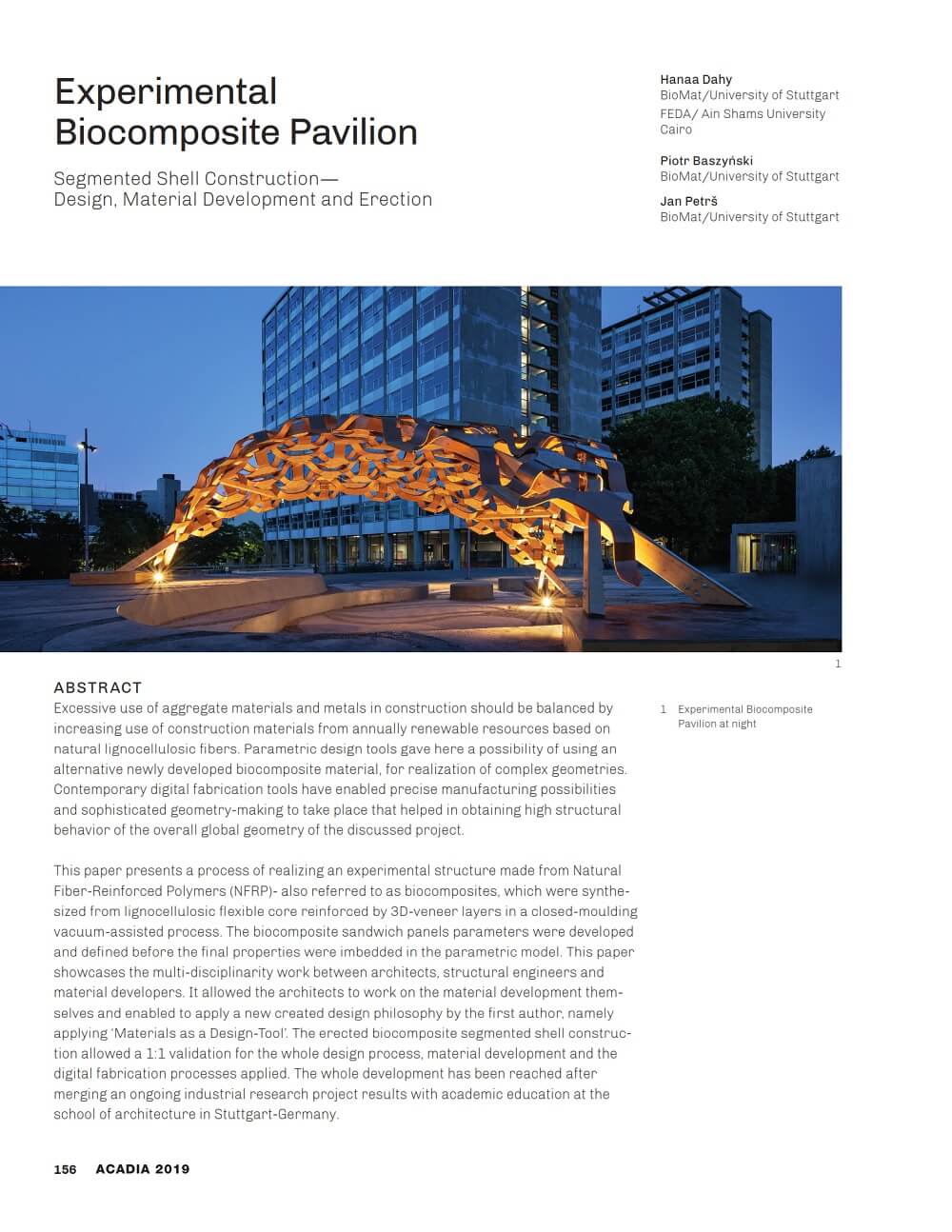

Biocomposite Pavilion

Excessive use of aggregate materials and metals in construction should be balanced by increasing use of construction materials from annually renewable resources based on natural lignocellulosic fibers. Parametric design tools gave here a possibility of using an alternative newly developed biocomposite material, for realization of complex geometries. Contemporary digital fabrication tools have enabled precise manufacturing possibilities and sophisticated geometry-making to take place that helped in obtaining high structural behavior of the overall global geometry of the discussed project.

This paper by Hanaa Dahy, Piotr Baszyński and Jan Petrš presents a process of realizing an experimental structure made from Natural Fiber-Reinforced Polymers (NFRP)- also referred to as biocomposites, which were synthesized from lignocellulosic flexible core reinforced by 3D-veneer layers in a closed-moulding vacuum-assisted process. The biocomposite sandwich panels parameters were developed and defined before the final properties were imbedded in the parametric model. This paper showcases the multi-disciplinarity work between architects, structural engineers and material developers.

It allowed the architects to work on the material development themselves and enabled to apply a new created design philosophy by the first author, namely applying ‘Materials as a Design-Tool’. The erected biocomposite segmented shell construction allowed a 1:1 validation for the whole design process, material development and the digital fabrication processes applied. The whole development has been reached after merging an ongoing industrial research project results with academic education at the school of architecture in Stuttgart-Germany.

Comments