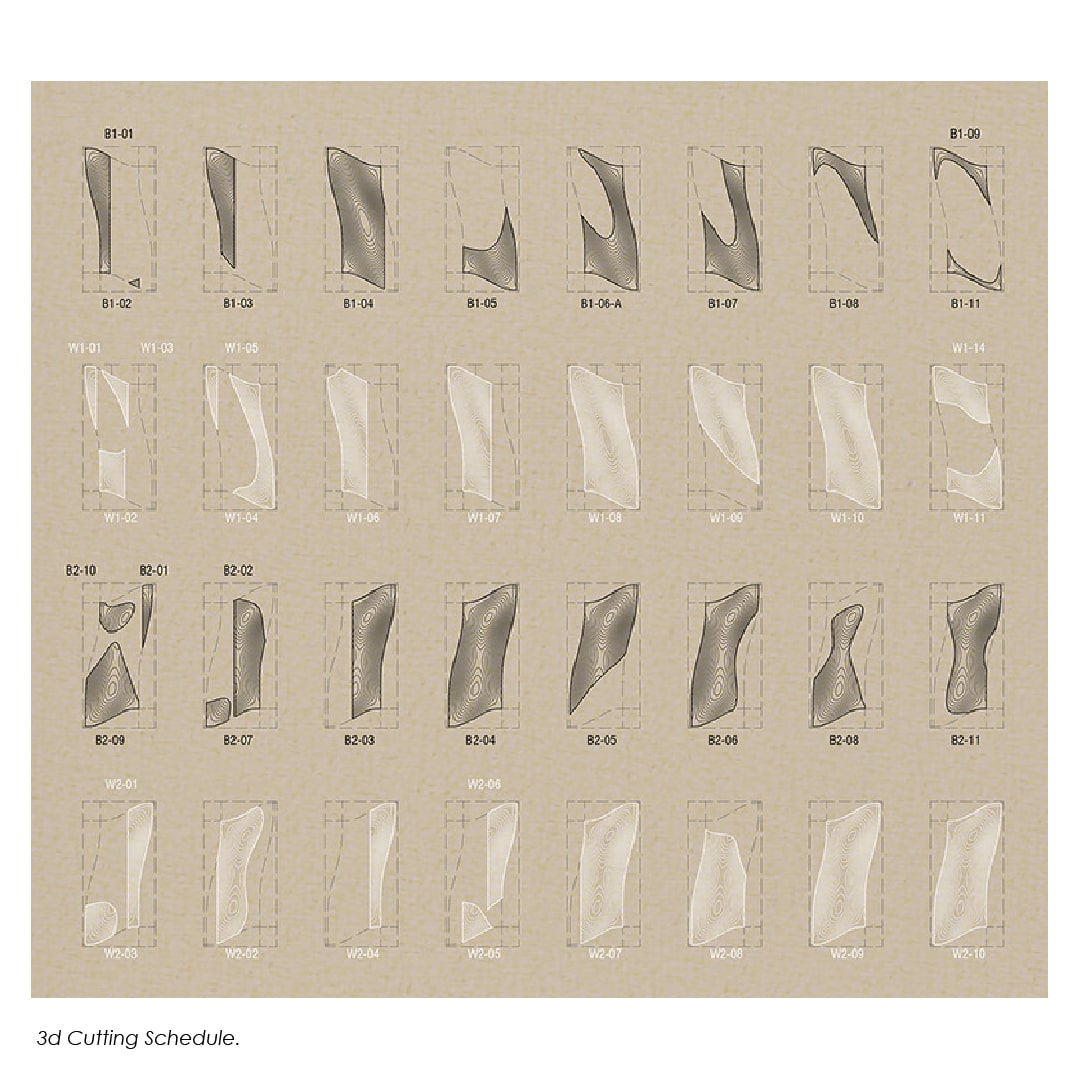

The panel fabrication therefore uses only two moulds so that the costs of mould fabrication can be minimised. The panels are then CNC-cut to custom shapes in order to align to the overall double-curved envelope geometry and to generate architectural detail and complexity at the same time.

Comments