Symmetrical Scissors

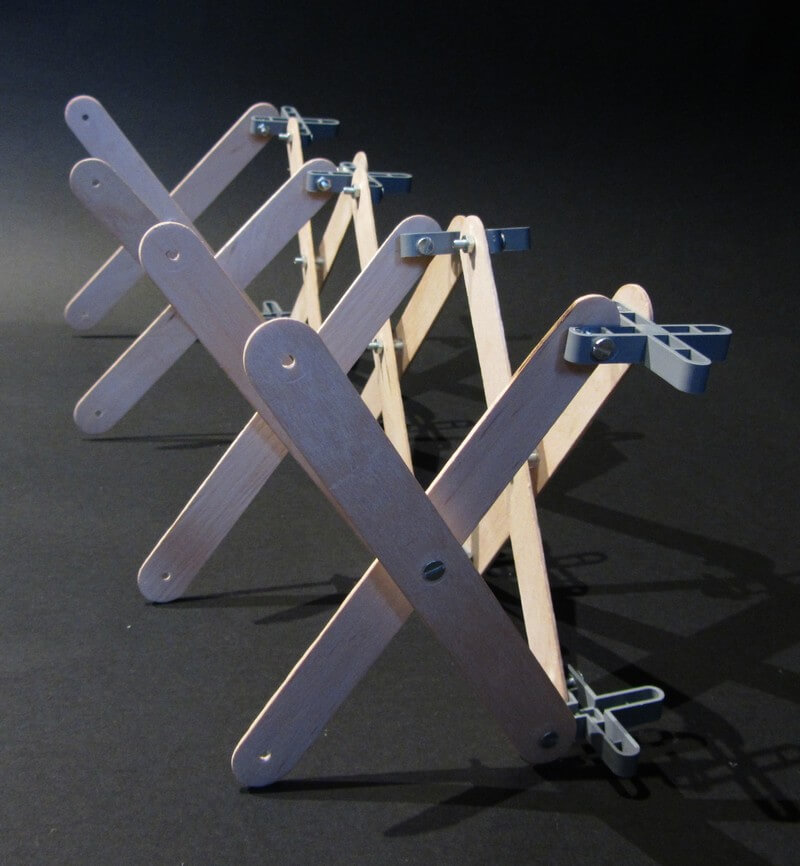

The central topic of this work by SMiA Research Group is the explanation of the making process of a scale model, which makes a spatial grouping of symmetrical straight scissors. In order to understand this kind of structure, first it is necessary to identify their components. A scissors is the joint of two straight bars, and the grouping is the joint of several scissors in two directions.

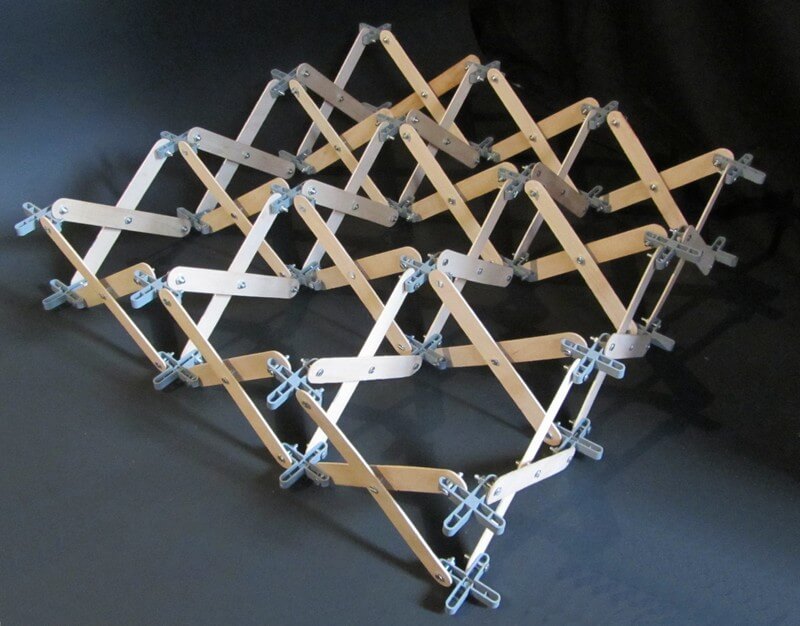

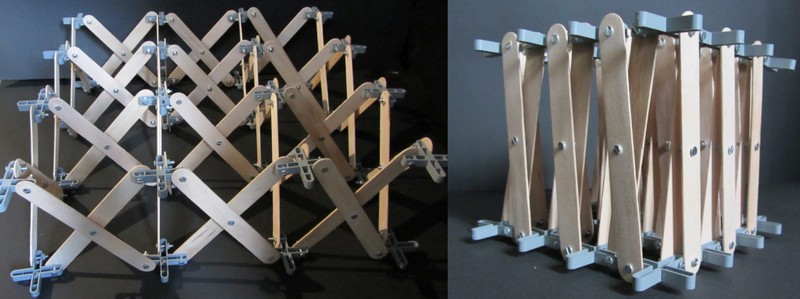

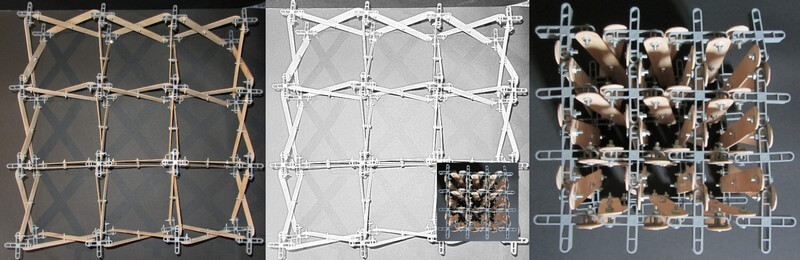

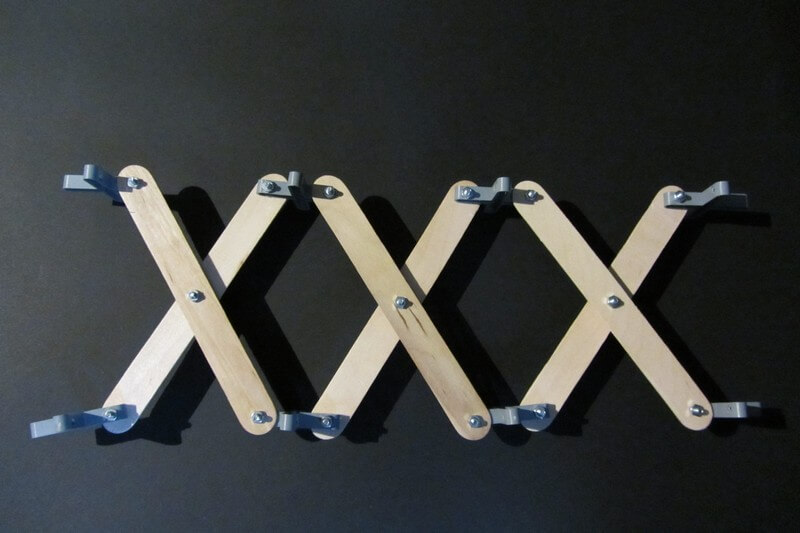

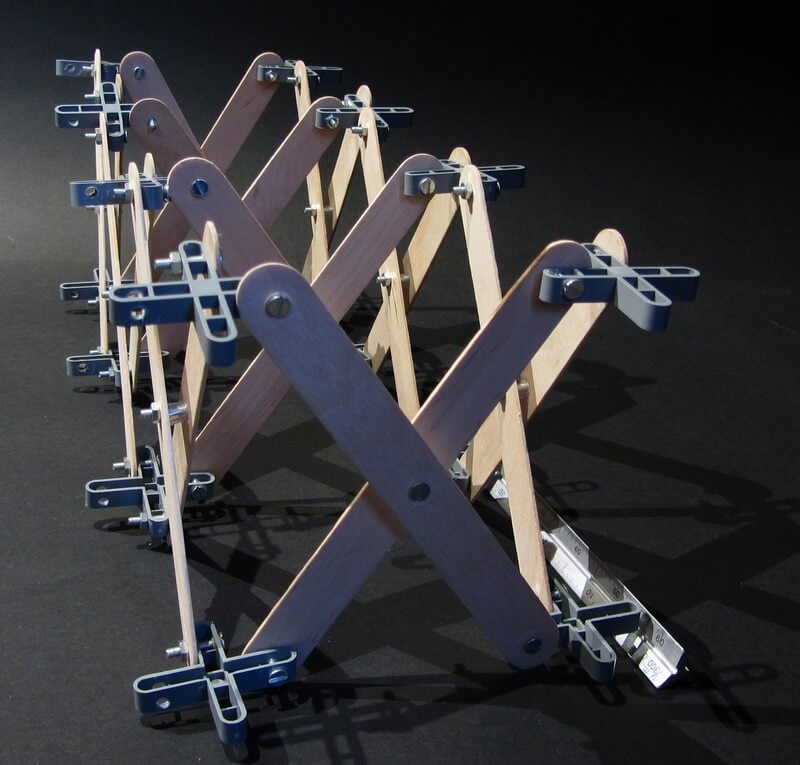

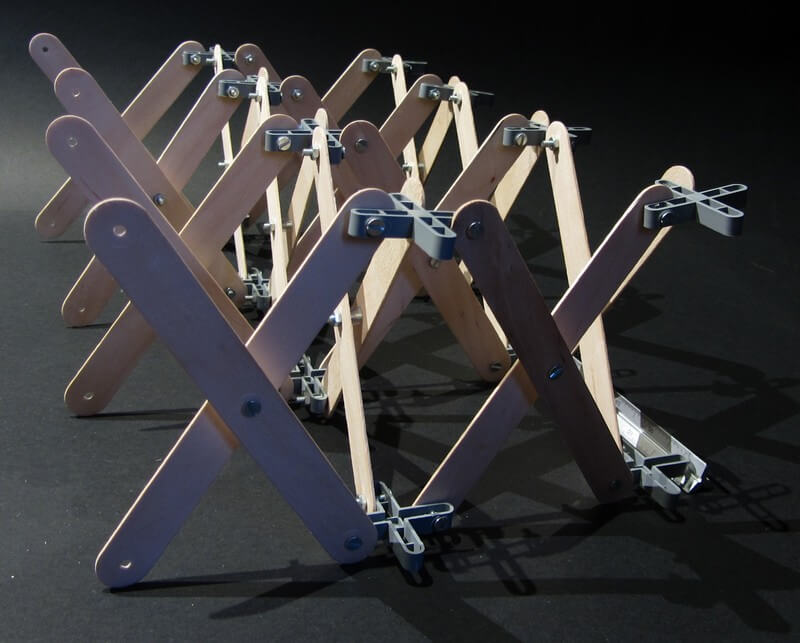

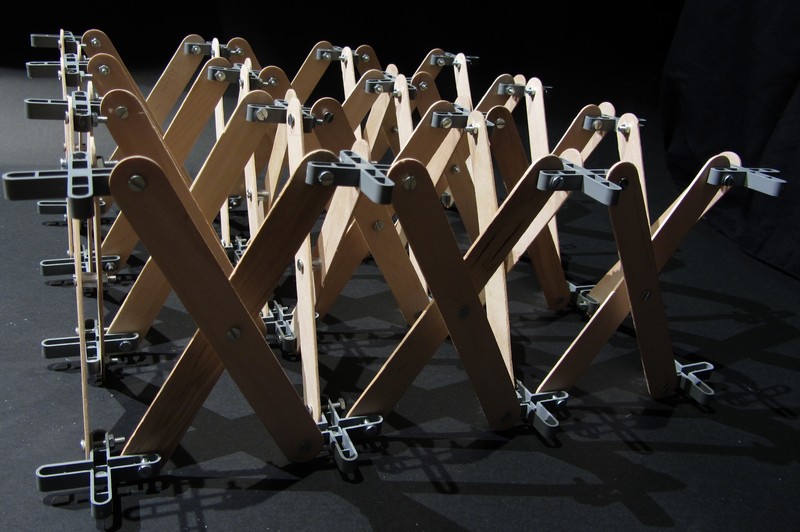

The grouping of scissors makes a different kind of geometry, which depend of the location of the central joint of the scissors. The development of physical prototypes allows to understand the geometry and the movement of scissors structures.. The model is made by grouping of symmetrical straight scissors with central joint. When the model is opened, it creates a flat surface, it does a lineal deployment in two directions.

The built model makes a 3×3 grid which is composed of four rows of scissors in both longitudinal and transversal directions. Each row contains three modules of scissors, therefore the model has a total of 24 scissors. All scissors in the model have the same dimension, which simplifies the model construction. The scissors grouping making a grid and the centrality of the joint in each scissors, generate a flat surface in the deployed position of the model, and a cube in the folded position

The model is made using bars of 15 cm of length. Using this bars, when the model is in the deployed position makes a volume of 50cm x 50cm x 3cm, and in the folding position a volume of 15cm x 15cm x 15cm. Taking in account the dimensions of the model in the two positions, the area of the generated flat surface in the folded position is equal to 1/9 of the area in the deployed position.

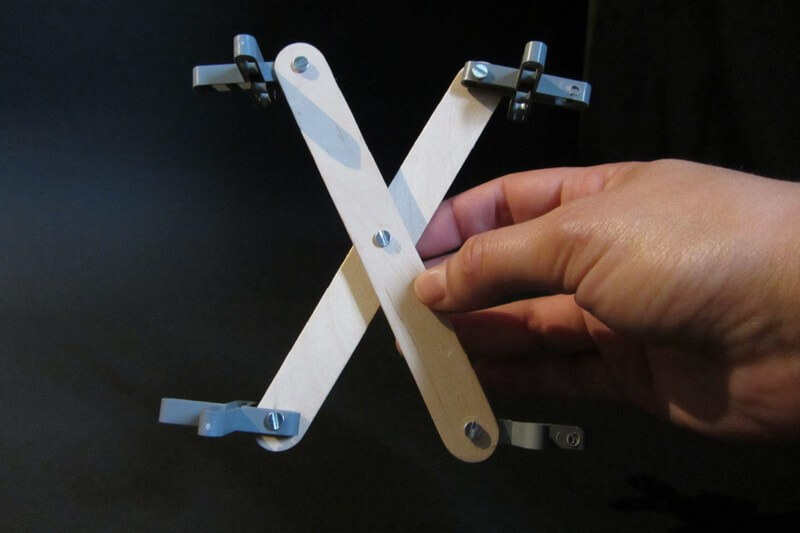

The making process of the model is very simple, the materials are easy to find and affordable. The scissors in this case are made by linear elements of wood (popsicle sticks) of 15 cm of length and 1.8 cm of width. The axes of the joints of the scissors are made by screws and nuts. The joints between scissors are made using joints spacer for tiles of 7 mm of thickness.

The scissors require a spacer for the central joint, this spacer assumes the 7 mm of thickness of the joint spacer for tiles (articulation node between scissors). This piece is made by transparent hose pipe of 5 mm of diameter, which is cutted in lengths of 7 mm. The Tools required for the making process are: ruler, pencil, mototool with 2 mm drill and sandpaper for wood.

The scissors require a spacer for the central joint, this spacer assumes the 7 mm of thickness of the joint spacer for tiles (articulation node between scissors). This piece is made by transparent hose pipe of 5 mm of diameter, which is cutted in lengths of 7 mm. The Tools required for the making process are: ruler, pencil, mototool with 2 mm drill and sandpaper for wood.

The second step is to assemble the central joint with two popsicle sticks. The central joint is made putting a screw in the center hole of a popsicle stick, which works as rotation axis between the bars, in this case the popsicle sticks. Then, a transparent hose pipe of 7 mm of length is inserted on the central screw, followed by another popsicle stick. Finally, a screw nut is inserted in the central joint in order to complete the scissors. The Model requires 24 scissors.

The third step is to drill the joints spacer for tiles (articulation node between scissors) in all their extremes, and to install them on the four corners of a scissors. The drillings of the joints spacer are made using a drill bit of 2 mm and they must be closer as possible to the edge, this prevents the collision between sticks and the joints spacer during the movement of the model. The model requires 32 drilled joints spacer for tiles, it also requires 4 screws with nuts for each scissor. For the assembly of the joints spacer, these must be assembled on the internal sides of the popsicle sticks of the scissors module, in order to keep the axis of the scissors centered.

Comments